Escolar Documentos

Profissional Documentos

Cultura Documentos

8202 2

Enviado por

Yang WuTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

8202 2

Enviado por

Yang WuDireitos autorais:

Formatos disponíveis

Standing pipe support for pipes with heat insulation,

surrounding pipe support,

slide bearing and fixed point, ferritic steel;

Werknorm

8202-2

temperature 20 C to 300 C; nominal diameter 25 to 200

August 2001

Replaces Standard 8202

Version 08.00

Dimensions in mm

Contents

1

2

3

3.1

3.2

4

5

Page

Layout, pipe configuration.......................................................................................................... 1

Piple supports, dimensions........................................................................................................ 2

Mounting the pipe support ......................................................................................................... 4

Mounting system types A, B and C............................................................................................ 4

Mounting system types D1 and D2 ............................................................................................ 6

Pipeline thermal expansion........................................................................................................ 8

Weights, drawings ..................................................................................................................... 9

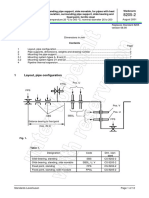

Layout, pipe configuration

FPSL

Pos. U

FPS

Pos. V

Pos. U

SBS

SBSL

FPS

Dist. bearing to fixed point

max. 30 m

Fig 1.

Table 1.

Designation

Slide bearing, standing

Slide bearing, standing, side movable

Fixed point, standing

Fixed point, standing, side movable

Code

SBS

SBSL, U, V

FPS

FPSL

Dim. standard

CS 8202-2

CS 8205-2

CS 8202-2

CS 8205-2

Pipe supports are selected on the basis of Company Standard 8202-2 according to:

-

outside pipe diameter

temperature (inside pipe temperature)

insulation thickness

Standards Leverkusen

Seite 1 von 10

Werknorm 8202-2 August 2001

Slide bearings specified in this standard are designed for a maximum distance from the fixed point of 30 m.

For longer distances, slide bearing length l1 must be checked and corrected as needed. The diagram in Fig.

8 on page 8 showing thermal expansion, fixed-point distances and temperature differences is intended as an

aid.

The specific pipe support type is determined with reference to the required insulation thickness s1 and the

base dimension h1.

Pipe support type 6 as shown in the standard drawings is specified for pipe supports conforming to this standard in which criteria (e.g. space problems, access) other than insulation thickness s1 (inside pipe temperature) must be taken into account in determining h1.

Pipe supports, dimensions

h2

h1

h3

d1

s1

SBS for all mounting system types

FPS for mounting system types D1, D2

T 80

l1

FPS:

SBS:

l1 = 200 mm

Insulation thickness s1 is selected with reference

inside pipe temperature

to inside pipe temperature in accordance with

20 C to 200 C

l1 = 200 mm

CS 81011.

over 200 C to 300 C

l1 = 300 mm

Fig. 2. SBS-type pipe support for all mounting system types, FPS for mounting system types D1 and D2

In the case of FPS-type pipe supports for mounting system types D1 and D2, additional parts (flat steel bar

35x8x35) are welded to the T-profile. See Section 3.2. for positioning.

FPS pipe supports for mounting system types A, B and C, l1 = 200 mm

s1

Cam,

angle steel

Nocken

L- Stahl DIN 1028

h1

h3

d1

h2

DN 25 bis DN 50 L20x3x30

DN 65 bis DN 200 L30x4x50

ND 25 to ND 50 L20x3x30

ND 65 to ND 200 L30x4x50

T 80

200

Fig. 3.

FPS-type pipe supports for mountings system types A, B and C

Standards Leverkusen

Seite 2 von 10

Werknorm 8202-2 August 2001

FPS-type pipe supports for mounting system types A, B and C must have two or four drilled holes measuring

18. The position of the holes depends upon the mounting system type and can be determined on the basis

of the diagrams in Section 3.1.

Table 2. Dimensions h1 for SBS and FPS pipe supports for mounting system types D1, D2

Pipe

Nominal

diameter

d1

25

33.7

32

42.4

40

48.3

50

60.3

65

76.1

80

88.9

100

114.3

125

139.7

150

168.3

200

219.1

Pipe support type

40

80+0

102

106

109

116

124

130

145

158

172

198

1

h1

Insulation thickness s1

60

80

100

h2 + h3

80+20 80+40 80+60

122

142

126

146

129

149

136

156

144

164

184

150

170

190

165

185

205

178

198

218

192

212

232

218

238

258

2

3

4

120

80+80

252

278

5

Nomenclature for a pipe support for a ND 50 pipe, slide bearing, standing, temperature up to 200 C, insulation thickness s1 = 60 mm, prepared for mounting system types A1, anti-corrosion treatment as specified in

CS 8110-F

Pipe support, CS 8202-2-50 SBS 200-60 A1-F

Table 3: FPS pipe supports for mounting system types A, B and C

Pipe

Nominal

diameter

d1

25

33,7

32

42,4

40

48,3

50

60,3

65

76,1

80

88,9

100

114,3

125

139,7

150

168,3

200

219,1

Pipe support type

40

1

h2 + h3 )

100-20

102

106

109

116

124

130

145

158

172

198

1

h1

Insulation thickness s1

60

80

100

h2 + h3

100+0 100+20 100+40

122

142

126

146

129

149

136

156

144

164

184

150

170

190

165

185

205

178

198

218

192

212

232

218

238

258

2

3

4

120

100+60

252

278

5

) For this insulation thickness, the bridge of the T 100 profile must be shortened by 20 mm.

Nomenclature for a pipe support for a ND 50 pipe, fixed point, standing, temperature up to 200 C, insulation

thickness s1 = 60 mm, prepared for mounting system type A1, anti-corrosion treatment as specified in CS

8110-F

Pipe support, CS 8202-2-50 FPS 200-60 A1-F

Standards Leverkusen

Seite 3 von 10

Werknorm 8202-2 August 2001

3

3.1

Mounting the pipe support

Mounting system types A, B and C

Mounting

SBS

101 mm for slide plate A80

121 mm for slide plate A100

Mounting, slide bearing, standing, with hook bolts

Fig. 4.

Table 4: Parts list, mounting system for slide bearing, standing, with hook bolts as shown in Fig. 4

Quantity

for

mounting

A

B

C

1

2

Nomenclature

Material

Pos.

no.

DIN no.

CS no.

Part no.

Remarks

USt 37-2/

RSt 37-2

Slide plate A80

1.4510

CS 8226

1 292 001

for

ND 125

Slide plate A100

1.4510

CS 8226

1 291 002

for

ND 150

Hook bolt M 16 x 32K

4.6/5

CS 8227

1 304 506

galvanized

Hook bolt M 16 x 90K

4.6/5

CS 8227

1 304 508

galvanized

Washer 16

St

DIN EN

ISO 7091

1 345 035

Lock washer C 18-F

St 37-2

CS 8399

1 290 752

Washer 17,5

St

DIN 436

1 345 115

Pipe support

)

)

)

) See Table 8 for drawing of individual parts.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other types of anti-corrosion treatment required are to be indicated in the order.

Standards Leverkusen

Seite 4 von 10

Werknorm 8202-2 August 2001

FPS

Mounting

Fig 5. Mounting, fixed point, standing, with hex bolts

Table 5. Parts list, mounting system for fixed point, standing, with hex bolts as shown in Fig. 5

Quantity

for

mounting

A

B

C

Nomenclature

Material

Pos.

no.

DIN no.

CS no.

Part no.

Remarks

USt 37-2/

RSt 37-2

Separator plate - C 100

1.4510

CS 8226

Hex bolt M 16 x 45

5.6/5-2

DIN EN ISO 4016/

DIN EN ISO 4034

galvanized

Hex bolt M 16 x 100

5.6/5-2

DIN EN ISO 4018/

DIN EN ISO 4034

galvanized

Washer 16

St

DIN EN ISO 7091

1 345 035

Lock washer C 18-F

St 37-2

CS 8399

1 290 752

Washer 17,5

St

DIN 436

1 345 115

Pipe support

)

)

)

) See Table 9 for individual part drawings.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other types of anti-corrosion treatment required are to be indicated in the order.

Standards Leverkusen

Seite 5 von 10

Werknorm 8202-2 August 2001

3.2

Mounting system types D1 and D2

SBS

Mounting system D

) 130 mm for ND 125,

150 mm for ND 150

Fig. 6. Mounting, slide bearing, standing, with guide claws

Table 6. Parts list, mounting system for slide bearing, standing, with guide claws as shown in Fig. 6

Quantity

for

mounting

Nomenclature

Pos.

no.

DIN no.

Drawing no.

Part no.

EL 44 599 - 4N

1 292 405

GTW 40

EL 44 598 - 4N

1 292 400

Material

Remarks

D1

D2

Pipe support

Guide claw, right

Guide claw, left

Hex bolt M 12 x 65

5.6/5-2

DIN EN ISO 4016/

DIN EN ISO 4035

galvanized

Hex bolt M 12 x 85

5.6/5-2

DIN EN ISO 4016/

DIN EN ISO 4034

galvanized

USt 37-2/

RSt 37-2

GTW 40

)

)

)

) See Table 8 for individual part drawings.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other types of anti-corrosion treatment required are to be indicated in the order.

Standards Leverkusen

Seite 6 von 10

Werknorm 8202-2 August 2001

FPS

Mounting system D

Pos. 5 for mounting

system D2

Pos. 6 for mounting

system D1

) 130 mm for ND 125,

150 mm for ND 150

Fig. 7. Mounting system, fixed point, standing, with guide claws

Table 7. Parts list, mounting system for fixed point, standing, with guide claws as shown in Fig. 7

Quantity

for

mounting

Nomenclature

Pos.

no.

DIN no.

Drawing no.

Part no.

Remarks

EL 44 599 - 4N

1 292 405

GTW 40

EL 44 598 - 4N

1 292 400

Material

D1

D2

Pipe support

Guide claw, right

Guide claw, left

Hex bolt M 12 x 65

5.6/5-2

DIN EN ISO 4016/

DIN EN ISO 4034

galvanized

Hex bolt M 12 x 85

5.6/5-2

DIN EN ISO 4016/

DIN EN ISO 4034

galvanized

Flat steel bar 35x8x35

USt 37-2/

RSt 37-2

DIN 1017-1

USt 37-2/

RSt 37-2

GTW 40

)

)

) See Table 8 for individual part drawings.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other types of anti-corrosion treatment required are to be indicated in the order.

Standards Leverkusen

Seite 7 von 10

Werknorm 8202-2 August 2001

Pipeline thermal expansion

Dist. from fixed point

Fig. 8. Ferritic steel

Standards Leverkusen

Seite 8 von 10

Werknorm 8202-2 August 2001

Weights, drawings

Table 8:

Pipe support weights

SBS, all mounting system types l1 = 200 or 300 mm

FPS, mounting system types D1 and D2, l1 = 200 mm

3

Nom.

diameter

25

32

40

50

65

80

100

125

150

200

25

32

40

50

65

80

100

125

150

200

40

Weight in kg ( = 7.85 kg/dm )

Insulation thickness s1

60

80

100

120

h2+h3

80+0

80+20

80+40

80+60

80+80

Inside pipe temperature 20 C to 200 C, and l1 = 200 mm

2.87

3.00

3.13

2.94

3.06

3.19

2.99

3.11

3.24

3.47

3.59

3.72

3.63

3.75

3.88

4.00

3.81

3.93

4.06

4.19

5.65

5.77

5.90

6.03

6.04

6.16

6.29

6.42

6.54

6.66

6.79

6.92

7.04

7.67

7.80

7.92

8.05

8.17

Inside pipe temperature over 200 C to 300 C, and l1 = 300 mm

3.94

4.07

4.20

4.00

4.13

4.26

4.06

4.18

4.31

4.54

4.66

4.91

4.70

4.83

4.95

5.08

4.88

5.00

5.13

5.26

6.71

6.84

6.97

7.09

7.11

7.24

7.36

7.49

7.61

7.74

7.86

7.99

8.11

8.74

8.86

8.99

9.11

9.24

Pipe support

drawing no.

LE 994 717-2N

LE 994 718-2N

LE 994 719-2N

LE 994 720-2N

LE 994 721-2N

LE 994 722-2N

LE 994 723-2N

LE 994 724-2N

LE 994 725-2N

LE 994 726-2N

Drawing no. same

as for inside pipe

temperatures from

20 C to 200 C

Table 9: FPS-type pipe support weights for mounting system types A, B and C, l1 = 200 mm

3

Nom.

diameter

25

32

40

50

65

80

100

125

150

200

Weight in kg ( = 7.85 kg/dm )

40

h2+h3

100-20

3.66

3.72

3.77

4.36

4.52

4.70

6.87

7.26

7.76

8.89

Standards Leverkusen

Insulation thickness s1

60

80

100

h2+h3

100+0

100+20

100+40

3.97

4.10

4.03

4.16

4.08

4.21

4.67

4.80

4.83

4.96

5.09

5.01

5.24

5.37

7.18

7.31

7.44

7.58

7.71

7.84

8.08

8.22

8.35

9.20

9.33

9.46

120

Pipe support

drawing no.

100+60

8.48

9.59

LE 994 727-2N

LE 994 728-2N

LE 994 729-2N

LE 994 730-2N

LE 994 731-2N

LE 994 732-2N

LE 994 733-2N

LE 994 734-2N

LE 994 735-2N

LE 994 736-2N

Seite 9 von 10

Werknorm 8202-2 August 2001

List of standards cited

DIN 436

Square washers for use in timber constructions

DIN 1017-1

Steel bars; Hot rolled flat steel for general Purpose, dimensions, weights, permissible

variations

DIN 1025-2

Hot rolled I-beams; Part 2: Wide flange I-beams, IPB-series; Dimensions, masses,

sectional properties

DIN EN 10 056-1

Structural steel equal and unequal leg angles; Part 1: Dimensions; German version

EN 10056-1:1998

DIN EN 10 056-2

Structural steel equal and unequal leg angles; Part 2: tolerances on shape and dimensions; German version EN 10056-2:1993

DIN EN ISO 4016

Hexagon head bolts; Product grades C (ISO 4016:1999); German version

ISO 4016:200

EN

DIN EN ISO 4018

Hexagon head screws; Product grade C (ISO 4018:1999) German version

ISO 4018:2000

EN

DIN EN ISO 4034

Hexagon nuts; Product grade C (ISO 4034:1999); German version EN ISO 4034:2000

DIN EN ISO 7091

Plain washers; Normal series, Product grade C; (ISO 7091: 2000); German version

ISO 7091:2000

CS 8101-1

Heat insulation; insulation layer thickness, definitions, terms

CS 8110

Pipe supports; anti-corrosion treatment; specifications

CS 8205-2

Pipe supports, standing, laterally mobile, for pipes with heat insulation, surround pipe

support, slide bearing and fixed point; temperature 20 C to 300 C; nominal diameter

25 to 200

CS 8226

Pipe supports; glide plates and separator plates for piping from ND 25 to 100

CS 8227

Pipe supports; hook bolts

CS 8250

Pipe supports; pipe clamps for nominal diameters 15 to 1000

CS 8252

Pipe supports; pipe clamps for nominal diameters 25 to 500

CS 8399

Pipe supports; lock washers for double-angle bridge

EN

Previous versions

CS 82-2: 1970-12; 1974-05; 1976-05; 1980-10; 1982-04; 1988-03; 1998-10; 2000-08

Changes

The following changes were made to the version of August 2000:

a) Company Standard 8202, version of March 1988, was revised and issued separately as CS 8202-2 for

ferritic steel.

b) DIN standards updated.

Standards Leverkusen

Seite 10 von 10

Você também pode gostar

- ASME Code Calculations For Companion FlangesDocumento9 páginasASME Code Calculations For Companion FlangesKamlesh DalavadiAinda não há avaliações

- V10 12d NZ - W03 Network AnalysisDocumento13 páginasV10 12d NZ - W03 Network AnalysisrenandAinda não há avaliações

- DIN 2093 2006-03 eDocumento18 páginasDIN 2093 2006-03 eLuis Testa100% (1)

- Drilling Fluids, Drill String, CirculatingDocumento10 páginasDrilling Fluids, Drill String, CirculatingBianca Quiroga AndiaAinda não há avaliações

- Body Flange Design-Appx-2Documento4 páginasBody Flange Design-Appx-2Matthieu100% (1)

- Din 8074 Pehd PipesDocumento20 páginasDin 8074 Pehd PipesAli MkawarAinda não há avaliações

- Expansion JointsDocumento20 páginasExpansion JointsFawas MudarAinda não há avaliações

- STD PipingDocumento51 páginasSTD PipingRodrigo Iván Latorre AlmirallAinda não há avaliações

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAinda não há avaliações

- Cast-In-Situ Bored Piling Works by ConventionalMethod1Documento11 páginasCast-In-Situ Bored Piling Works by ConventionalMethod1jitendraAinda não há avaliações

- Structural Steel Design to Eurocode 3 and AISC SpecificationsNo EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsAinda não há avaliações

- Aging Management Guideline For Commercial Nuclear Power PlantDocumento292 páginasAging Management Guideline For Commercial Nuclear Power PlantEuAinda não há avaliações

- Attachment 9 - Pipeline Stream Crossing Construction Mode DeterminationDocumento48 páginasAttachment 9 - Pipeline Stream Crossing Construction Mode DeterminationAly AnisAinda não há avaliações

- Pipeline Pig Launchers Recievers Design CodesDocumento2 páginasPipeline Pig Launchers Recievers Design Codesankur2061Ainda não há avaliações

- Centrifugal Pump BrochuresDocumento16 páginasCentrifugal Pump BrochuresAbsar Mamun100% (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceNo EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceNota: 5 de 5 estrelas5/5 (1)

- Din 939Documento5 páginasDin 939rafael_engineer100% (3)

- Anchor SupportsDocumento7 páginasAnchor Supportstejasp8388Ainda não há avaliações

- NORSOK M-630 Edition 6 Draft For HearingDocumento146 páginasNORSOK M-630 Edition 6 Draft For Hearingcaod1712100% (1)

- ASTT - Guidelines For Horizontal DirectiDocumento45 páginasASTT - Guidelines For Horizontal Directiamir_hayfa100% (1)

- Hydraulic Tubes and PipesDocumento18 páginasHydraulic Tubes and Pipeshp_vijaykAinda não há avaliações

- Brazing ProcedureDocumento2 páginasBrazing ProcedureNoel Delos SantosAinda não há avaliações

- OxyChem Caustic HandbookDocumento64 páginasOxyChem Caustic HandbookAnonymous Kr13NEBAinda não há avaliações

- 8217 2Documento7 páginas8217 2Yang WuAinda não há avaliações

- 1 Layout, Pipe ConfigurationDocumento12 páginas1 Layout, Pipe ConfigurationYang WuAinda não há avaliações

- Werknorm: Layout Diagram, Pipe RoutingDocumento6 páginasWerknorm: Layout Diagram, Pipe RoutingYang WuAinda não há avaliações

- Bimetal Thermometers Model 52, Industrial Series: ApplicationsDocumento4 páginasBimetal Thermometers Model 52, Industrial Series: ApplicationsAhrian BenaAinda não há avaliações

- Bayer: Pipes With Low-Temperature Insulation, SuspendedDocumento5 páginasBayer: Pipes With Low-Temperature Insulation, SuspendedYang WuAinda não há avaliações

- Un 2004-03 - Ud-Au-000-Eb-00009 PDFDocumento3 páginasUn 2004-03 - Ud-Au-000-Eb-00009 PDFManjeet SainiAinda não há avaliações

- PL 008748Documento10 páginasPL 008748ronaldxmenAinda não há avaliações

- DIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDocumento8 páginasDIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveLoander David GeronimoAinda não há avaliações

- Manual de Segurança Samson3241Documento20 páginasManual de Segurança Samson3241luis claudio c, vieiraAinda não há avaliações

- ValvulaDocumento8 páginasValvulaJosé Gasset Del ValleAinda não há avaliações

- Steam TrapDocumento2 páginasSteam TrapAmpornchai PhupolAinda não há avaliações

- RTDDocumento68 páginasRTDMaria DenetAinda não há avaliações

- Steel Supply Sub-Grades To EC3Documento22 páginasSteel Supply Sub-Grades To EC3Anonymous iS33V5Ainda não há avaliações

- Series 240 Pneumatic Control Valve Type 3241-1 and Type 3241-7 Globe Valve Type 3241Documento8 páginasSeries 240 Pneumatic Control Valve Type 3241-1 and Type 3241-7 Globe Valve Type 3241SantaAgataAinda não há avaliações

- Sigh Glass PDFDocumento2 páginasSigh Glass PDFMintone Sajayah BekabekaAinda não há avaliações

- ALPEMA Standards Rev1Documento8 páginasALPEMA Standards Rev1nattusharanAinda não há avaliações

- FCD VLENTB0200 Mark200TB AQ PDFDocumento36 páginasFCD VLENTB0200 Mark200TB AQ PDFmetal_dung2Ainda não há avaliações

- GI - Thermowell CatalogueDocumento18 páginasGI - Thermowell CatalogueMahdy MazinyAinda não há avaliações

- Att 2 - EdsDocumento30 páginasAtt 2 - Eds정동현Ainda não há avaliações

- ErmetoDocumento14 páginasErmetoJavier VespaAinda não há avaliações

- Catálogo DP InglêsDocumento20 páginasCatálogo DP Inglêsjf2003Ainda não há avaliações

- Catalog Tevi Pag FDocumento12 páginasCatalog Tevi Pag FGPAinda não há avaliações

- 11422Documento10 páginas11422balajivangaruAinda não há avaliações

- Oil Weiller NB65-200 02 0207 Lub OilDocumento20 páginasOil Weiller NB65-200 02 0207 Lub OiliradankeAinda não há avaliações

- Tip 3241-7 PozicionatorDocumento8 páginasTip 3241-7 PozicionatorEmir DelicAinda não há avaliações

- Piping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0Documento44 páginasPiping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0josphinvalarAinda não há avaliações

- SAMSON Globe 3241Documento12 páginasSAMSON Globe 3241Shaheen HydrosAinda não há avaliações

- p128 22 PDFDocumento3 páginasp128 22 PDFFernando CeballosAinda não há avaliações

- SL26X H 7Documento8 páginasSL26X H 7tecnicodakronAinda não há avaliações

- En10028 2Documento12 páginasEn10028 2Patilea Daniela100% (1)

- PB TW10 GBDocumento6 páginasPB TW10 GBfebri_bontangAinda não há avaliações

- Chapter1 TriClamp Connection CS003EDocumento0 páginaChapter1 TriClamp Connection CS003Ekingathur26681Ainda não há avaliações

- Asco Direct Acting Solenoid Valve - 320Documento6 páginasAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- rc61180 b09Documento9 páginasrc61180 b09eww08Ainda não há avaliações

- Techical Delivery Conditions PDFDocumento31 páginasTechical Delivery Conditions PDFGoran DjuricAinda não há avaliações

- DIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84Documento2 páginasDIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84nunosobralAinda não há avaliações

- Catalog Valve KSBDocumento58 páginasCatalog Valve KSByoboo100% (1)

- Clorius Controls 3-Way Control Valves TYPE Soft Seated: Nodular Cast Iron, DN 80 - 300 MM InstructionsDocumento29 páginasClorius Controls 3-Way Control Valves TYPE Soft Seated: Nodular Cast Iron, DN 80 - 300 MM InstructionsromanAinda não há avaliações

- High Temp Resistant SteelDocumento14 páginasHigh Temp Resistant SteelrajivashishAinda não há avaliações

- Hydraulic Check ValveDocumento8 páginasHydraulic Check ValveswainpiyushAinda não há avaliações

- 1717949Documento2 páginas1717949vikas_ojha54706Ainda não há avaliações

- All ValveDocumento7 páginasAll ValveDnyaneshwarAinda não há avaliações

- 3051CDocumento5 páginas3051CAntonio FloresAinda não há avaliações

- Alufusion Eng TrocalDocumento226 páginasAlufusion Eng TrocalSid SilviuAinda não há avaliações

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryAinda não há avaliações

- B 45-75kW IA102-BDocumento7 páginasB 45-75kW IA102-BYang WuAinda não há avaliações

- NHC NHU NH60Hz IA144-CDocumento9 páginasNHC NHU NH60Hz IA144-CYang WuAinda não há avaliações

- 60hz Cast Iron Pump ChineseDocumento2 páginas60hz Cast Iron Pump ChineseYang WuAinda não há avaliações

- Bayer: Pipes With Low-Temperature Insulation, SuspendedDocumento5 páginasBayer: Pipes With Low-Temperature Insulation, SuspendedYang WuAinda não há avaliações

- Wns Type Energy-Saving BoilerDocumento14 páginasWns Type Energy-Saving BoilerYang WuAinda não há avaliações

- Bayer AGDocumento5 páginasBayer AGYang WuAinda não há avaliações

- Bayer AGDocumento5 páginasBayer AGYang WuAinda não há avaliações

- 8249Documento13 páginas8249Yang WuAinda não há avaliações

- 06.-Medidor Cloro CL4000enDocumento18 páginas06.-Medidor Cloro CL4000enLeonel RubioAinda não há avaliações

- Chapter 04Documento49 páginasChapter 04rowatersAinda não há avaliações

- E 215 Self Stick Pipe MarkerDocumento2 páginasE 215 Self Stick Pipe MarkerGautam SawhneyAinda não há avaliações

- 2016 MacDougall - ACI - Measured Load Capacity of Buried PipesDocumento12 páginas2016 MacDougall - ACI - Measured Load Capacity of Buried PipesAdeel FaisalAinda não há avaliações

- 81btm001 Manual Tehnic Instal OrigDocumento8 páginas81btm001 Manual Tehnic Instal OrigSiretlicAinda não há avaliações

- Auto LiftDocumento22 páginasAuto LiftIshan RanganathAinda não há avaliações

- Dynasonics TFX Ultra ManualDocumento120 páginasDynasonics TFX Ultra ManualToto SukisnoAinda não há avaliações

- Concrete-Polymer Materials: Fifth Topical Report Edited by 6.W. L.EDocumento115 páginasConcrete-Polymer Materials: Fifth Topical Report Edited by 6.W. L.EPrathmesh BharukaAinda não há avaliações

- EngineTorqueSpecs - International MaxxForce 11 13 - 2007 PDFDocumento3 páginasEngineTorqueSpecs - International MaxxForce 11 13 - 2007 PDFRicardo Oliver Ruiz IbarraAinda não há avaliações

- Jacketing With Tedlar - PVF Both Al and SS AlloyDocumento1 páginaJacketing With Tedlar - PVF Both Al and SS AlloyVishnu DuttaAinda não há avaliações

- Hydraulic Lines and FittingsDocumento23 páginasHydraulic Lines and FittingsMohammed Al-OdatAinda não há avaliações

- Manual CDI 5200Documento2 páginasManual CDI 5200Martin CastroAinda não há avaliações

- Water Motor Gong (EA) DatasheetDocumento4 páginasWater Motor Gong (EA) DatasheetsalesAinda não há avaliações

- How To Build A Rubens TubeDocumento3 páginasHow To Build A Rubens TubeEinar Örn BergssonAinda não há avaliações

- BS 05306-4-2001 PDFDocumento76 páginasBS 05306-4-2001 PDFXAVIER RUBIOAinda não há avaliações

- Chemistry Laboratory: Group 1Documento51 páginasChemistry Laboratory: Group 1Rachel Ann De LeonAinda não há avaliações

- Discharge Hose FH-40HC - Rv05Documento1 páginaDischarge Hose FH-40HC - Rv05Pablo Sanchez AmpueroAinda não há avaliações

- Cortacesped Tractor LTH1842Documento16 páginasCortacesped Tractor LTH1842Diego ChamorroAinda não há avaliações

- 250 KVA DG Ex. Work BOQ of CommercialDocumento1 página250 KVA DG Ex. Work BOQ of CommercialSandeep SharmaAinda não há avaliações