Escolar Documentos

Profissional Documentos

Cultura Documentos

Evaluation of Elastic Contants For Different Types of Reinforcements - 2

Enviado por

chetanDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Evaluation of Elastic Contants For Different Types of Reinforcements - 2

Enviado por

chetanDireitos autorais:

Formatos disponíveis

Prof S C Lakkad

23-09-2016

EVALUATION OF PROPERTIES

BASED ON REIFORCEMENT AND

RESIN PROPERTIES

1.3 Material Properties

Suitable polyster resin is used for making the FRP components the estimated

properties of the resin and glass reinforcement in various forms are:

Heat distorsion temperaure(470-300)

THDT 98.9

Young's modulus of resin

Er 3600

Rupture strain of the matrix resin

Poissons ratio for resin

r 0.038

r 0.35

Specific gravity of the resin

r 1.2

Poissons ratio for glass

g 0.22

Young's modulus of glass

Specific gravity of glass

Estimated specific gravity of FRP material

Density of WR

Density of CSM

Density of Unidirectional WR

Density of (+/-) 45o mat

Thickness of gel coat

oC

MPa

Eg 77500 MPa

g 2.68

FRP 1.6

mwr 0.6

mcsm 0.45

mudl 0.6

m45 0.6

tgel 0.8

1/11

Prof S C Lakkad

23-09-2016

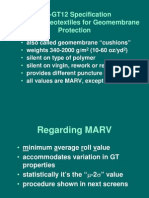

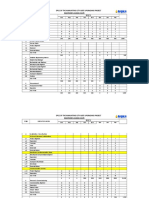

2. PROPERTIES OF COMPOSITE FRP LAMINATE

The minimum values of glass material in various forms, such as, chopped

strand mat (CSM), woven rovings (WR) and unidirectional woven (or

otherwise) rovings (UWR) for their surface mass desities (i.e. for kg/m2) are

given in Table 3 of EN 13121-3. An earlier version of it in the draft standard is

reproduced below.

2.1 Thickness of the Laminate

The thickness of the lamina per kg of the glass reinforcement per sq. meter is

given as

ti mg

100 mg

mg r

where m g is the reinforcement content by % mass and r is the resin specific gravity.

2/11

Prof S C Lakkad

23-09-2016

Assuming 35% glass content by weight for CSM and 45% for WR, for

"Hand-Lay-Up" process are respectively, the nominal thicknesses for 0.300 and

0.450 kg/m2 of CSM and 0.610 kg/m2 of WR are:

tcsm0.3 0.3 ti ( 35)

tcsm0.3 0.576

mm

twr0.60 0.60 ti ( 50)

twr0.60 0.724

mm

tcsm0.45 0.45 ti ( 35)

tcsm0.45 0.864

mm

For the pultrusion process with higher glass content the same values are:

tcsm0.3p 0.3 ti ( 65)

tcsm0.3p 0.247

mm

twr0.61p 0.61 ti ( 75)

twr0.61p 0.397

mm

tcsm0.45p 0.45 ti ( 75)

t45p m45 ti ( 75)

tcsm0.45p 0.293

2.1.1 Volume Frac ons

t45p 0.391

mm

mm

The glass content of often required as a volume fraction of glass to compute the

mechanical properties of composite lamiante. The volume fractiion of glass is

given by

Vg mgper

mgper r

100 g mgper g r

where mgper is the mass content of glass in percent.

2.2 Allowable Design Strains

The allowable design strain can be worked out from different considerations and

the lowest value has to be chosen as the allowable value.

Assuming the factor of safety for this kind of item as

K 6

(For chemical vessels this value is around 10)

3/11

Prof S C Lakkad

23-09-2016

1. The allowable strain from the resin properties:

ar 0.1 r

ar 3.8 10

2. Allowable strain from the lamina properties from Table 3

For CSM

200

14000 K

csm

For bidirectional WR

wr

csm 2.381 10

250

16000 K

wr 2.604 10

For Unidirectional WR along the length

uwrL

500

28000 K

uwrL 2.976 10

uwrN

60

4000 K

uwrN 2.5 10

For Unidirectional WR normal to the fibres,

For (+/-) 45o laminate one can a strain such that its resolved component normal

to the fibres does not exceed the value above.

45 2 uwrN

For pure shear considering the normal strain limit of the (+/-) 45o laminate, the

allowable shear strain is also,

d 2 uwrN

Since the laminate construction is going to be a combination of above types

of laminates the design strain is to taken as the minimum of the above

values:

d min ar csm uwrL uwrN 45

d 2.381 10

The allowable strain for only WR-CSM hand lay-up laminate is

dhl min ar csm wr

Hence the normal strain value of

is satisfactory.

dhl 2.381 10

d 2.381 10

4/11

Prof S C Lakkad

23-09-2016

Shear strain limited by across fibre strain is

3

d 2 uwrN

d 5 10

However, considering combined loading it can also be limited to

d d

2.3 Allowable Design Loading

2.3.1 Extensibility of Dierent Type of Reinforcements

The extensibility for each type of reiforcement per/kg of mass is given in the

table above.

However, the value for (+/-) 45o are not given. These values for per kg of mass

have to be derived from 'micro-mechanics' of composites. (Ref:Vinson &

Sierakowsky)

Shear modulus of glass

Gg

Shear modulus of the resin

Gr

Parameters

Gr

Gg

Eg

Er

Pr

1

Gr

2 1 g

2 1 r

Pg

Pr 1 Vg mgper Pg Vg mgper

P mgper

Vg mgper 1 Vg mgper

1

Gg

The shear modulus for unidirectional layer of mgper percent of glass by mass is:

G12 mgper

1

P mgper

The Poisson's ratio of unidirectional laminate is:

12 mgper g Vg mgper r 1 Vg mgper

5/11

Prof S C Lakkad

23-09-2016

Hence, the tensile extensibility of (+/-) 45o laminate for one kg/sq.m of glass

would be

Q11 mgper

Q12 mgper

28000

1 12 mgper

Q22 mgper

4000 12 mgper

1 12 mgper

4000

1 12 mgper

The extensibily for tensile load

X45 mgper Q11 mgper 2 Q12 mgper 2 G12 mgper

Q m

22 gper

4

1

Shear Extensibilities

The shear extensibily of (+/-) 45o laminate of (+/-) 45o laminate would be

X45sh mgper

2

1

Q11 mgper Q22 mgper 2 Q12 mgper

2

G12 mgper ( 0)

Shear extensibility of CSM

Xcsmsh

14000

2 ( 1 0.3)

being pseudo-isotropic

Shear extensibility of UDL

Shear extensibility of WR

Xudlsh mgper G12 mgper

Xwrsh mgper G12 mgper

These are all estimated values.

6/11

Prof S C Lakkad

23-09-2016

2.3.2 Extensibility of the Combined Laminates

The extensibility of the laminates for different type of construction in terms

of the mass of reinforcement is given as follows. For a combined

unidirectional, hoop filament winding and CSM laminate the extensibility

along 1-1 direction is

Xlam1 nudl1 nudl2 ncsm nwr n45 mgper 28000 nudl1 mudl

4000 nudl2 mudl

14000 ncsm mcsm

16000 nwr mwr

X45 mgper m45 n45

Extensibility in the 2-2 direction(perpendicular to earlier direction) with

UD,WR and CSM combination is

Xlam2 nudl1 nudl2 ncsm nwr n45 mgper 4000 nudl1 mudl

28000 nudl2 mudl

14000 ncsm mcsm

16000 nwr mwr

X45 mgper m45 n45

Xlam2 nudl1 nudl2 ncsm nwr n45 mgper 28000 nudl2 mudl

4000 nudl1 mudl

14000 ncsm mcsm

16000 nwr mwr

X45 mgper m45 n45

The extensibility of the laminate in shear is

Xlam12 nudl1 nudl2 ncsm nwr n45 mgper X45sh mgper m45 n45

Xudlsh mgper mudl nudl1

Xudlsh mgper mudl nudl2

Xwrsh mgper mwr nwr

Xcsmsh mcsm ncsm

mudl here includes udl-reinforcement in both 1-1 and 2-2 directions.

7/11

Prof S C Lakkad

23-09-2016

2.3.3 Nominal Thickness of the Laminate

The nominal thickness of the laminate for same content glass, depends on the

process of fabrication. It is much lower where compaction occurs.

The nominal thickness of a laminate made by Hand-lay-up process is:

tnomHL nudl1 nudl2 ncsm nwr n45 ncsm mcsm ti ( 35)

nwr mwr ti ( 50)

nudl1 mudl ti ( 50)

nudl2 mudl ti ( 50)

n45 m45 ti ( 50)

The nominal thickness for pultruded laminate would be

tnompl nudl1 nudl2 ncsm nwr n45 ncsm mcsm ti ( 60)

nwr mwr ti ( 60)

nudl1 mudl ti ( 60)

nudl2 mudl ti ( 60)

n45 m45 ti ( 60)

2.3.4 Elas c Contas of Laminates

For Hand-Lay-Up

The Young's modulus of the Hand-lay-up laminate in 1-1 direction is

E11hl nudl1 nudl2 ncsm nwr n45

tnomcsm450 ncsm ncsm mcsm ti ( 35)

E11csm450

Xlam1 ( 0 0 1 0 0 45)

tnomcsm450 ( 1)

Xlam1 nudl1 nudl2 ncsm nwr n45 45

tnomHL nudl1 nudl2 ncsm nwr n45

E11csm450 7.289 10

12 ( 35) 0.325

8/11

Prof S C Lakkad

23-09-2016

tnomwr600 nwr nwr mwr ti ( 50)

E11wr600

Xlam1 ( 0 0 0 1 0 45)

E11wr600 1.326 10

tnomwr600 ( 1)

12 ( 50) 0.31

In 2-2 direction

E22hl nudl1 nudl2 ncsm nwr n45

G12hl nudl1 nudl2 ncsm nwr n45

Xlam2 nudl1 nudl2 ncsm nwr n45 45

tnomHL nudl1 nudl2 ncsm nwr n45

Xlam12 nudl1 nudl2 ncsm nwr n45 45

tnomHL nudl1 nudl2 ncsm nwr n45

G12csm G12hl ( 0 0 1 0 0)

G12csm 2.803 10

G12wr G12hl ( 0 0 0 1 0)

G12wr 3.743 10

For Unidirectionally Reinforced Sections

The Young's modulus of the Pultruded sections in 1-1 direction is

E11pl nudl1 nudl2 ncsm nwr n45

E11ud E11pl ( 1 0 0 0 0)

In 2-2 direction

E22pl nudl1 nudl2 ncsm nwr n45

Xlam1 nudl1 nudl2 ncsm nwr n45 60

tnompl nudl1 nudl2 ncsm nwr n45

E11ud 3.015 10

Xlam2 nudl1 nudl2 ncsm nwr n45 60

tnompl nudl1 nudl2 ncsm nwr n45

3

9/11

Prof S C Lakkad

23-09-2016

E22ud E22pl ( 1 0 0 0 0)

E22ud 4.307 10

The shear modulus of the pultruded sections is:

G12pl nudl1 nudl2 ncsm nwr n45

G12ud G12pl ( 1 0 0 0 0)

Xlam12 nudl1 nudl2 ncsm nwr n45 60

tnompl nudl1 nudl2 ncsm nwr n45

G12ud 6.327 10

12 ( 60) 0.298

2.3.5 Allowable Tensile Loading

The allowable design unit loading in tension for a type of reinforcement is:

Ui Xi d d Xi

where Xi is the unit tensile modulus for that type of reinforcement.

Hand-Lay-Up

The allowable stress in the lengthwise 1-1 direction for HL laminate, based on

limiting strain is:

11hl nudl1 nudl2 ncsm nwr n45 d E11hl nudl1 nudl2 ncsm nwr n45

In 2-2 direction

22hl nudl1 nudl2 ncsm nwr n45 d E22hl nudl1 nudl2 ncsm nwr n45

Pultruded Sections

Allowable lengthwise (1-1) stress for pultruded sections is:

11pl nudl1 nudl2 ncsm nwr n45 d E11pl nudl1 nudl2 ncsm nwr n45

10/11

Prof S C Lakkad

23-09-2016

The allowable shear stress is

12pl nudl1 nudl2 ncsm nwr n45 d G12pl nudl1 nudl2 ncsm nwr n45

Note:

The glass content of the CSM is taken as 35%, of Woven Roving as 45% for

handlay-up process. The Values for pultrusion are taken as 75%. These values can

be changed in the functions.

11/11

Você também pode gostar

- Thin CylinderDocumento10 páginasThin Cylinderarunnical100% (3)

- HT Thin Film Strain GaugesDocumento5 páginasHT Thin Film Strain GaugesmukheshAinda não há avaliações

- Design of TurnbuckleDocumento9 páginasDesign of Turnbucklejaykyu75% (4)

- Bolt Tightening ForceDocumento1 páginaBolt Tightening Forceiwanguna71Ainda não há avaliações

- Bolt Strength PDFDocumento1 páginaBolt Strength PDFSilambarasi MurugesanAinda não há avaliações

- Product SpecificationDocumento31 páginasProduct SpecificationApple TeknisyanAinda não há avaliações

- DTS 10.2 Problems in Clutch DesignDocumento32 páginasDTS 10.2 Problems in Clutch Designr nilakandan100% (1)

- Composite Column - Calculation ExamplesDocumento62 páginasComposite Column - Calculation Examplesk1m1mak1Ainda não há avaliações

- Tightening ForceDocumento1 páginaTightening ForceLuisLauShAinda não há avaliações

- SM G610M SVC Manual PDFDocumento105 páginasSM G610M SVC Manual PDFJuan Carlos CarmonaAinda não há avaliações

- Geo SyntiticsDocumento25 páginasGeo SyntiticsTooba KhalidAinda não há avaliações

- Test DescriptionsDocumento20 páginasTest DescriptionsM KGAinda não há avaliações

- Screw Jack DesignDocumento17 páginasScrew Jack DesignMayur Prakash Jagtap75% (4)

- Samsung Galaxy J1 Ace Neo (SM-J111F) Service ManualDocumento81 páginasSamsung Galaxy J1 Ace Neo (SM-J111F) Service ManualLeonias Adrian100% (1)

- Hilti CatalogueDocumento194 páginasHilti CatalogueFeleki AttilaAinda não há avaliações

- Whiteboard-Shifter (2) Final Print (Repaired)Documento19 páginasWhiteboard-Shifter (2) Final Print (Repaired)Aklesh GuptaAinda não há avaliações

- Mak 214 Soru 3Documento3 páginasMak 214 Soru 3skeletonkey11Ainda não há avaliações

- AerodinamicaDocumento1 páginaAerodinamicaDaniel Cardenas RodriguezAinda não há avaliações

- Quay Walls - Combined - Wall - Buckling - TubesDocumento12 páginasQuay Walls - Combined - Wall - Buckling - TubesHugo LeiteAinda não há avaliações

- Lperiment NO-13: Tgle Juck Isatype Ot Surew Jack, Uhete Mimum Lasd Is LiftedwithDocumento18 páginasLperiment NO-13: Tgle Juck Isatype Ot Surew Jack, Uhete Mimum Lasd Is LiftedwithSahil NaikAinda não há avaliações

- Design of Bridge Sub Structure and FoundDocumento44 páginasDesign of Bridge Sub Structure and Foundsrinivasa raoAinda não há avaliações

- Raman Spectroscopic Determination of Residual Stresses in Diamond FilmsDocumento11 páginasRaman Spectroscopic Determination of Residual Stresses in Diamond FilmsEnriqe PuentesAinda não há avaliações

- Material PropertiesDocumento25 páginasMaterial PropertiesAbhijit SanjeevAinda não há avaliações

- Reducer SpoolDocumento13 páginasReducer SpoolSAGARAinda não há avaliações

- NE2571 Farmer DataSheet 10092018Documento1 páginaNE2571 Farmer DataSheet 10092018Gonzalo Suarez SanchezAinda não há avaliações

- Proper Bolt Axial Tightening Force and Proper Tightening TorqueDocumento1 páginaProper Bolt Axial Tightening Force and Proper Tightening Torquecmms88Ainda não há avaliações

- Product SpeDocumento39 páginasProduct SpeТолон СабыркулуулуAinda não há avaliações

- PROIECT-reductor CilindricDocumento68 páginasPROIECT-reductor CilindricMaxim Ionela100% (1)

- Solved Paper MST 1Documento3 páginasSolved Paper MST 1Shubham MahajanAinda não há avaliações

- Coefficient of Utilisation (Lighting Design)Documento3 páginasCoefficient of Utilisation (Lighting Design)Shrikant KajaleAinda não há avaliações

- Design of Diaphragm Word FileDocumento3 páginasDesign of Diaphragm Word Fileparas rahangdaleAinda não há avaliações

- Minimisation of Interlaminar Stress in Composite Wind Turbine BladesDocumento6 páginasMinimisation of Interlaminar Stress in Composite Wind Turbine Bladeslogeshboy007Ainda não há avaliações

- SM-J326AZ - SM-J327A - AZ - T - T1 Service Manual PDFDocumento101 páginasSM-J326AZ - SM-J327A - AZ - T - T1 Service Manual PDFAngel Ignacio Correa SerranoAinda não há avaliações

- SM-J111M SVC Manual PDFDocumento83 páginasSM-J111M SVC Manual PDFDija AgusAinda não há avaliações

- Design Against Fluctuating Loads of Helical SpringsDocumento29 páginasDesign Against Fluctuating Loads of Helical SpringsVikranth Deepak100% (1)

- Design of ChainDocumento9 páginasDesign of ChainArun Pravin APAinda não há avaliações

- Explicit Versus Implicit FEM in Rolling - 1990 PDFDocumento10 páginasExplicit Versus Implicit FEM in Rolling - 1990 PDFNikos VaxevanidisAinda não há avaliações

- Proper Bolt Axial Tightening ForceDocumento1 páginaProper Bolt Axial Tightening ForcePrabhu SelvaRajAinda não há avaliações

- Topal VikramDocumento24 páginasTopal Vikramvikram sethupathiAinda não há avaliações

- USYD Materials 2 Mech3362 Lab ReportDocumento4 páginasUSYD Materials 2 Mech3362 Lab ReportFlynn GouldAinda não há avaliações

- SM-J400F Pspec 2Documento42 páginasSM-J400F Pspec 2Beto VihAinda não há avaliações

- Screw Take UpsDocumento7 páginasScrew Take Upsjonodo89Ainda não há avaliações

- Shaft DesignDocumento18 páginasShaft DesignWest100% (1)

- Diepstraten Reflow Soldering With Tin Copper Eutectic SN100 Vs SACDocumento32 páginasDiepstraten Reflow Soldering With Tin Copper Eutectic SN100 Vs SACzloxyAinda não há avaliações

- ArukupuuuuuuuuuuuuuDocumento11 páginasArukupuuuuuuuuuuuuuGlaiza LacsonAinda não há avaliações

- Vibration Isolation For Machine Foundations - Guidelines: Indian StandardDocumento9 páginasVibration Isolation For Machine Foundations - Guidelines: Indian StandardUmar SabaAinda não há avaliações

- Samsung gt-p5200 Service Manual PDFDocumento95 páginasSamsung gt-p5200 Service Manual PDFJan SoukupAinda não há avaliações

- Amp 2021-07Documento9 páginasAmp 2021-07Renata OsunaAinda não há avaliações

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysNo EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysNota: 1 de 5 estrelas1/5 (1)

- Nuclear Magnetic Resonance: Petrophysical and Logging ApplicationsNo EverandNuclear Magnetic Resonance: Petrophysical and Logging ApplicationsNota: 5 de 5 estrelas5/5 (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresNo EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresNota: 4 de 5 estrelas4/5 (1)

- Fatigue Design: International Series on the Strength and Fracture of Materials and StructuresNo EverandFatigue Design: International Series on the Strength and Fracture of Materials and StructuresAinda não há avaliações

- Erbium-Doped Fiber Amplifiers: Fundamentals and TechnologyNo EverandErbium-Doped Fiber Amplifiers: Fundamentals and TechnologyNota: 5 de 5 estrelas5/5 (3)

- Dynamic Damage and FragmentationNo EverandDynamic Damage and FragmentationDavid Edward LambertAinda não há avaliações

- P-QAC-PLN-910-39451-Rev BDocumento23 páginasP-QAC-PLN-910-39451-Rev BAslaouiAinda não há avaliações

- Allowable Stress in PipingDocumento6 páginasAllowable Stress in PipingpelotoAinda não há avaliações

- Cost EstimateDocumento82 páginasCost EstimateSatya Prakash SinghAinda não há avaliações

- AGRU-Technical-Butt WeldingDocumento4 páginasAGRU-Technical-Butt Weldingrenne_mujicaAinda não há avaliações

- T-216.02-8 Rev3 Nov2014Documento1 páginaT-216.02-8 Rev3 Nov2014Suyudi Akbari HabibiAinda não há avaliações

- Building Materials Module 1 PPT NotesDocumento20 páginasBuilding Materials Module 1 PPT NotesmanojAinda não há avaliações

- ASME B18.17 - Wing-NutsDocumento2 páginasASME B18.17 - Wing-NutsMario FonsecaAinda não há avaliações

- KAT-A 1912 DUOJET Edition13 02-01-2017 ENDocumento6 páginasKAT-A 1912 DUOJET Edition13 02-01-2017 ENwinston11Ainda não há avaliações

- StrengthDocumento74 páginasStrengthAdrianKarlBonaAinda não há avaliações

- Rooms and Places in The House: David Ernesto Rico SaucedoDocumento10 páginasRooms and Places in The House: David Ernesto Rico SaucedoRICO RICOAinda não há avaliações

- Coorporate Office BuildingDocumento35 páginasCoorporate Office BuildingSivaiAinda não há avaliações

- Paling BillDocumento5 páginasPaling Billanon_b186Ainda não há avaliações

- Oi/N Malaysia Final Examination: SessionDocumento10 páginasOi/N Malaysia Final Examination: Sessionsharif100% (1)

- Manpower HistogramDocumento15 páginasManpower HistogramZaem Afifi100% (3)

- Trane AnalisisDocumento13 páginasTrane AnalisisHendri PoerbaAinda não há avaliações

- Speech Notes - Building NationsDocumento5 páginasSpeech Notes - Building NationsAnonymous ptVOSrGAinda não há avaliações

- Underwater ConstructionDocumento38 páginasUnderwater ConstructionAradhana SinghAinda não há avaliações

- Symbiosis University Hospital and Research CentreDocumento11 páginasSymbiosis University Hospital and Research Centre052 Deepak NaralaAinda não há avaliações

- CE 335 July 9 2020Documento5 páginasCE 335 July 9 2020Emmanuel CausonAinda não há avaliações

- Columns: 2 Order Moments in Sway and Non-Sway FramesDocumento62 páginasColumns: 2 Order Moments in Sway and Non-Sway FramesMISKIR TADESSEAinda não há avaliações

- 753 SN 5158 11001 Parts CatalogDocumento692 páginas753 SN 5158 11001 Parts CatalogГалина Карташова100% (2)

- Bridge Abutment Des.Documento91 páginasBridge Abutment Des.Ashraf KhanAinda não há avaliações

- Astm C 33Documento7 páginasAstm C 33alfonso mendoza0% (1)

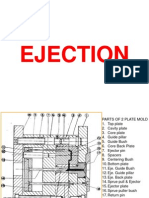

- K EjectionDocumento21 páginasK EjectionAmolPagdalAinda não há avaliações

- MEDocumento2 páginasMEliezl binAinda não há avaliações

- Multi Stage Centrifugal PumpDocumento72 páginasMulti Stage Centrifugal PumpTg Tarro100% (7)

- JDE 12 - Design of ColumnsDocumento47 páginasJDE 12 - Design of Columnsyedida viswanadhAinda não há avaliações

- MDB Lesson 4 Poisson's Ratio-Biaxial and Triaxial DeformationsDocumento12 páginasMDB Lesson 4 Poisson's Ratio-Biaxial and Triaxial DeformationsChan MirandaAinda não há avaliações

- 2020 Speck CatalogueDocumento48 páginas2020 Speck CatalogueKunming WangAinda não há avaliações

- Neca 600 (Medium Voltage Cable)Documento42 páginasNeca 600 (Medium Voltage Cable)UET MAIN100% (1)