Escolar Documentos

Profissional Documentos

Cultura Documentos

TP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel Rev - 3 PDF

Enviado por

zelite0 notas0% acharam este documento útil (0 voto)

284 visualizações127 páginasTítulo original

TP21 - BEC - DT - 0402 MAS for 11 KV chiller starter panel Rev - 3.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

284 visualizações127 páginasTP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel Rev - 3 PDF

Enviado por

zeliteDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 127

R PO THE WAVE, MUSCAT é

‘B. ie

WANE The Wane

Tear Fs

IT2 - BEC = DT- 0402 3

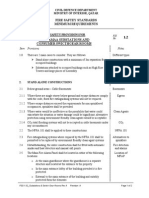

[SUBMITTAL TRANSMITTAL FORM [Date 03.08.2010

[TRANSMISSION OF DRAWINGS, DOCUMENTS, MATERIALS, ETC. SuourreD Fon” | S0E

hseaow

ICONTRACTOR: BAHWAN ENGINEERING CO. LLC frourneomuaron [2

IRE: CENTRALISED COOLING PLANT Package Nos [oanonnon z

feron™

Oo THE WAVE MUSCAT SAOS TP21 eon =

KA: _Mr. STUART INGRAM, CHIEF OPERATING OFFICER hreesovenaanored | 2

Fat ane Sexo nemewth Te SOSUWENTS SSTE=D BLOM har araven 3

FoR NrORAnON 2

w Ta SPE OF Tene Seow TPE 2008

MAS for-11 KVChillor Starter |g. |,

2 |SECTION 16345"

Panel

Baz

abe CERRO NES KOT

Dy RRISTNAN, ASST GENERAL MANAGER.

(Gusta oor Acton Goat a Harter Conmaor

warns

(CONSULTANT'S COMMENTS

pomesto:

[PROJECT MANAGER'S COMMENTS

|

(SoreSTS.

[FOR CONSULTANT

[FOR PROUECT MANAGER.

DATE

THD istang Cama Hae STSTTAST Grae TETRA WOT]

Sol ggemce rote mecien

routs cont ty

om a

Fre me eae ES z enacor

= ; + cai oon ety

— = HA er

BY:-

Mud

THE WA\

VE, MUSCAT

(Tent BEC™ DT - 0402

SUBMITTAL TRANSMITTAL FORM [Date: 15.

TRANSMISSION OF DRAWINGS DOCUNENTS, MATE: pasa z=

|CONTRAGTOR: SAHWAN ENGINEERING CO. LLC _ femur =e

RE: CENTRALISED COOLING PLANT ~ [Package No. [CLARIFICATION =

eo

Fo TRE WEISER ST TP21 =a z

A: _ Mr STUART NGRAM, CHEE OPERATING OFFICER | bepanersare [a

cia ee sean ea ao

Parameter

= Ee re ae eee

ae ine | caer aa?

> - lwasior-1tKvonitersieter| g, |, |S

5 Pane

1

i> \\

[FOR CONTRACTCS. ANAVIHA STR, ASST GENERAL WANG

[Sonstatto er Aaion Godor and Rema ard eum > Gorecke

cass: Te

CONSULTANT'S COMMENTS

a

. ah -

SS Balizo4

FR CONGICTNT CATE

PROJECT MANAGERS COMMENTS >

TPE

r

DELAY SP,

‘pescado econ steiner sau |

eae fF

ON hats

2 ib dtfy2/99.

= = row proeoromactie HE

WE ti Gag ABS Giang ETRE Tamer! CrGaewine TeTeTay FEN” WON

Crone Cleminms Trahan “wens

CUTS Toi oes

[To: Pe ‘Conmuttant PM ‘Gontrator 2 1 DEC) Sasi |

ous coe oe) elem coe tte ret

= rae sowere leurs i onto

12 086 amy

THE WAVE, MUSCAT

TP21 — CENTRAL COOLING PLANT

COMPLIANCE STATEMENT

ArOe 11KV CHILLER STARTER

PANEL

Part No

SECTION 16345

COMPLIANCE STATEMENT FOR MEDIUM VOLTAGE STARTER

15.3 KV reduced vollage soft starters for chiller motors and associated

Icomponents.

Metering relays in soft starter panels

Integral capacitor banks for power factor correction

[STANDARDS

References include: [|

[EG 50684 "Causes common to high Vategos Swtongear ane Conta

ocar

IEC 62271-200 : AC metal-enclosed switchgear and control gear for rated

Jvoltage above 1KV up to and including 52 KV-

IEC 62271-102 : Alternating current disconnectors and earthing swithes

IEC 60 265-1 = Switch Disconnectors.

IEC 60.470: Contactors.

IEC 60.044-1 : Current Transformers.

EC 60282-1 = High Voltage Fuses.

IEEE 519-1992 : Harmonnic control and Reactive Compensation of Static

Power Converters

INEMA IC3-2 _: Medium Voltage Controllers

[SUBMITTALS.

Product Data:

[Catalog descriotion of general construction, Dus ralings (volls phase,bus

bracing and capacity) branch and main protective devices and their

rating(voltage,current, short circuit level, IP rating. internal arc

classification) and special fetures and apparatus(e.g metering equipment

Jand protective relays. Include derating factors for 50 degrees Celsius

lambient temperature.

Wiring Diagram: ee

JAs Built Internal wiring of sensing and control devices. Please refer to drawings submitted

[Single Line Diagram containing all major components. Please refer to drawings submitted

PE

Type test certiicates shal be provided to confirm compliance with Riot apelcate

standards

[Submit third party declaration of conformity with the tender to validate

Jcompliance with the standerd, Netspoleabi

[The owner shall witness tost al the factory were the panels are tested ___| Not applicable

Factory test certificates to be Issued from place of manufacturer. Factory

11KV 3 phase system, 800A nominal bus

Jcapacity unknown bus SC Capacity,

lunknown short circuit level, NEMA 1, no

arc ciassification

Benshaw standard testing procedure TP.

153 (attached)

Not

plicable

Personnel Operating Instructions:

[Letter report identifying personnel attending and date of completion

[Operation & maintainance manuals:

[Shop drawings as previously described above.

[Wiring Diagrams as previously described above.

[Operating instructions, Parts List and Service Organization |

Mainiainanoe instructions and procedures manuals

lowers Stock Ld

Letter report identifying materials, Guantties date of delwery and Owners [x.y

representative receiving

a

DELIVERY, STORAGE AND HANDLING

Delivery products in their original packaging with legible manufacturers

identification,

[Store materil in accordance with manufacturers recommendations, [comph

While located in unheated space,prior to energization, maintain temporary [hota

Janti-condensation heat within medium voltage section,

.5__|SEQUENCING AND SCHEDULING. Pd

‘A __[Cutover steps appear schematically on the Drawings. Noted

[Conduct specitied tests betore energizing any new equipment. Noted

[Do not attempt any alternate sequence without specific permission of he

Iconsultant,

MAINTENANCE es

Provide the following tems and turn over to the consultant before ded

[Spare fuses and refill, Three spares of each size and type fuse for every

Y Noted

three soft starters.

Fuse handling tools:One complete set of tools required to insert or remove

fuse assemblies from their holders or clips and to replace refils.

Noted

Provide a list of spare parls for two years together with order code

Inumbers.Included in the spare parts list shall be individual prices valid for

six months. The spare parts list shall be approved and finalized by the

Iconsultant.This cost shall be included in the total tender cost.

[Al related software for transferring data(Up/down loading)between laptop |.

loted

Jand relay.Data cable to be provided

Pe

MANUFACTURERS |

fAccepatable soft starter manufacturers [Acceptable Starter manufactuers:

[Schneider Electr re |

[get

[Benshaw

[Benshaw Benshaw

[Ajlen Bradle a aT

[Equivalent other to be approved by the consultant PO

a

JAcceptable capacitor bank manufacturers: |Acceptable capacitor bank manufacturers:

[Schneider Electric

GE

a

[ABB capacitors provided,

[Equivalent otfer tg be approved by the consultant |

[The soft starter shall conform fo the following climatic conditions; [TT

[Altitude ; Below 1000 meters

[Ambient temperature: 50 degree Celsius

Humidity Upto 95%

11 KV MOTOR STARTER

REQUIREMENTS AND COMPONENTS :

[Compressor motor starters will be constructed as part of floor standing 8.3

IV motor control centers and installed in a separate air-conditioned

Not Applicable

HThe 3.3 KV starter shail be of a 6-pulse reduced-voltage solid state type

|All motor starters and controllers shall be designed,manufactured and

tested to meet or exceed the requirement of the latest published standards

lof NEMA or IEC in addition to local authority requirements. Manufacturer to

list the standards approved to the starter model

[Motor controllers shall accept accept nomial power of 3,300 volis AG (+=

10%).3-phase,50 Hz(+/- 5%)

Fhe motor control centers shall be designed and built specifically to

Jaccommodate the equipment contained within them ,jnciuding all

|controllers and equipment for the soft starting of the chillers.

Include power factor correction capacitors to improve power factor to 0.93

minimum inteligent electronic retays with data output ,and module

lcontroliers and the like to ensure the flexible operation of the equipment.

The panel manufacturer must be able to demonstrate that they experience

with the use of such equipment on previous successful operation project.

[The slarters shall be manufactured in section assembled and fully tested

in the factory.Thereatter,the complete unit shall be taken apart,shipped to

site,reassembled and tested again.The testing in the factory shall required

the panel manufacturer's provision of motor test loads to demonstrate all

the equipment.

The manufacturer's scope shal include the preparation of all detailed shop)

Jcrawings for the starters, including wiring diagram, test

certiticates,operating and maintenance manuals and a list of required test

lequipment such that the contractor has all necessory information.

[The manufacturer shall deliver the starter panels to site,place on the

site,assemble,test and commission and offer full co-operation and liaison

}with the contractor in his commissioning of the connected equipment. The

pane! manufacturer shall provide an experienced engineer at site during

the commissonning of the plant,

[The manufacturer shall provide minimum 4 Gays on sile operational

instruction to the Client's engineers and operators. These 4 days shall be

allocated after all commissioning procedures and tests have been

[The panel manufacturer shall provide a 24 hour por day,365 day por yor

Jomergency call-out service lo guarantee to be at site with in 4 hours of an

H 1kV 50/60 Hz

[Comply

Comply

starter runs against motor load in shop.

Full load testing is not available.

Not Applicable

[The medium voltage solid state controller shall consist of a metal-

lenclosed free-standing, vertical steel structure.

[Each structure shall be suitable for future expansion al each end Each

structure shall also have (2) non-removable base sill channels and

removable lifting angles or brackets for ease of handling and installation

Provide a minimum of NEMA 12 or [P42 gasketed enclosures for indoor

application

[Each starter enclosure shall be connecled and bolled to each other.

|Comply for 11kV DOL starter

[Not Applicable

[Provide a dedicated enclosure section for each starter to accommodate

the number and size of motor cables.Motor cables will exit the starters Jcomply

trom the bottom or top (as indicated on design drawings)

FThe controller shall be of modular Gesign to provide for ease and speed oF

maintenance. The modules shall be manufactured by one supplier and

éesigned to allow ease of maintenance ,inclucing removalof medium

voltage components and power electronic components by one

maintenance personnel.

FThe Structure shall be divided info lsolsted metal comparimenis 25

otiows:

Main power busbar and isolation switch compartment paiosinetycert seotonert22 eine

conductive fiberglass giastic material.

Power equipmentjuses/and SOR compartment

[Low voltage and control compariment

[Metal barriers shall be provided between each section between the low

{voltage compartment and the power cell and /or main power bus

Icompartment and between the power cell and main power bus

compartment .Personnel shall have access to the low voltage

Jcompariment,with the controller energized, without being exposed to any

mediumvoltage.

Each srucur shal conan te folowing tere Cd

!Bare copper horizontal power bus INot Applicable

i cons Bare copper Sut Rot hestastie

Not Applicable

Power electronics Not Applicable

[A main non-load break isolation switch and operating handle Not Applicable

[A vacuume isolation switch and operating handle Not Applicable

[A vacuume bypass contactor Not Applicable

[Three(3) power fuses or current limiting fuses INot Applicable

FThree(3) protection current transformers class 520 or batter Not Applicable

[rhree(3) metering current transformers class 0.5 or betler Not Applicable

[A low votage control panel complete with microprocessor based control j

module Comaly

Protection relay and mulli function meter Not Applicable

[Space for necessary auxiliary control and metering componenis, Not Applicable

[Capacitor Bank and contactor (if applicable)

[Aluminium or Brass plates to accommodate entry cable connectors,

Allowances to be made for top outgo power cable entry if so required

The sheet metal shall be coated with a thermo setting powder of an epoxy)

resin base modified by polyester resin,which provides perfect finish and

lexcellont protection against corrosion. Final enclosure color to be approved

by the consultant or alternatively matchexisting main incoming switchgear

[The horizontal main bus shall be located in is own Separate enclosure and

isolated from the starters.To allow for ease of maintenance or extension of

lin-ups without disassembling starters,the main bus shall be front,top and. {Comply

side accessible Altemative arrangement may be offered for approval by

the consuttant,

FHorzantal bus bar shal be rated for wanstormer forced arrraiing.Deraling [oo

ltactors to be taken into accourt, mp

Vertical bus bar shall be rated for isolator rating Dorating actors to be

jaken into account NetAppioebie

[All main bus bars shall be in-plated and made of copper. This shall include

Panes eta Jearth bar not tin plated

fall busing rating and Gmensions shall match the medium vokage Sock

switchgear ratings. np

1Sus bars shall be of a copper grade no less than 99.9%. Comply

[Bus connections shall ensure minimum resistivity ang temperature ase, |comply |

[Bus Bar phases shall be clearly marked in each panel for phase lcarics

identification. ene

—

ISOLATION SWITCH: |

he dis-connector shall either comprise of the following, manel) TS TTTTTCTCTCTCTCTCTCOC™~™CY

5

[A-3 phase,3-pole isolator with separate In-Line fuses after the dis~

connector switch OR.

[A 3-phase,3-pole fused isolator.

The isolation switch shall either be rated for 200 Amps or 400

|Amps,unless otherwise indicated on drawing provided.

ihe isolating switch shall be an externally operated manual three “pole

type ,such that in the open position it completely grounds and isolates the

leaving no exposed high-voltage components.

Integral mechanical interlocks shall prevent entry into the high-vollage

Jareas while the starter is energized or when the isolator switeh is in the

‘Closewa'" position and shall block accidental opening or closing of the

isolating switch when the door is open or the contactor is closed

|The isolating switch handle shall have provisions for three(3) padlocks in

the popsition.

Medium Voltage In-Line ((used isolator fuses included) fuses shall be

[current limiting fuses and shall be fast acting

[General fuses may be offered and shall only be accepted upon the

2 |eonsultant's approval. this option is approved by the consultant.the

manufacturer shall provided a letter starting that no damage to any

Icomponents shail occure in the event of any fault

Ibe used to mechanically activate a normally closed conta

the contactor in the event of a blown fuse.

[The fuses shall incorporated special time /current characteristics for motor

|service allowing proper co-ordination with the contactor and overload relay

ior maximum motor protection. This co-ordination shall be such that under

Ja low -fault concition the interrupting rating and drop-out time of the

[contactor shall be properiy co-ordinated with all posible fuse sizes to

leliminate contactor racing .The power fuses shall be vertically

|mounted, permitting easy inspection and replacement without starter

Idisassembly.A fuse puller shall be provided with each starter.

fuse puller not required or provided

|

|CONTACTORS:

[All contactors shal be rated be for AC-3 Utiizalion, INot Applicable

Ail contactors shall be rated for Type-2 Co-ordination. INot Applicable

Al contactors sha be equlpped wih sunlary corbci or oaBon Not Apglicable

Contactors shall be rated to withstand capacitor bank switching transients. |Not Applicable

Contactors shall be abe fo provide a minimum of 200.000 operations. Not Applicable

fan operation counter for each operation (one operation equals, ;

JOPEN/CLOSE) shall be included in the In-Line contactor. Net Appieeas

[The By-pass contactor connection shall be located after the In-Line Nit Apphesble

lcontactor and protection relay current transormer. sles

;

[Bypass contactor shall be provided to short out the SOAS ones he MOIOT [AO cane

is up to full speed.

When "Slop" funclon fs Selected jbypass contactor shall open bangin

Sorts neck ito power oveut pennant _ [Net Aoptcabie

jWhen in soft starter mode and a trip command is initiated,the In-Line and

IBy-pass contactors shall be opened simultaneously When in By-pass

mode and trip command is initited,the In-Line and By-pass contactors

shail be opened simultaneous!

Not Applicable

[The following integral mechanical & electrical interlocks shall be included

|

i

tay

3

2

9)

2)

RI

namely. INA

[An interlock preventing access into the high -vollage areas while the

starter is energized comply

An inieriock preventing access ino high-volage areas when the Nowior [oo

switch is in the "Closed" position,

[An interlock preventing accidental opening or closing of the Isolating

switch when the HV door is open.

(CURRENT TRANSFORMERS:

[Current transformers shall be used for protection as well as for metering

purpose.

Protection GT's Shall be raled for 5P20 and shall have @ Burden VA rating

Jas per the manufacturer recommendations.

[The Lightning Impulse withstand voltage shall be no less 60 KV.

available.

[All V's shall either have front or back enclosure access,

[AI V's shall be installed on ihe Ine side of each starter

VOLTAGE TRANSFORMERS:

[otage Transformers shall be used for metermg purpose, Not Applicable

[An accuracy Class of 0.5 shall be used and shell have a Burden VA rating

et ronnie

The Lightning impulse withstand voltage shall be no less than 60 KV. Not Appieable

W's shall be terminated in the low voltage compartment via approved VT

terminal blocks. VT test blocks shall have a ‘TEST’ position function made |Not Applicable

available,

[All VT's shall ether have front or back enclosure access. 2

JAILWT's shallbe installed on the line side of each starter, Not Ap

EE

LOW VOLTAGE COMPARTMENT:

The low voltage compartment shall contain the folowing

[Control Module

[rot applicable

5

Not applicable

LV incoming /Outgoing cireutt breakers and fuses

Selectot switches INot applicable

The low-voltage control compartment shall be Isolaled and barriered from

the high-voltage area and mounted on a panel with a separate low-voltage

Jaccess door. The low-voltage control components shall be accessible from

the front of the low -voltage control compartment.

The main incoming low voltage supply (if required) shail be the only low

power source to enter the enclosure. The main low voltage incoming three

3 phase supply shall terminate in the low voltage control panel via a circuit

breaker (3P + N).This circuit breaker in turn shall feed the following ciccult

Jwhich in turn shall have their own dedicated circuit breakers,namely

Not applicable

Power card Not applicable

[Enclosure light

Not applicable

[The control panel shall include a localremote selector switch. This shall bo

located within the low voltage panel and not on the panel enclosure

(surface mounted).The status of this selector switch shall be signaled back|Not applicable

io the SCADA via the standard communication protocol af the

Imanutacturer.

[The low voltage compartment shall include a'Soft StarlerIBy-Pass Mode"

selector switch. This will enable the operator to start the motor using a full

voltage starter(Direct On Line) in an emergency situation.A separate

protection relay will be required when in the "By-pass mode as the soft

starter controller shall be disconnected from the circuit.

[The display control unit event recorder shall be able to store the last 00

levents together with a time stamp.

[A built-in test circuit shall be included to permit checking of the slarter

control and pilot circuit,with the high-voltage de-energized and isolated, and|

the contactor in itsnormal closed position or in the open position.The

control circuit shall be capable of being energized through a polarized plug

connector from an external 240-volt supply while in the “TEST* mode. This

method will not required an external power source.

IMethod -voltage soft starter control module shall be microprocessor

controlled degital module with remote communications capabilities,

[The controller shall accept nominal plant power (Refer to the data sheet

ior the voltage used)AC (+/- 10%),3 phase 50 Hz (+/+ 5%)

[The control module logic shall provide one of the following sets of

functions within a single controller

Not applicable

Full-Voltage Start Not applicable

The following protection shall be provided during ‘Starting’ and Running

Imodes.When these conditions are detected, starting of the controller shall

be inshall be inhibited or thee controller shall be shut down if itis

Stan Fault

ting Fault

Temperature Fault

Not applicable

Not applicable

Not applicable

Not applicable

[The controller logic shall provide the following standard fetures:

[Adjustable Ramp Time (0-120 Secounds)

[Adjustable Initial Current(50 % - 400 %)

[Adjustable maximum Current (200 % - 600 96)

[Selectable Current Limitduring Motor Start

Line Phase Loss Detection

ISoft Stop operation

Tine Current Imbalance Detection (10% - 40%) Not applicable

[Over/Under Line Voltage Protection (10%-80%) with adjustable duration (0

HO sec)

Not applicable:

[Up to Speed Indication Not applicable

Line Phase Sequence Sensitivity, or Insenstivily INot applicable

[Selectable Solid State Overioad Class 10,20,30 Not applicable

Battery Backup of Starter Parameters, Not applicable

Line Voltage Independent Operation INot applicable

[Shorted SCR Detection

Software Selectable Relay Outputs

ECD Status Display

Not applicable

igable.

lot applicable.

Power Off Lock-out Retention Not applicable

Not applicable

Scroling Current and Voltage Meters INot applicable

lUndercurree Trip, Not applicable

Not applicable

Kilowatt hour meter INot applicable

Power factor meter Not applicable

IVAR meter INot applicable

uu__|Memory of overioad parameters Not applicable

[Each controller shall include a timer fo prevent unit from restarting during

Icompressor coast down ansand controls to automatically and immediately

reintiate chiller starting sequence after machine has stopped. Timer setting|comply

shall be co-ordinated with chiller and motor manufacturers to prevent

Jdamage to equipment from frequent starts.

[The control module shall communicate status and alarm information to the

aster Controller (SCADA).As an added option.the control module shall

receive motor starting commands over this same link.Initally remote

stop/starts shall be hard wired.Co-ordinate communications protocol with

system integrator. The factory default protocol shall be used for the

starters.

All protection shall be available when the By-pass contadlor has closed, [Not applicable

[All remote commands and metering shall be made available when the By-

lpass contactor is closed as well as when the solt starter is in the Not applicable

llocalremote mode.

[All SCR stacks shall have @ R-C snubber module inserted for voliage, "

spikes and to prevent false SCR firing Not applicable

a |

PROTECTION RELAY (BY-PASS MODE)

This method of starting shall only be used in an emergency.A full vollage

sytart will be required, thereby by-passing the soft starter control unit.

[The current transformer connections shall be located afer the In-Line

lcontactor_and before the By-pass contactor

The protection relay shall monitor and initiate @ trip (required ) under the

following conditions namely,

ae

Refer PLO/SCADA point schedule

Not applicable

Not applicable

Not applicable

Winding temperatures

[Drive / Non Drive bearing temperatures

In addition to the protection function, the relay shall display the following

Imeasurements,namely:

-phase current (A)

hase vollages(A)

[Power factor (corre.

rower (kW)

Reactive power (VAR)

Kwh)

S|

HO (4)

(Corrected power factor readings shall be Submited top he consultant Tor

pproval

FThe protestion relay shall be submited fo the consultant for approval

All meter and protection parameters shall be signaled baokto the SCADA

s

internal wiring shall ensure that tne capacitor bank contactor opens and

closes with the by-pass contactor switching philosoph

FThe following minimum contacts shal be made avallable on each sot

starter-All contacts shall be pre wired to a field terminal ral.f more than

Jone control unit is used or an addition protection relay is included into the

control philosophy,then both units shall have the below mentioned

terminals made available in the event that oniy one of the units Is used at

Jany given point in time.Alternative protection options may be considered it

[submitted to the consultant for approval.

ip.

“local remote

Remote Temperature Device (RTD)-8 -RYYIB windings (x6)

- Drive End bearing(xt)

= Non Drive End

lbearing(xt

INDICATION LIGHTS.

The following indication lights shall be provided as a minimum,

isolator earthed,

un

ip

pass mode

Bl=l=Ialale

a,

PUSH BUTTONS

Not applicable

Not applicable

Not applicable

INot applicable

INot applicable

Not applicable

Not applicable

Not applicable

Not applicable

Not applicable

ae

Not applicable

Not applicable

Not applicable

Not applicable

[The following push buttons shall be provided as a minimum:

Stop.

[Emergency Stopinall covered ang lockable) Not applicable

ee S|

CHILLER AND STARTER ENCLOSURE

JAUXILIARIES

CHILLER AND SOFT STARTER ENCLOSURE AUXILIARIES

[Each chiller shall have an independent S-phase supply feeder for all is

Jauxiliaries(cil heaters,oil pump.control panel, display module). The feeder

shall be from the LV MCC,and not from the 3.3kV starter. At each

chiller,the source supply will terminate into a main circuit breaker via an

isolation transformer(Delta /Star)in order to create the neutral.

[The soft starter auxilaries shail either come direclly from the chiller

Jauxiliary panel in the field or alternatively be tapped off the soft starter

Jenclosure main bus bars via step down transformers.Co-ordination

between the Chiller manufacturer and the soft starter manufacturer shall

be required,

INo current transformer or voltage transformer or any other equipment from

the chiller manufacturer shall be installed in the soft starter enclosure

panel

INTERNAL WIRING

[AIT internal wiring shall be tagged and numbered and shall match As-bullt 7

drawings. pony

Method of wiring shall be via the “Cross-ferruling” technique.

[Typical drawing will nol be accepted, Noted,

Include power factor correction capacitors to improve power factor to 0.93,

minim

[Capacitor Bank shall have three (3) in built resistors for discharging when

switched off,

[The capacitor bank shall included x3 In-Line fuses for protection against

Jany severe fault.

[Capacitor banks shall be over-rated and shall be connected to a phase

line reactor to accommodate harmonics as well as minimize voltage

Isurges when capacitor banks are switched in,

[Capacitor banksshailbe a single step with a set KVAr rating KVAr ralings

itor bank, value chosen

sha bo basos on manutacturer motor dala sheet using a power factor of [eNgle s'agecapactor bank, val

Ithe worst possible scenario,.namely at 50% loading. w

IC apacitor Banks shall be connected in Della

ee Ee EEE EE

[EXECUTION re |

[Examine areas and conditions under which works Is to be performed and

identity conditions detrimental to proper ot timely completion.

[Anchor enclosures to supporting concrete pads or as delalled on the

Jarawings.

reactor not provided

[Soft starter enclosures shall only be installed when the switchgear room

lots arch coal ot panting has boon cpl

Protect panels during construction with covering to keep it clean and ce

f i i Noted

Jdry.Provide heat necessary to eliminate condensation

[Co-ordinate raceway entry into switchgear so that sections wih spare

Jdevices or provision for future

[Ground panel frames and metal raceway entering switchboards as

Jdescribed in section 16060

IMake connection in soft starter panels complete and secure before

lenergizing and install or tighten fasteners with torques as recommended Applicable to 11KV chiller starter panel

by the manufacturer.

in fusible switches,install fuses specified Indicate fuse amperage,and type.

lusing adhesive labeis supplied by the fuse manufacturer,atfixed to the

INSTALLATION. [

[Verify numbering routing and poinls of connection of feeders. [Noted

[Guard edges and restore finish of new opening made in existing

Jenciosures.

ci

lose abandoned opening in boxes or enclosures with steal bolted plates

finished to match existing materials,

FIELD QUALITY CONTROL

[Secure the services of the manufacturer's technical representative,or few

Noted

those on an independent testing firm.to perform acceptance test equal to

INETA procedures.

[Check wire -1o-wire phasing of high vollage terminals across any breaker

Jor switch permitting parallel connection to another source, including

Jconnections made via low voltage ties and ties which are keyinterlocked

to prevent unintentional paralleling

Periorm, or assists in the performance of any Testing required by the

Electrical Utility.

DEMONSTRATION(PO})

Domonsirate the operation of the medium vollage soft starter and have

JOvner's personnel conduct "Hands-On" start,stop,trip and reset

procedures,

Demonstrate the operation of protective relays and Multi function meters. |N/A

[Demonstrate the operation of Key interlocks.

Noted

|As per manufacturer's standard

Noted

THE WAVE, MUSCAT

TP21 — CENTRAL COOLING PLANT

| TEST PROCEDURE FOR 11KV |

CHILLER STARTER PANEL

(SERIAL NO: 01-03)

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

SYSTEM DESCRIPTION: CFMVRMXATLDUALI25011KV__ SERIAL NO._©| -3

JOB NI

MBER: $200903327. DATE: _10-30-09

IL GENERAL,

‘THIS TEST PROCEDURE IS USED FOR MEDIUM VOLTAGE SYSTEMS WHICH UTILIZE

‘THE BENSHAW MX’ MICROPROCESSOR SYSTEM AS THE PRIMARY CONTROL. ALL

STEPS SHOULD BE FOLLOWED AS NOTED.

SEE THE SHOP RELEASE FOR ANY ADDITIONAL TESTING REQUIRED OR TEST

ADDENDUMS THAT MAY BE NEEDED FOR THE ORDER.

CAUTION

THERE ARE STEPS WITHIN THIS PROCEDURE WHICH REQUIRE TEST

MEASUREMENTS DURING THE TIME THAT MEDIUM VOLTAGE POTENTIAL IS ON

CONTROL POWER TRANSFORMERS IN THE SAME ENCLOSURE. THESE.

VOLTAGES ARE LOCATED AWAY FROM THE TEST MEASUREMENT SITES BUT

EXTREME CAUTION MUST BE USED WHEN MAKING THESE MEASUREMENTS.

MEDIUM VOLTAGE IS PRESENT IN THE ENCLOSUR!

ALL DATA SHOULD BE ENTERED IN THE SPACE PROVIDED AND THE TEST

PROCEDURE MUST ACCOMPANY THE JOB PACKET WHEN TESTING IS COMPLETED.

THE TEST PROCEDURE MUST BE STORED IN THE ENGINEERING JOB FILE ONCE IT IS

COMPLETED.

Page 1 of 35

REVO

TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

0 INITIAL RELEASE 09/013/06

Page 2 of 35,

REVO

TP-153

‘TP-153,

ENGINEERING DEPT.

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV_

MX* BASED SYSTEMS

Il. TEST EQUIPMENT:

THE FOLLOWING TEST EQUIPMENT WILL BE REQUIRED:

MULTIMETER (FLUKE 87 OR EQUIVALENT) 94850468

SCOPE METER (FLUKE 95 OR EQUIVALENT) 0000363

HI-POT TESTER (HIPOTRONICS HD -100 OR EQUIVALENT) P0409067

L-R-C METER 04080031

Il. TEST PROCEDURE

1. VISUAL INSPECTION:

CHECK THE FOLLOWING AGAINST THE JOB DRAWINGS FOR PROPER ASSEMBLY

TWETTAL Tian COMMENTS

NE ENCLOSURE LAYOUT

TE. ‘COMPONENT MOUNTING

NP, ‘CONTROL WIRING CONNECTIONS

BE POWER WIRING/BUS BAR TIGHTNESS

NP, ELECTRICAL CONNECTIONS

[ae ‘VERIFY ALL MECHANICAL CONNECTIONS,

NP VERIFY ELECTRICAL SPACING

MGW SSACING (FER CER C22. NO. 31, TABES a)

‘GEPOSTTS POLARITY Fo GROUND

THROUGH ATR ‘OVER SUFACE THROUGH ATR ‘OVER SUFACE

5.91 INCHES 7.87 INCHES 4.92 INCHES 5.71 INCHES

2,_SALES ORDER AND AS BUILT CHECK:

INITIAL,

TTEM

COMMENTS

Me

‘SALES ORDER MATCH

REVO

TP-153

Page 3 of 35

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX’ BASED SYSTEMS

3._SCR CHECK:

(Gxrrcan Trek RENTS 4

A CONTINGETY CHECK INGOT TO OOTROT

ACROSS EACH OF

NTR

TNUITY CHECK GATE TO

PAIRS

(EG. AB, CD, EF, ETC. AS REQUIRED

BY THE NUMBER OF SCR'S)

THEY SHOULD BE BETWEEN 10 TO 500.

4,_DVDT CHECK:

INITIAL

CoMRENTS

N/R MEASURE THE CAPACTTANCE

VALUE OF THE DVDT’S BY

CONNECTING A LRC METER

ACROSS EACH OF THE THE HEAT SINKS

JOB DRAWINGS FOR

\CK_PART NUMBER)

‘STACK B/N |___ CaBRCTANGE |

5-403005-01,-03, -04, 0.5uF = Se

7

3-403005-02 roa St

5. HI-POT TEST:

S SETUP

SLL

5.12

REVO

TP-1S3

TURN THE MAIN DISCONNECT SWITCH TO ON IF ONE IS PROVIDED

WITH SYSTEM. DISCONNECT THE PRIMARY FUSES TO THE VOLTAGE,

DIVIDER CARD & CPT (& PT'S IF PROVIDED) [USUALLY FUI6, 17, & 18).

CONNECT SHORTING JUMPER FROM LI TO L2 TO L3 TO TI TO T2 TO T3,

ON THE POWER POLES.

CONNECT THE HI-POT TESTER BETWEEN THE SHORTED POWER POLES

AND THE GROUND BUS BAR.

REMOVE ANY ADDITIONAL FUSES TO ISOLATE THE LOW VOLTAGE,

SECTION (SEE THE JOB DRAWINGS).

ENERGIZE BOTH INLINE AND BYPASS CONTACTORS (IF SUPPLIED) BY

APPLYING PROPER VOLTAGE TO THE COILS. USE AN EXTERNAL

VOLTAGE SOURCE FOR THIS STEP.

DISCONNECT ANY FILTER CAPACITORS, SURGE CAPACITORS, AND/OR

SURGE ARRESTERS FROM THE CIRCUIT, IF SUPPLIED.

Page 4 of 35

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

$.1.3 SET THE HI-POT TESTER TO DC OUTPUT AND FOLLOW THE SET-UP

PROCEDURE FROM THE HI-POT TESTER AS REQUIRED.

5.2. HEPOT

A) APPLY ISKVDC FOR I MINUTE AND RECORD THE LEAKAGE CURRENT.

INETIAL, TEEN. - COMMENTS i

We. TEAKAGE_CORRENT, BaADE

B) LEAVE THE VOLTAGE APPLIED FOR 10 MINUTES AND RECORD THE

LEAKAGE CURRENT. THE LEAKAGE CURRENT MUST DROP TO 50% OF

‘THE INITIAL LEAKAGE CURRENT TO PASS.

- TEN COMMENTS

we. TEAKAGE_CORRENT TRADE

C) RAISE VOLTAGE SLOWLY TO THE VALUE INDICATED BELOW FOR 1

MINUTE.

THE LEAKAGE CURRENT MUST BE LESS THAN Vi-por/ 250MOHM.

TRTTIAL | _S¥STEN HE-POT HALO GTOAL COMMENTS

VOLTAGE VOLTAGE z LEAKAGS

_ 10_KVAC 24.5 KVDC

i Tr RVAC 26.8 KVDC TORABE =

72.47 KvAC_ [30.0 KvDC

13.3 KVAC [31-7 ewoc

33.8 KVAC 33.0_KVDC =

Page 5 of 35,

REV.0

TP-1S3

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

6. PRINTED CIRCUIT CARD CHECK

VERIFY THAT ALL PC CARDS ARE THE PROPER VARIATION AS CALLED FOR ON

‘THE JOB DRAWINGS.

7. BIST (BUILT IN SELF TEST)

7.1 BIST - SETUP

APPLY 120VAC TO THE TEST PLUG FROM AN EXTERNAL SOURCE.

INSURE THAT THE DISCONNECT SWITCH OR CIRCUIT BREAKER, IF SUPPLIED,

IS CLOSED.

IF NO DISCONNECT OR CIRCUIT BREAKER IS SUPPLIED, JUMPER THE INPUT

TO THE STARTER WHERE THE DISCONNECT AUX CONTACT WOULD BE

WIRED (SEE JOB SCHEMATICS).

PLACE THE "TEST / RUN" SWITCH TO THE TEST POSITION.

7.2 CONTROL CARD CHECKS

CHECK THAT FOLLOWING LEDS ON THE CARDS ARE WORKING.

TRITTAL CARD. LED — FUNCTION

3 he TED I~ RED POWER

Wi LED 8 — GREEN CPU HEARTBEAT

[xe ‘ALPHA TED 1 ~ GREEN - HEARTBEAT

LED 3 ~ RED ~ POWER

We FIBER OPTIC TED 1 - RED - GATE POWER

‘TRANSMITTER LED 2 - GREEN GATE POWER OX STEADY ON

N/R ‘ADDITIONAL TED 1 — RED - GATE POWER ‘STEADY ON

optic LED 2 - GREEN GATE POWER OK STEADY ON

oprronaL) | TRANS: mm

7.3. TRANSFORMER CHECK

MEASURE THE GATE SUPPLY TRANSFORMER VOLTAGES

~ ACTURE.

[G2 PRIMARY VOLTAGE a5 720.3

108

Ta SECONDARY VOLTAGE 24 VACH]= av -

lot

ToR_PRIMARY VOLTAG! 120 VAG+7= 7A

(OPTIONAL) 108 :

T2A SECONDARY VOLTAGE 2a VACG]= wR

(OPTIONAL) 108

Page 6 of 35

REVO

TP-153

TP-153

ENGINEERING DEPT.

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

7.4 INITIAL TEST PARAMETER SETUP

SET THE SOFTWARE PARAMETERS AS FOLLOWS FOR THE INITIAL PORTION

OF THE TEST (NOTE - LEAVE THE PARAMETERS NOT LISTED AT THE

DEFAULT SETTINGS)

BARAT DISPLAY | DESCRIPTION | SETTING RANGE | UNITS | DEFAULT ) TEST

METER SETTING

QST 01 | WOTOR FEA | WOTGR FLA T-8a0o RAS To ‘SEE JOB

AMES Ducs

OST 04 | TOCRE SRC | LOCAL SOURCE | KEYPAD, TEENTNAD | SEE JOB

L “ TERMINAL, SERIAL NGS

[OST 05 | REMOTES GRC | HEVOTH SOURCE [XEYEAD, TERMINAL | SEE JOB

| TERMINAL, SERIAL pags

OST 06 | TNIT COR | ENFTEAE NOTOR | 50-600 ¥Fia piso 30

Lo CURRENT 1

OST 07 [WAX COR I WAIMUN MOTOR | 100 - 600 Fea | €00 700

SURRENT 1

(par oa | mane rive ean time a To — 300 1

[PEN OL | OVER CoN OvERCURRENT OFF, 50 - 800 30

WL ‘TRIP LEVEL

[BRT os | unox cox UNDERCURRENT | OFF, 5 — 160 30

WL TRIP LEVEL

BEN 10 | GvER WEF OVERVOLTAGH | OFF, 1 - 40 © RATED 30

LVL TRIP LEVEL yours

PEN I | UNDR VET UNDER VOLTAGE | OFF, i - 40 = RATED [OFF 30

LVL TRIP LEVEL voLTs

370 xx | DE x DIGITAL INPUT SEE JOB

(ox THRU | coNPrG 2x Dus)

08) CONFIGURATION

TOW CONFIG | RELAY = SES JOB

(10 tary | (Ri THRU CONFIGURATION bugs)

35) R6)

3/0 28 | KeD ST0F KEYPAD STOP | ENABLE, DISABLE ENABLED [SEE JOB

DISABLE Duce)

FON 03 RATIO Cr RATIO oF 288 SEE JOB

PRIMARY bwes)

RATED

AMPS. _

FON 05 [RATED VOLES | RATED RNS RMS Teo SET FOR

VOLTAGE vouTs STARTER

LINE

‘VOLTAGE

FON 23 | FE TIME ‘SET FOR

PRESENT

TIME

FON 2a | DATE DATE r ‘SET FOR

PRESENT

DATE.

NOTE: SEE JOB DRAWINGS FOR ADDITIONAL PARAMETER SETTINGS!

Page 7 of 35

REVO

‘TP-153

REV.

‘TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX* BASED SYSTEMS

7.3. BIST - DISCONNECT MONITOR

IN THE STARTER MENU "FUNCTION GROUP ~ MISCELLANEOUS COMMANDS”

SELECT STD BIST.

THE STARTER DISPLAY SHOULD SHOW THE FOLLOWING:

{BIST Mode

|_Open Disconnect _

PRESS THE "RUN" BUTTON ON THE KEYPAD (LOOK AT THE JOB DRAWINGS

FOR PERMISSIVES OR SWITCHES WHICH MUST BE MADE TO ENABLE THE

KEYPAD RUN).

NOTHING SHOULD HAPPEN.

OPEN THE DISCONNECT SWITCH, CIRCUIT BREAKER, OR REMOVE THE AUX

CONTACT JUMPER.

THE STARTER WILL LOG AN EVENT 193 “STANDARD BIST ENTERED” IN THE

EVENT RECORDER.

WHEN THE MX’ DETERMINES THAT THE DISCONNECT SWITCH IS OPEN, IT

WILL BE READY TO BEGIN THE SELF TEST SEQUENCE.

7.6 BIST - INLINE CONTACTOR

‘TO BEGIN THE BIST PROCESS, PRESS THE DISPLAY "RUN" BUTTON.

TO SKIP ANY PART OF THE BIST TEST, AND PROCEED TO THE NEXT SECTION

OF THE TEST, PRESS THE START BUTTON AGAIN. THE STARTER WILL BEGIN

THE BIST TEST BY CYCLING THE IN-LINE CONTACTOR ONCE AND ENSURE

THAT THE 120VAC FEEDBACK FROM THE IN-LINE AUX. CONTACT IS.

PRESENT.

IF THE IN-LINE FAILS TO OPERATE PROPERLY, THE STARTER WILL DISPLAY

AF49 — INLINE CONTACTOR FAULT AND LOG A CODE 49 IN THE FAULT AND

EVENT LOG.

DURING THE INLINE TEST, THE DISPLAY WILL SHOW

BIST Mode

Inline Closed

BIST Mode

|____ Inline Open

Page 8 of 35

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX’ BASED SYSTEMS

7.7 BIST - BYPASS CONTACTOR

THE STARTER WILL THEN TEST THE BYPASS CONTACTOR BY CYCLING IT

ONE TIME AND ENSURE THAT 120VAC FEEDBACK FROM THE AUX. CONTACT

IS PRESENT. IF THE BYPASS FAILS TO OPERATE PROPERLY, THE STARTER

WILL DISPLAY A F48 — BYPASS FAULT AND LOG A CODE 48 IN THE FAULT

AND EVENT LOG.

DURING THE BYPASS TEST, THE DISPLAY WILL SHOW THE FOLLOWING

BIST Mode

Bypass Closed

BIST Mode

Bypass Open

7.8 BIST-SCR GATING

THE STARTER WILL TEST THE SCR GATE CIRCUITRY BY “FIRING” THE SCR

GATES.

DURING THE FIRST PART OF THE GATING TEST, THE SCRS WILL BE GATED IN

THE ORDER G6 ~ G3 — G5 ~ G2 ~ G4 - G1, EACH SCR FOR 5 SECONDS. THIS

PATTERN IS REPEATED TWICE.

DURING THIS PART OF THE TEST, THE FOLLOWING IS DISPLAYED:

BIST Mode

GATE Gx ON

WHERE Gx IS THE GATE BEING “FIRED”.

‘THE DISPLAY THEN CHANGES TO

BIST Mode

ALL GATES ON |

‘THIS REMAINS ACTIVE FOR 60 SECONDS.

Page 9 of 35,

REV.0

TP-153

ENGINEERING DEPT.

TP-153

‘TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV_

MX* BASED SYSTEMS

DURING THE TIME THE SCRS ARE BEING GATED, THE FIRING CARDS.

SHOULD BE OBSERVED TO ENSURE THAT ALL OF THE GATE LED'S ARE ON

AND A SCOPE USED TO INSURE ALL OF THE SCR GATE SIGNALS ARE

CORRECT.

——

imgev

a

serens Fserins | rezses Urezns | 1750s

GATE SIGNAL CHECK:

TRETTAL,

TEN. - COMMENT

NTR

ALS BY USING THE SCOPE ACROSS THE

POINTS ON THE GATS DRIVER PC_CARD

REV.

TP-153

ONCE THE BIST TEST IS COMPLETE THE STARTER REGISTERS AN EVENT 195

~ BIST PASSED, IN THE EVENT RECORDER AND DISPLAYS THE FOLLOWING

MESSAGE.

BIST Mode

‘Test Complete

Page 10 0f 35,

MX° BASED SYSTEMS

8, 230VAC MOTOR TEST

81

8.2

83

84

85

8.6

CONNECT A 230V SOURCE 10 THE INPUT OF THE STARTER WITH 200:5 CTS IN

‘THE POWER LEADS.

CONNECT A 200HP, 460VAC MOTOR TO THE OUTPUT OF THE STARTER.

TEMPORARILY PLACE ~163KQ 1/4W RESISTORS ACROSS EACH PHASE OF THE,

DIVIDER CARD 10M RESISTORS (R1 AND R2, R4 AND RS, R8 AND R9) TO

SIMULATE A 13.8KV INPUT WHEN ONLY 230V IS APPLIED.

OWER UP THE STARTER.

CONFIRM THE STARTER DISPLAY READ 13.8KV FOR EACH PHASE, THE.

PHASE SEQUENCE IS ABC, AND THE FREQUENCY IS 60Hz.

START THE MOTOR

‘TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

ENGINEERING DEPT.

SET UP THE TEST TRANSFORMERS ACCORDING TO THE DIAGRAM IN

APPENDEX A.

THE TAPS ON Tl AND THE TAP SWITCH ON T2 SHOULD BE SET ACCORDING

TO THE CHART FOR THE SYSTEM VOLTAGE OF THE STARTER

CAUTION

THE FOLLOWING STEPS REQUIRE THAT TEST MEASUREMENTS BE MADE

WITH MEDIUM VOLTAGE POTENTIAL ON CONTROL POWER TRANSFORMERS

IN THE SAME ENCLOSURE. THESE VOLTAGES ARE LOCATED AWAY FROM

THE TEST MEASUREMENTS SITES, BUT EXTREME CAUTION MUST BE USED

WHEN MAKING THESE MEASUREMENTS.

10.1

MEDIUM VOLTAGE IS PRESENT IN THE ENCLOSURE!

10. VOLTAGE FEEDBACK CHEC

WITH VOLTAGE DIVIDER CARD (OR PT'S) STILL DISCONNECTED FROM THE

LINE, APPLY PROPER SYSTEM VOLTAGE (10KV, 1IKV, 12.47KV, 13.2KV, OR

13.8KV) TO DIVIDER CARD AT TBI, TB3, TB6 (OR PT PRIMARIES) AND TO THE

CPT. ALL MEASUREMENTS TO GROUND.

ENETIAD [WIRE [MEASURE [To000VAG[ TIO00VAG_[1247OVAC [ TSI00VAC | T3R0OVAC_]

WA acer TOVAC | 20VAC | OVC] 120VAC —] 120VAC

SECONDARY) -

WP TA (DIVIDER STREVAC | =ROIVAE | -BRVAC | =1040VAC | mIORTWAC

CARD TB2) =

WP 15(DIVI a DEVAS |= 10AOVAC | = 1087VAC

CARD TBA) _| _

iP TADIVIDER | ESV] “7B VAC DRVAC [=IOADVAC | =IOBTVAC

| CARD TB7) . a

OR —

Wa 14 @oFE SE9VAC|956VAC | T0RAVAC_[TIAaVAC | TIDGVAC

Page 11 0f35

REVO

7P-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

Toa rs T

NK 15 (Bg PT BEI VAC | OSBVAC | IORAVAC | TIRVAC | TIOGVAC

Wa 16(C PT BEI VAC | SBVAE | TOBAVAC | TISEVAC | T2OOVAE

SECONDARY) | — |

10.2. CONFIRM THE PHASE SEQUENCE AND FREQUENCY

TRETIAL- TEN T

ae CONFIRM THE PHASE SEQUENCE IS “ABC”

AND FREQUENCY IS 60Hz ON THE DISPLAY.

CONT

Page 12 of 35

REVO

TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

11. SYSTEM LOGIC CHECK:

INITIAL | ITEM _ _ COMMENTS

NP VERIFY THAT THE INTERLOCKS IDENTIFIED ON THE | 3KVA1T12T1

SYSTEM SCHEMATIC ARE ALL OPERATIONAL. XFMR

VERIFY THAT THE IN-LINE AND BYPASS VOLTAGES:

| CONTACTORS OPERATE PROPERLY PER THE 238V PRIMARY

SCHEMATIC. 120.5V

SECONDARY

12. POWER POLE CHECK:

INITIAL | ITEM - COMMENTS:

NIA POWER SYSTEM DOWN AND APPLY 240VAC OR

480VAC TO THE POWER POLES. CONNECT THE

MEDIUM VOLTAGE LOAD TO THE T-SIDE

CONNECTIONS OF THE STARTER.

RE-POWER THE SYSTEM AND VERIFY THAT SCR

LED'S ARE GLOWING DIMLY WHEN THE IN-LINE

CONTACTOR PULLS IN.

13. SCR CHECK: en a _

[INITIAL [ITEM COMMENTS

N/A POWER DOWN AND CONNECT THE DMM ACROSS A

POWER POLE L TOT.

MEASURE THE FINAL VOLTAGE ACROSS THE POWER

POLE WHEN THE SYSTEM IS UPTO SPEED AND THE

VOLTAGE ACROSS THE BYPASS CONTACTOR WHEN

IT PULLS IN.

POWER POLE VOLTAGE DROP | BYPASS CONTACTOR

VOLTAGE DROP

PHASE 1 |N/A _ Homv

PHASE 2 | N/A 10MV _

PHASE 3 | N/A. 9MV_

Page 13 of 35

REV.

TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX’ BASED SYSTEMS

14. MOTOR TEST:

DISCONNECT POWER.

CONFIGURE THE SYSTEM (MX° I/O PARAMETERS) TO HOW IT WILL BE SET UP IN

‘THE FIELD.

14.1 480 VAC TEST

SET UP THE TRANSFORMERS AS SHOWN IN ADDENDUM A.

- CONNECT THE 480 VAC TEST MOTOR LEADS TO THE 480 V SIDE OF

THE OUTPUT TRANSFORMER.

- CONNECT GND LEAD TO GND BUS AND LOOP MOTOR LEADS

THROUGH SYSTEM CT’S.

= CONNECT SECONDARY OF INPUT TRANSFORMER TO THE 'L! M.V.

LEADS,

- VERIFY PROPER SYSTEM VOLTAGE,

- APPLY POWER

= PROGRAM CPU AS FOLLOWS:

- FLA MULTIPLE OF WRAPS

- CT RATIO (SYSTEM CT’S)

- RAMP TO 15-18 SEC.

= INITIALITO 100% OR LESS

- MAXITO 300%

START SYSTEM AND ALLOW TO CYCLE 10 TIMES.

14.2 CURRENT CHECK:

WITH MOTOR RUNNING VERIFY THE CURRENT MEASUREMENT ACCURACY

Li CURRENT _ [12 CURRENT 13 CURRENT.

DISPLAY | CLAMP ON | DISPLAY | CLAMP ON | DISPLAY | CLAMP ON

TA [1A 1A 112A TOA 10.5A

14.3 POWER FACTOR:

WITH MOTOR UP TO SPEED

NP VERIFY POWER FACTOR IS .20+/-.04

Page 14 of 35,

REVO

TP-153

TP-153

ENGINEERING DEPT.

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX’ BASED SYSTEMS

IV. PREPARE FOR SHIPPING

%* SWITCH SETTINGS PER JOB DRAWINGS

= PROGRAM DEFAULT PARAMETERS PRIOR TO SHIPPING

Hidden Factory Parameters

Parameter Description ‘Setting Range Tai Default As] Verify ]

Built

FCTOO | Jump Cade 35 - T

FCTOI | Power Stack ‘Ot: OF Switch (normally closed) OF

Overtemperature Sensor | nte: Thermistors

L Type |

FCTO2 | Power Stack Relay Function | type Bypass Contactar yp

fan: Cooling Fan(s)

(Forming 0-150, % 100.

FCT 04 | V2-3 Sealin 50150 % 100)

FCT 0S _| V3-1 Sealin 30-150 % 100)

FCT 06 | 11 Sealing s0— 150. 3 iow.

FCTO? [Ti Sealing 50150, i 100)

ECT 08 |i Seal 50= 150, —% 100)

BCT 09 | PF Sealing 30-150) -_% 100,

FCT 10 | TruToreue Acceleration | 20-500 100)

Gain

FETT | TruTorque Decelertion | 20—500 109

Gain

Power Acceleration 3300 100)

10 1006 100,

— 10500 WFLA 175

‘Motor OL Powordown On, OFF On|

Retention |

FCT16 | DC Braking Configuration | Si: Standard Day 3a

Hv: Heavy Duty

FETT? | DC Brake Feedback iS: Curent Transfommers ow

HE: Hall Effect |

FCT IS | DC Brake Wall Eieet 10 999 “Aan 710 De

Scalin

FCTIO | Advanced Open SCR On

Detection ‘On: Enabled

FOTIO | Language Engh: English -

FCT 21 | Open/ Shorted SCR Trip | 0.1 -90.0 Seconds

FCTSS | No Current AtRun Level [Ta ELA iw

FCT23) No Current AtRun Trip [0.1 = 900 Sevonds 10

Time

FCT24 | Electomechanical Sater | 30350 "ILA s

“Transition Current Level

FCTI3_| Tach Control Gai 10300 100)

Page 15 of 35,

REV.

1P-153

ENGINEERING DEPT.

TP-153,

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX* BASED SYSTEMS

Enhanced LCD Paraneters

Group | Disvlay Destin Seting Range Taits —] Default] As] Verity

Bail

STO | Tomp Code [Tang ts pair Ts i

ST OI | MotorFLA | Motor FLA. 1606 WS Aas | 0a nF

[(gst02 | Motor SF Motor Service Factor, 1.00. =199 115

[[Q8T 03 | Running OL | Motor Overload Class Running | Of, 1 40 10. —

ST o0 | Lace Se | Local Sous Keypad Seral “emit

QST 05 | Remoie S| Remote Source Terminal Tera |

-QSr 06] int Curl | Initial Motor Cuma 0-00 sae [100

‘QST Or [ Max Cur || Maximum Moior Curent [100800 36rLA | 600

‘STO | Ranp Time] Ranip Tine | > 300 sens [8

L

‘GSTOS [US Tine | OS Tine Testion Time 900 Sexads_| 30

CENT] Tamp Cock [amp to pamelor 137 1

ENOL | Sten Mode | Star Move Volage TT Rap Carat

| Ramp Power Ramp

| curene Ramp

Ramp Tach Ramp

CENOD | Ramp Time | Ranp Tine T 7300 Semis | 5

1

CHNOS | alae] —[ Tata Mower Core ET

‘CN OS | Mx Maximum Mor Cures" [100800 %FLA | 600

‘CENOS | Rasp Tin] Ramp Time 2 0 300 Sesonds | 15

2

GENE [Tal Card | eal Mar Curent a0 aac | “100.

(CENO7 | Mix Gur —| Maximum Moor Cureat’3 [100800 FLA 600

CENO8 [Tait VP —[tntal Volage/TorquelPowst —[ 1-100 ve 35

CENOS | Max TP | Maximum Torque Power i095 % 105

CENTO | Accel Prof] Acceleration Ramp Profle] Lina’ —§-Cane a

I ‘Squared i

GENT | KEKE | Kick beet ‘100300 ‘tA | OF

[Cena [Kick Time T [Risk Time | a =109 Seconds [10

GENTS | Kick vi? —[ Kik Level 7 ‘On, 100800 seeta | OF |

GENIA | Rick Time | Rick Time 2 a1 100 Seconds | 1.0

CEN5 | Stop Mode | Siop Mode Coast TT Desst Const

Volt DCBrake

Decel

CENIG | Devel Besin_| Dezel Bega 190-1 % w

“GENT | Decel End | Decel End Level 1 % 20

‘CENTS | Dece! Time | Deel Time 1166 Szonde_[—1s

‘CENI9 | Devel Prof] Dece! Ramp Profle Ther] scone Tinear

Squared

GANG | Bake teal] DE Rake Tol 10100 % 3

CEN2I_| Brake Tine —[ DC brake Time — Seconds | 5

GEN 22 | Brake Delay_[ DC Brake Dela a3 Seconds | 02

GFN 23 | SSpd Speed | Siow Speed ORLA % oF

CEN 24 | SSps Cor_—| Siow Speed CureatLmel ——[ 10400 FLA [Too

(CEN 25-| SSp Tier Slaw Speed Timer ‘oT 900 Sends [10

[CEN 26 | Sspa Kick —| Slow Speed Kick Lave (OM 100-800 %ELA | OF

cu

(GEN2T [ Sspa Risk T | Slow Speed Kick Time t= Semae_[ 19

Page 16 of 35,

REVO

TP-153

ENGINEERING DEPT.

TP-153

‘TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

Group] Daly Desvition Setng Range Taine | Dalat | As] Very

Bull

BANOO [Jang Coie [Jang m paraneir — r

PENOI | Over Gur | Over Cure! Tip Lave ORS 300 HALA] OF

ia

PENGE | Over Cur] Over Cur Tip Daly Tims | OM OT 50D same)

Tim

BENOS Unde Car] Under Caret Trp Level] ORS —T00 SHA] OF

Lal

PENH | Unde Car | Under Curent Tip Delay Tine] OF, D150 Semnds | OT

Tim

PENS] Cr ni | Coren intaines Taplael | Of 3 a % =

FENOG ] Curinbl | Curent inbalance Tap Time [01-900 Seconds | 10.0

Tia

FINGT | Resid GF —| Raval Ground Paul Tap ORS 100 SHA] OF

i Leva,

FENG ] 25 GFInI | Zero Sequence Gromd Fait | OM TD=250 fags [OF

Tip Lovet

FEN | Gad Fi] Ground Fal Tip Time To-5a8 Seamts 30

Time

[PENIOC [Over Vico | Over Valine Tap Level ‘On _—a0 % oF

PENT | Unde Viebat | Under Volage Trip Lev FO 10 % om

PEN 2 | VieTrip i | Over Under Vollnge Trip Deby] 0.1” B00 Ssonds 0.1

Tame

FENTS | Fatow | Phase Low ip Tine a Seeals [OF

“Time

[PENTA [Over Rabo | Over egueny Tap Hoe Tz a

PENIS | Unde Fg Under Frequency Tap Baa Hi B

il

FENG | Fra Tip Ti | Fema Top Tine EM Sear

PENT | PE Lead Lot | PF Led Trp Level Off 080 gw OTT OF

ead

FANS | FF Lagat | FF Lag Tip Level Off O01 Tag O80 oF

lend

FNS [Fie | FFT Tine 711-900 Seconds] TO

Tine

PEND | Backspin | Backapn Ter OFT 180 Minas — OF

Tim

PEND | Time Biwi | Tine Betwasn Sas Of Minis | “OF

PEN 22 | Siarslour | Siar per Hour Om I-6 om

PENS | Ao Reset [Auto Fault Rese Tine Off. —-500 Sema or

PENH] Auto Ret] Ano PaltReset Count in’ ORT 10 OF

Lim

PENS | Car FEN | Controlled Faul Sop Of On On

PEN26 | Speed Sw | Speed Switch Tp Time Off 1-350 Sauk [OF

Ten

FENG | MPIC] Motor PICTip Time OnI-s Semis] OF

Tine

PENIS | Indep SR | Tndependeat Sang Raaing | OM Oa OF

OL Overton

FANGS Staring OL | Motor Oveond Cass Saring | Oa 0

PEN30_| Running OF | Motor Overload Class Running | Off 1 a io

FENST | OL We | Motor Overload HavCold Ratio [0-59 % %

Ratio

Page 17 0f 35

REVO

‘TP-153

TP-153

ENGINEERING DEPT.

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

Group | Display Daipion ‘Sering Rane Taine | Default [Av] Verity

uit

FENGE ] OL Coal | Meo Ove Cooling Tine | 10-505 Mines | 300

Tim

FENGS [OL Alama — | Motor O1 Alm Level 100 % %

Li

[BRNSE| OL Task Lat | Matar OL Lockout Lead = % is

PENS ] OL Cock] Motor OF Auto Lockout vel” OW, Auto OF

| cai

700 | jump Code —[ Tamp parameter Ta] T

WOO!) DI Conte] Di | Configuration Digial | OF] Local Re Sip

| tap) Sop | ot -

TOO DI Cenie [DIT Contigmaton (Digal | Feu | Heat Cn

Input #2)_ High Disable

TOUS] DIF Coat PDI3 Contguraion (Dieta | Faut | Heat ao

Input). Low | Enabie

TOO] Dia Contig PDI Configuration Digial— | Fut — | Rap

Input) Rest | Selec |

UOOS | DIS Config | Di 5 Configuration (Digital Disconn | Slow Spd

Input 5) eet Fad

TOO | BTSCoRIG | Dis Configmion Digial | Ile | Siow Spa oF

Input 86 Cofim | Rev

TO | DIF Coat] D7 Configwation Digial | Bypes | Brake OF

[" ake Cam | Diss

VO08 | DIS Config | DI 8 Configuration (Digital Bo pee OF

input st | Eble |

nt 8) ‘Speed Sw

NO |

Speed Sw

_ Ne

TOs | Din tip | Dig Fall lnpat Tap Tame | 01-900 Saane[ 7

Time

Page 18 of 35

REVO

‘TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

‘Growp | Davia Dacripion Sang Range] Waits] Deiat very

7010 Ri Cont —_| Ri Contmmion Rema) OF | SaaS FES a

TOIT RECoaie | REContqion (Relay) Fou FS | Shane NES OT SF

Fat | Grou

TOTE | RE Cong | RS Contgaion Relay) | NES | Fault oF WF

ee eo [Bo se) | Remon | Booey i

VO13 [RA Config | R4 Configuration (Relay #4) | UTS Saver’ Off ‘NP.

[014 R3 Config | RS Configuration (Relay #5) Alarm | Heating Or

WO1S | R6Config | R6 Configuration (Relay #6) Ready | Slow Spd oF

eka | Siow Spt

Ont | Fo

Overur | Stow Spd

or | Re

Todeou | Bing

| ment | Cool Fan

| OL cl

| ‘lam

[VOTe | Rint | Anan Tae Ty Tae of OF

| oe Law Level

I | High Level

[OTT tao Ag pa Tp Lae 0 wa

VOI [Ain Tp Tin Analog Input Tip Dey Tine — [07 Seconis | “01

VOIS[ Ain Spun | Aslog Input Span 1 % | 100

1020 Ain Oe | Atl apt Otte ov 1 a

TO21 | Aout Fen | Amiog Out Funaion OF oF

e

20%

oor

°

toons

our

e

130%

Vote

Q

130%

o

O10

bw

Toa neta | log Oo as a

1023--| Aout Ofset_ Anslog Oust Ofse T———5 %. v

Woa¢[nlne Cong [Ta Lins Conigualion oR TE =I Sooke [30

1025] Bypas Fok | Bypass /2M Coat ui sa Seconds 20

ta

TOHG | Kod op | Kapa Sep Deabis Ee DEEL Eatiad

O37” Auto Sst] Power Gn Sha Sesion | Dialed, Power, Fal Disbled

Power and Fat

REVO

TP153

Page 19 of 35,

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

[Group | Display Description Setting Range Tas as] Verily

| Built

RTD .00 | Jump Code | Jump to parameter T 5 T i

RIDOL | RTDModl —) RTD Module #1 Address Of 16-33 OF

Adde

RID | RIDMow | RID Module w2 Address oF

Adde

ETDS | RTDI Group | RTD! Group [Or | Bewine om

RTD 04 | RTD? Group | RTD? Group ] Stator | Other Of

RTD 0S | RTDS Group | RTD Group On

RTD 06 | RTD4 Group | RTDS Group OF

RTDO7 | RTDS Group | RTDS Group. wa

‘RID 08 | RTD6 Group | RID6 Group. ‘of

RTD 09 | RTD? Group | RTDT Group ‘of

‘RID 10 [RDS Group | RTDS Group Of

RTD | RTD9 Group | RTD Group om

RIDIZ]RIDIO | RIDIO Group Om

Group

RIS | RDI RTDIT Group OF

Group

RIDI |RIDID_—] RIDID Group of

Group

RIDIS | RIDIS RIDIS Group oF

Group

RIDIS | RIDIG | RIDI4 Group of

Group

RIDIT | RIDIS | RIDIS Grow OF

Group

RIDIS | RIDIS | RIDIE Group Of

Group

RDI | Stator Ale _| Stator Alarm Level 200 © 260

RTD 20 | Bearing | Bearing Alarm Level 200

Alm

RDI | Ouier Aim | Other Alas Level ~

RD 22 | Stator Trip | Stator Trp Level

RTD 23 | Bearing Trip | Bearing Trip Level

RID 24 | Other Trip _| Other Trip Level —

RID 25 | RTD Voting | RTD Voting

RID26 | RTD Biasing | RTD Motor OL Biasing On

RID27| RTD Bias | RTD Bias Minimum Level 0-198 c 40

Min

RID | RTD Biss | RTD Bias Mid Point Level 19 © 130

Mid

RID Bias | RTD Biss Maximum Level Tos 300 © 1s

| Max

Page 20 of 35,

REVO

‘TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

Grow Description Seng Range) Unf | Deft vert

FUN 00 | Jump Code | Jump to parameter, 1 =24 I i

FUNOI | Metrrl | Meter ave MW hours | Ave

Conent Phase ment

FONG | Mews] Maerz Li Onder ave

Curent Line Freq volts

12 Analog

Current Input

Lo Analog Ox

Curent Run Days

Can Run Hours

Imbal Stans

Ground ‘TrTerque

Ful %

Ave Power%

Volts Pkaceel

U2 Gur

Vols Last Stan

1213 Stator

Vos Temp

13.1 Bearing

Vols Temp

Oveloa Other Temp

4 allTenp

Power

Factor

‘wats

vA

iW

ours

FONDS | CT Rais | CT Ratio 72, 96, 1, DBR, 6A, Te [50s | NF

2640, 3800, 5760,

000, 1400, 28800, |

50, 200,800, 2000,

5000

FUN | Phase OR | Tapa Phase Seasiviy insensid CBA ines

a ga

ABC Phase

FUNGS | Rated Vals] Rated RMS Volage 00, 10,130,200, RNS [480 1000V | NF

208, 220,230,240, | Volage

350,380, 40, 415,

240,260, 480,500,

525,575, 60,660,

650, 80,1000, 1140,

2200, 2300, 2400,

3300, 4160, 4600,

$800, 6000, 6600,

900, 10000, 1100,

11500, 12000, 12470,

13900, 13800

FONGG | MoiarPF | Motor Rated Paver Fesor O01 (Lag) 1.00 ow

(Unity)

Page 21 of 35,

REVO

‘TP-1S3

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX* BASED SYSTEMS

‘Group | Display Description | Setting Range Units | Default Verity

FONG? | Suter Type | Starter Type | Newall Phase Ci Normal | ATL [NP

| Inside Curr

Delia’ Follow

Wye ATL

Del

FONG [Hee Tod [Wesel On, 1a LA I

FUNO? | Eneray | Energy Saver Off On

Saver

PONTO] PORTH | PORT Fal Tine ORO 90D Sends | OF

Tim

FONTT | PORTEyp | PORT Hypa old Time | OR OI=SO Same | OF

Tim

FONT? | PORT] PORT. Recovey Method] Valige | Cars Ramp Fai

Recover Ramp | 2 Recover

| Fast" | Romp

Recover | Select

Carreot_| Tach Ramp

Ramp

FONTS | Tach FST | Tachometer Full Speed Vong [1.00 1000 Vas [500

FUN IA | Tach Los | Tachometer Loss Tine @1-900 Seconds] 15

Tim

FONTS | Tach Los | Techomaer Tos Action Fault | TaiTorgve Fail

Act Curent [kW

TUNIC | Com Drop | Communication Aare 1-247 i

FUN 17 | Com ‘Communication Baud Rate 1200] 4800 | 1920 | bps 1200

Baudree 2400 _| 9e00_| 0

FONTS] Com Comamaniation Tinat ‘On 120 Seon | OF |

‘Timeout

FUNTD | Com Pargy | Communicators Bye Faring | Even, 1 None, T Tren,

SonBit Stop it 1St0p

as. None?

Stop Bit _ Stop bit

FOND | Sofie FN | Software Pat Number Display Onl

FUN2I | Mise Misellnsous Commands | None LoadParam None

| Commo Rest cers

RT Factores,

Rest at

mn Sapist

Reflsh Powered

Mode BIST (LV

Store Only)

Paramete

FONG | TD Format” Time and Das Format amid Tah mas

oid 23h 12h

Soma 12h

_ mad 24h

[FONE [ime Tine Prseat

Time _|

FONE [ae Dae Present

Da

FONDS | Passode —[Pasole or

Page 22 of 35

REVO

TP-153

ENGINEERING DEPT

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

INITIAL [ITEM COMMENTS

NP REMOVE ALL POWER CONNECTIONS AND SERIALIZE |

ALL PC CARDS AND RECORD STACK SERIAL | |

NUMBERS.

__NATHAN PEEKS 10-30-09

TECHNICIANS SIGNATURE AND DATE.

Page 23 of 35

REV.

TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

16. PRINTED CIRCUIT BOARD SERIAL NUMBERS: 2s

f [SERIAL NUMBER SERIAL WBA

STEAD 7 DISPLAY | Crasoaes2223/c12

| Soseszaaz

1 33059060023/0509

3060005 ee

[NX" “SOFTWARE NUMBER '810031-01-04

170

1/0 JARE NUMBER, -

FIBER OPTIC] SERIAL NOMBER FIBER OPTIC | SERIAL NUMBER

‘TRANSMIS TRANSMITTER

#3

SERIAL WAGER

RESISTOR DIVIDER | A0eSO 006

caRD n0830_002

[GATE POWER DISTRIBUTOR CARDS

I SERIAL NOMBER SERIAL WOMEER

[pst a aR

DIST 3A

DIST_¢ cH

DIET D Ba

DIST E _ EA

DIST a

Page 24 of 35

REVO

TP-153

ENGINEERING DEPT.

‘TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

GAT:

VER CARDS

PEASE i

SERIAL @

Cane,

ALB

c/o

E/E

G/H,

T/a,

K/L.

CaLE

Ase

C/o

=/e

Gf

Ifa.

K/L

FEASE ZA

‘SERIAL

——FERSE TR,

SERIAL #

PHASES

SERIAL #

Page 25 of 35,

REVO

TP-1S3

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

17. FINAL CHECK LIST

NP SWITCH SETTINGS TO AS BUILT POSITIONS.

NP PROGRAM DEFAULT PARAMETERS PRIOR TO SHIPPING.

NP TESTED STICKER APPLIED TO STARTER

NP PC BOARD BOOK FILLED OUT

STARTER PASSED © FAILED/REPAIRED

BY:

COMMENTS,

TESTED BY:_ NATHAN PEEKS DATE:_10-30-09

Page 26 of 35

REV.0

TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

Page 27 of 35,

REVO

TP-1S3

REVO

TP-153

ENGINEERING DEPT.

‘TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX’ BASED SYSTEMS

APPENDIX A

RATED VOLTAGE TEST CONFIGIURATION

Page 28 of 35

ENGINEERING DEPT.

‘TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

Page 29 of 35

REVO

TP-1S3

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

Page 30 of 35

REVO

‘TP-153,

ENGINEERING DEPT.

TP-153,

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX’ BASED SYSTEMS

Page 31 of 35,

REVO

TP-1S3

REV.

TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

APPENDIX B

FAULT AND ALARM CODES

Page 1 of 35,

estab,

Age

SE 40 | oBeg

yop vedo f paazous | ova | za

anes punoxo ecw armea punoxo aca ats

soustequr warm | icy souspeqr azn | cea | aa

| Sux66e7 a0r0e4 sonca | sew | | Suy6Ger zorves zenos | oea ore

aaead vanes sara wera

Saypeat zor903 son0a|_sev_| | 6uypeor zo20e4 zonor | sea gousonod andur | sw jon sonod andar | gta

Saad BTbaTe oauud oreaTe

jwazmozepun ve aesamozapen ves ao sono® ander | oi sou tonod andar | ta

cea fouenbozs surt usin | ew | | souonbora ours abn | ere

eca Fovenbosa sust not_|_erv aus

x

auermoreng |e ‘quassnor949 ua aou woysesox sera | tiv uoravaoy oswug | ata

| Teor ues) Dev Day ou 73030

sono swooueyuesser | of8 gou vorsesoy aewys | ory aoyaesey oseys | ots

snoouss wavora | ew snomms vwrora_| eza_| soa

7 aangaredaaaaond

senoa ousa on | _ sew zoos out on | ota rey ace 2000 | aov i soa

sect eseua | usw 2001 oeua ues sre azz Setse0a_| wv 403

j

wer ouyr usm | sev veer sup yoya_| ota rmry aim zoreas | 90v soa

exer eur yom | sev ereen eur bra | set vwrerv os zo10% | ov soa

env ouya ub | sev rev curt ub | ves | v0

reer ouyt mor | eee viet ouyr not_| cea soa

| exe oust aor | caw exer curt nor | tee luxery peotzeA0 z020H | _zov zoa

27-19 euET AT rev gira sun mor | tea suze tue / sin_| toa

355 4 a5 [spe

voradrzomea | arere woradyzose0 | 3 soracrsonsa | arerv uovadrzomeq | ste

“a1 ONIAAINIONA

SWALSAS GaSV4 .XW

AMS'ET QUALL AMOT

TOVITOA WAIGAW YOd RANGIIONd LSAL

std

esta

OATY

se30 a8

sea esa

exe asa

wa L usa

sua porsoys 20 odo au | oss

sua aimed 29 isi ssa

bus _| aise asta sa

ea yeubys zeveuowoes | es qesbrg “sovewoyses | esa

|

| za esa

wary dar Fan ares Saray TaeTTo

reser andur Borew | wv senor naar Boreey | ur | gosuss suet | tse

ous or sonog yoxaug | 05a

ares

98 sorsestoy water | ae

aiiwa zovoea0oD

o98 - we / eevdia ova

aaer @ Tare SEATED 7 sraqereduss79n0

| 1a wo srery qeurones | cov | | ra vo atnes qeuzoves | 19 we835 ae veess | ues

eda & seer

ra wo wrery teuzores | soy | | 10 uo atmeg teuzonny | 992 _ atnea seusoere | oa

ander 9 andar 5

yo wo wsety feuxorxs | soy | | 2¢ vo atneg teuxon | so sea

‘aedur andar §

ro wo wzery teuzorxa | sav | | 10 vo agneg reusoams | vou | sve

“sean andur ©

1g vo wsery teusoaes | esy | | x0 vo ayneg qeurone | cow Loe

“andur e

ta wo wzory teasers | poy 94 eva

ROUT z

re wo wrery reurone | tov 13a goas av wos | os

Sader 1

| ro vo uzety reuroamn | opv_| | 1a uo stnes teuzorxs | ose

pn Spo pes 355

woradyao8sa erty orsdrs0800 ares voradesoeec mere wosndrs00ed steed

SINALSAS (ASV XW

AMS] QUAL AMOT

ADVLTIOA WIGAN Od TANGIDIONd LSAL

eS

“Lda DNIUTANIDNG

esta,

Ont

St Jo ¢ o8eq

eae | ae

oat

eee | se

eae

Sanam | cs

[I sas

| sea

soem wou oft | aes

sss px oft | a

oT sousn ue oft |

suriro seo oft _| 90a

: Sac gaara” | sas

cress wwe pon | es

corer omen |e

= renee

‘rod | owe ‘urea ae | axe

seneyome —_[erree| [__wwrazoews | Ste

SIWALSAS GaSVa XIN

ANSEL UHL AMOT

AOVLIOA WAIGAW YOd TANGIDONd LSAL

€SI-d.

Ad DNIVAINIONA.

THE WAVE, MUSCAT

TP21 — CENTRAL COOLING PLANT

TEST PROCEDURE FOR 11KV

CHILLER STARTER PANEL

(SERIAL NO: 01-02)

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

SYSTEM DESCRIPTION: WRMXATLDUAL125011 KVL SERIAL

NO.__01-2

JOB NUMBER:S200903327, DATE: 11-2-09

I. GENERAL

THIS TEST PROCEDURE IS USED FOR MEDIUM VOLTAGE SYSTEMS WHICH UTILIZE

THE BENSHAW MX° MICROPROCESSOR SYSTEM AS THE PRIMARY CONTROL. ALL

STEPS SHOULD BE FOLLOWED AS NOTED.

SEE THE SHOP RELEASE FOR ANY ADDITIONAL TESTING REQUIRED OR TEST

ADDENDUMS THAT MAY BE NEEDED FOR THE ORDER.

CAUTION

THERE ARE STEPS WITHIN THIS PROCEDURE WHICH REQUIRE TEST

MEASUREMENTS DURING THE TIME THAT MEDIUM VOLTAGE POTENTIAL IS ON

CONTROL POWER TRANSFORMERS IN THE SAME ENCLOSURE. THESE

VOLTAGES ARE LOCATED AWAY FROM THE TEST MEASUREMENT SITES BUT

EXTREME CAUTION MUST BE USED WHEN MAKING THESE MEASUREMENTS.

MEDIUM VOLTA‘

ALL DATA SHOULD BE ENTERED IN THE SPACE PROVIDED AND THE TEST

PROCEDURE MUST ACCOMPANY THE JOB PACKET WHEN TESTING IS COMPLETED.

THE TEST PROCEDURE MUST BE STORED IN THE ENGINEERING JOB FILE ONCE IT IS

COMPLETED.

Page 1 of 35

REVO

1-133

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX’ BASED SYSTEMS

INITIAL RELEASE (09/013/06

Page 2 of 35

REVO

1P-153

ENGINEERING DEPT.

‘TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX’ BASED SYSTEMS

Ul. TEST EQUIPMENT:

‘THE FOLLOWING TEST EQUIPMENT WILL BE REQUIRED:

MULTIMETER (FLUKE 87 OR EQUIVALENT)86700859

SCOPE METER (FLUKE 95 OR EQUIVALENT)0000363

HLPOT TESTER (HIPOTRONICS HD -100 OR EQUIVALENT)P0409067

L-R-C METER

UL TEST PROCEDURE

1. VISUAL INSPECTION:

CHECK THE FOLLOWING AGAINST THE JOB DRAWINGS FOR PROPER ASSEMBLY

Tat COMMENTS

BNCLOSURE LAYOUT

‘COMPONENT MOUNTING.

CONTROL WIRING CONNECTIONS

ELECTRICAL CONNECTIONS

‘Als MECHANTCAL CONNECTTORS

VERIFY ELECTRICAL SPACING

c MININON SPACING (PER CSA C25-3 NO. 31, TABIE 4) ]

c ‘GEROSTTE POLARITY "FO_GROOND,

THROUGH_ATE ‘VaR SUFACE_ aoa aE ‘OVER _SUFACE

5.91 INCHES 7.87 INCHES 592 INCHES 5.71 INCHES

2,_SALES ORDER AND AS BUILT CHECK:

INETEAL | TTeM commen

a SALES ORDER WATCH

Page 3 of 35

REVO

TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX? BASED SYSTEMS

SCR CHECK:

SRESIAL =a T CORMENTE

N/a | CONPINOTTY CHECK INFUT TO OUTPUT

REROSS EACH OF

THE HEAT SINK ASSEMBLIES.

THEY SHOULD BE 50M) OR GREATER

NTR CONTINUITY CHECK GATE CATHODE 1

PAIRS

(EG. AB, CD, BP, BTC. AS REQUIRED

BY THE NUMBER OF SCR’S)

THEY SHOULD BE BETWEEN 10 70 500.

4, DVDT CHECK:

INTETAD TiN OVRERTE 1

NTR | WEREGHE THE CREACTTANCE

VALUE OF THE DVDT’S BY

CONNECTING A LRC METER

ACKOSS EACH OF THE THE HEAT SINKS

ASSEMBLE

(CHECK THE JOB DRAINGS OR

| PROPER STACK PART NUMBER)

~ STACK P/N ‘CAPACITANCE:

SHAGIOOS-01,-03, 08, onus SY

=35

‘S-403005-02 1.0ur + 5%

5. HLPOT TEST:

5.1 SETUP

5.1.1 TURN THE MAIN DISCONNECT SWITCH TO ON IF ONE IS PROVIDED

WITH SYSTEM. DISCONNECT THE PRIMARY FUSES TO THE VOLTAGE

DIVIDER CARD & CPT (& PT'S IF PROVIDED) [USUALLY FUI6, 17, & 18]

§.1.2 CONNECT SHORTING JUMPER FROM LI TO L2 TOL3 TO TI TO 12 T0 73,

ON THE POWER POLE!

CONNECT THE HI-POT TESTER BETWEEN THE SHORTED POWER POLES

AND THE GROUND BUS BAR.

REMOVE ANY ADDITIONAL FUSES TO ISOLATE THE LOW VOLTAGE

SECTION (SEE THE JOB DRAWINGS).

ENERGIZE BOTH INLINE AND BYPASS CONTACTORS (IF SUPPLIED) BY

APPLYING PROPER VOLTAGE 10 THE COILS. USE AN EXTERNAL

VOLTAGE SOURCE FOR THIS STEP.

DISCONNECT ANY FILTER CAPACITORS, SURGE CAPACITORS, AND/OR,

SURGE ARRESTERS FROM THE CIRCUIT, IF SUPPLIED.

Page 4 of 35

REV.0

TP-153

ENGINEERING DEPT.

TP-153

TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX’ BASED SYSTEMS

§.1.3 SET THE HI-POT TESTER TO DC OUTPUT AND FOLLOW THE SET-UP

PROCEDURE FROM THE HI-POT TESTER AS REQUIRED.

5.2 HLPOT

A) APPLY ISKVDC FOR 1 MINUTE AND RECORD THE LEAKAGE CURRENT.

TREY. — COMMENTS.

EAGE_CORRENT FEARS,

a

B) LEAVE THE VOLTAGE APPLIED FOR 10 MINUTES AND RECORD THE

LEAKAGE CURRENT. THE LEAKAGE CURRENT MUST DROP TO 50% OF

‘THE INITIAL LEAKAGE CURRENT TO PASS.

THEM COMMENTS

LEAKAGE CURRENT SUaNES

C) RAISE VOLTAGE SLOWLY TO THE VALUE INDICATED BELOW FOR 1

MINUTE.

‘THE LEAKAGE CURRENT MUST BE LESS THAN Viitror / 250MOHM.

INETIAE BT-POT RTO ACTUAL | ——ConnENTS

VOLTAGE LEAKAGE LEAKAGE

24.5 KVDC 30.2 uk

26.8 KVDC 38-0-un.

He 30.0 KvDe 105, Sua SEAMS

33.3 KVAC 31.7 KDC a5 3ua

13-8 KVAC 35.0 -KvDC 120 uA = 7:

Page 5 0f 35

REV.O

TP-153

ENGIN

EERING DEPT.

‘TP-153,

‘TEST PROCEDURE FOR MEDIUM VOLTAGE

10KV THRU 13.8KV

MX° BASED SYSTEMS

PRINTED CIRCUIT CARD CHECK

VERIFY THAT ALL PC CARDS ARE THE PROPER VARIATION AS CALLED FOR ON

THE JOB DRAWINGS.

7. BIST (BUILT IN SELF TEST)

7.1 BIST -SET UP

APPLY 120VAC TO THE TEST PLUG FROM AN EXTERNAL SOURCE.

INSURE THAT THE DISCONNECT SWITCH OR CIRCUIT BREAKER, IF SUPPLIED,

1S CLOSED.