Escolar Documentos

Profissional Documentos

Cultura Documentos

8214 2

Enviado por

Yang WuTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

8214 2

Enviado por

Yang WuDireitos autorais:

Formatos disponíveis

Hanging pipe support for pipes with heat insulation,

surrounding pipe support,

slide bearing and fixed point, ferritic steel

temperature 20 C to 300 C; nominal diameter 25 to 200

Werknorm

8214-2

August 2001

Replaces Standards 8214

version 08.2000

Contents

1

2

3

3.1

3.2

4

5

Page

Layout, pipe configuration..................................................................................................................... 1

Pipe supports, dimensions.................................................................................................................... 2

Mounting the pipe support .................................................................................................................... 5

Mounting system types A, B and C....................................................................................................... 5

Mounting system types D1 and D2 ....................................................................................................... 7

Pipeline thermal expansion................................................................................................................... 9

Weights, Drawings.............................................................................................................................. 10

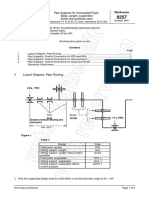

Layout, pipe configuration

Pos. U

FPH

Pos. V

Pos. U

SBH

SBHL

FPH

Distance from bearing to fixed point

max. 30 m

Fig. 1.

Table 1.

Designation

Slide bearing, hanging

Slide bearing, hanging, side movable

Fixed point, hanging

Standards Leverkusen

Code

Dim. standard

SBH

CS 8214-2

SBHL, U, V

CS 8217-2

FPH

CS 8214-2

Page 1 of 11

Werknorm 8214-2 August 2001

Pipe supports are selected on the basis of Company Standard 8214-2 according to:

-

outside pipe diameter

temperature (inside pipe temperature)

insulation thickness

Slide bearings specified in this standard are designed for a maximum distance from the fixed point of 30 m.

-

For longer distances, slide bearing length l1 must be checked and corrected as needed. The diagram in Fig. 8 on

page 9 showing thermal expansion, fixed-point distances and temperature differences is intended as an aid.

The specific pipe support type is determined with reference to the required insulation thickness s1 and the base

dimension h1.

Pipe support type 6 as shown in the standard drawings is specified for pipe supports conforming to this standard in

which criteria (e.g. space problems, access) other than insulation thickness s1 (inside pipe temperature) must be

taken into account in determining h1.

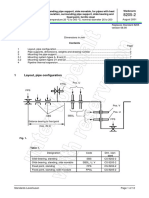

Pipe supports, dimensions

SBH for all mounting system types

FPH for mounting system types D1, D2

b

l1

s1

d1

h3

h1

h2

T 80

FPH:

SBH:

Fig. 2.

l1 = 200 mm

Inside pipe temperature

20 C to 200 C

l1 = 200 mm

over 200 C to 300 C

l1 = 300 mm

WN

CS 8250

8250

Insulation thickness s1 is selected with reference

to inside pipe temperature in accordance with

CS 81011, Part 1

SBH-type pipe supports for all mounting system types, FPH supports for mounting system types D1

and D2

In the case of FPH-type pipe supports for mounting system types D1 and D2, additional parts (flat steel bar

30x8x35) are welded to the T-profile. See Section 3.2. for positioning.

Standards Leverkusen

Page 2 of 11

Werknorm 8214-2 August 2001

FPH for mounting system types A, B and C, l1 = 200 mm

b

l1

T 80

h1

h2

d1

h3

s1

A

A-A

Cam, angle steel

Nocken

L- Stahl DIN EN 10055-1

ND 25 to ND 50 L20x3x30

ND 65 to ND 200 L30x4x50

DN 25 bis DN 50 L20x3x30

DN 65 bis DN 200 L30x4x50

Fig. 3. FPH-type pipe supports for mounting system types A, B and C

FPH-type pipe supports mounting system types A, B and C must have two or four drilled holes measuring 18.

The position of the holes depends upon the mounting system type and can be determined on the basis of the

diagrams in Section 3.1.

Table 2. Dimension h1 for SBH and FPH pipe supports

Nominal

diameter

d1

40

h1

Insulation thickness s1

60

80

100

25

33.7

122

142

162

182

232

32

42.4

126

146

166

186

236

40

48.3

129

149

169

189

239

50

60.3

135

156

176

196

246

65

76.1

144

164

184

204

254

80

88.9

150

170

190

210

260

100

114.3

165

185

205

225

275

125

139.7

178

198

218

238

288

150

168.3

212

232

252

272

302

200

219.1

238

258

278

298

328

Pipe

Pipe supports

120

Nomenclature for a pipe support for a ND 50 pipe, Slide bearing, hanging, temperature to 200 C, insulation

thickness s1 = 60 mm, prepared for mounting system type A1:

Pipe support CS 8214-2-50 SBH 200-60 A1

Standards Leverkusen

Page 3 of 11

Werknorm 8214-2 August 2001

Table 3. Dimensions h2 and h3 for SBH-type pipe supports for all mounting system types and FPHtype pipe supports for mounting system types D1 and D2

Pipe

Nominal

diameter

d1

25

33.7

32

42.4

40

48.3

50

60.3

65

76.1

80

88.9

100

114.3

125

139.7

150

168.3

200

219.1

Pipe support type

h2 + h3

Insulation thickness s1

40

60

80

100

120

80+20

80+40

80+60

80+80

80+130

80+40

80+60

80+80

80+100

80+130

Table 4. Dimensions h2 and h3 for FPH-type pipe supports for mounting system types A, B and C

Pipe

Nominal

diameter

d1

25

33.7

32

42.4

40

48.3

50

60.3

65

76.1

80

88.9

100

114.3

125

139.7

150

168.3

200

219.1

Pipe support type

Standards Leverkusen

h2 + h3

Insulation thickness s1

40

100

120

100+20 100+40

100+60

100+110

100+20 100+40 100+60

100+80

100+110

100

60

80

Page 4 of 11

Werknorm 8214-2 August 2001

3

3.1

Mounting the pipe support

Mounting system types A, B and C

Mounting

101 mm for slide plate A80

121 mm for slide plate A100

9mm for ND 200

Fig. 4. Mounting system, slide bearing, hanging, with hook bolts.

The distance from the middle of the pipe support to the lower edge of the I-beam is h1 + 8 mm.

Table 5. Parts list for mounting system, slide bearing, hanging, with hook bolts as shown in Fig. 4

Quantity

for

mounting

A

B

C

1

1

1

Pipe support

Nomenclature

Material

Pos.

no.

DIN no.

CS no.

Part no.

Remarks

Slide plate A80

USt 37-2

RSt 37-2

1.4510

Slide plate A100

1.4510

Hook bolt M 16 x 32K

4.6/5

for

ND 125

for

ND 150

galvanized

Hook bolt M 16 x 90K

4.6/5

CS 8226

1 292 001

CS 8226

1 291 002

CS 8227

1 304 506

CS 8227

1 304 508

Washer 16

St

DIN EN ISO 7091

1 345 035

Lock washer C 18-F

St 37-2

CS 8399

1 290 752

Washer 17.5

St

DIN 436

1 345 115

galvanized

2

) See Table 8 for individual part drawings.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other types of anti-corrosion treatment

required are to be indicated in the order.

Standards Leverkusen

Page 5 of 11

Werknorm 8214-2 August 2001

mounting

Fig. 5. Mounting system, fixed point, hanging, with hex bolts

Table 6. Parts list for mounting system, fixed point, hanging, with hex bolts as shown in Fig. 5

Quantity

for

mounting

A

B

C

Nomenclature

DIN no.

CS no.

Part no.

Remarks

PP

Material

Pos.

no.

USt 37-2

RSt 37-2

Pipe support

Separator plate - D 100

Hex bolt M 16 x 40

4.6/5

DIN EN ISO 4018

DIN EN ISO 4034

galvanized

Hex bolt M 16 x 100

4.6/5

DIN EN ISO 4016

DIN EN ISO 4034

galvanized

Washer 16

St

DIN EN ISO 7091

1 345 035

Lock washer C 18-F

St 37-2

CS 8399

1 290 752

Washer 17.5

St

DIN 436

)

)

)

1 345 115

1

) See Table 10 for individual part drawings.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other types of anti-corrosion treatment

required are to be indicated in the order.

Standards Leverkusen

Page 6 of 11

Werknorm 8214-2 August 2001

3.2

Mounting system types D1 and D2

Mounting system D

SBH

130 mm for ND 125,

150 mm for ND 150

20,5 mm for ND 200

Fig. 6. Mounting system, slide bearing, hanging, with guide claws

The distance from the middle of the pipe support to the lower edge of the I-beam is h1 + 19,5 mm.

Table 7. Parts list for mounting system, slide bearing, hanging, with guide claws as shown in Fig. 6

Quantity

for

mounting

D1

D2

Nomenclature

Pipe support

Guide claw, right

Guide claw, left

DIN no.

Drawing no.

Part no.

Material

Pos.

Nr.

1.4541/1.4301

EL 44 599 - 4N

1 292 405

EL 44 598 - 4N

GTW 40

GTW 40

Hex bolt M 12 x 65

4.6/5

Hex bolt M 12 x 90

4.6/5

Remarks

1 292 400

DIN EN ISO 4016

DIN EN ISO 4034

DIN EN ISO 4016

DIN EN ISO 4034

galvanized

galvanized

) See Table 8 for individual part drawings.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other types of anti-corrosion treatment

required are to be indicated in the order.

Standards Leverkusen

Page 7 of 11

Werknorm 8214-2 August 2001

Mounting system D

FPH

Pos. 5 for mounting

system D2

Pos. 5 for mounting

system D1

for

for

for

130 mm for ND 125,

150 mm for ND 150

20,5 mm for ND 200

Fig. 7. Mounting system, fixed point, hanging, with guide claws

Table 8. Parts list for mounting system, fixed point, hanging, with guide claws as shown in Fig. 7

Quantity

for

mounting

D1

D2

Nomenclature

Pipe support

Guide claw, right

Guide claw, left

Material

Pos.

no.

USt 37-2

RSt 37-2

GTW 40

GTW 40

DIN no.

Drawing no.

Part no.

Remarks

EL 44 599 - 4N

)

)

1 292 405

3

EL 44 598 - 4N

1 292 400

2

Hex bolt M 12 x 65

4.6/5-2

DIN EN ISO 4016

DIN EN ISO 4034

galvanized

Hex bolt M 12 x 90

4.6/5-2

DIN EN ISO 4016

DIN EN ISO 4034

galvanized

Flat steel bar 35x8x35

USt 37-2

DIN 1017-1

galvanized

) See Table 8 for individual part drawings.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other types of anti-corrosion treatment

required are to be indicated in the order.

Standards Leverkusen

Page 8 of 11

Werknorm 8214-2 August 2001

Pipeline thermal expansion

Dist. from fixed point

Fig. 8.

Thermal expansion: ferritic steel

Standards Leverkusen

Page 9 of 11

Werknorm 8214-2 August 2001

Weights, Drawings

Table 9.

Pipe support weights

SBH, all mounting system types l1 = 200 or 300 mm

FPH, mounting system types D1 and D2, l1 = 200 mm

Nominal

diameter

25

32

40

50

65

80

100

125

150

200

25

32

40

50

65

80

100

125

150

200

40

Weight in kg ( = 7.85 kg/dm )

Insulation thickness s1

60

80

100

120

Inside pipe temperature 20 C to 200 C, and l1 = 200 mm

3.00

3.13

3.25

3.38

3.69

3.06

3.19

3.31

3.44

3.75

3.11

3.24

3.36

3.49

3.80

3.59

3.72

3.84

3.97

4.28

3.75

3.88

4.00

1.13

4.44

3.93

4.06

4.19

4.30

4.61

5.77

5.90

6.03

6.15

6.46

6.16

6.29

6.42

6.54

6.85

6.79

6.92

7.04

7.17

7.36

7.92

8.05

8.17

8.30

8.49

Inside pipe temperature over 200 C to 300 C. and l1 = 300 mm

4.07

4.13

4.18

4.66

4.83

5.00

6.84

7.24

7.86

8.99

4.20

4.26

4.31

4.91

4.95

5.13

6.97

7.36

7.99

9.11

4.32

4.39

4.43

5.04

5.08

5.26

7.09

7.49

8.11

9.24

4.45

4.51

4.56

5.16

5.20

5.38

7.22

7.61

8.24

9.37

Pipe support

drawing

no.

4.76

4.82

4.87

5.47

5.51

5.69

7.53

7.92

8.43

9.56

Table 10. FPH-type pipe support weights, mounting system types A, B and C, l1 = 200 mm

Nominal

diameter

25

32

40

50

65

80

100

125

150

200

40

3.97

4.03

4.08

4.67

4.83

5.01

7.18

7.58

8.22

9.33

Standards Leverkusen

Weight in kg ( = 7.85 kg/dm )

Insulation thickness s1

60

80

100

120

4.10

4.16

4.21

4.80

4.96

5.24

7.31

7.71

8.35

9.46

4.67

4.73

4.78

5.37

5.53

5.81

7.88

8.28

8.80

9.91

4.23

4.29

4.34

4.93

5.09

5.37

7.44

7.84

8.48

9.59

4.36

4.42

4.47

5.06

5.22

5.50

7.57

7.97

8.61

9.72

Pipe support

drawing

no.

Page 10 of 11

Werknorm 8214-2 August 2001

List of standards cited

DIN 436

Square washers for use in timber constructions

DIN 1017-1

Steel bars; Hot rolled flat steel for general purpose; Dimensions, weights, permissible

variations

DIN 1025-2

Hot rolled I-beams; Part 2: Wide flange I-beams, IPB-series; Dimensions, masses,

sectional properties

DIN EN 10055

Hot rolled steel equal flange tees with radiused root and toes; Dimensions and tolerances

on shape and dimensions; German version EN 10055:1995

DIN EN 10 056-1

Structural steel equal and unequal leg angles; Part 1: Dimensions; German version

EN 10056-1:1998

DIN EN ISO 4016

Hexagon head bolts; Product grade C (ISO 4016:1999); German version

EN ISO 4016:2000

DIN EN ISO 4018

Hexagon head screws; Product grade C (ISO 4018:1999); German version

EN ISO 4018:2000

DIN EN ISO 4034

Hexagon nuts; Product grade C (ISO 4034:1999); German version EN ISO 4034:2000

DIN EN ISO 7091

Plain washers; Normal series; Product series C; (ISO 7091: 2000); German version

EN ISO 7091:2000

CS 8101-1

Heat insulation; insulation layer thickness, definitions, terms

CS 8110

Pipe supports; anti-corrosion treatment; specifications

CS 8217-2

Pipe supports, hanging, side movable, for pipes with heat insulation, surrounding pipe

support, slide bearing and fixed point; ferritic steel, temperature 20 C to 300 C; nominal

diameter 25 to 200

CS 8226

Pipe supports; slide plates and separator plates for piping from ND 25 to 200

CS 8227

Pipe supports; hook bolts

CS 8250

Pipe supports; pipe clamps for nominal diameters 15 to 1000

CS 8252

Pipe supports; pipe clamps for nominal diameters 25 to 500

CS 8399

Pipe supports; lock washers for double-angle bridges

Previous versions

CS 8214: 1970-12; 1974-05; 1976-05; 1980-10; 1982-04; 1982-6; 1982-08;1998-04;1999-08; 2000-08

Changes

The following changes were made to the version of August 2000:

a) Company Standard 8214 was revised and issued separately as CS 8214-2 for ferritic steel.

b) DIN standards updated

Standards Leverkusen

Page 11 of 11

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- GE Basic Appliance Training 31 91611Documento68 páginasGE Basic Appliance Training 31 91611dreamyson1983Ainda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Ch-21 Sand CastingDocumento156 páginasCh-21 Sand CastingDivya SoniAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Column Web and Beam Web BoltedDocumento5 páginasColumn Web and Beam Web BoltedGURUPRASAD SHETTY100% (1)

- Steel Design 2Documento19 páginasSteel Design 2John Pierce Gumapac67% (3)

- Finite Element Analysis of Laminated Structural Glass Plates With Polyvinyl Butyral (PVB) Interlayer PDFDocumento8 páginasFinite Element Analysis of Laminated Structural Glass Plates With Polyvinyl Butyral (PVB) Interlayer PDFRobert VochescuAinda não há avaliações

- Threaded Couplings, Steel, Black or Zinc-Coated (Galvanized) Welded or Seamless, For Use in Steel Pipe JointsDocumento5 páginasThreaded Couplings, Steel, Black or Zinc-Coated (Galvanized) Welded or Seamless, For Use in Steel Pipe JointsBillAinda não há avaliações

- API 510 Exam Q.bank-V VVV ImportantDocumento138 páginasAPI 510 Exam Q.bank-V VVV ImportantJeganeswaranAinda não há avaliações

- 22-23-4 Iec60598 - NovalitingDocumento61 páginas22-23-4 Iec60598 - NovalitingLuis Fernando ValenciaAinda não há avaliações

- Damage of Refractory Bricks Lined in Cement Rotary Kiln: Technical Research Laboratory, Mino Yogyo Co. LTD., JapanDocumento10 páginasDamage of Refractory Bricks Lined in Cement Rotary Kiln: Technical Research Laboratory, Mino Yogyo Co. LTD., JapanPham tony1604Ainda não há avaliações

- Eyectors PDFDocumento110 páginasEyectors PDFDiego Rincon100% (1)

- B 45-75kW IA102-BDocumento7 páginasB 45-75kW IA102-BYang WuAinda não há avaliações

- 60hz Cast Iron Pump ChineseDocumento2 páginas60hz Cast Iron Pump ChineseYang WuAinda não há avaliações

- NHC NHU NH60Hz IA144-CDocumento9 páginasNHC NHU NH60Hz IA144-CYang WuAinda não há avaliações

- Wns Type Energy-Saving BoilerDocumento14 páginasWns Type Energy-Saving BoilerYang WuAinda não há avaliações

- Bayer: Pipes With Low-Temperature Insulation, SuspendedDocumento5 páginasBayer: Pipes With Low-Temperature Insulation, SuspendedYang WuAinda não há avaliações

- Bayer AGDocumento5 páginasBayer AGYang WuAinda não há avaliações

- Bayer AGDocumento5 páginasBayer AGYang WuAinda não há avaliações

- 8217 2Documento7 páginas8217 2Yang WuAinda não há avaliações

- 8249Documento13 páginas8249Yang WuAinda não há avaliações

- Werknorm: Layout Diagram, Pipe RoutingDocumento6 páginasWerknorm: Layout Diagram, Pipe RoutingYang WuAinda não há avaliações

- 8202 2Documento10 páginas8202 2Yang WuAinda não há avaliações

- 1 Layout, Pipe ConfigurationDocumento12 páginas1 Layout, Pipe ConfigurationYang WuAinda não há avaliações

- FN Steel Datasheet Spring Steels ENG-V2Documento2 páginasFN Steel Datasheet Spring Steels ENG-V2ariAinda não há avaliações

- AISI 4130: Incoloy Alloys, Fast QuoteDocumento5 páginasAISI 4130: Incoloy Alloys, Fast QuoteSantanu SahaAinda não há avaliações

- ASMEDocumento77 páginasASMEJitendra BhosaleAinda não há avaliações

- Singly Reinforced Beam in Excel FormatDocumento6 páginasSingly Reinforced Beam in Excel FormatVEERKUMARAinda não há avaliações

- Durafit Installation GuideDocumento3 páginasDurafit Installation GuideBrian EnderwitzAinda não há avaliações

- Z0011542-2008-A Air-Cooled AHYZ1 Series TC2Documento52 páginasZ0011542-2008-A Air-Cooled AHYZ1 Series TC2mgs nurmansyahAinda não há avaliações

- Ferro Electric MaterialsDocumento39 páginasFerro Electric MaterialsMohanrajRajangamAinda não há avaliações

- Simplair Evolution Brochure - US PDFDocumento20 páginasSimplair Evolution Brochure - US PDFRubén Bautista BalderasAinda não há avaliações

- AspalDocumento104 páginasAspalKholis FindmeAinda não há avaliações

- CIP35 - Testing Compressive Strength of ConcreteDocumento2 páginasCIP35 - Testing Compressive Strength of ConcreteGerardo BeckerAinda não há avaliações

- Holophane RSL-200 Series Brochure 8-78Documento8 páginasHolophane RSL-200 Series Brochure 8-78Alan MastersAinda não há avaliações

- Lime in ConstructionDocumento7 páginasLime in Constructionsriatul2006Ainda não há avaliações

- Series: Technical DataDocumento8 páginasSeries: Technical DataAnonymous yPWi8p3KkAAinda não há avaliações

- Emergency Estimate $72,590.61Documento19 páginasEmergency Estimate $72,590.61Corporate OfficeAinda não há avaliações

- Compressible Flow ExamplesDocumento3 páginasCompressible Flow ExamplesMikaila Denise LoanzonAinda não há avaliações

- Moment Calculations - CORRECTDocumento5 páginasMoment Calculations - CORRECTBipul PoudelAinda não há avaliações

- Dieless Wire Drawing-An Experimental and Numerical Analysis: P. Tiernan, M.T. HilleryDocumento6 páginasDieless Wire Drawing-An Experimental and Numerical Analysis: P. Tiernan, M.T. HillerycostytzuAinda não há avaliações

- Consider A Steam Power Plant Operating On The Ideal Rankine CycleDocumento1 páginaConsider A Steam Power Plant Operating On The Ideal Rankine CyclegandhiramAinda não há avaliações

- Cvp68 - Mini Project Synopsis: Title of The Project: Analysis and Design of Multistoried FrameDocumento3 páginasCvp68 - Mini Project Synopsis: Title of The Project: Analysis and Design of Multistoried FrameSHAHBAZ M MAINUDDINAinda não há avaliações