Escolar Documentos

Profissional Documentos

Cultura Documentos

Light Vehicle Transmission Systems PDF

Enviado por

Maulana FajriansyahTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Light Vehicle Transmission Systems PDF

Enviado por

Maulana FajriansyahDireitos autorais:

Formatos disponíveis

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

Unit 12:

Light Vehicle Transmission

Systems

NQF Level 3:

BTEC National

Guided learning hours: 60

Unit abstract

This unit will provide learners with an understanding of the various designs,

constructional details and fundamental operating principles of a range of

transmission systems currently fitted to both production and motorsport vehicles.

The unit covers the conventional aspects of vehicle transmission systems, their

function, principal components and operating principles. This will include a detailed

examination of the three major systems a vehicles clutch mechanism, gearbox and

the driveline and final drive systems.

Learners will be introduced to the most recent developments in the use of

electronics for the control and operation of transmissions systems in both standard

production vehicles and motorsport applications. These developments are now

frequently integrated into the overall electronic management of the vehicle and can

provide significant improvements in terms of driveability, economy and performance.

Learners will appreciate the fundamental operating principles of these

developments, their integration within transmission systems and their significance in

the maintenance of a vehicles transmission system.

Finally, learners will carry out specific tests and checks to identify transmission

system faults such as clutch slip, gearbox linkage problems and failing constant

velocity joints. Learners will use these tests and checks, together with on-board

diagnostic equipment, in order to maintain a vehicles transmission system. This will

include the maintenance requirements relating to driver/passenger safety and

component reliability, whilst ensuring that learners work in a safe manner.

Learning outcomes

On completion of this unit a learner should:

1

Understand the construction and operation of a vehicle clutch mechanism

Understand the construction and operation of a vehicle gearbox

Understand the construction and operation of a vehicle driveline system and final

drive

Be able to maintain a vehicles transmission system.

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

Unit content

Understand the construction and operation of a vehicle clutch mechanism

Principal clutch components: pressure plate, disc, flywheel (including bearings

and bushes); release bearings; release systems eg production vehicles (hydraulic,

mechanical and cable), motorsport vehicles (push/pull and electro-hydraulic

actuating mechanisms)

Types of clutch mechanisms: eg production clutches (coil and diaphragm spring,

single plate, wet and dry types), automatic clutches (torque converter, fluid

flywheel, one way clutch), motorsport clutches (paddle, slipper and multi-plate)

Operating principles of clutch: constructional design and use of materials (linings,

drive plates and friction surfaces, springs); engagement and disengagement of

clutch (single and multiplate, one way clutches and automatic clutches);

provision for adjustment/self-adjustment; torque calculations and coefficient of

friction; power flow; common faults eg wear, misalignment; fault symptoms (slip,

drag, judder, overheating); fluid flywheels

Understand the construction and operation of a vehicle gearbox

Principal gearbox components: gear design (spur and helical); bearings, shafts,

casing, selector and sealing arrangements; gear locking and interlock

mechanisms; gear speed synchronisation and engagement mechanisms eg sliding

mesh, synchromesh and dog type

Types of gearboxes: eg manual (single stage, double stage, sliding mesh, constant

mesh), automatic (epicyclic gear train, hydraulic control systems); layout eg

transverse, longitudinal and transaxle

Operating principles of gearbox: manual gearbox gear ratios, power flow eg

constant mesh single and double stage; torque and speed calculations; gear ratio

characteristics and number of available gears; selection and engagement methods

eg synchromesh and dog type, selector forks, interlocks and linkages, remote

control mechanisms, motorsport (sequential, electro-hydraulic); automatic

gearbox torque converters (lock-up mechanism); epicyclic gear trains (simple

and compound); brake bands; multiplate and unidirectional clutches; power flow

paths; function of key hydraulic components (pump, governor, actuators, servos,

regulator and shift valves); electronic control system including mode selection;

electronic selection of conventional gear arrangements; lubrication eg method

(splash and pump assisted); oil requirements and types (mineral, synthetic); seals

and sealing arrangements (static and dynamic types)

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

Understand the construction and operation of a vehicle driveline system and

final drive

Principal components of driveline system: propeller shaft arrangement eg single,

divided; driveline arrangements eg front, rear and four wheel; universal joints eg

Hooke type and rubber; constant velocity joints, sliding joints; drive systems eg

two-wheel, four-wheel (transfer box, centre differentials, viscous couplings,

differential locks, automatic and manual)

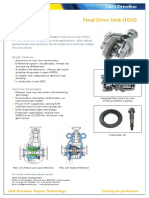

Principal components of final drive: axle types and support arrangements eg

transaxles, live and independent; final drives eg bevel, spiral and hypoid;

differentials eg planetary gears, limited slip systems; axle types eg semi, three

quarter and fully floating; bearings

Operating principles of driveline: universal joints (Hooke type and rubber);

constant velocity joints (angular limitations and conditions required to achieve

constant velocity, basic consideration of balance requirements, alignment and

torque capacity of hollow and solid shafts); suspension and transmission

characteristics giving rise to the requirement for sliding joints and centre

propshaft bearings

Operating principles of final drive: gear ratio, speed reduction and torque

multiplication in the final drive; final drive arrangements for transaxles; driving

thrust and torque reaction; differential (effects on torque/speed at the driven

wheels, limited-slip differentials); lubrication methods (final drive and rear

axles); oil requirements and types (mineral, synthetic); oil seals and sealing

arrangements (static and dynamic)

Be able to maintain a vehicles transmission system

Transmission system faults: eg clutch (slip, drag, judder, loss of drive, excessive

noise, wear, misalignment, operating mechanism faults), gearbox (gear selection,

oil leaks, linkages and fittings), driveline and finals drives (prop/drive shafts,

universal and CV joints, bearings, gaiters and seals), use of on-board diagnostic

(OBD) equipment, reporting methods (inspection records, oral report to

supervisor)

Maintenance operations: working to manufacturers maintenance and service

procedures eg manuals, job cards, direct supervision; maintenance operations eg

clutch adjustments/alignment, gearbox oil change, gear selection linkage repair,

driveshaft gaiter condition check/replacement, security of mountings and

fittings; context of the maintenance operations eg routine maintenance, repair or

adjustment due to a system failure, alternative service procedures for adverse

condition (vehicles operating in dry, dusty environments, race/rally vehicles and

vehicles working in extreme temperature environments)

Critical safety considerations: procedures relating to maintenance operations

carried out eg materials handling (protection against dust, oil and chemical

exposure), vehicle and system protection (application of four-wheel drive diff

locks, lifting and supporting vehicles), personal protective equipment (PPE),

control of substances hazardous to health regulations (COSHH), component and

environmental waste disposal

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

justify the use of a specific type of

driveline and final drive arrangement for

two different vehicle applications in

terms of purpose, function and

performance.

D2

explain the advantages and

disadvantages of increasing the number

of available gears in a gearbox

compare two different vehicle driveline

and final drive arrangements.

M2

M3

explain the operating principles of one

type of clutch

identify and describe the function of the

principal components of one type of

gearbox

explain the operating principles of two

different types of vehicle gearbox

identify and describe the principal

components in a vehicle driveline and

final drive

explain the operating principles of a

vehicles driveline and final drive

arrangement

P2

P3

P4

P5

P6

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

justify the use of a specific clutch type

for two different vehicle applications in

terms of purpose, function and

performance

D1

compare two different vehicle clutch

types in terms of their principal

components and operating principles

M1

identify and describe the function of the

principal components of two different

types of clutch mechanism

P1

To achieve a distinction grade the evidence

must show that, in addition to the pass and

merit criteria, the learner is able to:

To achieve a merit grade the evidence must

show that, in addition to the pass criteria,

the learner is able to:

To achieve a pass grade the evidence must

show that the learner is able to:

Grading criteria

In order to pass this unit, the evidence that the learner presents for assessment needs to demonstrate that they can meet all of the learning

outcomes for the unit. The criteria for a pass grade describes the level of achievement required to pass this unit.

Grading grid

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

carry out a maintenance operation on a

vehicles transmission system

explain and apply critical safety

considerations relating to the inspection

and maintenance of a vehicles

transmission system.

P8

P9

To achieve a merit grade the evidence must

show that, in addition to the pass criteria,

the learner is able to:

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

inspect a vehicles transmission system,

report faults and attribute symptoms to

the faults identified

P7

To achieve a pass grade the evidence must

show that the learner is able to:

Grading criteria

To achieve a distinction grade the evidence

must show that, in addition to the pass and

merit criteria, the learner is able to:

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

Essential guidance for tutors

Delivery

This unit can be delivered in the context of the learners chosen area (eg light

vehicle, motorsport), although a generic approach is also suitable. The term

maintenance in this unit is used in a generic way and can be taken to mean either

routine maintenance (a regular service) or less routine work (a repair due to a

component failure or adjustment to correct a misalignment).

Delivery of this unit would ideally include a balance of theoretical and practical

study. Whatever approach is taken, the learners experience should be sufficiently

varied to give them the knowledge and skills needed to perform routine motor

vehicle workshop operations. In addition, learners need to develop the skills and

understanding needed to diagnose transmission system faults in an industrial setting.

Health and safety considerations should be given appropriate emphasis when learners

are undertaking practical activities.

The learning outcomes could be delivered in the order they are listed. In this way,

learners will begin to understand the function and operating principles of the

relevant parts of the power train from the clutch to the gearbox and through the

driveline to the final drive.

Learners should be introduced to the range of clutches production, automatic and

motorsport variations. However, centres may wish to specialise on a specific clutch

type to meet local needs and cover the others in a more general way. The approach

taken with clutches could be replicated with gearboxes, the driveline and final drive.

However, tutors should ensure that learners gain sufficient understanding of all types

and delivery should not be limited to just the one or two required to meet the

assessment criteria.

For the final learning outcome learners will need access to vehicles and workshop

facilities. The delivery of this part of the unit could consist of lectures to introduce

the transmission system and likely faults, learner-led research into the maintenance

requirements followed by practical application on vehicles in the workshop. Again,

learners should experience a range of routine maintenance operations in line with

those suggested in the unit content.

During practical work, the critical safety aspects of each operation need to be

emphasised. Learners should be encouraged to recognise and explain these aspects of

safety during their practical workshop activities to reinforce the importance to

themselves and others.

The use of a record of practical work carried out should be standard practice. This is

likely to be in the form of a workshop logbook. Such a record will enable learners to

capture and reflect on their experience and will provide support and guidance during

the activities chosen for the final assessment.

Note that the use of eg in the content is to give an indication and an illustration of

the breadth and depth of the area of topic. As such, not all content that follows an

eg needs to be taught or assessed.

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

Assessment

This unit provides opportunities for assessment evidence to be generated from a

combination of assignments, projects and practical work. Centres may wish to devise

tests that require learners to describe, explain, compare or justify, as required by

the criteria. However, although most of the pass criteria require identification,

explanation and descriptive evidence it is not expected that centres only use tests to

achieve this. The unit lends itself to an investigative, practical approach and this

should be reflected in the assessment strategy wherever possible. The range of

evidence presented could include notes, diagrams, investigative test data and the

records of the maintenance and diagnostic procedures carried out.

Proving authenticity and plagiarism is always a problem, particularly with open

written report-type assignments. The assessment of P1 and P3 is suited to and could

be carried out through on-the-job oral questioning or through a written time

constrained assessment to ensure authenticity.

To achieve a pass, learners will need to identify and describe the function of the

principal components of two types of clutch mechanism (P1), one gearbox (P3) and a

vehicles driveline and final drive (P5). In addition, learners need to explain the

operating principles of one of the clutches (P2), two types of gearbox (P4) and one

vehicles driveline and final drive (P6). The unit content for each of these areas

provides a range of choices through the examples listed. For clutches, this includes

production, automatic and motorsport, and within these groupings there are further

examples. Tutors are expected to cover as wide a range of these as possible during

delivery of the unit but need only select the one or two of these, as indicated by the

criteria, for assessment purposes. This will enable tutors to concentrate on a specific

specialisation as the main focus of assessment (eg motorsport paddle clutch). Where

a criterion identifies that learners must consider two types then this is to ensure that

the learning process is sufficiently wide. For example whilst a centre may specialise

in motorsport it is important that learners are equally aware of a production

vehicles clutch or vice-versa. The purpose here is to make sure that learners

employment potential is not limited. The range of choices available should mean that

for any one group, each learner could be considering the function of the principle

components for a different type of vehicle and clutch type. This can be beneficial

when considering the issue of authenticity of learner evidence.

At pass level, learners should also be able to inspect a vehicles transmission system

(P7), carry out a routine maintenance operation (P8) and explain and apply critical

safety considerations (P9). P7 and P8 would be best assessed through investigation

and practical examination of a live vehicle layout and configuration. P9 should be an

integral part of the assessment for P7 and P8. It is strongly recommended that the

explain part of P9 is assessed before learners start any work on either P7 or P8. The

assessment evidence for P9 could be in two forms. Firstly, a written assessment of

the critical safety considerations relating to the inspection and maintenance

operation to be carried out, followed by oral questioning to ensure an understanding

of the dangers associated with the task before starting work.

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

A suitable transmission system fault may need to be simulated for P7 and learners

provided with the typical symptoms of the fault, as would be reported by a driver of

the faulty vehicle. Assessment of this criterion is likely to be in three parts a

written inspection record completed by learners at the time of the inspection, a

verbal report back to the supervisor/customer (tutor record of oral

questioning/observation) and tutor observation of the process (eg use of logical and

efficient diagnostic techniques, safe working). A similar approach could be taken

with P8 and it would be sensible to link these two criteria together identify the

fault and carry out the maintenance operation to effect the necessary adjustment or

repair. The main assessment evidence for P8 would be the final product the

completed maintenance task. However, a record of tutor observation will also be

necessary to cover the process aspects of the task (eg working to the manufacturers

procedures, correct and safe working). The final link is with P9 and the application of

critical safety considerations relating to the maintenance operation being carried

out. For example, tutors will need to observe learners handling materials correctly,

using relevant system protection, using appropriate PPE, working to COSHH

regulations and correctly disposing of waste, as required by the task undertaken.

To achieve a merit, learners need to compare the constructional differences of two

different clutch types (eg production diaphragm spring versus motorsport paddle or

production wet versus production dry types). The two clutches could be the same as

those considered for P1, or if tutors wish to encourage learners to have wider

experience then one or two completely different clutches could be used. The focus

of the comparison should be based on the understanding developed through P1 and

P2. Learners must also explain the advantages and disadvantages of multiple gear

ratio applications (eg 3 speed versus 4 speed, 5 speed versus 6 speed). Finally, they

need to compare two different vehicle driveline and final drive arrangements (eg

longitudinal, in line versus transverse or rear engine, rear wheel drive versus rear

engine four wheel-drive). Again, one of these could be the driveline and final drive

considered for P5 and P6.

To achieve a distinction, learners need to justify the use of two different clutch

types and two different types of driveline and final drive arrangements for differing

applications (eg production, fast road, motorsport track, motorsport rally), in terms

of purpose, function and performance. Once again, these could be the same

clutches, driveline and final drives that learners have been working with through the

pass and merit criteria.

Links to National Occupational Standards, other BTEC units, other BTEC

qualifications and other relevant units and qualifications

This unit provides some of the knowledge and understanding for the NVQ Level 3 in

Vehicle Maintenance and Repair, particularly:

Unit MR13: Diagnose and Rectify Vehicle Transmission and Driveline System Faults

Unit MR13HV: Diagnose and Rectify Commercial Vehicle Transmission and

Driveline System Faults.

The unit builds on the knowledge gained from Unit 1: Operation of Vehicle Systems

and supports Unit 3: Vehicle Fault Diagnosis and Rectification.

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

Essential resources

Learners will need access to a range of transmission types (clutches, gearboxes and

driveline/final drives) and their components for this unit. A variety of information

and data sources specific to the transmission systems will also be required. The

necessary special tools and equipment will be needed for investigation and routine

maintenance of the selected transmission systems as defined in the unit content and

grading criteria.

Indicative reading for learners

Denton T Advanced Automotive Fault Diagnosis (Butterworth-Heinemann, 2006)

ISBN 0750669918

Heisler H Advanced Vehicle Technology (Butterworth-Heinemann, 2002)

ISBN 0750651318

Hillier V and Coombes, P Hilliers Fundamentals of Motor Vehicle Technology: Book

1 (Nelson Thornes, 2004) ISBN 0748780823

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

Key skills

Achievement of key skills is not a requirement of this qualification but it is

encouraged. Suggestions of opportunities for the generation of Level 3 key skill

evidence are given here. Tutors should check that learners have produced all the

evidence required by part B of the key skills specifications when assessing this

evidence. Learners may need to develop additional evidence elsewhere to fully meet

the requirements of the key skills specifications.

Communication Level 3

When learners are:

They should be able to develop the following

key skills evidence:

C3.2

Read and synthesise information from at

least two documents about the same

subject. Each document must be a

minimum of 1000 words long.

C3.3

Write two different types of documents

each one giving different information

about complex subjects. One document

must be at least 1000 words long.

selecting materials and

researching information on

vehicle transmission systems

(eg safety, maintenance and

diagnostic data)

explaining the operating

principles of vehicle

clutches, gearboxes,

drivelines and final drives.

Information and communication technology Level 3

When learners are:

They should be able to develop the following

key skills evidence:

searching for information on

specific vehicle transmission

systems

ICT3.1 Search for information, using different

sources, and multiple search criteria in at

least one case.

preparing and presenting

technical reports on the

various aspects of vehicle

transmission systems and

their components and

arrangements

ICT3.2 Enter and develop the information and

derive new information.

10

ICT3.3 Present combined information such as

text with image, text with number,

image with number.

completing maintenance

documents and records.

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

UNIT 12: LIGHT VEHICLE TRANSMISSION SYSTEMS

Improving own learning and performance Level 3

When learners are:

They should be able to develop the following

key skills evidence:

researching, planning and

carrying out diagnostic and

maintenance procedures

LP3.1

Set targets using information from

appropriate people and plan how these

will be met

evaluating maintenance,

diagnostic and repair

strategies.

LP3.2

Take responsibility for your learning,

using your plan to help meet targets and

improve your performance

LP3.3

Review progress and establish evidence of

your achievements.

Problem solving Level 3

When learners are:

They should be able to develop the following

key skills evidence:

PS3.1

Explore a problem and identify different

ways of tackling it.

PS3.2

Plan and implement at least one way of

solving the problem.

PS3.3

Check if the problem has been solved and

review your approach to problem solving.

carrying out diagnostic

procedures and attributing

symptoms to faults.

Working with others Level 3

When learners are:

They should be able to develop the following

key skills evidence:

WO3.1 Plan work with others.

researching, planning and

carrying out diagnostic and

maintenance procedures with

colleagues and supervisors

evaluating maintenance,

diagnostic and repair

strategies with colleagues

and supervisors.

WO3.2 Seek to develop co-operation and check

progress towards your agreed objectives.

WO3.3 Review work with others and agree ways

of improving collaborative work in the

future.

Edexcel Level 3 BTEC Nationals in Vehicle Technology Issue 1 June 2007 Edexcel Limited 2007

11

Você também pode gostar

- DrivetrainsDocumento27 páginasDrivetrainsArthur AyresAinda não há avaliações

- Automotive Driveline Overview PDFDocumento8 páginasAutomotive Driveline Overview PDFKarniAinda não há avaliações

- Chapter 3 (A) - Transmission SystemDocumento36 páginasChapter 3 (A) - Transmission Systemfaris iqbalAinda não há avaliações

- Transmission Elements Technical Data IndexDocumento6 páginasTransmission Elements Technical Data IndexKamga ChilotAinda não há avaliações

- Gear Box TypesDocumento4 páginasGear Box TypespenihaniAinda não há avaliações

- An Overview of DrivetrainDocumento13 páginasAn Overview of DrivetrainjmithAinda não há avaliações

- Semi Automatic Transmission ReportDocumento52 páginasSemi Automatic Transmission ReportPranav EkhandeAinda não há avaliações

- Introduction To DrivetrainsDocumento10 páginasIntroduction To DrivetrainsThiago PereiraAinda não há avaliações

- Designing Gear in Catia V5R14 HowtoDocumento90 páginasDesigning Gear in Catia V5R14 HowtoArjun100% (4)

- POWERTRAINDocumento15 páginasPOWERTRAINIan Harvey MendozaAinda não há avaliações

- Shift and Select MechanismDocumento7 páginasShift and Select MechanismDwi UpariadiAinda não há avaliações

- GradeabilityDocumento2 páginasGradeabilityArun KattuparambilAinda não há avaliações

- Synchro Shift Feel TesterDocumento15 páginasSynchro Shift Feel TesterPrakash ChandrasekaranAinda não há avaliações

- Double Cone Synchronizer For Vehicle TransmissionDocumento17 páginasDouble Cone Synchronizer For Vehicle TransmissionMujammil Choudhari50% (2)

- Automation of VW Transmission 02k-DNZ: Internal TraineeshipDocumento48 páginasAutomation of VW Transmission 02k-DNZ: Internal TraineeshipMarcos MontesAinda não há avaliações

- ZF 10M TransmissionDocumento4 páginasZF 10M Transmissionisland14Ainda não há avaliações

- Transmission Removal and Installation at PDFDocumento4 páginasTransmission Removal and Installation at PDFOskars ŠtālsAinda não há avaliações

- Transmission TrainingDocumento22 páginasTransmission Trainingkeval patel100% (1)

- 10 Automatic Transaxle SystemDocumento35 páginas10 Automatic Transaxle SystemYun ZhenAinda não há avaliações

- Clutch: Automobile PowertrainDocumento2 páginasClutch: Automobile PowertrainHarish Padmanaban100% (1)

- Automotive Transmission: Clutch and Gear BoxDocumento28 páginasAutomotive Transmission: Clutch and Gear BoxMohan100% (1)

- Chapter 4 - Vehicle Transmission SystemDocumento35 páginasChapter 4 - Vehicle Transmission SystemMuhammad Asyrafuddin HanafiahAinda não há avaliações

- Belt Drive SystemsDocumento8 páginasBelt Drive SystemsYavuz KeskinAinda não há avaliações

- Gearboxes ClassDocumento35 páginasGearboxes ClassNaveen Vachipalli100% (1)

- Chapter 4 Drum Brake SystemDocumento1 páginaChapter 4 Drum Brake Systemvijendra1125Ainda não há avaliações

- Transmission (Mechanics) PDFDocumento11 páginasTransmission (Mechanics) PDFFrancisco Botella JuanAinda não há avaliações

- Chapter 13 (Automatic Transmission)Documento26 páginasChapter 13 (Automatic Transmission)ZIBA KHADIBIAinda não há avaliações

- Brake Assisted Differential LockDocumento5 páginasBrake Assisted Differential LockKunal JainAinda não há avaliações

- Suspension DynamicsDocumento30 páginasSuspension DynamicsZoscalesAinda não há avaliações

- Chapter 3 (B) - Manual TransmissionDocumento56 páginasChapter 3 (B) - Manual Transmissionfaris iqbalAinda não há avaliações

- Coupling: This Article Is About A Mechanical Connection Between Two Objects. For Other Uses, SeeDocumento24 páginasCoupling: This Article Is About A Mechanical Connection Between Two Objects. For Other Uses, Seerupesh8989Ainda não há avaliações

- Driveline Dynamics NotesDocumento19 páginasDriveline Dynamics NotesprabhjotbhangalAinda não há avaliações

- Differential (Mechanical Device) - WikipediaDocumento9 páginasDifferential (Mechanical Device) - Wikipediakirthi83100% (1)

- Ac Compressor ServicingDocumento25 páginasAc Compressor Servicingsonny1234100% (1)

- Clutch DesignDocumento7 páginasClutch DesignHla Min HtunAinda não há avaliações

- An Investigation On Frictionless Electromagnetic Braking SystemDocumento21 páginasAn Investigation On Frictionless Electromagnetic Braking SystemAvin100% (2)

- Fabrication of Four Wheel Steering SystemDocumento14 páginasFabrication of Four Wheel Steering SystemRenju PaulAinda não há avaliações

- Diaphragm ClutchDocumento13 páginasDiaphragm Clutchravi0% (1)

- Planetary Gear Unit-PPT 3Documento24 páginasPlanetary Gear Unit-PPT 3Gemechu DemeAinda não há avaliações

- Planetery GearDocumento19 páginasPlanetery GearDipakAinda não há avaliações

- Chapter 10 (Standard Transmission) PDFDocumento42 páginasChapter 10 (Standard Transmission) PDFZIBA KHADIBIAinda não há avaliações

- Wheel-Balancing SSOUDocumento14 páginasWheel-Balancing SSOUSumitAinda não há avaliações

- Steering System AEDocumento46 páginasSteering System AEShubham GuptaAinda não há avaliações

- Steering System and TyresDocumento32 páginasSteering System and TyresFraolAinda não há avaliações

- How Clutches WorkDocumento8 páginasHow Clutches WorkSachenderAinda não há avaliações

- Air Suspension SystemDocumento7 páginasAir Suspension SystemSridhar DineshAinda não há avaliações

- Automatic Transmission5 ReportDocumento17 páginasAutomatic Transmission5 ReportManhar MidhaAinda não há avaliações

- Brake Report 2015Documento38 páginasBrake Report 2015Pratyush NagareAinda não há avaliações

- A Method To Optimize Brass Type Single Synchronizer Ring For Manual GearboxDocumento6 páginasA Method To Optimize Brass Type Single Synchronizer Ring For Manual GearboxaravindhAinda não há avaliações

- Vehicle Dynamics ProDocumento15 páginasVehicle Dynamics ProChirag D PatelAinda não há avaliações

- POWERTRAINDocumento10 páginasPOWERTRAINarpitaAinda não há avaliações

- Manual de Transmisiones Chrysler Años 90 PrincipalmenteDocumento188 páginasManual de Transmisiones Chrysler Años 90 PrincipalmenteMarbelmen100% (1)

- Continuously Variable TransmissionDocumento33 páginasContinuously Variable Transmissionsk9145100% (1)

- Klein Technical GuidelineDocumento21 páginasKlein Technical GuidelinePeter100% (2)

- 39-148 Final Drive Gear SetDocumento31 páginas39-148 Final Drive Gear Setmefisto06cAinda não há avaliações

- Final ReportDocumento45 páginasFinal ReportKuppu Raj100% (1)

- Unit - 1: Automotive FundamentalsDocumento26 páginasUnit - 1: Automotive FundamentalsvedhhAinda não há avaliações

- Unit 2: Vehicle Engine Principles, Operation, Service and RepairDocumento12 páginasUnit 2: Vehicle Engine Principles, Operation, Service and RepairsaiemAinda não há avaliações

- BTEC L3 Unit 12 - Applications of Mechanical Systems in EngineeringDocumento11 páginasBTEC L3 Unit 12 - Applications of Mechanical Systems in Engineeringalexandre_motta_3Ainda não há avaliações

- Automobile Engineering Scheme and Credits Credits Semester-VIIIDocumento2 páginasAutomobile Engineering Scheme and Credits Credits Semester-VIIIVikash KumarAinda não há avaliações

- Final Drive Unit (FDU) : Driving To Perfection GKN Driveline Torque TechnologyDocumento1 páginaFinal Drive Unit (FDU) : Driving To Perfection GKN Driveline Torque TechnologyMaulana FajriansyahAinda não há avaliações

- Motor Grader Terex DimensionDocumento16 páginasMotor Grader Terex DimensionMaulana Fajriansyah100% (2)

- Toronado 3.21 Planetary Final DriveDocumento22 páginasToronado 3.21 Planetary Final DriveMaulana FajriansyahAinda não há avaliações

- Final DriveDocumento12 páginasFinal DriveMaulana FajriansyahAinda não há avaliações

- Swinburne University of Technology (Sarawak Campus) : Mee20003 Fluid Mechanics 1Documento2 páginasSwinburne University of Technology (Sarawak Campus) : Mee20003 Fluid Mechanics 1Peter AdamAinda não há avaliações

- 543Q-7 Parts List (2) Bomba Quintuplex (TWM)Documento121 páginas543Q-7 Parts List (2) Bomba Quintuplex (TWM)JOHNME8205Ainda não há avaliações

- Aircraft Pneumatic Systems and Air SystemDocumento11 páginasAircraft Pneumatic Systems and Air SystemRaihan AkbarAinda não há avaliações

- Motor Selection NewerDocumento2 páginasMotor Selection Newerdan paluskaAinda não há avaliações

- CaterpillarDocumento4 páginasCaterpillarCarlos MartinezAinda não há avaliações

- Workpiece Tool Clamping NANNDocumento4 páginasWorkpiece Tool Clamping NANNyraju88Ainda não há avaliações

- SP Brochure 60HzDocumento4 páginasSP Brochure 60HzDerahamaniAinda não há avaliações

- Cat19579-Tachometer Cable PDFDocumento1 páginaCat19579-Tachometer Cable PDFshahrol effendy rodziAinda não há avaliações

- Motors For Rotax Kiln DriveDocumento17 páginasMotors For Rotax Kiln DrivesreeganeshrAinda não há avaliações

- ENG-STAG-4 Eco (PS-01) Connection (2011.10.25)Documento1 páginaENG-STAG-4 Eco (PS-01) Connection (2011.10.25)German SalasAinda não há avaliações

- SHEF50/100: Performance DataDocumento8 páginasSHEF50/100: Performance Dataallen_worstAinda não há avaliações

- Aisin Aw Tr-60snDocumento1 páginaAisin Aw Tr-60snJesus Alejandro Miranda PalaciosAinda não há avaliações

- Lubricant Viscocities 140hDocumento8 páginasLubricant Viscocities 140hPablo Gaspar D'Agostini AmengualAinda não há avaliações

- Turbo Compressor BrochureDocumento16 páginasTurbo Compressor Brochureyohanesaji1993Ainda não há avaliações

- Definition of PumpDocumento14 páginasDefinition of Pumpimate77Ainda não há avaliações

- Manual Reloj PumaDocumento59 páginasManual Reloj PumaKevin Zúñiga50% (2)

- Piston Displacement - 104132Documento36 páginasPiston Displacement - 104132Usman GhaniAinda não há avaliações

- Warning: Installation, Operating, & Maintenance InstructionsDocumento9 páginasWarning: Installation, Operating, & Maintenance InstructionsAnggi SujiwoAinda não há avaliações

- Tutorial 1 Impact of JetDocumento1 páginaTutorial 1 Impact of JetBhuvanesh MuleyAinda não há avaliações

- 5 TC Update by S Koblenz PDFDocumento25 páginas5 TC Update by S Koblenz PDFg arvAinda não há avaliações

- Manual Juki PDFDocumento71 páginasManual Juki PDFLaura BurtanAinda não há avaliações

- 90 Degree Turning Motorized Steering MechanismDocumento62 páginas90 Degree Turning Motorized Steering MechanismMani Kandan100% (1)

- DC Motors: Engineering Information For Catalog DA 12Documento44 páginasDC Motors: Engineering Information For Catalog DA 12Karim IsmailAinda não há avaliações

- Driving To The Future: Product Catalogue: CLUTCHES & FLYWHEEL ASSYDocumento48 páginasDriving To The Future: Product Catalogue: CLUTCHES & FLYWHEEL ASSYmanoj_doshi_1100% (2)

- Active Suspension SeminarDocumento12 páginasActive Suspension Seminarmujeeb0% (1)

- Chapter 6 Energy ConDocumento6 páginasChapter 6 Energy ConLuelsonCordovaDeclarador0% (1)

- Jeep AW-4 ASTG Automatic Transmission Service ManualDocumento115 páginasJeep AW-4 ASTG Automatic Transmission Service Manualdan themanAinda não há avaliações

- Spare Part Designation S40.1 S50.1 S63.1 S80.1: N/a N/aDocumento3 páginasSpare Part Designation S40.1 S50.1 S63.1 S80.1: N/a N/aeli saAinda não há avaliações

- Diaphragm Valve Series - ' S2K ' DS00W5: Fluroplastic LinedDocumento1 páginaDiaphragm Valve Series - ' S2K ' DS00W5: Fluroplastic LinedThiruThirunavukkarasuAinda não há avaliações

- Service Bulletin - Piston Rings:: Piston Ring Failure Diagnosis - Foreign Particle ContaminationDocumento0 páginaService Bulletin - Piston Rings:: Piston Ring Failure Diagnosis - Foreign Particle ContaminationVelshankar MJAinda não há avaliações