Escolar Documentos

Profissional Documentos

Cultura Documentos

(Corrosion Reviews) Sulfidic Corrosion in Refineries - A Review

Enviado por

mario_gTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

(Corrosion Reviews) Sulfidic Corrosion in Refineries - A Review

Enviado por

mario_gDireitos autorais:

Formatos disponíveis

Corros Rev 29 (2011): 123133 2011 by Walter de Gruyter Berlin Boston. DOI 10.1515/CORRREV.2011.

021

Sulfidic corrosion in refineries a review

Raul B. Rebak

GE Global Research, Schenectady, NY, USA,

e-mail: rebak@ge.com

Abstract

Sulfidic corrosion of steels in refineries is a prevalent

phenomenon that occurs in oil containing sulfur species

between 230C and 425C. There are several internal and

external variables controlling the occurrence of sulfidic corrosion. The most important external factors are temperature,

concentration and type of sulfur species, and presence of

naphthenic acid. The most important internal or metallurgical

factor to control sulfidic corrosion is the amount of chromium

in the steel. The refinery industry relies today in a vast industrial experience on the variables affecting sulfidic corrosion

but very little is known on the basic mechanism of attack.

There is ample room for research and the basic understanding

of this phenomenon.

Keywords: corrosion; refinery; sulfidic; temperature.

1. Introduction

Iron (Fe) or steel reacts readily with hydrogen sulfide (H2S)

to form iron sulfide (FeS or FexSy). Since H2S is a ubiquitous compound in the oil and gas industry, sulfidation of steel

occurs under upstream (exploration and production) and

downstream (refinery) conditions. Reaction of Fe with sulfur (S) also occurs in power generation during the burning of

fossil fuels. Table 1 shows three areas of sulfidation corrosion

of steels.

In the temperature range from ambient to approximately

200C, the sulfidation of carbon steel is a common occurrence

under upstream aqueous conditions (Kane, 2006). Several

types of FeS were identified; including amorphous, pyrrhotite, mackinawite, troilite, cubic, greigite, marcasite and

pyrite (Vedage, Ramanarayanan, Mumford, & Smith, 1993;

Harmandas & Koutsoukos, 1996; Sun & Nesic, 2007; Smith,

Brown, & Sun, 2011). The establishment of the various stoichiometric and non-stoichiometric forms of FexSy may be

influenced by factors such as the partial pressure of H2S, the

pH, and the temperature (Smith et al., 2011). For example, at

ambient temperature and at pH 4 mostly mackinawite forms

at all concentrations of H2S; however when the pH is 7, the

formation of pyrrhotite is favored for the higher concentrations of H2S (Smith et al., 2011).

At temperatures higher than 538C the sulfidation mode of

attack of steel by sulfur compounds may change from mostly

an external uniform corrosion reaction of a component to an

internal localized attack, when sulfur diffuses inside the bulk

metal (Table 1). The higher temperature sulfidation attack

generally occurs in gases, for example, in the gasification

of coal, in the refining industry and in gases that result from

burning fossil fuels (gas, liquid and coal) (Lai, 2007). In other

cases steel could be attacked by the combined presence of S

and O2, such as in the phenomenon known as hot corrosion

(Type I and Type II) (Rapp, 2002). The presence of molten

alkali metal sulfate, sulfur trioxide as well as vanadium pentoxide may destroy a protective oxide film on the metal surface accelerating corrosion locally. The hot corrosion process

may also happen in refineries in the fire side of heater tubes

(Wen & Mucek, 2011).

The higher (above 500C gaseous) and lower (upstream

wet) temperature sulfidation issues are not part of this review.

Only the sulfidation corrosion in refineries, often called sulfidic corrosion, is reviewed here. Sulfidic corrosion is the

corrosion process of engineering alloys (mainly steels) in

presence of hydrocarbons containing sulfur species, mainly

H2S. The temperature range in which the phenomenon of

sulfidic corrosion occurs is 232427C (Table 1). Several

subgroups of sulfidic corrosion in refineries may be listed,

including presence of H2S, presence of H2S plus S and/

or S-containing compounds (mercaptans), presence of H2S

plus H2, and presence of H2S plus naphthenic acids, and the

combination of all of above.

Typical sulfidic corrosion in refineries can occur in a large

number of components such as fittings and pressure vessels but it seems more prominent in piping. Sulfidic corrosion manifests itself as more or less uniform thinning of the

wall of the component, but in horizontal pipes the 12 oclock

position may be preferentially attacked (Niccolls, Gallon, &

Yamamoto, 2008). The mechanism of sulfidic attack is by

direct reaction of the sulfur with the metal.

Several review documents on sulfidic corrosion have

been published (NACE, 2004; API, 2008) to capture the

current understanding and consensus on the sulfidic phenomenon in refineries. However, very little is found in the

literature regarding fundamental research of sulfidic corrosion including kinetics and thermodynamics (Farrell &

Roberts, 2010).

The main objective of the current review is to analyze the

most recent (newer than 2006) published data on sulfidic

corrosion and to highlight incomplete and contradictory data.

1.1. Crude oil in a refinery

A crude oil refinery contains more than a thousand components housing nearly a hundred internal environments

(Jenkins, 1998). In such a refinery crude oil or petroleum is

converted into end products such as gasoline, kerosene, diesel oil, etc. Crude oil is a complex mixture of several 100

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

124 R.B. Rebak: Sulfidic corrosion in refineries a review

Table 1

Sulfidation corrosion of steels.

Application

Temperature range

Corrosion characteristics

Upstream oil and gas exploration

and production, geothermal wells

Ambient to 230C

Uniform type of corrosion in presence of water. Different type of iron

sulfide scales may form depending on the environmental characteristics

including oxidizing vs. reducing environments, pH, bacterial activity, etc.

Downstream oil refineries

232 427C

Sulfidic corrosion could be in the presence of liquid or vapor phase oil

containing sulfur species. The attack is generally uniform.

Fossil fuel power production

538 1100C

Sulfidation attack could be localized. It is generally a gaseous phase

corrosion. There are several types of corrosion environments, including

gasifiers (syngas), oxidizing conditions (SO2), reducing conditions (H2S),

hot corrosion, coal ash corrosion, etc. (Lai, 2007)

hydrocarbons containing approximately 84% carbon, 14%

H and 13% S and <1% each of metals, salts and oxygen

(Ruschau & Al-Anezi, 2001; Guedes Soares, Garbatov,

Zayed, & Wang, 2008). There are more than 150 varieties of

crudes produced worldwide (Bacon & Tordo, 2005). Crude

oils may be classified in different ways, for example: (1) as

paraffinic, naphthenic or aromatic based on the predominant

type of hydrocarbon molecule (Ruschau & Al-Anezi, 2001;

Guedes Soares et al., 2008); (2) as sour or sweet depending on

the amount and type of reactive sulfur species, such as H2S.

Sour oils contain more H2S; (3) as light or heavy depending

on the API gravity number (oils with a high API number and

high proportion of H are considered light) and (4) as acidic or

not acidic depending of the total acid number (TAN). A TAN

value higher than 1 can be considered acidic (Bacon & Tordo,

2005). The acidity in the oil is given by the amount and type

of carboxylic organic acids. A crude with a TAN number

lower than 0.5 will be less corrosive to a refinery plant (Kane

& Cayard, 2002).

Refineries may use blends of different varieties of crude

and at the same time there is variation in the oil that is being

processed (distilled) in one refinery from point to point of

the flow. Similarly, the contaminants that the oil carries are

different from different blends that come into the refinery

and for a typical blend, the amount and type of species also

change from sector to sector in the refinery. During the refining process, other substances may be added to the oil, such

as hot water (hydro treating) or emulsifiers to remove salts

and metals (desalting). In other treatments, the oils may be

sweetened by neutralizing H2S using amines or other caustics

(Jayaraman & Saxena, 1995).

2. The sulfidation corrosion process

The actual sulfidic corrosion mechanism of steel is not known

(Niccolls, 2005). It is generally accepted that the corrosion

progresses in the steels via a film on the surface. This film is

formed by metal sulfides and it is pseudo-passive, i.e., it

is semi-protective and not tenacious (Jayaraman & Saxena,

1995).

The following steps could lead to the formation of an FeS

film

FeFe2++2e-

(1)

H2SHS-+H+

(2)

as iron oxidizes, the hydrogen cation gets reduced and then it

may get dissolved in the metal or it may evolve as molecular

hydrogen gas in the stream

H++e-Ho

(3)

o

Ho Hdiss

(4)

Ho+HoH2

(5)

If Equation 4 is dominant over Equation 5, the dissolved

hydrogen in the steel may cause hydrogen embrittlement,

especially in welds. FeS forms on the surface by the reactions

in Equations 6 and 7

HS-+Fe2+FeS+H+

(6)

or it may form non-stoichiometric sulfide products such as

yHS-+xFe2+FexSy+yH+

(7)

The stability of the film will depend among other variables on the presence of flow or turbulence. As turbulence

increases, the pseudo-passive film becomes minimal. The

transport of sulfur through the pseudo-passive metal sulfide

layer is confirmed by a parabolic decrease in the film thickness as a function of time suggesting a diffusion controlled

mechanism (Qu, Zheng, Jing, Yao, & Ke, 2006).

If the temperature is high enough (500C and higher) it

is possible that besides forming a metal sulfide scale on the

surface, sulfur may diffuse inside the metal (mainly though

grain boundaries) and react with the metal forming internal

sulfides. The presence of sulfur inside the metal may interfere

with the dissolved and carbide precipitated carbon. The metal

carbides disappear where the sulfides form and the liberated carbon diffuses deeper into the metal (Hucinska, 2006).

This process of carbide decomposition is accelerated if H2 is

present in the environment (Hucinska, 2006).

3. Previous reviews on sulfidic corrosion

Sulfidic corrosion has occurred since modern refineries were

in operation and it is still pervasive today. However, refineries are familiar with sulfidation and know how to control

it by alloy selection and corrosion and materials monitoring

and management. Niccolls et al. (2008) state that refining is a

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

R.B. Rebak: Sulfidic corrosion in refineries a review

mature industry and therefore almost all of the types of degradation modes are well known to seasoned materials engineers

and inspectors. Shut downs or failures due to sulfidic corrosion are currently rare. The previous knowledge on sulfidic

corrosion has been summarized in a series of comprehensive

reports that were prepared by the experts in the field. These

reports include the NACE 34103 Overview and the API

939-C Guidelines.

3.1. NACE 34103 overview of sulfidic corrosion

in petroleum refining

The NACE International Specific Technology Group (STG)

34 on Petroleum Refining and Gas Processing formed the task

group TG176 called Prediction Tools for Sulfidic Corrosion.

This task group issued a consensus document in February

2004. This document states that little fundamental research

has been published studying the mechanism, thermodynamics

and kinetics of sulfidic corrosion in the temperature range of

interest for the refining industry. Most of the current understanding on the corrosion behavior of materials is based on

plant experience.

Some basic facts from the NACE 34103 document:

1. Carbon steels form an iron deficient sulfide scale (Fe1-xS)

on the surface that, as it grows, slows down the corrosion

process as a function of time.

2. Steels that contain chromium form a two-layer scale the

inner layer is a sulfo-spinel (FeCr2S4) and the outer layer

is the Fe1-xS. It is generally accepted that the sulfo-spinel

layer is more protective than the Fe1-xS.

3. Several steps may be involved in the corrosion process in

presence of sulfur compounds chromium (Cr) may poison a critical decomposition step of the sulfur compounds

previous to the incorporation of sulfur to the scale and

H2 may promote the decomposition of these sulfur compounds (therefore H2 may counteract the beneficial effect

of Cr).

4. Carbon steels can be used until 260C. The corrosion

resistance of carbon steel is marginal at 316C.

5. Lower than 5% Cr steels are not currently used in refineries,

5Cr steels are used up to 343C and 9Cr steels are used up

to 400C. Austenitic type 18/8 stainless steels have excellent resistance to sulfidic corrosion even under long-term

use at high temperature like in furnace tubes and furnace

transfer lines. Sensitization of the stainless steel does not

decrease its resistance to sulfidic general corrosion. If H2

is present in the system the austenitic 18/8 stainless steels

may need to be used above 260C.

6. The mechanism of increased aggressiveness due to the

presence of H2 has not been established yet. Some postulated that H2 does not allow for beneficial formation of

coke, others argue that H2 promotes the decomposition of

other sulfur bearing compounds into H2S, thus increasing

the aggressiveness of the environment.

7. The FeS scale that forms on the surface generally contains

cracks, fissures and spalls that may provide avenues for

sulfur ingress and promote more corrosion. Some argue

125

that the presence of coke may seal these paths for sulfur

ingress. That is, when coking starts occurring, the corrosion attack by sulfidation generally decreases.

3.2. API RP 939-C guidelines for avoiding sulfidic

corrosion

In January 2008 the API Subcommittee on Corrosion and

Materials issued the Version 5.0 of the RP 939-C Guideline

for Avoiding Sulfidation Corrosion (API, 2008). RP stands

for recommended practice to provide a practical guidance to

corrosion engineers and other personnel, such as inspectors,

project and maintenance engineers on how to address sulfidic

corrosion. The Subcommittee on Corrosion and Materials is

part of the API Committee on Refinery Equipment (CRE).

The mission of the CRE is to promulgate safe and proven

engineering practices for the design, fabrication, installation,

inspection, and use of materials and equipment in refineries and

related processing facilities. The Subcommittee on Corrosion

& Materials deals with issues, such as: (1) Fabrication requirements; (2) Corrosion mechanisms; (3) Equipment reliability;

(4) Refractory systems; and (5) Reducing capital and maintenance costs. The RP 939-C document is applicable to hydrocarbon process streams containing sulfur compounds, with

and without the presence of H2, which operate at temperatures

above approximately 230C up to about 540C. A threshold

limit for sulfur content is not provided because within the past

decade significant corrosion has occurred in the reboiler/fractionator sections of some hydroprocessing units at sulfur or

H2S levels as low as 1 ppm.

The API RP 939-C document captures the state of the art

consensus in the industry of the state of knowledge dealing

with sulfidation corrosion. That is, any significant contributions on the understanding of variables that affect sulfidation

corrosion are captured in this document. The information in

RP 939-C has been mined from published technical papers,

information exchanges at the API and NACE levels and also

from refinery owners and operators. This does not mean that

some findings previous to 2008 that may also be relevant may

not be captured in this document since they may be proprietary or because consensus has not been reached in the matter.

The following basic findings can be summarized from the

API RP 939-C document:

1. The sulfidic corrosion rate increases with the temperature

from 230C until 425C and then it decreases as the temperature increases until 540C. The rate of increase in the

corrosion rate between 230C and 425C is faster as the

temperature is increased.

2. Chromium is a beneficial alloying element protecting

against sulfidation corrosion, i.e., the corrosion rate of steel

with 5% Cr is lower than the corrosion rate of carbon steel.

3. The corrosion rate increases with the amount of sulfur in

the stream. The influence of sulfur on the corrosion rate is

less important than the effect of the temperature.

4. The presence of H2 tends to accelerate the corrosion rate.

The beneficial effect of Cr in the steel may be less effective when H2 is present in the oil mixture.

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

126 R.B. Rebak: Sulfidic corrosion in refineries a review

5. Carbon steels containing <0.1% silicon (Si) have a faster

rate of sulfidic corrosion than carbon steels with higher

contents of Si.

6. Other variables that may affect the corrosion rate include

flow velocity, coking, and presence of steam (stripping).

3.3. McConomy and Couper-Gorman curves

McConomy and Couper-Gorman curves are prediction

tools based on survey data from refinery experience that

are used to estimate the corrosion rate of different steels

in crude oil as a function of the temperature (API, 2008).

The McConomy curves developed by API in 1963 are

used in the absence of dissolved hydrogen and the CouperGorman curves developed in 1971 are used when H2

and H2S are present (Qu et al., 2006; API, 2008; Farrell

& Roberts, 2010). Neither the McConomy nor the CouperGorman curves take into consideration the effect of flow

velocity. The McConomy curves were later modified in

1986 since the original ones were too conservative, i.e.,

the original curves predicted higher sulfidic corrosion rates

than the actually observed in refineries (API, 2008; Farrell

& Roberts, 2010). The modified McConomy curves were

developed from empirical data at a total sulfur concentration of 0.6 wt% in the crude oil. A correction factor may

be applied for higher sulfur levels (API, 2008; Farrell &

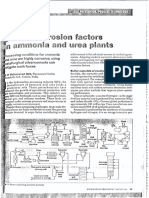

Roberts, 2010). The McConomy curves (Figure 1) show that

the corrosion rate of the different steels increases monotonically as the temperature increases. The highest corrosion

rates are for carbon steel and the lowest are for type 18/8

stainless steels. The curves do not cross each other in the

entire range of temperature reported from 260C to 400C.

The predictions from both types of curves (McConomy and

Couper-Gorman) are still conservative compared to industry experience (Riley, 2005). Materials behave differently

in H2S environment and in H2S+H2 environments, since the

beneficial effect of chromium for the H2S environment is

less effective in the H2S+H2 environment (Setterlund, 1991;

Niccolls, 2005).

4. Variables affecting sulfidic corrosion

As stated in the NACE 34103 document Overview of

Sulfidic Corrosion in Petroleum Refining very little basic

research has been dedicated to the understanding of the thermodynamics and kinetics of sulfidic corrosion. The little

interest in research may have resulted from the 40 years plant

experience that led to the preparation of guidelines to deal

with materials selection and plant performance in the field

(Chambers & Kane, 2008). Materials engineers may have felt

comfortable predicting the lifetime of several types of steels

according to the temperature and sulfur content of the process

and replacing the part at scheduled shut downs rather than

trying to fully understand the sulfidic corrosion mechanisms.

Table 2 shows a few of the internal and external variables that

influence sulfidic corrosion in refinery applications. Internal

variables pertain to the metallic component (pipe), such as

composition and phase distribution, heat treatment, etc.

External variables include temperature, type of crude, sulfur

content in the crude, flow velocity, etc.

4.1. Effect of the temperature

It is accepted that the most important variable affecting corrosion of a component in a refinery is the temperature. The

temperatures of interest for sulfidic corrosion are in the range

230425C. The temperature generally defines what material

is used in that application. For example, depending on the

particular application in the refinery and crude blend, carbon

steel may be used up to 260288C. Similarly, the upper limit

for the 5Cr steel could be 329343C and for temperatures

up to 400C 9Cr steel may be used. In general, for all materials, the corrosion rate increases as the temperature increases;

however, the relationship between corrosion rate and temperature may not be the same in the entire range of temperature.

As the temperature increases the activation energy value

seems to increase (API, 2008). For temperatures higher than

427C, sulfidic corrosion may actually decrease due to additional protection from coking (Gutzeit, 1986).

1.000

Carbon steel

0.100

1-3Cr

4-6Cr

7Cr

9Cr

0.010

Sultur content WT%

Corrosion rate (mm/year)

10.000

12Cr

18Cr/8

0.001

250

270

290

310

330

350

370

10

1

0.1

0.01

0.4

0.8

1.2

1.6

Corrosion rate multiplier

390

410

Temperature (C)

Figure 1

Modified McConomy curves to predict sulfidic corrosion.

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

R.B. Rebak: Sulfidic corrosion in refineries a review

Table 2 Variables influencing sulfidic corrosion.

Internal variables

External variables

Type of steel

Heat treatment amount and

distribution of pearlite colonies

Cr content

Si content

Mo content

Temperature

Type and concentration of

sulfur species in the oil stream

Naphthenic (carboxylic) acids

Fluid velocity

Hydrogen in oil stream

Steam

Amines and other chemicals

Activation energy values for sulfidic corrosion are

scarce. No data were found for pure sulfidic corrosion in

contact with crude oil in the temperature range 230425C.

The activation energy was measured for the sulfidation

of Fe exposed to 10 mm Hg sulfur vapor (gas phase) for

up to 10 h in the temperature range from 250C to 500C

(Foroulis, 1978). It was reported that the formation of the

sulfide scale on the Fe surface followed an Arrhenius relationship between the parabolic rate constant and the inverse

of the absolute temperature. However, two ranges were

found; the activation energy was 59 kJ/mol in the higher

temperature range from 370C to 500C and 113 kJ/mol in

the lower temperature range (250370C) (Foroulis, 1978).

For the lower temperature range the scale consisted in an

inner layer of pyrrhotite and a thin external layer of pyrite;

however, for the higher temperature range the scale was

only pyrrhotite (Foroulis, 1978). The activation energy values reported by Foroulis (1978) may not be fully relevant

to oil refineries since it was in presence of sulfur vapor and

for pure Fe instead of steel.

For naphthenic acid corrosion Gutzeit reported that for

both carbon steel and 410SS the Arrhenius activation energy

was approximately 69 kJ/mol at temperatures higher than

288C (Gutzeit, 1977). More recently, an Arrhenius relationship was also reported for the sulfidic corrosion rate of carbon

steel between 210C and 300C in oil containing two types

of naphthenic acid. Values of activation energy from 23.8 to

31.8 kJ/mol were reported (Slavcheva, Shone, & Turnbull,

1998).

Two steels (carbon steel and 5Cr0.5Mo) were tested for

their response to sulfidic corrosion in the temperature range

between 230C and 270C (Qu et al., 2006). The carbon steel

was mostly a ferrite phase and the 5Cr0.5Mo steel was mostly

a pearlite phase. The tests were performed in a static autoclave for up to 65 h of testing time. As expected, for both

steels, the corrosion rate increased linearly with the temperature; however, the corrosion rate was higher for the carbon

steel than for the 5Cr0.5Mo steel. For the carbon steel the

corrosion rate increased from approximately 0.4 mm/year

at 230C to approximately 2 mm/year at 270C (Qu et al.,

2006). However Qu et al. did not report the value of activation energy for these experiments (Qu et al., 2006).

It seems a little surprising that activation energy for the

pure or single sulfidic corrosion mechanism were not found

in the literature for carbon or alloy steels. A few activation

energy values are published for the combined mechanism of

127

sulfidic corrosion and naphthenic acid corrosion. In general

the activation energy values available for steels in presence

of sulfur species and naphthenic acid seem to suggest that the

activation energy above 300C could be approximately twofold higher than the activation energy below 300C.

4.2. Sulfur species

The second materials selection criteria are the presence in the

stream of H2S and other sulfur containing species. As the concentration of sulfur species increase the corrosion rate of refinery plants components increase. For example, it was reported

that the corrosion rate of carbon steel exposed to a 329C oil

stream in a hydro-processing distillation column increased

practically 10-fold from 5 mpy to 45 mpy when the H2S concentration increased approximately three-fold from 800 ppm

to 2500 ppm (Niccolls, 2005). Sulfur is present in crude oil as

H2S, as thiols, mercaptans, sulfides, benzothiophenes, polysulfides, or as elemental sulfur (de Jong et al., 2007; API, 2008;

Guedes Soares et al., 2008). Sulfur becomes aggressive to steel

if its proportion in the crude oil is 0.2% or higher (Ruschau &

Al-Anezi, 2001). At temperatures higher than 230C, Fe reacts

with S to form FeS. In general, in the refineries crudes are classified as sweet (<1% S) and as sour (more than 0.5% S) (Bota,

Qu, Nesic, & Wolf, 2010). Sour crudes are blamed for sulfidic

corrosion in refineries. During refining some crude oils may

be treated with a caustic wash to remove sulfur in a so-called

sweetening process. Since the reactivity or corrosivity of these

different forms of sulfur varies from molecule to molecule, the

corrosion rate of steel generally is not proportional to the total

sulfur content in the oil stream (Bota et al., 2010). Smaller

molecules of sulfur compounds tend to be more corrosive than

the large ones (Setterlund, 1991). It was also reported that

sulfur species that have the ability to decompose into H2S at

the exposure temperature would have an impact on the corrosion rate of the steel (Kane & Cayard, 2002). Sometimes it is

reported that mercaptans are even more aggressive than H2S in

affecting sulfidic corrosion (Niccolls, 2005).

A study was carried out to determine the corrosion behavior of 1018 carbon steel in presence of mercaptans in crude

oil in the liquid phase in the temperature range 200300C

(de Jong et al., 2007). Coupons of carbon steel were exposed

to crude containing four different mercaptans at different concentrations ranging from 100 ppm to 3000 ppm (de Jong et

al., 2007). It was reported that at 275C the corrosion rate of

steel increased significantly with the concentration of mercaptans up to 1000 ppm and more slowly for the higher mercaptan concentrations. The highest corrosion rate at 275C

corresponded to the higher molecular weight mercaptan but

an explanation was not given for this behavior (de Jong et

al., 2007). It was also reported that the corrosion rate did

not increase monotonically as the temperature increased but

peaked at approximately 280290C and then decreased for

the higher temperatures (de Jong et al., 2007).

In general the information in the published literature regarding the effect of sulfur species on sulfidic corrosion is highly

contradictory, some argue that thiols and mercaptans are more

corrosive than H2S and some argue just the opposite.

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

128 R.B. Rebak: Sulfidic corrosion in refineries a review

4.3. Effect of naphthenic acid

Fe+2RCOOHFe(RCOO)2+H2

(8)

Fe(RCOO)2+H2SFeS+2RCOOH

(9)

The corrosion of iron by naphthenic acid is given by Equation

8. Iron naphthenate is soluble in oil, but if enough sulfur is

present in the oil, it may react with iron naphthenate to reform

the FeS layer on the surface of the component (Equation 9).

However, this reaction regenerates naphthenic acid in the system. Therefore, it is claimed that crude with high naphthenic

acid and low sulfur may be more corrosive than crude with

a similar naphthenic acid content with a higher sulfur level

(Turnbull et al., 1998; Laredo et al., 2004).

Two type of steels (carbon steel and 5Cr0.5Mo) were

tested for 24 h in presence of two naphthenic acids at a concentration of 0.25 mol/L, and in presence of the same naphthenic acid plus 0.1% H2S (in argon) at 275C in two types

of oil (heavy vacuum gas oil and mineral oil) (Slavcheva et

al., 1998). Figure 2 shows that the presence of H2S reduced

the corrosion rate of the steels promoted by naphthenic acids.

The inhibitive effect also depended on the type of naphthenic

acid and the type of steel. Figure 2 also shows that in the

presence of the naphthenic acid mixture the corrosion rate of

10

8

Corrosion rate (mm/year)

The third important criteria for materials selection in refineries is the total acid number (TAN), which is an indication of

the relative amount of carboxylic acids or naphthenic acid in

the oil. Naphthenic acid corrosion (NAC) is most prevalent

in the temperature range 200400C and it seems to peak at

approximately 370C (Jayaraman & Saxena, 1995). The corrosion caused by naphthenic acid is more important for TAN

higher than 0.5 (Laredo, Lopez, Alvarez, & Cano, 2004).

There is also a complex relationship between sulfidic corrosion and naphthenic acid corrosion. For example, it has been

claimed that the naphthenic acid and sulfidic mechanisms

act synergistically, i.e., the presence of sulfur may accelerate naphthenic acid corrosion, but the opposite has also been

defended, i.e., that the presence of sulfur may inhibit naphthenic corrosion (Slavcheva et al., 1998; Tebbal, 1999; Kane

& Cayard, 2002; Kanukuntla, 2008; OKane, Rudd, Cooke,

Dean, & Powell, 2010). It is claimed sometimes that there is

a continuum between naphthenic acid corrosion and sulfidic

corrosion (Kane & Cayard, 2002). Other researchers state

that the relationship between the two modes of corrosion may

change depending on the levels of sulfur and naphthenic acid

in the system (Messer, Tarleton, Beaton, & Phillips, 2004;

Chambers & Kane, 2008). Since FeS is insoluble in oil, this

may protect the steel from attack by naphthenic acid (Piehl,

1988; Turnbull, Slavcheva, & Shone, 1998; Kanukuntla,

2008; Bota et al., 2010). However, since iron naphthenate is

soluble in oil, the presence of naphthenic acid may weaken

the protectiveness of FeS on the surface promoting scale debonding and favoring more corrosion. In a corroded refinery

component, the evidence of naphthenic acid corrosion may be

supported by the absence of a surface scale on the corroded

component (Gutzeit, 1977).

The following reactions have been proposed to explain the

interaction between naphthenic acid (RCOOH) and FexSy

Inhibitive effect of H2S on

naphthenic acid corrosion

mineral oil, 24 h, 275C

Cyclohexane carboxilic acid

Cyclohexane carboxilic acid+H2S

Naphthenic acid mixture

Naphthenic acid mixture+H2S

0

Carbon steel 1018

5Cr 0.5Mo steel

Figure 2 Inhibiting effect of hydrogen sulfide on the corrosion caused by naphthenic acid. Plot prepared from table 9 data in

Slavcheva et al. (1998).

the 5Cr0.5Mo steel was higher than the corrosion rate of the

carbon steel. The latter result is one of the surprising findings

in which a 5Cr steel is found more prone to corrosion than

plain carbon steel. The authors claim that the inhibitive effect

of sulfur also depended of the type of carrier oil (not shown in

Figure 2) (Slavcheva et al., 1998).

Two steels (5Cr and 9Cr) were tested for resistance to

impingement corrosion in Tufflo 1200 oil at 343C using

flow velocities of 1697 m/s. The tests were performed in

oil containing only naphthenic acid (up to TAN 3.5) and in

oil containing naphthenic acid plus two different levels of

H2S (0.2 and 0.45 psia) (Kane & Cayard, 2002). For the pure

naphthenic acid environment, the impingement corrosion

was evident for TAN values higher than 1.5. Both the 5Cr

and the 9Cr steel had similar degradation rate. As the TAN

value increased, the velocity to onset impingement corrosion

decreased. When the 0.2 psia level of H2S was added it caused

inhibition of impingement corrosion in both steels. When the

H2S was increased to the higher level (0.45 psia) the 5Cr steel

started to corrode but the 9Cr still maintained the inhibition

(Kane & Cayard, 2002).

The interaction between naphthenic acid and sulfidic corrosion was also investigated at 270C using 5Cr0.5Mo steel

(Qu et al., 2006). For a solution containing a TAN between 6

and 16, the corrosion rate was inhibited by adding 1% S (Qu

et al., 2006). However, then the TAN was 32, the addition of

1% S was detrimental (increased the corrosion rate promoted

by naphthenic acid). For the carbon steel, the addition of 1% S

always increased the corrosion rate by naphthenic acid. Sulfur

inhibited corrosion caused by naphthenic acid only in the

5Cr0.5Mo steel (Qu et al., 2006). It was more recently claimed

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

R.B. Rebak: Sulfidic corrosion in refineries a review

that no fundamental studies were carried out to investigate the

mechanism of interaction between the sulfide layer and the

naphthenic acid in solution (El Kamel et al., 2010b). Coupons

of four different alloys (carbon steel, 2.25Cr1Mo, 5Cr0.5Mo

and 304L) were pre-sulfidized in 150 mbar of pure H2S at

300C. The FeS that formed on the surface was pyrrhotite.

Then the coupons were exposed to white oil containing naphthenic acid to a total TAN=4 at 260C for different amount of

times and the effect of the naphthenic acid on the pre-existing

H2S scale was monitored (El Kamel et al., 2010b). It was

reported that the naphthenic acid attacked locally the sulfide

scale on the coupons causing eventual detachment of the scale

from the surface of the coupons. Figure 3 shows a representation of the required testing time to produce detachment of the

FeS scale from the coupons (El Kamel et al., 2010b). Scale

detachment from the 304L steel (18Cr) did not occur even

after 9 h of exposure to the oil. Figure 3 also shows an exponential fit of the data for the first three points (carbon steel,

2.25Cr1Mo and 5Cr0.5Mo). An extrapolation of these results

show that detachment may have occurred for the 304L steel

only after more than 100 h exposure (Figure 3).

Recent laboratory results show the intricacy of the relationships between steel compositions, temperature, sulfur species,

naphthenic acid, etc. Current laboratory data do not contradict

findings from the plants but at the same time do not provide

too much insight on the corrosion mechanism or mechanisms.

Interestingly, the interaction between sulfidic corrosion and

naphthenic acid seems to be one of the most widely tested

phenomena in the laboratory.

4.4. Effect of composition of the steel

The selection of materials in a refinery is not only based on

the ability to resist corrosion but also on price, availability and

ability to weld. Table 3 shows some regular materials used in

1000

Sulfide scale detachment time (min)

Exponential fit, R2=0.97

304L

100

5Cr

2.25Cr

Carbon steel

Sulfided coupons

white oil, TAN=4, 260C

10

0

12

16

20

Weight % Cr

Figure 3 Detachment time for a sulfide scale when exposed to

white oil containing naphthenic acid TAN=4 at 260C (plotted from

data by El Kamel et al., 2010b).

129

the petroleum refining industry. For carbon steels it is known

that steels containing <0.1% Si corrode faster than steels with

higher Si content (API, 2008). The presence of Si in the steel

may help to form a more adherent and stable sulfide scale

on the surface (API, 2008). The modified McConomy curves

(Figure 1) do not differentiate between low and high Si steel.

These curves show that at each temperature the corrosion rate

is practically reduced about half its value for series carbon

steel >2.25Cr steel >5Cr steel >9Cr steel >12Cr >18/8 steel. It

has also been reported that the corrosion rate can be reduced

10-fold when ferritic 9Cr steel is used instead of carbon steel

(Hucinska, 2006). In general the resistance of the steels to

sulfidic corrosion increases according to the following order

(Farraro & Stellina, 1996; Qu et al., 2006): Carbon steel,

Carbon steel +0.5Mo, 5Cr+0.5Mo, 9Cr+1Mo, 12Cr (410),

17Cr (430), 304SS, 316SS, and 317SS.

Stainless steels are used to resist high temperature sulfidic

corrosion (Farraro & Stellina, 1996). Stainless steels containing molybdenum are used to combat corrosion mainly by

naphthenic acid (Farraro & Stellina, 1996). The effect of Cr

to protect against sulfidic corrosion may be more important

under flow conditions (Qu et al., 2006). The beneficial effect

of Cr may originate of its ability to poison the decomposition

of sulfur compounds (Farrell & Roberts, 2010).

Two steels (carbon steel and 5Cr0.5Mo) were tested for

their response to naphthenic acid corrosion and sulfidic

corrosion (Qu et al., 2006). The carbon steel was mostly a

ferrite phase and the 5Cr0.5Mo steel was mostly a pearlite

phase. The tests were performed in a static autoclave for up

to 65 h of testing time. Coupons were exposed to the liquid

and vapor phase inside the vessel. Testing temperature was

from 220C to 320C (at 20C intervals). The base fluid (carrier) was transformer oil to which (1) naphthenic acid to a

TAN=2 to 14.51 and (2) dimethyl disulfide with [S]=1% were

added separately (Qu et al., 2006). It was reported that in

the naphthenic acid environment with TAN=2 at 270C, the

carbon steel was found more resistant to corrosion than the

5Cr0.5Mo steel. However, in the dimethyl disulfide solution

([S]=1%) the 5Cr0.5Mo steel was found more resistant to

corrosion. Cross sections of the scale formed on the testing

coupons showed that on the 5Cr0.5Mo steel the scale consisted of two layers while in the carbon steel the scale consisted of only one layer (Qu et al., 2006). Laboratory tests and

field results may suggest that the presence of Cr in the steel

may not be beneficial to protect against naphthenic acid corrosion (Qu et al., 2006).

In the case when hydrogen is present, the Couper-Gorman

curves do not predict a large decline of the corrosion rates

between carbon steel and 5Cr0.5Mo steel. Only when the 9Cr

steel was used there is modest decrease in the corrosion rate,

and a distinctive improvement was noticed when the 18%Cr

austenitic steel was used (Hucinska, 2006).

Coupons of three steels (carbon steel, P5 and 304L) were

exposed to flowing high sulfur crude oil at 300C and 35 bar

pressure for times as long as 98 h (El Kamel et al., 2010a).

Mass losses after cleaning the sulfide layer were transformed

to pyrrhotite layer thickness. For carbon steel and P5 steel

(5Cr0.5Mo) the same thicknesses were found, indicating

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

130 R.B. Rebak: Sulfidic corrosion in refineries a review

Table 3 Typical materials in sulfidic corrosion applications.

Material

Designation

Typical composition, weight %

Single figures are maximum

A53

Grade B ASTM A53

Fe, 0.3C, 0.4Cr, 1.2Mn, 0.045S, 0.05P, 0.4Cu, 0.4Ni, 0.15Mo,

0.08V, (Cu+Ni+ Cr+Mo +V= max 1.0 %)

A106

Grade B ASTM A106

(K03006)

Fe, 0.3C, 0.4Cr, 0.29 1.06Mn, 0.1Si, 0.035S, 0.035P, 0.4Ni,

0.4Cu, 0.08V

5Cr 0.5Mo (pipe)

ASTM A335 P5

Fe, 0.15C, 4 6Cr, 0.45 0.65Mo, 0.3 0.6Mn, 0.5Si,

0.025S+ 0.025P

9Cr 1Mo (pipe)

ASTM A335 P91

Fe, 0.08 0.12C, 8 9.5Cr, 0.85 1.05Mo, 0.3 0.6Mn, 0.2 0.5Si,

0.18 0.25V, 0.01S, 0.02P

12Cr 410SS

UNS S41000

Fe, 0.15C, 11.5 13Cr, 1.00Mn, 0.040P, 0.030S, 1.00Si

316LSS (pipe)

ASTM A312 (S31603)

Fe, 0.03C, 16 18Cr, 10 14Ni, 2 3Mo, 2Mn, 1Si, 0.03S, 0.045P

317SS (pipe)

ASTM A312 (S31700)

Fe, 0.08C, 18 20Cr, 1115Ni, 3 4Mo, 2Mn, 1Si, 0.03S, 0.045P

little beneficial effect of the presence of 5% Cr in the steel.

However, there was a strong benefit with the 18% Cr since

they could not find weight change for the 304L coupons (El

Kamel et al., 2010a).

Current laboratory findings and some plant operation

experience may not support the use of 5Cr steel in refineries since in many applications its corrosion behavior cannot

be fully differentiated from the behavior of carbon steels.

Moreover, some current commercial 5Cr steel pipes now

contain <4.5% Cr. In plant applications when there are limitations to the performance of carbon steel, some plant engineers may find it appropriate to upgrade the pipe material

directly to 9Cr steel, skipping the recommendation of 5Cr

steel.

4.5. Effects of velocity, hydrogen and steam

Fluid velocity and turbulence are important factors affecting sulfidic attack (Kane & Cayard, 2002). It is accepted

that the lowest corrosion is found when the surface of the

metal is completely wetted with the hydrocarbon under low

flow (Gutzeit, 1986). Fluid velocity up to 60 m/s may hamper the ability of the steel to form a semi protective sulfide

film on the surface and therefore high velocity may accelerate corrosion (API, 2008). An adherent sulfide scale may

control further attack of the steel either by more sulfidation or by naphthenic acid attack. However, if the sulfide

scale is removed by the shear stress resulting from fluid

flow, the attack of the underlying steel may be accelerated

(Kane & Cayard, 2002; Qu, Liu, Jiang, Lan, & Shan, 2011).

This is especially true in presence of naphthenic acids (Bota

et al., 2010; Qu et al., 2011). It has also been argued that

too little flow may also be detrimental since more H2S may

be allowed to evolve and concentrate in certain pipe areas

(API, 2008).

Materials behave differently in H2S environment than in

H2S+H2 environments, since the beneficial effect of chromium for the H2S environment may seem less effective

in the H2S+H2 environments (Setterlund, 1991; Niccolls,

2005). It has been argued that the presence of H2 may be

detrimental for the corrosion resistance of the steels since

it inhibits the formation of semi-protective coke on the surface (NACE, 2004). Another explanation for the hydrogen

effect is that it reacts with less corrosive sulfur containing

species and forming more H2S and therefore increasing the

corrosiveness of the system (Gutzeit, 1986; NACE, 2004).

In general, if H2 is present in the stream above 260C it is

recommended to use 18Cr steel (e.g., type 316SS) and avoid

carbon steel and lower Cr steels altogether (Gutzeit, 1986;

NACE, 2004).

The presence of vaporization and steam may yield higher

corrosion rates in steels. The most detrimental corrosion may

happen within a spray flow with vapor loads higher than

60% containing liquid droplets that may destroy the sulfide

scale via impingement (Gutzeit, 1986). It was reported that

in sulfidic environments the corrosion rate is approximately

six-fold higher when the metal surface is exposed to vapor

vs. liquid (McLaughlin, 2005). Carbon steel and 5Cr0.5Mo

steels were tested for resistance to sulfidic corrosion at

230C, 250C and 270C (Qu et al., 2006). In the sulfidic

solution ([S]=1%), the corrosion rate of both steels increased

monotonically as the temperature increased both for the

liquid and vapor phases. For both steels the corrosion rate

was the same in the liquid and vapor phases (Qu et al., 2006).

However, the corrosion rate was higher for the carbon steel

than for the 5Cr0.5Mo steel (Qu et al., 2006). The effect

of the sulfur concentration on the corrosion rate was also

studied at 270C. When the sulfur concentration increased

from 0.5 to 1.25, the corrosion rate increased up to [S]=1

and then decreased from 1 to 1.25. The corrosion rate for

both steels was higher in the vapor phase than in the liquid

phase and the corrosion rate in both phases of the carbon

steel was higher than the corrosion rate of the 5Cr0.5Mo.

When mixtures of naphthenic acid with sulfur compounds

were tested, a complex relationship of the variables involved

was reported (Qu et al., 2006). Nevertheless, the corrosion

rate of the 5Cr0.5Mo steel was lower than the corrosion rate

of the carbon steel (Qu et al., 2006).

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

R.B. Rebak: Sulfidic corrosion in refineries a review

4.6. Effect of other chemical species, such as amines

and ammonium disulfide

Crude oil may contain many other chemicals, such as amines

added to control wax deposition, enhance flow characteristics, aid in water separation, etc. (Kapusta, van den Berg,

Daane, & Place, 2003). For example, amines such as monoethanolamine, di-ethanolamine, aminoethoxyethanol, methyl

di-ethanolamine and di-isopropanolamine are added at different points in the refinery to remove H2S, mercaptans and

carbon dioxide from the process stream (Shahid & Faisal,

2009; Lagad, Cayard, & Srinivasan, 2010). The presence of

amines and other chemicals add another degree of complexity

to the sulfidic corrosion mechanism. Little or no information

is available in this area.

Some crude oils may also contain species such as cyanide ions (CN-), which may destroy the protective layers of

FexSy on the surface and promote hydrogen ingress into the

steel what eventually may cause hydrogen induced cracking

(Groysman, Feldman, Kaufman, & Balali, 2011).

4.7. Effect of testing time

The sulfide scale that forms on the test metallic coupons

could be semi-protective depending on the testing conditions. That is, as the time increases the corrosion rate may

decrease. When coupons of carbon steel and 5Cr0.5Mo steel

were tested in the liquid and vapor phase of transformer oil

containing 1% [S] as dimethyl disulfide at 270C, the corrosion rate initially increased (up to 8 h) and then decreased

as the time increased up to 65 h (Qu et al., 2006). These

results suggest that diffusion of sulfur through the sulfide

scale is the rate limiting step in the corrosion rate (Qu et al.,

2006). Since the parabolic law rate constant for the carbon

steel was higher than for the 5Cr0.5Mo steel, it was concluded that under the tested conditions the 5Cr0.5Mo steel

was more resistant to sulfidic corrosion than the carbon steel

(Qu et al., 2006).

4.8. Plant experience

Corrosion issues in crude refineries are generally solved

by alloy selection based on experience accumulated by the

industry in many decades. Trade documents cited before

(API RP 939-C, NACE 34103) provide a guide for alloy

selection under the different conditions found in the plants.

Some refineries may use additional measures, such as inhibition or neutralization (Tuttle, 2005). Continuous monitoring

is essential in many plants to measure the degradation rate

of some components and to determine if these components

need replacement in the next scheduled shut down. Most of

the recent failures due to sulfidic corrosion were traced to the

use of carbon steel pipes with insufficient amount of silicon

(API, 2008).

An unusual high temperature sulfidic corrosion has been

reported in the catalytic refining unit in a plant in Indiana

(Wilks, 2000). The failure occurred in a hot dip aluminized

steel pipe elbow that was exposed to a turbulent two-phase

131

flow. Failure occurred after the aluminized layer was corroded or eroded (Wilks, 2000). This pipe operated above

316C. Some of the corrosion attack progressed under the

aluminized layer lifting it away into the flowing stream. The

leaking failure was ductile overload due to the thinning of the

pipe wall. As a consequence of the reported failure, all piping in the area operating above 260C has been upgraded to

5Cr0.5Mo (Wilks, 2000).

A corrosion study was conducted for 20 days at a refinery

during a sour operation when a blend of high sulfur crudes

were processed (Farrell & Roberts, 2010). The total amount

of sulfur in the blend was 1.80.2 wt% and the TAN number was relatively low (0.24). Weight loss coupons of five

different steels were exposed to the oil stream in piping at

two points in the plant, (1) in the heavy atmospheric gas

oil (HAGO) with a flow of 1.5 m/s at 354C and (2) in the

light vacuum gas oil (LVGO) with a higher flow of 2.4 m/s

but at a lower temperature of 204C. The tested materials

were: (a) carbon steel, (b) 5Cr, (c) 9Cr, (d) 410SS 12Cr and

(e) cast CA6NM 12Cr4Ni0.5Mo (Farrell & Roberts, 2010).

For the coupons exposed to the LVGO (204C), the carbon

steel, the 5Cr and the 9Cr steel performed well with corrosion rates below the detection limit of 0.1 mpy (<0.0025

mm/year). This agrees well with the common knowledge

that sulfidic corrosion is becoming an important issue at

temperatures above 232C, which is above the temperature

in the LVGO. Surprisingly it was reported that in the LVGO

both the 410SS and the CA6NM coupons showed a measurable corrosion rate of 1.8 mpy (0.05 mm/year) for the 410SS

and 0.2 mpy (0.005 mm/year) for the CA6NM steel (Farrell

& Roberts, 2010). Figure 4 is a graphic representation of

results reported by Farrell and Roberts in their Table 2 for

the HAGO system at 354C. Figure 4 shows that the corrosion rates of carbon steel, 5Cr and 9Cr materials were higher

than 10 mpy (>0.254 mm/year). The highest corrosion rate

was for the 5Cr steel at 29.1 mpy (0.74 mm/year) (Farrell

& Roberts, 2010). It may seem unanticipated that under the

tested conditions the corrosion rate of the 5Cr steel was

higher than the corrosion rate of the carbon steel. Figure 4

also shows a sharp decline in the corrosion rates between

the 9Cr and the 12Cr steels, since for the latter materials

the corrosion rate was <1 mpy (<0.025 mm/year). Other

results from Farrell and Roberts show a significant effect

of the temperature on the sulfidic rate of the steels between

204C and 354C, since the corrosion rate increased more

than two orders of magnitudes between these temperatures.

Under the tested conditions, the effect of fluid flow was not

significant since for the higher velocity of 2.4 m/s at 204C

the corrosion rate was approximately two orders of magnitude lower than for the lower velocity of 1.5 m/s at 354C

(Farrell & Roberts, 2010). These results seem to indicate that

the temperature is a more important factor controlling

corrosion than the fluid velocity. It was also noted by Farrell

and Roberts that, after the in-situ plant tests, the carbon steel

coupons yielded corrosion rates lower than the values predicted from the McConomy curves, while the 5Cr and 9Cr

steel yielded higher corrosion rates than the McConomy

curves predicted values (Farrell & Roberts, 2010).

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

132 R.B. Rebak: Sulfidic corrosion in refineries a review

Coupons in plant piping

sour crude ~2% [S], 20 days, 354C

100

10

0.1

mm/year

Corrosion rate (mpy)

1

0.01

0.1

Carbon

steel

5Cr

9Cr

410SS CA6NM

Figure 4 Corrosion behavior of engineering alloys coupons

exposed to a plant stream containing sulfur (plotted from tabular data

by Farrell & Roberts, 2010).

5. Summary and conclusions

Sulfidic corrosion is a complex mechanism of steel degradation in crude refineries occurring between 232C and 427C.

Internal and external factors affect the sulfidic corrosion

degradation rate including alloy composition, temperature,

total sulfur content in the oil, and presence of naphthenic

acid. Two review consensus documents have been issued by

NACE International in 2004 and API in 2008 capturing the

state of knowledge in plant experience of how the environmental variables affect the sulfidic corrosion performance of

the engineering steels. Most of the process of material selection to replace degraded parts or for new refineries is based on

almost a century of data from plant experience.

The main aim of the current review was to bring together

the most recent research results from laboratory testing and

evaluate their findings in perspective of the plant experience.

Based on the reviewed literature it seems apparent that the

basic mechanism of sulfidic corrosion of carbon steel and

alloy steels is not fully understood. Little or no systematic

research has been carried out in laboratory or in plant to

measure, for example, kinetics of sulfide scale growth, the

mechanical properties and adherence of the scales, the activation energy for scale formation and its dependence of temperature ranges, alloy composition, sulfur species, etc. Little

or no information exists to determine why the presence of

Cr in the steel is beneficial for sulfidic corrosion resistance.

There is ample room for systematic laboratory testing on the

sulfidic corrosion of engineering alloys in simulated and plant

refinery environments, mainly on the effect of temperature,

sulfur species, alloy composition, and microstructure.

References

API. RP 939-C Guidelines for avoiding sulfidation (sulfidic) corrosion railures in oil refineries. API Subcommittee on Corrosion &

Materials, Version 5.0, February 2008. New Orleans, LA: API,

2008.

Bacon R, Tordo S. Crude oil price differentials and differences in

oil qualities: a statistical analysis. ESMAP Technical paper 081,

October 2005. Washington, DC: ESMAP, 2005.

Bota GM, Qu D, Nesic S, Wolf HA. Naphthenic acid corrosion of

mild steel in the presence of sulfide scales formed in crude oil

fractions at high temperature. Corrosion/2010, Paper 10353.

Houston, TX: NACE International, 2010.

Chambers BD, Kane RD. Refining high acid crudes. PTQ Q4 2008;

137149.

De Jong J-P, Dowling N, Sargent M, Etheridge A, Saunders-Tack A,

Fort W. Effect of mercaptans and other organic sulfur species on

high temperature corrosion in crude oil and condensate distillation units. Corrosion/2007, Paper 07565. Houston, TX: NACE

International, 2007.

El Kamel M, Galtayries A, Vermaut P, Albinet B, Foulonneau G,

Roumeau X, Roncin B, Marcus P. Sulfidation kinetics of industrial steels in a refinery crude oil at 300C: reactivity at the nanometer scale. Surface Interface Anal 2010a; 42: 605609.

El Kamel M, Galtayries A, Foulonneau G, Roumeau X, Morel G,

Marcus P. High temperature corrosion of sulfided steels in naphthenic acid environments. Eurocorr 1317 September 2010,

Moscow. Paper 9377. 2010b.

Farraro T, Stellina RM Jr. Materials of construction for refinery applications. Corrosion/1996, Paper 614, Conference and Exposition.

Houston, TX: NACE International, 1996.

Farrell D, Roberts L. A study of high temperature sulfidation

under actual process conditions. Corrosion/2010, Paper 10358.

Houston, TX: NACE International, 2010.

Foroulis ZA. Kinetics and mechanism of the reaction of iron with sulfur vapor in the temperature range of 250 to 500C. Werkstoffe

Korros 1978; 29: 385393.

Groysman A, Feldman B, Kaufman A, Balali R. Hydrogen damage

and prevention in the oil refinery. Corrosion/2011, Paper 11295.

Houston, TX: NACE International, 2011.

Guedes Soares C, Garbatov Y, Zayed A, Wang G. Corrosion wastage

model for ship crude oil tanks. Corros Sci 2008; 50: 30953106.

Gutzeit J. Naphthenic acid corrosion in oil refineries. Mater Perform

1977; 16: 24.

Gutzeit J. Refinery corrosion overview. In: Process industry corrosion

the theory and practice. Houston, TX: NACE International,

1986. pp. 171189.

Harmandas NG, Koutsoukos PG. The formation of iron(II) sulfides

in aqueous solutions. J Crystal Growth 1996; 167: 719724.

Hucinska J. Influence of sulphur on high temperature degradation of

steel structures in the refinery industry. In: Advances in materials

science. Gdansk, Poland: Versita Open, 2006.

Jayaraman A, Saxena RC. Corrosion and its control in petroleum refineries a review. Corros Prevent Control 1995; 42:

123131.

Jenkins W. A refinery process equipment database. Corrosion/1998,

Paper 401. Houston, TX: NACE International, 1998.

Kane RD. Corrosion in petroleum production operations. In: ASM

metals handbook, Volume 13C Corrosion: environments and

industries. Metals Park, OH: ASM International, 2006. pp.

922966.

Kane RD, Cayard MS. A comprehensive study on naphthenic acid

corrosion. Corrosion/2002, Paper 02555. Houston, TX: NACE

International, 2002.

Kanukuntla V. Formation of sulfide scales and their role on the naphthenic acid corrosion of steels. Master of Science Thesis. Athens,

OH: Ohio University, 2008.

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

R.B. Rebak: Sulfidic corrosion in refineries a review

Kapusta S, van den Berg F, Daane R, Place MC. The impact of oil

field chemicals on refinery corrosion problems. Corrosion/2003,

Paper 03649. Houston, TX: NACE International, 2003.

Lagad VV, Cayard MS, Srinivasan S. Prediction and assessment

of rich amine corrosion under simulated refinery conditions.

Corrosion/2010, Paper 10183. Houston, TX: NACE International,

2010.

Lai GY. (2007). Sulfidation. In: High-temperature corrosion and

materials applications. Metals Park, OH: ASM International,

2007. pp. 201234.

Laredo GC, Lopez CR, Alvarez RE, Cano JL. Naphthenic acids,

total acid number and sulfur content profile characterization in

Isthmus and Maya crude oils. Fuel 2004; 83: 16891695.

McLaughlin J. Sulfidation corrosion due to H2S/H2, effect of H2

partial pressure, effect of fluid flow. API Spring Conference, 19

April 2005. New Orleans, LA: API, 2005.

Messer B, Tarleton B, Beaton M, Phillips T. New theory for naphthenic

acid corrosivity of Athabasca oilsands crudes. Corrosion/2004,

Paper 04634, Conference and Exposition. Houston, TX: NACE

International, 2004.

NACE International. Overview of sulfidic corrosion in petroleum

refining. Publication 34103. Task Group 176 of Prediction Tools

for Sulfidic Corrosion. Houston, TX: NACE International,

2004.

Niccolls EH, Gallon AE, Yamamoto K. Systematic integration of

advanced NDE and corrosion monitoring for improved refinery reliability. Corrosion/2008, Paper 08280, Conference and

Exposition. Houston, TX: NACE International, 2008.

Niccolls N. Sulfidation: thoughts on theory and practice. Energy

Technology Company, ChevronTexaco. Augusta, GA: Doe

Hydrogen Pipeline Working Group, 2005.

OKane JM, Rudd TF, Cooke D, Dean FWH, Powell SW. Detection

and monitoring of naphthenic acid corrosion in a visbreaker

unit using hydrogen flux measurements. Corrosion/2010, Paper

10351. Houston, TX: NACE International, 2010.

Piehl RL. Naphthenic acid corrosion in crude distillation units. Mater

Perform 1988; 27: 3743.

Qu DR, Zheng YG, Jing HM, Yao ZM, Ke W. High temperature

naphthenic acid corrosion and sulphidic corrosion of Q235 and

5Cr0.5Mo steels in synthetic refining media. Corros Sci 2006;

48: 19601985.

Qu D, Liu X, Jiang X, Lan Z, Shan G. Setting critical operational

TAN and sulfur level for crude distillation units. Corrosion/

133

2011, Paper 11362. Houston, TX: NACE International,

2011.

Rapp RA. Hot corrosion of materials: a fluxing mechanism? Corros

Sci 2002; 44: 209221.

Riley J. Roundtable on Sulfidation. API Spring Conference, 19 April

2005. New Orleans, LA: API, 2005.

Ruschau GR, Al-Anezi MA. Petroleum refining: corrosion control

and prevention. In Corrosion costs and preventive strategies in

the United States, Appendix U. Washington, DC: US Department

of Transportation, 2001.

Setterlund RB. Selecting process piping materials. Hydrocarb

Process 1991; 70: 93100.

Shahid M, Faisal M. Effect of hydrogen sulfide gas concentration

on the corrosion behavior of ASTM A-106 Grade A carbon

steel in 14% diethanol amine solution. Arab J Sci Eng 2009; 34:

179186.

Slavcheva E, Shone B, Turnbull A. Factors controlling naphthenic

acid corrosion. Corrosion/1998, Paper 579. Houston, TX: NACE

International, 1998.

Smith SN, Brown B, Sun W. Corrosion at higher H2S concentrations and moderate temperatures. Corrosion/2011, Paper 11081.

Houston, TX: NACE International, 2011.

Sun W, Nesic S. A mechanistic model of H2S corrosion of mild steel.

Corrosion/2007, Paper 07655. Houston, TX: NACE International,

2007.

Tebbal S. Critical review of naphthenic acid corrosion. Paper 380.

NACE Corrosion Conference, 1999. Houston, TX: NACE

International, 1999.

Turnbull A, Slavcheva E, Shone B. Factors controlling naphthenic

acid corrosion. Corrosion 1998; 54: 922930.

Tuttle RN. Petroleum production and refining. In: Corrosion tests

and standards: application and interpretation, 2nd ed., Chapter

76. West Conshohocken, PA: ASTM International, 2005. pp.

812821.

Vedage H, Ramanarayanan TA, Mumford JD, Smith SN.

Electrochemical growth of iron sulfide films in H2S-saturated

chloride media. Corrosion 1993; 49: 114121.

Wen S, Mucek M. Low-temperature hot corrosion in the refining

industry. Corrosion/2011, Paper 11365. Houston, TX: NACE

International, 2011.

Wilks GW. Unusual aspects of corrosion failures in refinery

hydrotreater units. Corrosion/2000, Paper 00702, Conference

and Exposition.

- 10.1515/CORRREV.2011.021

Downloaded from PubFactory at 08/22/2016 04:09:50PM

via free access

Você também pode gostar

- Sulfidic Corrosion in Refineries - A ReviewDocumento13 páginasSulfidic Corrosion in Refineries - A Reviewrogerh44Ainda não há avaliações

- 9 CorrosDocumento25 páginas9 CorrosFrancisco Beltran100% (1)

- Materials Degradation in Wet H2S and Alkaline Sour Water EnvironmentsDocumento14 páginasMaterials Degradation in Wet H2S and Alkaline Sour Water Environmentsyiyita01Ainda não há avaliações

- Oil and Gas Corrosion Prevention: From Surface Facilities to RefineriesNo EverandOil and Gas Corrosion Prevention: From Surface Facilities to RefineriesNota: 5 de 5 estrelas5/5 (6)

- Corrosion and Materials Selection For Amine ServiceDocumento1 páginaCorrosion and Materials Selection For Amine ServicealikajbafAinda não há avaliações

- Naphthenic Acid CorrosionDocumento6 páginasNaphthenic Acid Corrosionbkmuduli100% (1)

- Coke Drum Drum MonitoringDocumento22 páginasCoke Drum Drum Monitoringsantino_gentile2893Ainda não há avaliações

- Steam Reformer Outlet Header Failure: Charles Ormsbee, B.SC., P.EngDocumento6 páginasSteam Reformer Outlet Header Failure: Charles Ormsbee, B.SC., P.Engvaratharajan g rAinda não há avaliações

- Biological Treatment of Microbial Corrosion: Opportunities and ChallengesNo EverandBiological Treatment of Microbial Corrosion: Opportunities and ChallengesAinda não há avaliações

- CuiDocumento6 páginasCuiأحمد صبحىAinda não há avaliações

- Mitigate Corrosion in CondensateDocumento27 páginasMitigate Corrosion in CondensateGeorge MarkasAinda não há avaliações

- Avoiding Common Pitfalls in CO2 Corrosion Rate Assessment For Upstream Hydrocarbon IndustriesDocumento15 páginasAvoiding Common Pitfalls in CO2 Corrosion Rate Assessment For Upstream Hydrocarbon IndustriesKen's CornerAinda não há avaliações

- Guidelines For Prediction of Co2 Corrosion in Oil and Gas Production SystemsDocumento19 páginasGuidelines For Prediction of Co2 Corrosion in Oil and Gas Production SystemsMartín Diego Mastandrea100% (1)

- Corrosion Management For Seawater Injection SystemsDocumento5 páginasCorrosion Management For Seawater Injection SystemszaxaderAinda não há avaliações

- Pitting CorrosionDocumento29 páginasPitting Corrosionatikahj_3Ainda não há avaliações

- Internal Carburization and Carbide Precipitation in Fe-Ni-Cr Alloy Tubing Retired From Ethylene Pyrolysis ServiceDocumento7 páginasInternal Carburization and Carbide Precipitation in Fe-Ni-Cr Alloy Tubing Retired From Ethylene Pyrolysis ServiceSergey Iakovlev67% (3)

- ECS-The Electrochemical SocietyDocumento1 páginaECS-The Electrochemical Societyariel terrazasAinda não há avaliações

- Prediction and Assessment of Ammonium Bisulfide Corrosion Under Refinery Sour Water Service Conditions (51300-06576-Sg)Documento20 páginasPrediction and Assessment of Ammonium Bisulfide Corrosion Under Refinery Sour Water Service Conditions (51300-06576-Sg)Hasrul HilmiAinda não há avaliações

- I HRSGDocumento7 páginasI HRSGJayanath Nuwan SameeraAinda não há avaliações

- Ifan Rifandi - Pertamina Hulu Energi ONWJDocumento30 páginasIfan Rifandi - Pertamina Hulu Energi ONWJRizky SyahputraAinda não há avaliações

- Manuscript Predicting and Mitigating Corrosion in Amine UnitsDocumento13 páginasManuscript Predicting and Mitigating Corrosion in Amine UnitsSatria 'igin' Girindra NugrahaAinda não há avaliações

- Filming Corrosion Inhibitor For Oil and Gas FieldDocumento20 páginasFilming Corrosion Inhibitor For Oil and Gas FieldelsyakiebAinda não há avaliações

- Breaking Down AC Corrosion of PipelinesDocumento7 páginasBreaking Down AC Corrosion of PipelinesHenryAinda não há avaliações

- Coating SDocumento51 páginasCoating SBalaji GuruAinda não há avaliações

- Flow Accelerated Corrosion of Pressure Vessels in Fossil Plants - DooleyDocumento6 páginasFlow Accelerated Corrosion of Pressure Vessels in Fossil Plants - Dooleyvandrake10Ainda não há avaliações

- Article CO2CorrosionCHEM409 - Background of CO2 CorrosionDocumento4 páginasArticle CO2CorrosionCHEM409 - Background of CO2 Corrosionmohamed samyAinda não há avaliações

- Mohammad Rasul Ed. Thermal Power Plants Advanced ApplicationsDocumento185 páginasMohammad Rasul Ed. Thermal Power Plants Advanced Applicationssurafel amareAinda não há avaliações

- Tech Coating SelectionDocumento8 páginasTech Coating SelectionKarthikeyan Shanmugavel100% (1)

- Corrosion prevention in CDU overhead systemDocumento10 páginasCorrosion prevention in CDU overhead systemOmid Hn100% (1)

- Refinery H2/H2S Corrosion GuideDocumento9 páginasRefinery H2/H2S Corrosion GuideBOB100% (1)

- Carbonate Stress Corrosion Cracking (ACSCC)Documento11 páginasCarbonate Stress Corrosion Cracking (ACSCC)Ajmi HmidaAinda não há avaliações

- 2-Metals and Corrosion ResistanceDocumento3 páginas2-Metals and Corrosion ResistanceRolly SocorroAinda não há avaliações

- A Strategy For Preventing Corrosion Under Insulation On Pipeline in The Petrochemical IndustryDocumento6 páginasA Strategy For Preventing Corrosion Under Insulation On Pipeline in The Petrochemical Industry이영준Ainda não há avaliações

- Corrosion Models and Inhibitor AvailabilityDocumento6 páginasCorrosion Models and Inhibitor AvailabilitymaterialguysAinda não há avaliações

- Chemical Water InjectionDocumento47 páginasChemical Water InjectionM. ade Dwi Maesandi100% (1)

- 7 - Pipeline Corrosion PDFDocumento27 páginas7 - Pipeline Corrosion PDFSimone SanAinda não há avaliações

- Naphthenic Acid Corrosion Risk Assessment and MitigationDocumento24 páginasNaphthenic Acid Corrosion Risk Assessment and MitigationSampat100% (3)

- A Refinery Approach To Address Corrosion Under Insulation & External CorrosionDocumento35 páginasA Refinery Approach To Address Corrosion Under Insulation & External CorrosionIshan ShahAinda não há avaliações

- Control of Corrosion in Cooling Waters PDFDocumento93 páginasControl of Corrosion in Cooling Waters PDFVictor SabAinda não há avaliações

- Failure Analysis and Creep Remaining Life of Hydrogen Reformer Outlet Pigtail TubesDocumento12 páginasFailure Analysis and Creep Remaining Life of Hydrogen Reformer Outlet Pigtail TubesAndrea CalderaAinda não há avaliações

- Corrosion Conference and ExpoDocumento25 páginasCorrosion Conference and ExpoLenin S.Ainda não há avaliações

- Superior Spun Cast Material For Steam Reformer Furnaces: Alloy Centralloy 4852 Micro RDocumento12 páginasSuperior Spun Cast Material For Steam Reformer Furnaces: Alloy Centralloy 4852 Micro Rvaratharajan g r100% (1)

- Crude Unit Corrosion and Corrosion ControlDocumento14 páginasCrude Unit Corrosion and Corrosion Controlparmindarrana86% (7)

- Corrosion Protection in Amine Treating Units PDFDocumento12 páginasCorrosion Protection in Amine Treating Units PDFMubeenAinda não há avaliações

- 3050 Using This Manual: Chevron Corporation 3050-1 August 1999Documento8 páginas3050 Using This Manual: Chevron Corporation 3050-1 August 1999milecsa100% (1)

- Membranes For Hydrogen Separation 2007 PDFDocumento33 páginasMembranes For Hydrogen Separation 2007 PDFRavi Mohan Prasad100% (1)

- Engineering Approach To Control Corrosion Under Thermal Insulation (Cuti) in Petrochemical IndustriesDocumento9 páginasEngineering Approach To Control Corrosion Under Thermal Insulation (Cuti) in Petrochemical IndustriesHuynh Phuc PhungAinda não há avaliações

- 1566016Documento6 páginas1566016Yudhistira Perdana PutraAinda não há avaliações

- Scale Inhibitor Laboratory SelectionDocumento20 páginasScale Inhibitor Laboratory SelectionguruhnurizalAinda não há avaliações

- Damage Mechanism in Refinery AreaDocumento83 páginasDamage Mechanism in Refinery AreaKevin PradanaAinda não há avaliações

- Diagnosing Microbiologically Influenced CorrosionDocumento13 páginasDiagnosing Microbiologically Influenced CorrosionFebriana WulandariAinda não há avaliações

- RyznarDocumento12 páginasRyznarJim FrenkenAinda não há avaliações

- Corrosion Monit GuidelinesDocumento35 páginasCorrosion Monit GuidelinesPaulaAinda não há avaliações

- 2015corrosion Inhibitor Selection Guideeversion PDFDocumento4 páginas2015corrosion Inhibitor Selection Guideeversion PDFPhelia Kosasih0% (1)

- Effect of Demineralized Water On Carbon Steel and Stainless SteelDocumento75 páginasEffect of Demineralized Water On Carbon Steel and Stainless SteelNicolasAinda não há avaliações

- CorrosionDocumento79 páginasCorrosionAnonymous zTUWsMAinda não há avaliações

- 06189G FrontmatterDocumento11 páginas06189G FrontmatterEd Marti100% (1)

- Corrosion Problems in Petroleum Industry and Their SolutionDocumento8 páginasCorrosion Problems in Petroleum Industry and Their SolutionAsma SedAinda não há avaliações

- Overclocking CPU Performance by Changing Multiplier ValuesDocumento7 páginasOverclocking CPU Performance by Changing Multiplier Valuesmario_gAinda não há avaliações

- Natural Frequency in A 10 Story BuildingDocumento21 páginasNatural Frequency in A 10 Story Buildingmario_gAinda não há avaliações

- 2007 Tanks EQSpectraDocumento22 páginas2007 Tanks EQSpectraPrasad BarveAinda não há avaliações

- UBC97 Seismic Design PresentationDocumento55 páginasUBC97 Seismic Design Presentationmario_gAinda não há avaliações

- Pressurized Mech Seals Piping PlansDocumento9 páginasPressurized Mech Seals Piping PlanssachinumaryeAinda não há avaliações

- 14 - 05 01 0221 PDFDocumento8 páginas14 - 05 01 0221 PDFMikel IBAinda não há avaliações

- Simplified Seismic Analysis Procedures For Elevated TanksDocumento19 páginasSimplified Seismic Analysis Procedures For Elevated TanksCesar Yoshio Sanchez HuchiyamaAinda não há avaliações

- External Loads On Nozzles Dekker MethodDocumento16 páginasExternal Loads On Nozzles Dekker Methodmario_gAinda não há avaliações

- AutoPIPE TutorialDocumento158 páginasAutoPIPE Tutorialmario_gAinda não há avaliações

- PV Elite WebinarDocumento24 páginasPV Elite WebinarAndrea Hank LattanzioAinda não há avaliações

- API 682 Dual Seal Design ConfigurationsDocumento12 páginasAPI 682 Dual Seal Design Configurationsmario_gAinda não há avaliações

- Evolution of UBC and IBC Static Lateral ForceDocumento5 páginasEvolution of UBC and IBC Static Lateral ForcexpertsteelAinda não há avaliações

- Integral Equations and Their ApplicationsDocumento385 páginasIntegral Equations and Their Applicationsjmlanwar100% (9)

- Understanding the Kellogg Equivalent Pressure MethodDocumento4 páginasUnderstanding the Kellogg Equivalent Pressure MethodLucky Jaswal0% (1)

- EagleBurgmann - AP4-BKTE - E4 - API 682 4th Edition Piping Plans - EN - 30.05.2017Documento68 páginasEagleBurgmann - AP4-BKTE - E4 - API 682 4th Edition Piping Plans - EN - 30.05.2017Saqib AminAinda não há avaliações

- MSN 1676Documento112 páginasMSN 1676tuyenbsrAinda não há avaliações

- The Kellogg Method ReloadedDocumento1 páginaThe Kellogg Method ReloadedNathan BlackburnAinda não há avaliações

- Optimized Skid Design For Compressor PackagesDocumento9 páginasOptimized Skid Design For Compressor Packagesmario_gAinda não há avaliações

- EN 14439 Increased Tower Crane Safety 2010 PDFDocumento23 páginasEN 14439 Increased Tower Crane Safety 2010 PDFmario_gAinda não há avaliações

- Solitons and Chaos I. Antoniou and J. F. LambertDocumento340 páginasSolitons and Chaos I. Antoniou and J. F. Lambertmario_gAinda não há avaliações

- Adrian Scarlat Soft Stories-An Appropriate Choice For Failure TheoryDocumento6 páginasAdrian Scarlat Soft Stories-An Appropriate Choice For Failure Theorymario_g100% (1)