Escolar Documentos

Profissional Documentos

Cultura Documentos

The Behavior of A514 Steel Tension Members

Enviado por

qazim7860 notas0% acharam este documento útil (0 voto)

36 visualizações2 páginasDiscussion- The Behavior of A514 Steel Tension Members

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDiscussion- The Behavior of A514 Steel Tension Members

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

36 visualizações2 páginasThe Behavior of A514 Steel Tension Members

Enviado por

qazim786Discussion- The Behavior of A514 Steel Tension Members

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

The Behavior Of A514 Steel Tension Members

Paper presented by G. L. K U L A K (January 1971 issue)

Discussion by John N. Macadam

T h e standard tension coupon tests described in the beginning of the paper, were conducted in a rather nonstandard manner as far as many laboratories and producers are concerned. In the normal tension test procedure the machine is not stopped for some ten minute

intervals to obtain a static yield stress level. Typical

autographic load-strain curves for tension tests on A514

steel do not exhibit an upper and lower yield point nor

any significant yield point elongation region as the author

has noted. T h e writer wonders whether the type of stressstrain curve shown as typical by the author is due to a

metallurgical effect or the method of testing.

T h e author's tension tests on small bars of A514 steel

with different hole patterns pointedly demonstrated the

overall tensile deformation capacity in terms of the net

section-to-gross section ratio. If such members should be

proportioned to achieve gross section yield prior to net

section tensile failure as suggested, then AjAg

^ YS/TS

or0.87forA514.

John N. Macadam is Supervising Research Structural Engineer,

Armco Steel Corporation, Middletown, Ohio.

Ill

J U L Y / 1971

H i g h strength steels in general have an inherently

high YS/Ts ratio. I n addition to A514 steel, other steels

included within the scope of the A I S C Design Specification also have high YS/TS ratios. Examples are coldformed carbon steel structural tubing (0.87 for A500

G r a d e A Shaped Tubing) and the higher yield strength

grades of A572. T h e author concludes that the spread

between yiejd and tensile strengths of as-delivered A514

steel is even less than indicated by m i n i m u m specified

properties. However, this would probably be the case for

all common structural steels.

T h e author's point about previous bolted joint experiments being concerned only with joint behavior

without including the full member is well taken. H e

refers to his tests as members with simulated joints, b u t in

fact the specimens were simply single bars with holes in

the central portion. In actual joints, such as double-shear

butt joints for instance, several other effects are present

which contribute to the total deformation of the member

and joint. Slip in the bolted joint, fastener deformation,

and bearing deformation, together with the basic member

strain, add u p to the total elongation. There is probably

justification for experimental work on actual complete

A514 tension members with joints.

Undoubtedly, it would be desirable to proportion a

bolted connection such that gross section yielding would

occur prior to failure in the joint itself, but it may not be

a necessary design philosophy. Very often other considerations such as fatigue 1 may control, which would

make gross section yielding impossible to attain.

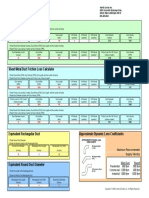

Consider the design of A514 joint using the 1969

A I S C Design Specification. Section 1.5.1.1 limits the

allowable tension stress on the net section to 0.6 Fy b u t

not more than 0.5 time the m i n i m u m tensile strength of

steel. Since the YS/TS ratio of A514 steel is greater than

5/6, the latter provision applies. Furthermore, Section

1.14.3 limits the net section to no more than 85 percent of

the corresponding gross section. These two criteria result

in a gross section stress limit of:

<rg ^

ag ^ 48.9 ksi for A514

Hence, there is a m i n i m u m safety factor of 2.05 against

yield in the gross section and 2.0 against ultimate tensile

strength of the net section. T h e writer feels that this

design philosophy represents good engineering practice.

Research has shown 2 that the behavior of A514 joints

can be predicted accurately on the same general basis as

for lower strength structural steels. A current research

investigation 3 includes bolted connection tests using

steels with YS/ TS ratios very near unity. Although these

materials are of a different class and thickness category,

the bolted connection test results indicate that a high

YS/ TS ratio has little effect on behavior in tension on the

net section.

Use of constructional alloy steel naturally requires

certain new and different design considerations than

those associated with lower strength steels. Continuing

research, such as reported by the author, is necessary

and valuable to the engineering profession. However,

A514 tension members are amenable to satisfactory design and offer attractive material savings in many cases.

REFERENCES

1. Birkemoe, P. C, Meinheit, D. F., and Munse, W. H. Fatigue of

A514 Steel in Bolted Connections Journal of the Structural

Division, ASCE Vol. 95, No. ST 10, Oct. 1969.

2. Kulak, G.L. and Fisher, J. W. A514 Steel Joints Fastened by

A490 Bolts Journal of the Structural Division, ASCE Vol. 94.

No. ST 10, Oct., 1968,

3. Dhalla, A. K., Err era, S. J., and Winter, G. Connections ir

T h i n Low-Ductility Steels Paper presented at ASCE Specialt)

Conference on Steel Structures, Columbia, Missouri, June, 1970.

112

AISC

ENGINEERING

JOURNAL

0.85(0.5)a r 5

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Geometric Design of Highways Part 3Documento7 páginasGeometric Design of Highways Part 3jun junAinda não há avaliações

- Halliburton PESA 2010 Spring JanniseDocumento29 páginasHalliburton PESA 2010 Spring JanniseFerdana EldriansyahAinda não há avaliações

- TMK Premium ConnectionsDocumento71 páginasTMK Premium Connectionsqazim786Ainda não há avaliações

- ViscosityDocumento14 páginasViscosityAnurag JaiswalAinda não há avaliações

- How Acoustic Levitation WorksDocumento8 páginasHow Acoustic Levitation WorksclarinvalAinda não há avaliações

- Jfe Steel OctgDocumento39 páginasJfe Steel Octgzdq02Ainda não há avaliações

- Basics of Light Microscopy ImagingDocumento55 páginasBasics of Light Microscopy Imagingqazim786Ainda não há avaliações

- Summative Test in Grade 10 ScienceDocumento2 páginasSummative Test in Grade 10 ScienceRomeo GabitananAinda não há avaliações

- Coiled Tubing Introduction-Part 1Documento109 páginasCoiled Tubing Introduction-Part 1qazim786100% (3)

- Flexible Duct Friction Loss CalculatorDocumento1 páginaFlexible Duct Friction Loss CalculatorThinh TranAinda não há avaliações

- HajjOUmraKiMasnoonDuaainBySheikhMuhammadYunusPalanpuri PDFDocumento76 páginasHajjOUmraKiMasnoonDuaainBySheikhMuhammadYunusPalanpuri PDFMoulana Mohammad Musa ShakirAinda não há avaliações

- Madinah Landmarks 2014 PDFDocumento41 páginasMadinah Landmarks 2014 PDFqazim786Ainda não há avaliações

- Istefsaraat 1Documento438 páginasIstefsaraat 1qazim786Ainda não há avaliações

- Jadeed JahayleeatDocumento314 páginasJadeed Jahayleeatqazim786Ainda não há avaliações

- Ehsan Kya Hai PDFDocumento25 páginasEhsan Kya Hai PDFqazim786Ainda não há avaliações

- Candy Exercise Simple Data AnalysisDocumento5 páginasCandy Exercise Simple Data Analysisqazim786Ainda não há avaliações

- Candy Exercise Simple Data AnalysisDocumento5 páginasCandy Exercise Simple Data Analysisqazim786Ainda não há avaliações

- Al Ihtijaj by Allama Abu Mansur Ahmad Tibrisi Vol 2 PDFDocumento187 páginasAl Ihtijaj by Allama Abu Mansur Ahmad Tibrisi Vol 2 PDFqazim786Ainda não há avaliações

- KAIZEN Forum Global KAIZEN StrategyDocumento4 páginasKAIZEN Forum Global KAIZEN Strategyqazim786100% (1)

- Imex Canada INC.-Drill Pipe and AccessoriesDocumento16 páginasImex Canada INC.-Drill Pipe and Accessoriesqazim786Ainda não há avaliações

- ALI As Ek Deomalai Sach by DR Ali Shariati PDFDocumento104 páginasALI As Ek Deomalai Sach by DR Ali Shariati PDFqazim786100% (1)

- Rust Veto AsDocumento8 páginasRust Veto Asqazim786Ainda não há avaliações

- Concrete Under Uniaxial CompressionDocumento11 páginasConcrete Under Uniaxial Compressionsreejithp1040% (1)

- Curva de Empastamiento Harina de ChontaduroDocumento32 páginasCurva de Empastamiento Harina de ChontaduroJaider Santiago PastranaAinda não há avaliações

- Collisions in Two DimensionsDocumento3 páginasCollisions in Two DimensionsalienlightningAinda não há avaliações

- Thermodynamics 2Documento20 páginasThermodynamics 2SHIVAMAinda não há avaliações

- Experiment No: 1: Slotted Link Mechanism ExperimentDocumento4 páginasExperiment No: 1: Slotted Link Mechanism ExperimentSamina TariqAinda não há avaliações

- Spring StiffnessDocumento29 páginasSpring Stiffnessahmed osmanAinda não há avaliações

- 2015 H2 Promo P1 EditedDocumento15 páginas2015 H2 Promo P1 EditedLim Kew ChongAinda não há avaliações

- 05 NAC Initial Longitudinal Stability (160213)Documento22 páginas05 NAC Initial Longitudinal Stability (160213)Silver BlazeAinda não há avaliações

- Motion in One DimensionDocumento8 páginasMotion in One DimensionSukanya VedavyasaAinda não há avaliações

- DARPA Instant Flame Suppression Phase II - Final RepostDocumento23 páginasDARPA Instant Flame Suppression Phase II - Final Repostyikes salAinda não há avaliações

- Codal Provisions For Pile FoundationDocumento12 páginasCodal Provisions For Pile FoundationAshutoshWankhade100% (1)

- Ultrasonic DetectionDocumento8 páginasUltrasonic DetectionSaravanan ViswakarmaAinda não há avaliações

- Engineering Mechanics Practice ProblemsDocumento4 páginasEngineering Mechanics Practice Problemsjc casordAinda não há avaliações

- By Ferdinand P. Beer & E. Russell Johnston Jr. With Notes by J. Walt Oler (Texas Tech University)Documento20 páginasBy Ferdinand P. Beer & E. Russell Johnston Jr. With Notes by J. Walt Oler (Texas Tech University)Aizabelle FerrerasAinda não há avaliações

- Class 9 Sci Topic 1 - Laws of Motion - Notes - Awatade ClassesDocumento7 páginasClass 9 Sci Topic 1 - Laws of Motion - Notes - Awatade ClassesRamkrishnahari RaskarAinda não há avaliações

- Ch26 Giancoli7e ManualDocumento24 páginasCh26 Giancoli7e ManualRMAinda não há avaliações

- APSC 178 - Assignment 1Documento2 páginasAPSC 178 - Assignment 1700spymaster007Ainda não há avaliações

- Lecture 3 - Airworthiness and Flight EnvelopeDocumento24 páginasLecture 3 - Airworthiness and Flight EnvelopeCATIA BACKUPAinda não há avaliações

- Fatiga Vigas Con GeosintéticosDocumento13 páginasFatiga Vigas Con GeosintéticosRuben PolischukAinda não há avaliações

- Momentum Worksheet1 2Documento4 páginasMomentum Worksheet1 2trical27 tricalAinda não há avaliações

- Physically Distanced But Academically EngagedDocumento11 páginasPhysically Distanced But Academically EngagedMa. Teresa OcularAinda não há avaliações

- 25.06.23 - JR - Star Co-Sc (Model-B) - Jee - Main - CTM-3 - Key&solDocumento14 páginas25.06.23 - JR - Star Co-Sc (Model-B) - Jee - Main - CTM-3 - Key&solAnonymous A6Jnef04Ainda não há avaliações

- Unit 2 DYNAMIC FORCE ANALYSISDocumento39 páginasUnit 2 DYNAMIC FORCE ANALYSISswetha shree chavan mAinda não há avaliações

- Student Exploration: Waves: Vocabulary: Amplitude, Compression, Crest, Frequency, Longitudinal Wave, Medium, PeriodDocumento7 páginasStudent Exploration: Waves: Vocabulary: Amplitude, Compression, Crest, Frequency, Longitudinal Wave, Medium, PeriodNims DaydaAinda não há avaliações

- Chapter 29-Magnetic FieldsDocumento43 páginasChapter 29-Magnetic FieldsGled HysiAinda não há avaliações