Escolar Documentos

Profissional Documentos

Cultura Documentos

Additions, Revisions, or Updates: Subject Date

Enviado por

Saša Oljača0 notas0% acharam este documento útil (0 voto)

112 visualizações4 páginasTítulo original

487-12.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

112 visualizações4 páginasAdditions, Revisions, or Updates: Subject Date

Enviado por

Saša OljačaDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 4

4 87-12

4 87-12

SUBJECT

DATE

Installation of Oil Cooler/Filter Housing

May 2012

Additions, Revisions, or Updates

Publication Number / Title

DDC-SVC-MAN-0026

Platform

Section Title

Change

EPA07 MBE

4000

Installation of Oil Cooler/

Filter Housing

Added torque specification for banjo fittings.

All information subject to change without notice.

4 87-12

Copyright 2012 DETROIT DIESEL CORPORATION

2 Installation of the Oil Cooler/Filter Housing

Installation of the Oil Cooler/Filter Housing

Install the oil cooler/filter housing as follows:

1. Check the oil cooler element and the inside of the cooler housing for corrosion, contamination by metal particles, or

abrasive material, such as sand.

a. If corrosion is found, clean or replace the oil cooler, as necessary.

b. Clean the mating surfaces of the oil cooler element and cooler housing. Remove any bits of adhering gasket material.

2. Install the oil cooler element and new gaskets on the oil cooler/filter housing. Tighten the element bolts to 25 Nm (18

lbft).

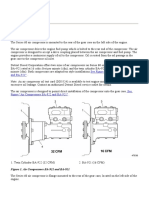

3. Install the oil cooler/filter housing on the cylinder block. Install the housing bolts and tighten them in the order shown

below. Tighten each bolt to 60 Nm (44 lbft).

Figure 1. Oil Cooler Housing Bolts

a. Clean the mating surfaces of the oil cooler/filter housing and the cylinder block. Remove any bits of adhering gasket

material.

b. Replace the oil cooler/filter housing gasket.

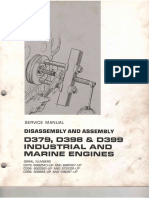

4. Install a new oil filter element (3) and O-ring (2) in the oil filter cap (1).

All information subject to change without notice.

Copyright 2012 DETROIT DIESEL CORPORATION

4 87-12

4 87-12

1. Oil Filter Cap

2. O-ring

3. Oil Filter Element

Figure 2. Oil Filter Element

5. Install the oil filter cap. Tighten the cap nut to 25 Nm (18 lbft).

6. Secure the oil lines to the oil cooler/filter housing with a banjo bolt and new washers. Tighten the banjo bolt to 25 Nm

(18 lbft).

7. Install the oil pressure/temperature sensor on the oil cooler/filter housing. Refer to section "Installation of the Engine Oil

Pressure/Temperature Sensor" .

8. Connect the wiring harness to the oil pressure/temperature sensor.

9. Install the turbocharger on the engine. Refer to section "Installation of the Turbocharger" .

10. Connect the coolant pump shunt line to the coolant pump inlet pipe.

11. Fill the cooling system. Refer to section "Draining and Flushing the Cooling System" .

WARNING: ENGINE EXHAUST (i)(eov34)

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

12. Start the engine. Check the gauge for the correct oil pressure; check the oil lubrication system and the coolant pump inlet

pipe for leaks. The correct oil pressures are listed in "Engine Oil Pressures" below.

All information subject to change without notice.

4 87-12

Copyright 2012 DETROIT DIESEL CORPORATION

2 Installation of the Oil Cooler/Filter Housing

Table 1.

Engine Oil Pressures

Engine Speed

Minimum Pressure kPa (psi)

At idling rpm

50 (7)

At maximum rpm

250 (36)

All information subject to change without notice.

Copyright 2012 DETROIT DIESEL CORPORATION

4 87-12

Você também pode gostar

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAinda não há avaliações

- Exhaust System - Catalytic Converter-1.6L Duratorq-TDCi (74kW-100PS 81kW-110PS) - DV 110 PSDocumento12 páginasExhaust System - Catalytic Converter-1.6L Duratorq-TDCi (74kW-100PS 81kW-110PS) - DV 110 PSaalin14Ainda não há avaliações

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- 2AZ FE CoolingDocumento35 páginas2AZ FE CoolingLuks Fernandez50% (2)

- Oil Pump: Removal ProcedureDocumento40 páginasOil Pump: Removal Proceduremiguelx69Ainda não há avaliações

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesAinda não há avaliações

- Series 60 - Section 6.3 Intake ManifoldDocumento7 páginasSeries 60 - Section 6.3 Intake ManifoldJuan RiveraAinda não há avaliações

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementAinda não há avaliações

- Chinh Kim CoDocumento67 páginasChinh Kim ColeminhAinda não há avaliações

- Compressor WabcoDocumento6 páginasCompressor Wabcoruben_cruz_34Ainda não há avaliações

- Cylinder Head - Installation (Cylinder Head Assembly) - Fiat 500Documento8 páginasCylinder Head - Installation (Cylinder Head Assembly) - Fiat 500Fran SanchezAinda não há avaliações

- 2012 5.7 Hemi Cylinder Head InstallationDocumento6 páginas2012 5.7 Hemi Cylinder Head InstallationzackAinda não há avaliações

- Fuel System InspectDocumento8 páginasFuel System InspectsxturboAinda não há avaliações

- 06T Semihermetic Screw CompressorDocumento8 páginas06T Semihermetic Screw CompressorAbu Malak CiprianoAinda não há avaliações

- Fuel SistemDocumento55 páginasFuel SistemRodolfo AlbertoAinda não há avaliações

- Oil CoolerDocumento3 páginasOil CoolerCahyo Utomo100% (1)

- d8k Tractor - Power Shift - 66v00001-02084 (Machine) (Hebp1007 - 01) - Sistemas y ComponentesDocumento5 páginasd8k Tractor - Power Shift - 66v00001-02084 (Machine) (Hebp1007 - 01) - Sistemas y ComponentesJose MontalvoAinda não há avaliações

- 2.5l 4 Cyl Vin HDocumento17 páginas2.5l 4 Cyl Vin HFrank MartínezAinda não há avaliações

- 2GR FE CoolingDocumento36 páginas2GR FE CoolingLuks FernandezAinda não há avaliações

- KTA50 - Oil CoolerDocumento4 páginasKTA50 - Oil CoolerSebastian Nicușor PărăoanuAinda não há avaliações

- Diesel Engine Maintenance ManualDocumento108 páginasDiesel Engine Maintenance ManualSilas F Pimenta100% (10)

- Holley Contender Intake ManifoldDocumento4 páginasHolley Contender Intake Manifoldpaul_a_rodriguezAinda não há avaliações

- 3126 Air in FuelDocumento4 páginas3126 Air in FuelArnon Rutsalam50% (2)

- Dodge / Jeep: Provided Hardware May Damage The Intake Tube, Throttle Body and EngineDocumento3 páginasDodge / Jeep: Provided Hardware May Damage The Intake Tube, Throttle Body and EngineLuis Fernando Hurtado LoayzaAinda não há avaliações

- Service - Service Manual Code 950 - 994 - 653Documento30 páginasService - Service Manual Code 950 - 994 - 653Victor UribeAinda não há avaliações

- CH 8 - Lubricating Oil Pump, Oil Filter & CoolerDocumento33 páginasCH 8 - Lubricating Oil Pump, Oil Filter & CoolerEnrrique LaraAinda não há avaliações

- Section 11 - Special EquipmentDocumento11 páginasSection 11 - Special EquipmentRamonAinda não há avaliações

- 5 MBE900 04aDocumento36 páginas5 MBE900 04aRoger Lechado Garcia100% (1)

- .Archivetempsection 15 - StorageDocumento6 páginas.Archivetempsection 15 - StorageFernando MirandaAinda não há avaliações

- Desmontaje y Montaje D 379398 y 399Documento137 páginasDesmontaje y Montaje D 379398 y 399Yuriy Senyk100% (6)

- Sezione 2 PDFDocumento8 páginasSezione 2 PDFMAZZI1978100% (1)

- General Information: Engine CoolingDocumento13 páginasGeneral Information: Engine Coolinganonymous2abcAinda não há avaliações

- Recall N28Documento18 páginasRecall N28cxAinda não há avaliações

- MC 10127081 9999Documento4 páginasMC 10127081 9999Jose yanezAinda não há avaliações

- Modulo de Acondicionamiento DE COMBUSTIBLEDocumento4 páginasModulo de Acondicionamiento DE COMBUSTIBLEErnesto Martinez FonsecaAinda não há avaliações

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 7Documento12 páginasRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 7anony8103Ainda não há avaliações

- 8011 Ford Intake Manifold InstallationDocumento2 páginas8011 Ford Intake Manifold InstallationFabio Luis ArgentaAinda não há avaliações

- DD15 Detroit DieselDocumento10 páginasDD15 Detroit Dieselstarsky100% (4)

- Focus RS Cylinder Head RemovalDocumento20 páginasFocus RS Cylinder Head RemovalRobertSorokanich75% (4)

- Hydraulic Oil TankDocumento3 páginasHydraulic Oil Tankalsief1951Ainda não há avaliações

- 00M12 PDFDocumento6 páginas00M12 PDFurania22000Ainda não há avaliações

- CamryShiftFlare TSIBDocumento6 páginasCamryShiftFlare TSIBVadim Urupa100% (2)

- D3 LCCDocumento36 páginasD3 LCCstankovukanovicAinda não há avaliações

- LT303-001 - Discovery II - Change in Method of Radiator Removal - TOPIxDocumento12 páginasLT303-001 - Discovery II - Change in Method of Radiator Removal - TOPIxRui MiguelAinda não há avaliações

- PT Cruiser 2009 2.2LDocumento275 páginasPT Cruiser 2009 2.2LPatrik MendozaAinda não há avaliações

- 1998 Sec 7-Manual TransmissionDocumento25 páginas1998 Sec 7-Manual TransmissionAdal VeraAinda não há avaliações

- Intake and Exhaust Specifications for 2.6L and 3.0L EnginesDocumento16 páginasIntake and Exhaust Specifications for 2.6L and 3.0L EnginesGonzalez RubenAinda não há avaliações

- 1.6L 4cyl Diesel & Turbo DieselDocumento18 páginas1.6L 4cyl Diesel & Turbo DieselLeomir BrandaoAinda não há avaliações

- John Deere PowerTech 10.5L Diesel Engines Level 6 Electronic Fuel Systems With Lucas EUIs Service Repair Manual (CTM188)Documento17 páginasJohn Deere PowerTech 10.5L Diesel Engines Level 6 Electronic Fuel Systems With Lucas EUIs Service Repair Manual (CTM188)laopaodunAinda não há avaliações

- Trucks Mechanic Only: Additions, Revisions, or UpdatesDocumento8 páginasTrucks Mechanic Only: Additions, Revisions, or UpdatesLUIS CONDORIAinda não há avaliações

- D8R Pruebas y AjustesDocumento109 páginasD8R Pruebas y AjustesMiguel Angel Garrido CardenasAinda não há avaliações

- Outlet Temperature HighDocumento5 páginasOutlet Temperature HighOzan Gürcan100% (3)

- Manual de Motor Elantra-Tiburón 1998 G4GRDocumento6 páginasManual de Motor Elantra-Tiburón 1998 G4GRRodolfo SilvaAinda não há avaliações

- Windstar 2000-2001 3.8 v6Documento77 páginasWindstar 2000-2001 3.8 v6pegoAinda não há avaliações

- Allison Transmission Oil ChangeDocumento3 páginasAllison Transmission Oil ChangeMelissa GrayAinda não há avaliações

- Operating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpDocumento10 páginasOperating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpdocrafiAinda não há avaliações

- Pole Position 14 VKMC 01250 1 EN Highres PDFDocumento6 páginasPole Position 14 VKMC 01250 1 EN Highres PDFRita PcomputerAinda não há avaliações

- 2.0l 4 Cyl Nissan b13Documento52 páginas2.0l 4 Cyl Nissan b1325912530Ainda não há avaliações

- MM 36Documento23 páginasMM 36renganathan21051990Ainda não há avaliações

- Engine OM 471 PDFDocumento225 páginasEngine OM 471 PDFAlberjose Sanchez Ruiz100% (5)

- mm37 PDFDocumento32 páginasmm37 PDFSaša OljačaAinda não há avaliações

- mm37 PDFDocumento32 páginasmm37 PDFSaša OljačaAinda não há avaliações

- Engine OM 471 PDFDocumento225 páginasEngine OM 471 PDFAlberjose Sanchez Ruiz100% (5)

- Engine RepairDocumento156 páginasEngine RepairJCEID100% (2)

- DBZ TorqueDocumento22 páginasDBZ TorqueSaša OljačaAinda não há avaliações

- mm37 PDFDocumento32 páginasmm37 PDFSaša OljačaAinda não há avaliações

- Engine RepairDocumento156 páginasEngine RepairJCEID100% (2)

- Engine RepairDocumento156 páginasEngine RepairJCEID100% (2)

- Mercedes Training MechanicalDocumento65 páginasMercedes Training MechanicalSaša Oljača92% (25)

- ZF As Tronic Schematic EDocumento2 páginasZF As Tronic Schematic ESaša Oljača78% (18)

- Mercedes Training MechanicalDocumento65 páginasMercedes Training MechanicalSaša Oljača92% (25)

- Engine OM 471 PDFDocumento225 páginasEngine OM 471 PDFAlberjose Sanchez Ruiz100% (5)

- MAN D20 Eng PDFDocumento157 páginasMAN D20 Eng PDFjwd83% (52)

- MAN D20 Eng PDFDocumento157 páginasMAN D20 Eng PDFjwd83% (52)

- MAN D2876 - CR - EngDocumento182 páginasMAN D2876 - CR - EngSilas F Pimenta75% (4)

- MAN D2876 - CR - EngDocumento182 páginasMAN D2876 - CR - EngSilas F Pimenta75% (4)

- ZF As Tronic Schematic EDocumento2 páginasZF As Tronic Schematic ESaša Oljača78% (18)

- MAN D0836 - CR - enDocumento121 páginasMAN D0836 - CR - enSilas F Pimenta86% (56)

- Engine RepairDocumento156 páginasEngine RepairJCEID100% (2)

- ZF Servocom EnglischDocumento21 páginasZF Servocom EnglischSaša OljačaAinda não há avaliações

- 5HP500-590 4139 - 751 - 627dDocumento273 páginas5HP500-590 4139 - 751 - 627ddejanflojd100% (24)

- GEARBOX DIAGRAM AND PARTS LIST FOR 4S-120 GP R.9,16-1,00Documento6 páginasGEARBOX DIAGRAM AND PARTS LIST FOR 4S-120 GP R.9,16-1,00Saša OljačaAinda não há avaliações

- J 1 B 1211 CCDDocumento3 páginasJ 1 B 1211 CCDRegion 51Ainda não há avaliações

- PVT Correlations McCain - ValkoDocumento17 páginasPVT Correlations McCain - ValkoAlejandra Maleja RivasAinda não há avaliações

- How Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?Documento6 páginasHow Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?joseAinda não há avaliações

- 3 Phase Induction Motors Objective Questions With AnswersDocumento3 páginas3 Phase Induction Motors Objective Questions With AnswersMohan Raj0% (2)

- XHLE Long Coupled Centrifugal Pump EnglishDocumento8 páginasXHLE Long Coupled Centrifugal Pump Englishgagi1994brahimAinda não há avaliações

- Lab5 AnswerSheetDocumento3 páginasLab5 AnswerSheetnislam57Ainda não há avaliações

- Huawei EHuawei - Erelay - Solution - OverviewRelay Solution OverviewDocumento31 páginasHuawei EHuawei - Erelay - Solution - OverviewRelay Solution Overviewtariq8283% (6)

- CUCM Intracluster Port Usage GuideDocumento3 páginasCUCM Intracluster Port Usage GuideAbhinayMylavarapuAinda não há avaliações

- Ceramic Terminal BlocksDocumento1 páginaCeramic Terminal BlockselijbbAinda não há avaliações

- Unit Conversion Heat TransferDocumento5 páginasUnit Conversion Heat TransferFamela GadAinda não há avaliações

- Microsoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbaDocumento14 páginasMicrosoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbashubhamformeAinda não há avaliações

- Motores SumergiblesDocumento68 páginasMotores SumergiblescyberespiaAinda não há avaliações

- Timing Chain Tensioner ResetDocumento4 páginasTiming Chain Tensioner ResetHybrid RacingAinda não há avaliações

- 1986 Lobel RobinsonDocumento18 páginas1986 Lobel RobinsonNathallia SalvadorAinda não há avaliações

- Unit 4 - Software Engineering - WWW - Rgpvnotes.inDocumento12 páginasUnit 4 - Software Engineering - WWW - Rgpvnotes.inNazma QureshiAinda não há avaliações

- Studio GPGL LogDocumento5 páginasStudio GPGL LogCarlos Julian LemusAinda não há avaliações

- كتاب الهيدروديناميكا-4 The HydrodynamicDocumento25 páginasكتاب الهيدروديناميكا-4 The HydrodynamicHocine Gherbi FaycelAinda não há avaliações

- TMC 421 PDFDocumento82 páginasTMC 421 PDFJamie MooreAinda não há avaliações

- Models - Rf.bowtie Antenna OptimizationDocumento14 páginasModels - Rf.bowtie Antenna OptimizationbkmmizanAinda não há avaliações

- The Synergies of Hybridizing CNC and Additive ManufacturingDocumento8 páginasThe Synergies of Hybridizing CNC and Additive ManufacturingdemuxAinda não há avaliações

- Exploratory Boring Spacing & DepthDocumento24 páginasExploratory Boring Spacing & Depth18106 Mahmudur RahmanAinda não há avaliações

- Operating Instructions, FormulaDocumento35 páginasOperating Instructions, FormulaandymulyonoAinda não há avaliações

- Quotation 615-4078 BabulalDocumento14 páginasQuotation 615-4078 Babulaldevrajan631Ainda não há avaliações

- Physics ExamDocumento30 páginasPhysics Examjomar bolasocAinda não há avaliações

- Java Topics To Cover in InterviewsDocumento5 páginasJava Topics To Cover in InterviewsHemanth KumarAinda não há avaliações

- Fajs FSXDocumento8 páginasFajs FSXJunhy Bandeira CassandraAinda não há avaliações

- JU P-Tool Engineering DataDocumento1 páginaJU P-Tool Engineering Dataazze bouzAinda não há avaliações

- Crompton Greaves LimitedDocumento3 páginasCrompton Greaves LimitedNitish SinghAinda não há avaliações

- Technical Publications: Direction 2190775 100Documento21 páginasTechnical Publications: Direction 2190775 100zakaria alhosinyAinda não há avaliações

- G. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFDocumento2 páginasG. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFinitbashAinda não há avaliações