Escolar Documentos

Profissional Documentos

Cultura Documentos

Effects of Aging Time On Mechanical Properties of Sand Cast Al-4.5cu Alloy

Enviado por

esatjournalsTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Effects of Aging Time On Mechanical Properties of Sand Cast Al-4.5cu Alloy

Enviado por

esatjournalsDireitos autorais:

Formatos disponíveis

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

EFFECTS OF AGING TIME ON MECHANICAL PROPERTIES OF SAND

CAST Al-4.5Cu ALLOY

S.Ilangovan1, R.Srikanthan2, G. Veda Vyass3

1

Assistant Professor (SG), Department of Mechanical Engineering, Amrita School of Engineering, Amrita Vishwa

Vidyapeetham, Coimbatore, Tamil Nadu, India

2

Third Year B.Tech, Department of Mechanical Engineering, Amrita School of Engineering, Amrita Vishwa

Vidyapeetham, Coimbatore, Tamil Nadu, India

3

Third Year B.Tech, Department of Mechanical Engineering, Amrita School of Engineering, Amrita Vishwa

Vidyapeetham, Coimbatore, Tamil Nadu, India

Abstract

An investigation was carried out to understand the effects of aging time of a cylindrical specimen on hardness, tensile strength and %

elongation of sand cast Aluminium alloy (Al-4.5Cu). The alloy was melted in an electric furnace and the molten alloy was poured into

sand moulds. The cast rods were tested for Vickers micro-hardness, ultimate tensile strength and % elongation. The aging time was

varied from 4 to 40 hours in steps of 4 hours and the maximum hardness was achieved when the specimen was aged for 36 hours. It

was found that the hardness of the alloy decreases when further aging was done. Moreover, it was observed that the tensile strength

increases with increase in hardness, whereas the % elongation decreases.

Key Words: Al-4.5Cu, Aging Treatment, Mechanical Properties, Sand cast.

----------------------------------------------------------------------***---------------------------------------------------------------------1. INTRODUCTION

2. EXPERIMENTAL PROCEDURE

Aluminium alloys have a wide range of applications in the

aerospace and automotive industries. This is mainly due to its

advantageous characteristics that include high electrical and

thermal conductivities, high ductility, high specific strength,

ease of casting, low density, high strength to weight ratio and

reasonable corrosion resistance. A relative balance of

properties is attained using appropriate heat treatment

techniques [1-6] and is exploited by many industries,

especially the automotive industry which has recently

increased the production of aluminium alloys castings for

engine blocks and cylinder heads [6-7].

2.1 Material Preparation

Aluminium alloy (Al-4.5Cu) castings were produced by

melting commercially available pure aluminium ingots and

electrolytic copper rods. The appropriate weight percent of the

elements were melted in a graphite crucible using an electric

furnace in an inert argon atmosphere. The molten metal was

poured at a temperature of 720C into sand moulds at room

temperature to make rods of 16 mm and length of 150

mm.The chemical composition of the cast alloy was tested

using a spectrometer and the results are reported in Table 1.

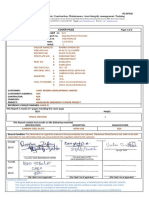

Table -1: Cast alloy composition

Copper has been the most common alloying element almost

since the beginning of the aluminum industry, and a variety of

alloys in which copper is the major addition were later

developed. Copper is added to aluminium to increase its

strength, hardness, fatigue, creep resistance and machinability

[8].

Al

Cu

Others

94.5

4.5

2.2 Microstructure

In this work, the cast aluminium alloy of composition Al4.5Cu was studied in order to find out the effect of aging time

on hardness, tensile strength, % elongation. This was done to

compare the results with as-cast properties of Al-4.5Cu alloy

in order to study the enhancement of mechanical properties on

aging.

The microstructure of the alloy was observed through optical

microscope in various stages of aging process. The specimen

was prepared for microscopic observation using standard

metallographic techniques. The etchant used was Krolls

Reagent (92% Distilled Water, 6% Nitric Acid, 2% HF). The

photographic image of the optical microscope is shown in

Figure 1.

__________________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org

57

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

Fig-3: Drawing of Tensile Test Specimen

Fig-1: Image of Optical Microscope

2.3 Hardness Testing

To assess the effect of aging heat treatment, the hardness of

the all the specimens were measured using a micro-hardness

tester as shown in Figure 2. A number of readings were taken

at different locations for each specimen and an average value

was calculated. The specimens were prepared and tested as per

ASTM- E384 standard. The parameters used in this test were:

50 gm-f applied load and 20 s duration. The hardness values

varied in each sample was within 5 HV.

Fig-4: Photograph image of tensile test specimen

Fig-5: Universal tensile testing machine

Fig-2: Mitutoyo make micro-hardness tester

3. RESULTS AND DISCUSSION

2.4 Tensile Testing

3.1 Microstructure

The tensile test was conducted to predict the tensile strength

(TS) of the material as well as to find the ductility in terms of

% elongation of the alloy. The test specimens were prepared

according to ASTM - E4 standard as shown in Figure 3. The

photographic image of the specimen is shown in Figure 4. The

specimens were tested using computerized universal testing

machine (Make: Tinius Olsen M25KT) as shown in Figure 5.

Age hardening characteristics are evident in Al-Cu aluminum

alloy; with an increase in aging time, the mechanical strength

of the alloy increased considerably and dropped gradually

after a maximum value of aging time. Effect of aging is

affected by various factors viz. solid solution strengthening,

substrates recovery and recrystallization and new phase

precipitation. The first two factors lower the strength of the

alloy with the increase in aging time, but phase precipitation

__________________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org

58

IJRET: International Journal of Research in Engineering and Technology

strengthens the alloy. The microstructures obtained are shown

in Figure 6(a-c) with a magnification of 20m.

eISSN: 2319-1163 | pISSN: 2321-7308

3.2 Hardness

The influence of aging time on hardness is shown in Figure 7.

It was observed from the plot that the hardness of the

specimen increases from 70 HV to 154 HV maximum as the

aging time increased from 0 to 36 hours. The hardness value

decreases upon further aging. The increase in hardness was

due to the formation of precipitates which interacted with the

dislocation movements. The decrease in hardness might have

been due to over-aging of the specimen. Therefore it maybe

concluded that the hardness increases with increasing aging

time up to a certain limit which depends on the alloy

composition and aging temperature. It was found to be

consistent with previous reports [9-11].

Fig-6a: Microstructure of as-cast Al-4.5Cu alloy

Fig-7: Hardness versus aging time

Fig-6b: Microstructure of 16 hours age-hardened specimen

Figure 8 shows the variation of % elongation with hardness of

the alloy as a function of aging time. As stated above the

hardness of the alloy increases with aging time. Generally, %

elongation decreases with increasing hardness. The same

behaviour was obtained in this study. Hence it maybe

concluded that the % elongation varies inversely with

hardness of the alloy.

Fig-6c: Microstructure of 36 hours age-hardened specimen

Fig-8: % Elongation versus hardness

__________________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org

59

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

3.3 Tensile Strength

4. CONCLUSIONS

Figure 9 shows the variation of Tensile strength with aging

time. It is seen that the tensile strength of the alloy increases

from 147.5 to 226 MPa as time increases from 0 to 36 hours. It

is observed that the tensile strength value decreases to 217

MPa with further aging treatment. It may be due to overaging.

The findings of this particular experiment are summarised as

follows:

The hardness increases with aging time up to a

particular aging time which depends on the alloy

composition and aging temperature.

The % elongation decreases as the hardness of the alloy

increases.

The tensile strength of the alloy increases gradually

with increase in aging time up to a specific aging time.

The tensile strength is found to increase linearly with

increase in hardness of the alloy.

REFERENCES

[1]

[2]

[3]

Fig-9: Tensile strength versus aging time

Figure 10 shows the variation of tensile strength with the

hardness of the alloy. It was found that the tensile strength

inreases with increase in hardness of the specimen. Hence it

maybe concluded that the tensile strength is a linearly varying

function of the hardness of the alloy.

[4]

[5]

[6]

[7]

[8]

[9]

Fig-10: Tensile Strength versus hardness

Wislei.R.Osorio,Daniel,

J..Moutinho,

Leandro

C.Peixoto, Ivaldo L.Ferreira, Amauri Garcia (2011),

Macro segregation and microstructure dendritic array

affecting the electrochemical behavior of ternary AlCu-Si alloys, Electrochimica Acta, Vol. 56, pp. 84128421.

G.A.Capuano and W.G.Davenport, Electrodeposition

of Aluminium from Alkyl Benzene Electrolytes,

Journal of The Electrochemical Society, Vol.118, Issue

10, pp. 1688-1695.

Mortaza Azarbarmas, Masoud Emamy, Jafar

RasizaDeh, Mohammed Alipour, Mostafa Karamouz

(2011), The effects of Be on Mechanical Properties of

Al-Mg2Si in situ composite, The Minerals, Metals and

Materials Society.

V.V.Krisyuk, L.Aloui, N.Prud Home, B.Saraprata,

F.Senocq, D.Samelor and C.Vahlas (2009), CVD of

Pure copper Films from a novel Amidinate Precursor,

The Electrochemical Society, Vol. 25, pp. 581-586.

G. Garca-Garca, J. Espinoza-Cuadra, H. ManchaMolinar (2007), Copper content and cooling rate

effects over second phase particles behavior in

industrial aluminumsilicon alloy 319, Mater Des,

Vol. 28, pp. 428433.

A.M.Samuel,

F.H.Samuel,

H.W.Doty

(1996),

Observations on the formation of -Al5FeSi phase in

319 type Al-Si alloys, Journal of Materials Science ,

Vol.31 , pp. 5529-5539.

I.Guillot,

B.Barlas,

G.Cailletaud,

M.Clavel,

D.Massinon (2002), Thermomechanical fatigue and

aging cast aluminium alloy: A link between numerical

modeling and microstructural approach, International

Conference on Temperature-Fatigue Interaction,

Vol.29, pp. 75-84.

E.L.Rooy, Metals Handbook, vol. 15, ASM

International, Materials Park, Ohio.1988, pp. 743.

Ilangovan, S. and Sellamuthu, R. (2012), An

Investigation of the effect of Ni Content and Hardness

on the wear behavior of Sand Cast Cu-Ni-Sn Alloys,

International Journal of Microstructure and Materials

Properties, Vol.7, pp.316-328.

__________________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org

60

IJRET: International Journal of Research in Engineering and Technology

[10]

[11]

eISSN: 2319-1163 | pISSN: 2321-7308

Ilangovan, S. and Sellamuthu, R. (2013), Effects of

Tin on Hardness, Wear Rate and Coefficient of Friction

of Cast Cu-Ni-Sn Alloys, Journal of Engineering

Science & Technology, Vol.8, No.1, pp. 44-54.

Dongmei Zhao, Q.M. Dong, P. Liu, B.X. Kang, J.L.

Huang, Z.H. Jin (2003), Aging behavior of Cu-Sn

Alloy, Materials Science and Engineering A, Vol.361,

pp. 93-99.

BIOGRAPHIES

Dr. S. Ilangovan has completed his

Bachelors

Degree

in

Mechanical

Engineering and Masters Degree in

Production Engineering. He has fourteen

years of experience in industry and sixteen

years in teaching. He has also completed

Ph.D. in Materials Engineering

R. Srikanthan is a third-year Mechanical

Engineering student currently pursuing

Bachelor of Technology degree from

Amrita Vishwa Vidyapeetham, Tamil Nadu.

G. Veda Vyass is a third-year Mechanical

Engineering student currently pursuing

Bachelor of Technology degree from

Amrita Vishwa Vidyapeetham, Tamil

Nadu.

__________________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org

61

Você também pode gostar

- Analytical Assessment On Progressive Collapse Potential of New Reinforced Concrete Framed Structure PDFDocumento5 páginasAnalytical Assessment On Progressive Collapse Potential of New Reinforced Concrete Framed Structure PDFesatjournalsAinda não há avaliações

- A Review On Fake Biometric Detection System For Various ApplicationsDocumento4 páginasA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsAinda não há avaliações

- PTE 3 Week Study ScheduleDocumento3 páginasPTE 3 Week Study ScheduleesatjournalsAinda não há avaliações

- An Improved Geo-Encryption Algorithm in Location Based Services PDFDocumento4 páginasAn Improved Geo-Encryption Algorithm in Location Based Services PDFesatjournalsAinda não há avaliações

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDocumento8 páginasA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsAinda não há avaliações

- Analysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFDocumento6 páginasAnalysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFesatjournalsAinda não há avaliações

- Analysis and Characterization of Dendrite Structures From Microstructure Images of Material PDFDocumento5 páginasAnalysis and Characterization of Dendrite Structures From Microstructure Images of Material PDFesatjournalsAinda não há avaliações

- An Efficient Information Retrieval Ontology System Based Indexing For Context PDFDocumento7 páginasAn Efficient Information Retrieval Ontology System Based Indexing For Context PDFesatjournalsAinda não há avaliações

- Analysis of Outrigger System For Tall Vertical Irregularites Structures Subjected To Lateral Loads PDFDocumento5 páginasAnalysis of Outrigger System For Tall Vertical Irregularites Structures Subjected To Lateral Loads PDFesatjournalsAinda não há avaliações

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFDocumento6 páginasAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsAinda não há avaliações

- An Octa-Core Processor With Shared Memory and Message-Passing PDFDocumento10 páginasAn Octa-Core Processor With Shared Memory and Message-Passing PDFesatjournalsAinda não há avaliações

- A Servey On Wireless Mesh Networking ModuleDocumento5 páginasA Servey On Wireless Mesh Networking ModuleesatjournalsAinda não há avaliações

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFDocumento4 páginasAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsAinda não há avaliações

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDocumento7 páginasAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsAinda não há avaliações

- A Review Paper On Smart Health Care System Using Internet of ThingsDocumento5 páginasA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsAinda não há avaliações

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDocumento3 páginasA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsAinda não há avaliações

- A Critical Review On Experimental Studies of Strength and Durability Properties of Fibre Reinforced Concrete Composite PDFDocumento7 páginasA Critical Review On Experimental Studies of Strength and Durability Properties of Fibre Reinforced Concrete Composite PDFesatjournalsAinda não há avaliações

- A New Type of Single-Mode Lma Photonic Crystal Fiber Based On Index-Matching Coupling PDFDocumento8 páginasA New Type of Single-Mode Lma Photonic Crystal Fiber Based On Index-Matching Coupling PDFesatjournalsAinda não há avaliações

- A Review Paper On Smart Health Care System Using Internet of ThingsDocumento5 páginasA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsAinda não há avaliações

- I JR Et 20160503007dfceDocumento5 páginasI JR Et 20160503007dfcegtarun22guptaAinda não há avaliações

- A Comparative Investigation On Physical and Mechanical Properties of MMC Reinforced With Waste Materials PDFDocumento7 páginasA Comparative Investigation On Physical and Mechanical Properties of MMC Reinforced With Waste Materials PDFesatjournalsAinda não há avaliações

- I JR Et 20160503007dfceDocumento5 páginasI JR Et 20160503007dfcegtarun22guptaAinda não há avaliações

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDocumento6 páginasA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsAinda não há avaliações

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDocumento8 páginasA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsAinda não há avaliações

- A Servey On Wireless Mesh Networking ModuleDocumento5 páginasA Servey On Wireless Mesh Networking ModuleesatjournalsAinda não há avaliações

- A Review On Fake Biometric Detection System For Various ApplicationsDocumento4 páginasA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsAinda não há avaliações

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Documento3 páginasA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsAinda não há avaliações

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDocumento6 páginasA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsAinda não há avaliações

- Ad Hoc Based Vehcular Networking and ComputationDocumento3 páginasAd Hoc Based Vehcular Networking and ComputationesatjournalsAinda não há avaliações

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesDocumento9 páginasA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Cover PageDocumento2 páginasCover PageAbubakar lawan moduAinda não há avaliações

- Uncertainty - Tensile Testing FinalDocumento9 páginasUncertainty - Tensile Testing FinalJoby George100% (1)

- A1005Documento6 páginasA1005hamidharvardAinda não há avaliações

- Paper Con PetDocumento9 páginasPaper Con Petcarlos delgadoAinda não há avaliações

- B31.3 Process Piping Course - 03 Materials PDFDocumento19 páginasB31.3 Process Piping Course - 03 Materials PDFNguyen Anh TungAinda não há avaliações

- Assignment PDFDocumento4 páginasAssignment PDFzayanAinda não há avaliações

- Torque For BoltDocumento18 páginasTorque For BoltZoebairAinda não há avaliações

- 1950 MagnelDocumento11 páginas1950 MagnelPonnada Markandeyaraju100% (1)

- Material Properties and Chemical CompositionDocumento20 páginasMaterial Properties and Chemical CompositionMani Maran89% (9)

- Tut Failure TheoriesDocumento39 páginasTut Failure TheoriesKamil Hakan TuranAinda não há avaliações

- Ankeri SI JediniceDocumento30 páginasAnkeri SI Jedinicepperic13Ainda não há avaliações

- Composite Engineering MaterialsDocumento69 páginasComposite Engineering MaterialsvialmaAinda não há avaliações

- Bars, Rods & RebarsDocumento9 páginasBars, Rods & RebarskxalxoAinda não há avaliações

- IS 1148-1982-Reaffirmed 2004 PDFDocumento10 páginasIS 1148-1982-Reaffirmed 2004 PDFNav TalukdarAinda não há avaliações

- 18MEL37A, 47A - Material Testing LabDocumento62 páginas18MEL37A, 47A - Material Testing LabKarthik BhavanashiAinda não há avaliações

- Hanson c301Documento2 páginasHanson c301m4x4rtAinda não há avaliações

- Strenght of Material ExplanationDocumento7 páginasStrenght of Material ExplanationMohamed MostafaAinda não há avaliações

- RequirementsDocumento18 páginasRequirementsmpedraza-1Ainda não há avaliações

- X6CrNiTi18 10Documento64 páginasX6CrNiTi18 10Amir GrbicAinda não há avaliações

- Aluminum 6061Documento3 páginasAluminum 6061Ali FahemAinda não há avaliações

- Technical Contact:: Seyed Saleh Yousefi, Crafco, Inc. 6975 W Crafco Way Chandler, AZ 85226 USADocumento10 páginasTechnical Contact:: Seyed Saleh Yousefi, Crafco, Inc. 6975 W Crafco Way Chandler, AZ 85226 USAJORGE ARMANDO CASTRO ESCUDEROAinda não há avaliações

- ISM2006 Plasticity Modelling Abaqus FEM Code v2Documento27 páginasISM2006 Plasticity Modelling Abaqus FEM Code v2EsoElmoghazyAinda não há avaliações

- 06-Composites Failure PDFDocumento26 páginas06-Composites Failure PDFHéctor Sanmanuel TorresAinda não há avaliações

- Experimental Analysis of Sissimilar Metal Weld Joint Ferritic To Austenitic Stainless TeelDocumento10 páginasExperimental Analysis of Sissimilar Metal Weld Joint Ferritic To Austenitic Stainless TeelIvan PicchiAinda não há avaliações

- Asme B16.44 2012Documento24 páginasAsme B16.44 2012Nguyen Anh TungAinda não há avaliações

- I.S 1785 - P1Documento13 páginasI.S 1785 - P1Gajendrasingh RajputAinda não há avaliações

- Material Allowable Strength DataDocumento84 páginasMaterial Allowable Strength DataKazimieras PAinda não há avaliações

- British Standard for Swaged Collar Grooved Rivets 12.7-34.9mmDocumento12 páginasBritish Standard for Swaged Collar Grooved Rivets 12.7-34.9mmMadhivanan.S Selvam100% (1)

- Elastic Properties of MatterDocumento65 páginasElastic Properties of MatterBumpdustAinda não há avaliações

- Current Cognition of Rock Tensile Strength Testing by Brazilian Test - PB - EnglDocumento15 páginasCurrent Cognition of Rock Tensile Strength Testing by Brazilian Test - PB - EnglSen HuAinda não há avaliações