Escolar Documentos

Profissional Documentos

Cultura Documentos

Qualitity Con

Enviado por

Malith De SilvaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Qualitity Con

Enviado por

Malith De SilvaDireitos autorais:

Formatos disponíveis

HITACHI PLANT TECHNOLOGIES (PVT) LTD

BASIC INDUSTRIAL TRAINING

CHAPTER 16

QUALITY CONCROL

NATIONAL DIPLOMA IN ENGINEERING SCIENCES

INSTITUTE OF ENGINEERING TECHNOLOGY, KATUNAYAKE

HITACHI PLANT TECHNOLOGIES (PVT) LTD

BASIC INDUSTRIAL TRAINING

QUALITY CONCROL

Concrete is one of the principle construction materials used world-wide. Although

developments in materials and performance have widened the scope for the use of

concrete, they have also affected its properties, particularly in the long term.

From this it becomes clear that quality control, which is of vital importance for the

building industry in general, needs special attention in its application to concrete

structures.

Hence following methods can be adopted when we are doing formwork,

reinforcement and concreting.

Following material testing will be done at the recognize institute and get the

approval from the Engineer to improve the qualities of Concrete.

Fine aggregate

- Following testing will be done for Fine aggregate

- Gradation

- Specific gravity

- Organic content

Course aggregate

- Following testing will be done for Course aggregate

- Gradation

- Specific Gravity

- Los Angelese Abrasion Test

- Magnesium Sulphate Soundness Test

Water

- Clean and free from injurious amounts of oils, acid,

alkali, organic matter or other deleterious substances is used.

Admixture

- here two types of admixtures are used for the

concrete.

o Supercrete

- Used for G35A concrete

o Adcrete

- For other grade of concrete

Following testing will be done at site.

Concrete cube and Slump test

o Slump test would be taken every truckload of fresh concrete prior to

use in the construction

NATIONAL DIPLOMA IN ENGINEERING SCIENCES

INSTITUTE OF ENGINEERING TECHNOLOGY, KATUNAYAKE

HITACHI PLANT TECHNOLOGIES (PVT) LTD

BASIC INDUSTRIAL TRAINING

o It would be taken 3 numbers of test cubes per 20Cum of concrete and

minimum 6 numbers of Cubes to be caste for less than 40 m 3 Capacity.

o 3 Nos of cubes for 7 days.

o 3 Nos of cubes for 28 days.

Concrete Curing

o Curing will commence after the final set of concrete with compaction

and finishing

o Cover the surface of fresh compacted concrete with wet gunny bags

or black colour polyethylene.

o To continuously replenish with top water on the top of gunny bags.

Before pouring the concrete following factors will be considered to improve the

quality of the concrete.

During the construction if the temperature of concrete is grater than 32

Degree centigrade by using ice, it can be maintained the required

temperature during construction.

When concrete is transporting, under weather conditions contributing to

early initial setting of the concrete or when the temperature of the

concrete is 30 degree centigrade or above, a time less than 45 minutes is

taken between discharge and placing.

When a truck mixer is used for transporting concrete to the delivery point,

discharge and placing is maintained within one hour as per the specification.

At the time of Concreting

Mammoties and shovels will be used to move concrete.

When concrete is pouring, vibration must be thoroughly

supervised by a Supervisor so that no honey combs can occur.

Gap between the pump car boom and the formwork should not be

more than 2.0m.

Concrete should be placed such a way that cold joints will not be

formed.

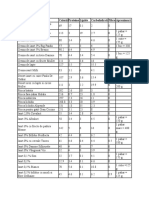

Concrete pouring sequence can be shown as in Fig. No. 07.

NATIONAL DIPLOMA IN ENGINEERING SCIENCES

INSTITUTE OF ENGINEERING TECHNOLOGY, KATUNAYAKE

HITACHI PLANT TECHNOLOGIES (PVT) LTD

BASIC INDUSTRIAL TRAINING

When placing concrete near the holding down bolts, there

location should not be disturbed.

Final finishing required for concrete surface will be hand trowel

semi rough finish.

Compaction will be done with electrically or engine driven

vibrators & shutter vibrators. Refer Fig. No. 08

Base slab will be casted with kicker walls to continue the walls.

Ready mixed Grade 35A Concrete (Slump 120 mm) is used.

CONCRETR POURING SEQUANCE

2700

2700

3700

3700

3575

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Fig No 07: Concrete Pouring Sequence

NATIONAL DIPLOMA IN ENGINEERING SCIENCES

INSTITUTE OF ENGINEERING TECHNOLOGY, KATUNAYAKE

HITACHI PLANT TECHNOLOGIES (PVT) LTD

BASIC INDUSTRIAL TRAINING

Compaction Method

450

450

Vibrator

450

45 0

Vibrator

NATIONAL DIPLOMA IN ENGINEERING SCIENCES

INSTITUTE OF ENGINEERING TECHNOLOGY, KATUNAYAKE

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Vaeco Form Manual 31aug 2015Documento588 páginasVaeco Form Manual 31aug 2015Knashye NhAinda não há avaliações

- Warehouse Assessment QuestionaireDocumento18 páginasWarehouse Assessment Questionairebgmenotman0% (1)

- 1-Introduction To The Training EstblishmentDocumento10 páginas1-Introduction To The Training EstblishmentMalith De SilvaAinda não há avaliações

- 327-Engineering ManagementDocumento5 páginas327-Engineering ManagementMalith De SilvaAinda não há avaliações

- 6 SurveyDocumento7 páginas6 SurveyMalith De SilvaAinda não há avaliações

- Subject - Request To Fulfill The Requirement of Superintendent (Civil) - Trainee - 07 Nos For UDA ProjectsDocumento1 páginaSubject - Request To Fulfill The Requirement of Superintendent (Civil) - Trainee - 07 Nos For UDA ProjectsMalith De SilvaAinda não há avaliações

- 2-Introduction To The Work SiteDocumento7 páginas2-Introduction To The Work SiteMalith De SilvaAinda não há avaliações

- KPK 1Documento1 páginaKPK 1Malith De SilvaAinda não há avaliações

- Site LocationDocumento1 páginaSite LocationMalith De SilvaAinda não há avaliações

- Document Maintain at SiteDocumento2 páginasDocument Maintain at SiteMalith De SilvaAinda não há avaliações

- MarkingDocumento6 páginasMarkingMalith De SilvaAinda não há avaliações

- Vehicle Movement BooksDocumento3 páginasVehicle Movement BooksMalith De SilvaAinda não há avaliações

- 11.1.2.2. Role of Engineering StaffDocumento3 páginas11.1.2.2. Role of Engineering StaffMalith De SilvaAinda não há avaliações

- 8.3 Ceiling WorkDocumento1 página8.3 Ceiling WorkMalith De SilvaAinda não há avaliações

- 12.1 Site and Site Office ManagementDocumento8 páginas12.1 Site and Site Office ManagementMalith De SilvaAinda não há avaliações

- Site LocationDocumento1 páginaSite LocationMalith De SilvaAinda não há avaliações

- Chapter 1Documento2 páginasChapter 1Malith De SilvaAinda não há avaliações

- 3Documento4 páginas3Malith De SilvaAinda não há avaliações

- Chapter 10 Store ManagementDocumento4 páginasChapter 10 Store ManagementMalith De SilvaAinda não há avaliações

- Summery of Training PerformanceDocumento2 páginasSummery of Training PerformanceMalith De SilvaAinda não há avaliações

- Store ManagementDocumento3 páginasStore ManagementMalith De SilvaAinda não há avaliações

- Material Storage: Storing of Fine and Course AggregatesDocumento2 páginasMaterial Storage: Storing of Fine and Course AggregatesMalith De SilvaAinda não há avaliações

- Summery of The Training PerformanceDocumento2 páginasSummery of The Training PerformanceMalith De SilvaAinda não há avaliações

- 5.0 TillingDocumento4 páginas5.0 TillingMalith De SilvaAinda não há avaliações

- TilingDocumento4 páginasTilingMalith De SilvaAinda não há avaliações

- 12.3 Stores Management: IntrtoductionDocumento4 páginas12.3 Stores Management: IntrtoductionMalith De SilvaAinda não há avaliações

- Summery of The Training PerformanceDocumento2 páginasSummery of The Training PerformanceMalith De SilvaAinda não há avaliações

- Open Light Is The Whole or Part of A Window That Can Be Opened by Being Hinged or Pivoted To Frame or Which Cam Slide Open Inside The FrameDocumento1 páginaOpen Light Is The Whole or Part of A Window That Can Be Opened by Being Hinged or Pivoted To Frame or Which Cam Slide Open Inside The FrameMalith De SilvaAinda não há avaliações

- Durra Board CellingDocumento4 páginasDurra Board CellingMalith De SilvaAinda não há avaliações

- 9Documento4 páginas9Malith De SilvaAinda não há avaliações

- Windows and DoorsDocumento6 páginasWindows and DoorsMalith De SilvaAinda não há avaliações

- 6.6.5 TRUSSES: 6.6.5.1 Steel Truss ConstructionDocumento3 páginas6.6.5 TRUSSES: 6.6.5.1 Steel Truss ConstructionMalith De SilvaAinda não há avaliações

- Formwork 150318073913 Conversion Gate01Documento59 páginasFormwork 150318073913 Conversion Gate01mit rami100% (1)

- A-070 Handover MasterDocumento4 páginasA-070 Handover MasterShanAlan100% (1)

- Incoterms 2011Documento81 páginasIncoterms 2011abdul_jamesAinda não há avaliações

- Bus Ticket Invoice 1654452073Documento2 páginasBus Ticket Invoice 1654452073Viraj GaonkarAinda não há avaliações

- Pharma - MumbaiDocumento27 páginasPharma - MumbaiBusiness100% (1)

- GP Posters 36-42Documento7 páginasGP Posters 36-42Tom AlexAinda não há avaliações

- Content Uploads 109 200 37038 Aramex Comprehensive ProfileDocumento10 páginasContent Uploads 109 200 37038 Aramex Comprehensive ProfileNoor AliAinda não há avaliações

- Directors, Auditors and Corporate Executive Officers The History of The Ajinomoto GroupDocumento4 páginasDirectors, Auditors and Corporate Executive Officers The History of The Ajinomoto GroupPramavirsa WnwAinda não há avaliações

- CBA-123 Design Frozen: Brasilia Stretch StudiedDocumento1 páginaCBA-123 Design Frozen: Brasilia Stretch Studieddagger21Ainda não há avaliações

- Marine Insurance: Coverage Classes of Inland InsuranceDocumento1 páginaMarine Insurance: Coverage Classes of Inland InsuranceKit ChampAinda não há avaliações

- Hospital DeconstructionDocumento2 páginasHospital DeconstructionRaja GopalAinda não há avaliações

- Soal UTS BIP PagiDocumento7 páginasSoal UTS BIP PagiCappo RqAinda não há avaliações

- Account Statement For Account:0141000108051555: Branch DetailsDocumento7 páginasAccount Statement For Account:0141000108051555: Branch DetailsStratosFair StoreAinda não há avaliações

- FAMDocumento36 páginasFAMxiaogangzhu75% (4)

- INS-P-006-Procedure For Inspection of PlatesDocumento4 páginasINS-P-006-Procedure For Inspection of PlatesDeepak100% (1)

- 6-Gorgon Project Downstream Execution OverviewDocumento19 páginas6-Gorgon Project Downstream Execution OverviewAnonymous TAkNn6Ainda não há avaliações

- RIVNUT US Version EN PDFDocumento36 páginasRIVNUT US Version EN PDFAnonymous 1JHrgYAinda não há avaliações

- Tabel Calorii LactateDocumento14 páginasTabel Calorii LactateDorina StăetuAinda não há avaliações

- Carriage of Goods by SeaDocumento50 páginasCarriage of Goods by SeaTay MonAinda não há avaliações

- Davao ProjectDocumento18 páginasDavao ProjectAngelique Rae AlmonteAinda não há avaliações

- Kanban AssignmentDocumento12 páginasKanban AssignmentআশরাফুলইসলামAinda não há avaliações

- Sandwich Panel Lindab AssemblyDocumento24 páginasSandwich Panel Lindab AssemblyIsye RuisAinda não há avaliações

- Project Turnover and CloseoutDocumento31 páginasProject Turnover and CloseoutJovani G. Ballon67% (3)

- Studi Penerapan Haccp Pada Produsen Mi Glosor Di Kota Bogor Studi Penerapan Haccp Pada Produsen Mi Glosor Di Kota BogorDocumento10 páginasStudi Penerapan Haccp Pada Produsen Mi Glosor Di Kota Bogor Studi Penerapan Haccp Pada Produsen Mi Glosor Di Kota Bogorpraj parAinda não há avaliações

- DesignDocumento15 páginasDesignMuhammed Sulfeek100% (1)

- Agriculture and Farming in BahrainDocumento20 páginasAgriculture and Farming in BahrainMeenakshie ChaudrieAinda não há avaliações

- Piling Works Mos RevisedDocumento4 páginasPiling Works Mos RevisedPrince Car-chang50% (2)

- Apparel Industry Plant LayoutDocumento9 páginasApparel Industry Plant LayoutHemant KumarAinda não há avaliações