Escolar Documentos

Profissional Documentos

Cultura Documentos

Development of Beneficiation Process For High Alumina Iron Ores of Bellary - Hospet Region

Enviado por

kselvan_1Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Development of Beneficiation Process For High Alumina Iron Ores of Bellary - Hospet Region

Enviado por

kselvan_1Direitos autorais:

Formatos disponíveis

Proceedings of the International Seminar on Mineral Processing Technology - 2006,

Chennai, India. pp. 459 - 460.

Development of Beneficiation Process for High Alumina Iron Ores

of Bellary - Hospet Region

Srinivas Dwarapudi, T. Uma Devi, M.G. Sampath Kumar,

D.L. Saralaya and S.S. Gupta

JSW Steel Ltd., Toranagallu, Bellary, Karnataka, India.

Abstract

JSW Steel is operating a 4.2 Mtpa capacity Pellet Plant to produce iron oxide pellets from the

iron ore fines available in the surrounding Bellary-Hospet region of southern India. Iron ore

fines which get generated during mining are soft and rich in alumina with high amount of ultra

fines. These characteristics of iron ore fines make it difficult to produce good grade pellets for

use in COREX iron making units. Apart from this, high alumina in the pellets increases the

slag volume in Corex, which demands additional heat energy, resulting in increased fuel rate.

Hence, it was decided to set up a beneficiation plant to reduce the alumina content of the ore

fines. Iron ore fines from several sources available in the Bellary- Hospet region were

evaluated for their suitability for beneficiation as each source differs in chemistry, particle size

distribution and washability characteristics. A technique called "Sizewise Washability

Technique" was developed to study the washability characteristics of the ore fines to determine

the extent of alumina reduction on washing and corresponding yield of concentrate. Iron ore

fines from 13 sources were tested and were classified as Preferable, Tolerable and NotWashable depending on their suitability for beneficiation. Mineralogical studies were also

undertaken to understand the liberation characteristics of gangue minerals to achieve proper

alumina reduction during beneficiation.

Considering the washability characteristics, size distribution and mineralogy of iron ore fines,

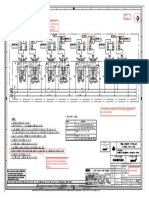

pilot plant scale (2 tonnes/hr and 10 tonnes/hr) tests were conducted and a flow sheet was

developed with. Spiral Classifier and Hydrocyclones. Based on the pilot scale test data,

commercial scale unit of 3 Mtpa was designed and successfully commissioned. The

performance of the plant is in accordance with the projected projections from laboratory and

pilot scale studies.

Table 1: Washability Characteristics of Different Sources of Iron Ore Fines

KMP

TSML

VSL-EL

VMPL

KFIL

FOMENTO

(Vesco)

2.44

3.83

2.01

3.97

2.64

1.21

2.83

1.48

2.38

2.04

70.8

41.9

43.7

68

51.0

%

Drop

in

A1203

50.4

26.1

26.4

40.1

22.7

0.84

0.86

9.8

-2.4

Yield,

A1203 A1203

"A

Total circuit

Cyclone circuit

%

%

Class

A120,

, Yield, Drop m 0 Yield, drop

ificat

in

;

in

2 3

%

%

ion

A1203

A1203

1.64 51.0 69.7

1.28 86.0 47.5

1.47 54.0 67.8

2.25 73.0 41.3

1.00 57.7 58.8

1.28 76.0 36.3

4.62 21.3 37.1

2.58 75.0 35.0

1.74 83.0 34.1

1.26 64.5 61.5

Iron ore

Source

Name

Classifier

Preferable

Feed

0.52 80.5 38.1

459

0.56 82.0

33.3

Development of Beneftciation Process for High Alumina Iron Ores of Bellary - Hospet Region

Total circuit

Cyclone circuit

%

%

%

Class

, ,..

Yield, Drop Ai _0_ Yield, Drop A1 0_ Yield, drop

A1203

.14.12..,3

A1203 A1203

Fun',

meat

in

in

3 3

%

in

3 %

%

A1203

ion

A124:3

A1203

1.31 76.0 23.8

11.0

1.02 58.2 45.2

1.72 1.53 42.6

1.43

1.35

39.4

5.6

0.91 71.9 38.5

1.12 83.0 21.7

2.35

1.93

68.7

17.9

1.53 52.7 53.2

1.85 85.2

21.3

3.82

3.64

52.2

4.7

1.95 53.8 51.5

3.08 78.0

19.4

1.72

2.02

1.67

2.23

48.0

49.6

2.9

-10.4

1.12 68.1 36.4

1.21 70.8 33.5

1.44 83.0 16.3

1.8 85.0' 10.9

2.54

3.11

45.6

-22.4

1.28 59.9 37.9

2.35 78.0

Table 2: Mineralogy of Iron Ore Fines

Percentage

80 - 85

10 -15

2- 3

Minerals

Hematite

Goethite

Quartz

460

7.5

Tolerable

VSL-AL

VSLMINING

SWML

NMDC

(Low grade)

MML

DMS

FOMENTO

(Slonl)

Classifier

Not washable

Feed

Iron ore

Source

Name

Você também pode gostar

- Extractive Metallurgy 3: Processing Operations and RoutesNo EverandExtractive Metallurgy 3: Processing Operations and RoutesAinda não há avaliações

- Designing The Optimal Flotation Circuit - The Prominent Hill Case - Barns - DD - From Mill Ops 2010 PDFDocumento10 páginasDesigning The Optimal Flotation Circuit - The Prominent Hill Case - Barns - DD - From Mill Ops 2010 PDFkennedysupAinda não há avaliações

- Effective Beneficiation of Low Grade Iron Ore Through Jigging OperationDocumento11 páginasEffective Beneficiation of Low Grade Iron Ore Through Jigging OperationOana MovileanuAinda não há avaliações

- Irom Ore PropertiesDocumento19 páginasIrom Ore PropertiesMunishTrichyAinda não há avaliações

- Indian Minerals Yearbook 2011: 50 EditionDocumento12 páginasIndian Minerals Yearbook 2011: 50 Editionmujib uddin siddiquiAinda não há avaliações

- Chapter-3: Profile of Visakhapatnam Steel PlantDocumento18 páginasChapter-3: Profile of Visakhapatnam Steel PlantrajuAinda não há avaliações

- 171Documento8 páginas171ravibelavadiAinda não há avaliações

- Training Report PRASADDocumento32 páginasTraining Report PRASADshekharazad_suman85% (13)

- Beneficiation of Ajabanoko Iron Ore Deposit, Kogi State, Nigeria Using Magnetic MethodsDocumento3 páginasBeneficiation of Ajabanoko Iron Ore Deposit, Kogi State, Nigeria Using Magnetic MethodsInfogain publicationAinda não há avaliações

- Column Flotation TechnologyDocumento10 páginasColumn Flotation TechnologyCarlos de la TorreAinda não há avaliações

- SRPC 2019 Paper 29Documento7 páginasSRPC 2019 Paper 29Umer MuzammilAinda não há avaliações

- My Final ThesisDocumento98 páginasMy Final Thesissujit_sekharAinda não há avaliações

- Assignment 1Documento16 páginasAssignment 1i7ech ArtsAinda não há avaliações

- Ilovepdf MergedDocumento33 páginasIlovepdf MergedSatyam vankayalaAinda não há avaliações

- HPGR Comminution Optimization Copper LeachingDocumento5 páginasHPGR Comminution Optimization Copper LeachingRollerJonnyAinda não há avaliações

- Behaviour of NINL Blast Furnace With 100% Calibrated Lump Iron OreDocumento9 páginasBehaviour of NINL Blast Furnace With 100% Calibrated Lump Iron OreROWHEITAinda não há avaliações

- Ijmet: ©iaemeDocumento8 páginasIjmet: ©iaemeIAEME PublicationAinda não há avaliações

- Research ArticleDocumento7 páginasResearch ArticleantoniocljAinda não há avaliações

- Vinayak R V Synbpr (8519) PDFDocumento22 páginasVinayak R V Synbpr (8519) PDFravibelavadiAinda não há avaliações

- Ester Volina Kim (I 0508039)Documento10 páginasEster Volina Kim (I 0508039)olongkodokAinda não há avaliações

- A Comparative Characterization of Iron Ore Pellet Agglomerates Prepared From Low Grade Goethite Raw Ultrafine and Beneficiated Goethite Ultrafine.Documento11 páginasA Comparative Characterization of Iron Ore Pellet Agglomerates Prepared From Low Grade Goethite Raw Ultrafine and Beneficiated Goethite Ultrafine.vitaliy khmelAinda não há avaliações

- J Powtec 2020 04 047Documento63 páginasJ Powtec 2020 04 047BISWAJEET BEHERAAinda não há avaliações

- In Mould DuctileDocumento6 páginasIn Mould Ductilejose.figueroa@foseco.comAinda não há avaliações

- Application of Magnetic SeparationDocumento11 páginasApplication of Magnetic Separationhasan70 sheykhiAinda não há avaliações

- Effects of Varied Process Parameters On Froth Flotation Efficiency: A Case Study of Itakpe Iron OreDocumento9 páginasEffects of Varied Process Parameters On Froth Flotation Efficiency: A Case Study of Itakpe Iron Oresamuel sanchezAinda não há avaliações

- SGS MIN TP2008 50 IOCG Recovery in Scandinavia PDFDocumento8 páginasSGS MIN TP2008 50 IOCG Recovery in Scandinavia PDFPedro PabloAinda não há avaliações

- Rourkela Steel Plant WikipediaDocumento5 páginasRourkela Steel Plant Wikipediadroy21Ainda não há avaliações

- Priyanshu Final PPT DSPDocumento28 páginasPriyanshu Final PPT DSPShrilayan MazumderAinda não há avaliações

- The Behaviour of Coke in Submerged Arc Furnace Smelting of FerromanganeseDocumento11 páginasThe Behaviour of Coke in Submerged Arc Furnace Smelting of FerromanganeseSuljic AlminAinda não há avaliações

- Sharan JSWDocumento30 páginasSharan JSWLAXMI GUNTUKAinda não há avaliações

- Influence of Thermal Stability of Quartz and The ParticleDocumento7 páginasInfluence of Thermal Stability of Quartz and The ParticleValentina LópezAinda não há avaliações

- Kotta 2019Documento11 páginasKotta 2019Spica RegulusAinda não há avaliações

- GMJPaperDocumento9 páginasGMJPaperPaulina Salgado De la ParraAinda não há avaliações

- The Behaviour of Coke in Submerged Arc FDocumento11 páginasThe Behaviour of Coke in Submerged Arc FosamaaaAinda não há avaliações

- Mineralogical Characterization of Dilband Iron Ore Deposits of Balochistan, PakistanDocumento6 páginasMineralogical Characterization of Dilband Iron Ore Deposits of Balochistan, PakistanUmer MuzammilAinda não há avaliações

- Pelletizing ذكيDocumento8 páginasPelletizing ذكييوسف عادل حسانينAinda não há avaliações

- Mineral Processing and MetallurgicalDocumento14 páginasMineral Processing and MetallurgicalJoel CuevaAinda não há avaliações

- Honeyands 2012 Calculating The Value of Iron Ores in Ironmaking and SteelmakingDocumento6 páginasHoneyands 2012 Calculating The Value of Iron Ores in Ironmaking and SteelmakingCh V S RajuAinda não há avaliações

- Chromite Separation IndiaDocumento8 páginasChromite Separation Indiarsrizwan2392Ainda não há avaliações

- MPT2017 Paper01Documento6 páginasMPT2017 Paper01sharma karamjithAinda não há avaliações

- Optimisation of The Proeminent Hill Flotation CircuitDocumento14 páginasOptimisation of The Proeminent Hill Flotation CircuitThiago JatobáAinda não há avaliações

- Nickel Pig Iron Production From Lateritic Nickel Ores PDFDocumento8 páginasNickel Pig Iron Production From Lateritic Nickel Ores PDFMuhammad AfniAinda não há avaliações

- SLR English Exe - SummaryDocumento31 páginasSLR English Exe - SummarybalaasenthilAinda não há avaliações

- ALS Metallurgy - Iron Ore Process DevelopmentDocumento8 páginasALS Metallurgy - Iron Ore Process DevelopmentDeepakKumarGoraiAinda não há avaliações

- Magnetic Separation in South AfricaDocumento28 páginasMagnetic Separation in South AfricaDaniel TangkauAinda não há avaliações

- Fines RecoveryDocumento7 páginasFines RecoveryAniket MishraAinda não há avaliações

- Case Study Maximizing Low Fe Hygroscopic Iron Ore Consumption in BlastDocumento10 páginasCase Study Maximizing Low Fe Hygroscopic Iron Ore Consumption in Blastluv kanoriaAinda não há avaliações

- Solvent Extraction in Southern AfricaDocumento27 páginasSolvent Extraction in Southern AfricaYassine GouzzaliAinda não há avaliações

- Asghari 2018Documento19 páginasAsghari 2018CatalinaSoledadBelloCarrascoAinda não há avaliações

- Flujo Turbulento de Pulpas Mineras en Tuberias Con Trasnporte de SolidosDocumento13 páginasFlujo Turbulento de Pulpas Mineras en Tuberias Con Trasnporte de SolidosIvan Flores VargasAinda não há avaliações

- Specularite Magnetic Separation Reverse FlotationDocumento8 páginasSpecularite Magnetic Separation Reverse FlotationsonficyusAinda não há avaliações

- Recovery of Iron Values From Iron Ore Slimes by Vertical Ring Pulsating High Gradient Magnetic SeparatorDocumento6 páginasRecovery of Iron Values From Iron Ore Slimes by Vertical Ring Pulsating High Gradient Magnetic SeparatorravibelavadiAinda não há avaliações

- Steel Authority of India Limited: Presentation of Vocational Training atDocumento11 páginasSteel Authority of India Limited: Presentation of Vocational Training atSudip MondalAinda não há avaliações

- 2 5424836624502490024 PDFDocumento7 páginas2 5424836624502490024 PDFtauficsAinda não há avaliações

- G Effect On Gravity ConcentrationDocumento3 páginasG Effect On Gravity Concentrationboanerges wino pattyAinda não há avaliações

- MPT-10 (RK Rath)Documento7 páginasMPT-10 (RK Rath)Bibhuranjan NayakAinda não há avaliações

- Characterization and Recovery of Copper Values From Discarded SlagDocumento7 páginasCharacterization and Recovery of Copper Values From Discarded SlagMacarena BlancoAinda não há avaliações

- Beneficiation of Iron Ore Slime Using Aspergillus Niger and Bacillus CirculansDocumento4 páginasBeneficiation of Iron Ore Slime Using Aspergillus Niger and Bacillus CirculansminingnovaAinda não há avaliações

- Heap Leaching Copper OreDocumento6 páginasHeap Leaching Copper OreRodrigo GarcíaAinda não há avaliações

- Composition, Mineral Matter Characteristics and Ash Fusion BehaviorDocumento6 páginasComposition, Mineral Matter Characteristics and Ash Fusion BehaviorSAMBIT DALAIAinda não há avaliações

- CokemakingTechnologies ComparisonDocumento9 páginasCokemakingTechnologies Comparisonkselvan_1100% (1)

- Acse Research Report 488bDocumento74 páginasAcse Research Report 488bkselvan_1Ainda não há avaliações

- Is 1172 1993Documento21 páginasIs 1172 1993ShekharShirkeAinda não há avaliações

- UBC ASHRAE Competition Report PDFDocumento34 páginasUBC ASHRAE Competition Report PDFmech118100% (1)

- Ag 5095213Documento8 páginasAg 5095213kselvan_1Ainda não há avaliações

- Full Text 01Documento71 páginasFull Text 01kselvan_1Ainda não há avaliações

- Discussion - Design Concepts For Jib CranesDocumento2 páginasDiscussion - Design Concepts For Jib Cranesheitor29Ainda não há avaliações

- Sturt Air ClassifierDocumento6 páginasSturt Air ClassifierHenry Vladimir VianchaAinda não há avaliações

- RiskDocumento1 páginaRiskkselvan_1Ainda não há avaliações

- Teddington Layman S GuideDocumento7 páginasTeddington Layman S GuideAdnan Ahmed KidwaiAinda não há avaliações

- Double Flap Gate ValvesDocumento16 páginasDouble Flap Gate Valveskselvan_1Ainda não há avaliações

- Jib Crane CalculationDocumento32 páginasJib Crane CalculationManoj PatilAinda não há avaliações

- Size Gearmotors For ConveyorDocumento4 páginasSize Gearmotors For Conveyorkselvan_1Ainda não há avaliações

- Beskrivning Av ExpansionsbalgarDocumento25 páginasBeskrivning Av ExpansionsbalgarNopparutAinda não há avaliações

- Dynamic Analysis of Self Supported Steel Chimney As Per Indian StandardDocumento81 páginasDynamic Analysis of Self Supported Steel Chimney As Per Indian StandardrodrigoperezsimoneAinda não há avaliações

- U.S. Bellows 101: Expansion Joint BasicsDocumento35 páginasU.S. Bellows 101: Expansion Joint Basicskselvan_1Ainda não há avaliações

- Lifting Lug Calculation RefDocumento2 páginasLifting Lug Calculation Refmarc_albertoAinda não há avaliações

- Wind Analysis of Tall Stack Like Structure: Jigar K. SevaliaDocumento4 páginasWind Analysis of Tall Stack Like Structure: Jigar K. Sevaliag4goharAinda não há avaliações

- Short Circular Steel StacksDocumento12 páginasShort Circular Steel Stackskselvan_1Ainda não há avaliações

- Expansion Joint Manual 1501uk 5-12-12 20 DownloadDocumento323 páginasExpansion Joint Manual 1501uk 5-12-12 20 DownloadivanmatijevicAinda não há avaliações

- B.4.4 - STD Spec For Steel StacksDocumento6 páginasB.4.4 - STD Spec For Steel StacksEkta SanguleAinda não há avaliações

- Eurocodes Worked ExamplesDocumento185 páginasEurocodes Worked ExamplesPaskal Drazhich100% (9)

- L18 - Masts, Towers, Chimneys PDFDocumento48 páginasL18 - Masts, Towers, Chimneys PDFsrvshAinda não há avaliações

- StAccMill Stack DesignDocumento3 páginasStAccMill Stack Designkselvan_1Ainda não há avaliações

- PSC 53613 C 6 PDFDocumento1 páginaPSC 53613 C 6 PDFkselvan_1Ainda não há avaliações

- PSC 53613 C 6 PDFDocumento1 páginaPSC 53613 C 6 PDFkselvan_1Ainda não há avaliações

- Comments As Marked in This Drawing Is Applicable For All Such SchematicDocumento1 páginaComments As Marked in This Drawing Is Applicable For All Such Schematickselvan_1Ainda não há avaliações

- Dimensions Shall Be Clearly Marked For All Such Marking: Upgradation of Bf. No. 1 Unitdescr AreadescrDocumento1 páginaDimensions Shall Be Clearly Marked For All Such Marking: Upgradation of Bf. No. 1 Unitdescr Areadescrkselvan_1Ainda não há avaliações

- PSC 53613 C 6 PDFDocumento1 páginaPSC 53613 C 6 PDFkselvan_1Ainda não há avaliações

- Bgrim 1q2022Documento56 páginasBgrim 1q2022Dianne SabadoAinda não há avaliações

- 9881 enDocumento345 páginas9881 enSaid BenAinda não há avaliações

- June 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelDocumento16 páginasJune 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelNyraStardollAinda não há avaliações

- Quanta To QuarksDocumento32 páginasQuanta To QuarksDaniel Bu100% (5)

- Operations Management Interim ProjectDocumento4 páginasOperations Management Interim ProjectABAYANKAR SRIRAM (RA1931201020042)Ainda não há avaliações

- Operating Instructions: HTL-PHP Air Torque PumpDocumento38 páginasOperating Instructions: HTL-PHP Air Torque PumpvankarpAinda não há avaliações

- The Reason: B. FlowsDocumento4 páginasThe Reason: B. FlowsAryanti UrsullahAinda não há avaliações

- Transparency and Digitalization in The Public Administration of RomaniaDocumento8 páginasTransparency and Digitalization in The Public Administration of RomaniaMădălina MarincaşAinda não há avaliações

- Additional Article Information: Keywords: Adenoid Cystic Carcinoma, Cribriform Pattern, Parotid GlandDocumento7 páginasAdditional Article Information: Keywords: Adenoid Cystic Carcinoma, Cribriform Pattern, Parotid GlandRizal TabootiAinda não há avaliações

- Algorithms For Automatic Modulation Recognition of Communication Signals-Asoke K, Nandi, E.E AzzouzDocumento6 páginasAlgorithms For Automatic Modulation Recognition of Communication Signals-Asoke K, Nandi, E.E AzzouzGONGAinda não há avaliações

- DNA Vs RNA - Introduction and Differences Between DNA and RNADocumento10 páginasDNA Vs RNA - Introduction and Differences Between DNA and RNAKienlevyAinda não há avaliações

- Marketing Micro and Macro EnvironmentDocumento8 páginasMarketing Micro and Macro EnvironmentSumit Acharya100% (1)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Documento1 páginaS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaAinda não há avaliações

- Lightning Protection Measures NewDocumento9 páginasLightning Protection Measures NewjithishAinda não há avaliações

- Module-29A: Energy MethodsDocumento2 páginasModule-29A: Energy MethodsjhacademyhydAinda não há avaliações

- Low Speed Aerators PDFDocumento13 páginasLow Speed Aerators PDFDgk RajuAinda não há avaliações

- Introduction To Password Cracking Part 1Documento8 páginasIntroduction To Password Cracking Part 1Tibyan MuhammedAinda não há avaliações

- RECYFIX STANDARD 100 Tipe 010 MW - C250Documento2 páginasRECYFIX STANDARD 100 Tipe 010 MW - C250Dadang KurniaAinda não há avaliações

- Riqas Ri RQ9142 11aDocumento6 páginasRiqas Ri RQ9142 11aGrescia Ramos VegaAinda não há avaliações

- Toshiba MotorsDocumento16 páginasToshiba MotorsSergio Cabrera100% (1)

- How To Add Attachment Using JAVA MappingDocumento4 páginasHow To Add Attachment Using JAVA MappingmvrooyenAinda não há avaliações

- Roles and Responsibilities of An InstructorDocumento4 páginasRoles and Responsibilities of An InstructorMohanlal SainiAinda não há avaliações

- Paper 1 AnalysisDocumento2 páginasPaper 1 AnalysisNamanAinda não há avaliações

- Operator'S Manual Diesel Engine: 2L41C - 2M41 - 2M41ZDocumento110 páginasOperator'S Manual Diesel Engine: 2L41C - 2M41 - 2M41ZMauricio OlayaAinda não há avaliações

- Adaptive Leadership: Leadership: Theory and PracticeDocumento14 páginasAdaptive Leadership: Leadership: Theory and PracticeJose Daniel Quintero100% (1)

- Strategic Marketing: The University of Lahore (Islamabad Campus)Documento3 páginasStrategic Marketing: The University of Lahore (Islamabad Campus)Sumaira IrshadAinda não há avaliações

- Preparing For CPHQ .. An Overview of Concepts: Ghada Al-BarakatiDocumento109 páginasPreparing For CPHQ .. An Overview of Concepts: Ghada Al-BarakatiBilal SalamehAinda não há avaliações

- Enrico Fermi Pioneer of The at Ted GottfriedDocumento156 páginasEnrico Fermi Pioneer of The at Ted GottfriedRobert Pérez MartinezAinda não há avaliações

- Marion Nicoll: Life & Work by Catharine MastinDocumento147 páginasMarion Nicoll: Life & Work by Catharine MastinArt Canada InstituteAinda não há avaliações

- SavannahHarbor5R Restoration Plan 11 10 2015Documento119 páginasSavannahHarbor5R Restoration Plan 11 10 2015siamak dadashzadeAinda não há avaliações