Escolar Documentos

Profissional Documentos

Cultura Documentos

Pact MBR & MBBR

Enviado por

melpomenneTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pact MBR & MBBR

Enviado por

melpomenneDireitos autorais:

Formatos disponíveis

Regional Offices

LOS ANGELES / USA SHANGHAI / CHINA

DUBAI / U.A.E.

Contact your local PACT office below:

PACT Environmental Technology Co.,Ltd.

5/F, No.700 Luban Road

Shanghai,200023,China

Tel: 021 5301 9081

Fax: 021 5301 8771

Email: sales@pactchina.com

www.pactchina.com

COMPACT

TM

COMPACT

Package Membrane BioReactor (MBR) Sewage Treatment Plant

Advantages

COMPACTmembrane modules are submerged directly within the bioreactor. It

TM

is typically operated in a considerably different range of parameters for the mean

cell residence time (c) and substrate utilization rate (U) than the conventional

Brief Introduction

activated sludge processes. Due to this difference, COMPACT TM offers several

COMPACT TM is state-of-the-art pre-engineered sewage treatment system utilizing PACTs biological treatment expertise with TORAYs

benefits over the conventional activated sludge process. These benefits include:

submerged membrane technology, it contains the process elements of secondary, tertiary and advanced wastewater treatment in a single

containerized package. The membrane separation process eliminates the conventional sedimentation tank and allows high volumetric

much smaller space requirements;

loading resulting in a much smaller footprint. COMPACT can produce high quality effluent with high BOD5 removal (about 98%),

better solids removal (elimination of bulking);

complete nitrification and partial denitrification. it also achieves virtually complete TSS removal. Treated effluents have low turbidity

disinfection;

TM

values (<0.3 NTU) and SDI values (<3) which can be re-used for landscaping, flushing or feed to NANO or RO for higher purity water.

increased volumetric loading;

de-coupling of hydraulic and biomass retention time;

production of less sludge due to high sludge age;

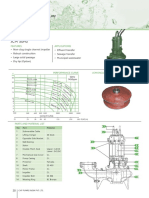

Rotary Drum screen

high SRT which allows the development of slow-growing

Activated Sludge Tank

and MBR Separation Tank

(optional

Euqlization Tank

(optional

microorganisms such as nitrifying bacteria; and

Anoxic Tank

(optional

CIP Tank

retention of high molecular weight organic compounds that can

Control panel

enhance the biodegradation process.

The modular concept allows for phased construction of

wastewater treatment plants and makes it adaptable to a

wide range of sizes and flow rates.

COMPACT MBR

COMPACT TM uses TORAY flat sheet membranes, immersed in the process tank and in direct contact with the mixed liquor. Air ejected from a

COMPACT can be delivered as a containerized unit. This

manifold and the bottom of the membrane assembly help keep the membrane surfaces clean as well as to supply oxygen for biological growth.

solution has some advantages such as:

factory installed and tested

no construction works on-site

COMPACT is equipped with a high level of automation, ensuring the plants simple operation and low maintenance cost.

TM

short delivery period

easy to relocate

Submerged Flat Sheet Membrane Module Advantages

MBR technology enhances

wastewater treatment efficiency

Using membranes to separate sludge

ensures much higher quality for treated

water free from suspended solids.

Combination with RO membranes allows

producing waterquality as good as

potable water.

Membranes can retain activated

sludge at high concentrations,

allowing BOD as well as nitrogen to

be removed more efficiently.

Unique membrane configuration having

an immense number of minuscule pores

delivers stable high water permeability

with minimal clogging and higher

permeated water quality.

Smaller footprint

The module can be submerged

directly in an activated sludge tank

for combining biological treatment

and membrane separation. It

eliminates the sedimentation or

sludge concentration process.

More effective biological treatment

allows activated sludge tank size to

be reduced.

Fewer chemical cleaning

requirements and coarse screen

pretreatment

The plate-and-frame configuration that

employs flat sheet membranesis inherently

stronger against fouling than the hollow fiber

membrane configuration. Therefore, it results

in fewer chemical cleaning requirements.

Reduced module fouling from human hair and

other obstructive substances allows coarse

screening as a pretreatment process.

Energy efficient

Flat Sheet Membrane consumes less energy

compared to hollow fiber membrane due to

more effective scouring aeration and lower

trans-membrane pressure.

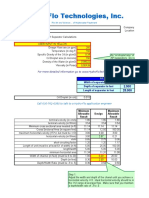

Specification of COMPACT

Model

C OMP AC T

TM

Package MBR Sewage Treatment Plant

50

C OMP AC T

TM

75

C OMP AC T

TM

100

C OMP AC T

TM

150

C OMP AC T

TM

200

T reatment C apac ity

550 m3/day

5075 m3/day

75100 m3/day

100150 m3/day

150200 m3day

P opulation(1)

25250

250375

375500

500750

7501000

Inlet C ondition (B OD/S S)

3 0 0 mg/L /3 0 0 mg/L

E ffluent Quality (B OD/S S )

5mg/L /5mg/L

P ac kage Dimens ions(2)

4.0m x 2.4m x 2.4m

6.0m x 2.4m x 2.4m

(L ength x Width x Height)

Note:

(1) Calculation is based on the discharge of 200 liters/person/day.

(2) Dimensions are subject to change and modification without notice.

9.0m x 2.4m x 2.4m

12.0m x 2.4m x 2.4m

18.0m x 2.4m x 2.4m

Você também pode gostar

- Signet 8900 Multi-Parameter Compatibility Overview BrochureDocumento1 páginaSignet 8900 Multi-Parameter Compatibility Overview BrochuremelpomenneAinda não há avaliações

- How To Select A Chemical Coagulant and FlocculantDocumento24 páginasHow To Select A Chemical Coagulant and FlocculantAugustoPertotAinda não há avaliações

- API SizingDocumento13 páginasAPI SizingJayesh SanganiAinda não há avaliações

- Fracwater Tss ExplainedDocumento2 páginasFracwater Tss ExplainedprakdoraAinda não há avaliações

- Astral Upvc Sch40 Pipes and Fittings PricelistDocumento4 páginasAstral Upvc Sch40 Pipes and Fittings PricelistThiyaga Rajan0% (1)

- Parham WW TreatmentDocumento60 páginasParham WW TreatmentmelpomenneAinda não há avaliações

- Homework 5 So LNDocumento7 páginasHomework 5 So LNMuhammadUsmanAinda não há avaliações

- Oil-water separator design guideDocumento17 páginasOil-water separator design guidemelpomenne100% (1)

- TORAY Membrane EuropeDocumento25 páginasTORAY Membrane EuropemelpomenneAinda não há avaliações

- Raven Ho Riz FlowDocumento30 páginasRaven Ho Riz FlowmelpomenneAinda não há avaliações

- Sodium Azide Reduction of Protozoa ActivityDocumento50 páginasSodium Azide Reduction of Protozoa ActivitymelpomenneAinda não há avaliações

- Aaplesarkar Mahaonline GovDocumento9 páginasAaplesarkar Mahaonline GovmelpomenneAinda não há avaliações

- Cheesemaking EbookDocumento282 páginasCheesemaking Ebookalbinuta100% (6)

- Sorption and Release of Organics by Primary, Anaerobic, and Aerobic Activated Sludge Mixed With Raw Municipal WastewaterDocumento15 páginasSorption and Release of Organics by Primary, Anaerobic, and Aerobic Activated Sludge Mixed With Raw Municipal WastewatermelpomenneAinda não há avaliações

- Lecture 9-Lime Soda Softening (Part 2)Documento7 páginasLecture 9-Lime Soda Softening (Part 2)Harold TaylorAinda não há avaliações

- QP7498-DEQ-Chapter 5 Corrections - PG 54 PDFDocumento1 páginaQP7498-DEQ-Chapter 5 Corrections - PG 54 PDFmelpomenneAinda não há avaliações

- Aadhar Enrolment Correction FormDocumento2 páginasAadhar Enrolment Correction Formapi-249989744Ainda não há avaliações

- Un V em Site Master Plan Arch 09.02.16-ModelDocumento1 páginaUn V em Site Master Plan Arch 09.02.16-ModelmelpomenneAinda não há avaliações

- Steel pipe pressure ratings and flow ratesDocumento2 páginasSteel pipe pressure ratings and flow ratesNarendra ChavdaAinda não há avaliações

- Endless Belt Type Oil Skimmer-293Documento6 páginasEndless Belt Type Oil Skimmer-293melpomenneAinda não há avaliações

- Hsin-Hui Sebastien Yue 2011Documento37 páginasHsin-Hui Sebastien Yue 2011melpomenneAinda não há avaliações

- The Challenge of Removing Surface Oil PDFDocumento4 páginasThe Challenge of Removing Surface Oil PDFmelpomenneAinda não há avaliações

- AMPC Review Paper - Removal of Fats Oil and Greases From EffluentsDocumento26 páginasAMPC Review Paper - Removal of Fats Oil and Greases From EffluentsmelpomenneAinda não há avaliações

- Techinfo Cooling TowersDocumento23 páginasTechinfo Cooling TowersKokil JainAinda não há avaliações

- Perfomance DataDocumento1 páginaPerfomance DatamelpomenneAinda não há avaliações

- 426Documento9 páginas426melpomenneAinda não há avaliações

- Achieving Zero Discharge in Industrial Waste Water Treatment PlantsDocumento13 páginasAchieving Zero Discharge in Industrial Waste Water Treatment PlantsEswaramoorthi Sellappa GounderAinda não há avaliações

- Vision Valves Manufacturer and Industrial Valve DealerDocumento10 páginasVision Valves Manufacturer and Industrial Valve DealermelpomenneAinda não há avaliações

- JCM SeriesDocumento2 páginasJCM SeriesmelpomenneAinda não há avaliações

- Performance Data - K3H Series: 100mbar 200mbar 300mbar 400mbar 500mbar 600mbar 700mbar 800mbar 900mbar 1000mbarDocumento3 páginasPerformance Data - K3H Series: 100mbar 200mbar 300mbar 400mbar 500mbar 600mbar 700mbar 800mbar 900mbar 1000mbarmelpomenneAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Engineering HydrologyT1Documento2 páginasEngineering HydrologyT1Manish ChaudharyAinda não há avaliações

- Presentation IEE of Aqeela HeightsDocumento23 páginasPresentation IEE of Aqeela HeightsJahangeer AsadAinda não há avaliações

- Assessment of The Impact of Variations in Riparian Landuse On Stream Channel Morphology and Flow Regime in The Kilange River Catchment, Adamawa State, NigeriaDocumento7 páginasAssessment of The Impact of Variations in Riparian Landuse On Stream Channel Morphology and Flow Regime in The Kilange River Catchment, Adamawa State, NigeriaInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Ali-Shakir2018 Article SustainableSedimentManagementODocumento10 páginasAli-Shakir2018 Article SustainableSedimentManagementOAdnan AmjidAinda não há avaliações

- Table of Contents and Basic Hydraulic PrinciplesDocumento6 páginasTable of Contents and Basic Hydraulic Principleskawser zamanAinda não há avaliações

- Unit 4 Irrigation CanalsDocumento25 páginasUnit 4 Irrigation CanalsAmal ZakirAinda não há avaliações

- Earth and Life Science: Quarter 1 - Module 20 Mitigation To Coastal Processes and HazardsDocumento26 páginasEarth and Life Science: Quarter 1 - Module 20 Mitigation To Coastal Processes and HazardsJoed MortelAinda não há avaliações

- Flow Nets: Dipanjan Mukherjee Civil & Soil Engineering Wbut (Ait)Documento23 páginasFlow Nets: Dipanjan Mukherjee Civil & Soil Engineering Wbut (Ait)Prasenjit PaulAinda não há avaliações

- Irrigation Methods GuideDocumento45 páginasIrrigation Methods GuideIain Choong WK100% (1)

- Morphologic Adjustments of Actively Evolving Highly Curved Neck CutoffsDocumento15 páginasMorphologic Adjustments of Actively Evolving Highly Curved Neck CutoffsJOSE ANTONIO JACOBO GARCIAAinda não há avaliações

- Alternative Onsite Sewage Disposal Technology: A ReviewDocumento38 páginasAlternative Onsite Sewage Disposal Technology: A ReviewWashington State Institute for Public PolicyAinda não há avaliações

- 00-Flash Flood Risk Assessment For Kyushu Island, JapanDocumento20 páginas00-Flash Flood Risk Assessment For Kyushu Island, JapanAdly Al-SaafinAinda não há avaliações

- Tugas Bahasa InggrisDocumento6 páginasTugas Bahasa InggrisBrendi Bloods QuotesAinda não há avaliações

- 13048Documento8 páginas13048massera.p2540Ainda não há avaliações

- Designofcrossdrhnageworks-Codeofbracticb: Indian StandardDocumento15 páginasDesignofcrossdrhnageworks-Codeofbracticb: Indian Standardrvkumar3619690Ainda não há avaliações

- (Water Science and Technology Library 57) Sharad K. Jain, Pushpendra K. Agarwal, Vijay P. Singh (Auth.) - Hydrology and Water Resources of India-Springer Netherlands (2007)Documento1.277 páginas(Water Science and Technology Library 57) Sharad K. Jain, Pushpendra K. Agarwal, Vijay P. Singh (Auth.) - Hydrology and Water Resources of India-Springer Netherlands (2007)kushalAinda não há avaliações

- Compit Pump Station: Complete Pump Station For Sewage and Pressurized Sewage Systems, and For GroundwaterDocumento5 páginasCompit Pump Station: Complete Pump Station For Sewage and Pressurized Sewage Systems, and For GroundwaterEva Fici Dosa FulopAinda não há avaliações

- SANRAL Drainage Manual (South Africa)Documento464 páginasSANRAL Drainage Manual (South Africa)BalarkaAinda não há avaliações

- WTP Boq-FinalDocumento3 páginasWTP Boq-FinalT M Murshed Mukul100% (1)

- J. Power, Water, and Communication NetworkDocumento2 páginasJ. Power, Water, and Communication Networkkerwin jayAinda não há avaliações

- CHE 262 Chemical Processes and SustainabilityDocumento24 páginasCHE 262 Chemical Processes and SustainabilityMohd Shahrul Nizam SallehAinda não há avaliações

- 15.docx 1 1Documento21 páginas15.docx 1 1Nathan EscobalAinda não há avaliações

- Chapter Iireview of Related LiteratureDocumento2 páginasChapter Iireview of Related LiteratureDranoel Yob MalinaoAinda não há avaliações

- Bams BAMS D 22 0226.1Documento24 páginasBams BAMS D 22 0226.1Vagner AnaborAinda não há avaliações

- Causes, Effects and Solutions of Global Water Shortages, with a Focus on CaliforniaDocumento5 páginasCauses, Effects and Solutions of Global Water Shortages, with a Focus on CaliforniakvsnlrAinda não há avaliações

- Assessment of Temporal Variation of Water Quality Parameters and The Trophic State Index in A Subtropical Water Reservoir of BangladeshDocumento21 páginasAssessment of Temporal Variation of Water Quality Parameters and The Trophic State Index in A Subtropical Water Reservoir of BangladeshHasrat ArjjumendAinda não há avaliações

- Oil Grit SeparatorDocumento2 páginasOil Grit SeparatorolhevlaAinda não há avaliações

- Septic System Design ManualDocumento31 páginasSeptic System Design ManualtonyAinda não há avaliações

- Water ResourcesDocumento20 páginasWater ResourcesKanishkha Sivasankar67% (3)

- Water Supply NumericalDocumento9 páginasWater Supply NumericalAashish ShresthaAinda não há avaliações