Escolar Documentos

Profissional Documentos

Cultura Documentos

Content The STP Guide - Design, Operation and Maintenance Content The STP Guide - Design, Operation and Maintenance

Enviado por

Benadict JoshuaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Content The STP Guide - Design, Operation and Maintenance Content The STP Guide - Design, Operation and Maintenance

Enviado por

Benadict JoshuaDireitos autorais:

Formatos disponíveis

The Operating Principle of STPs

Typical Process in an STP

Benefits of a well-run STP

Understanding the STP Stages

Bar Screen Chamber

11 Function

12 How It Works

13 Design Criteria

14 Construction And Engineering

15 Operation And Maintenance Considerations

16 Troubleshooting

Oil And Grease/Grit Trap

21 Function

22 How It Works

23 Design Criteria

24 Construction And Engineering

25 Operation And Maintenance Considerations

26 Troubleshooting

Equalization Tank

31 Function

32 How It Works

33 Design Criteria

34 Construction And Engineering

35 Operation And Maintenance Considerations

36 Troubleshooting

Raw Sewage Lift Pumps

41 Function

42 How It Works

43 Design Criteria

44 Construction And Engineering

45 Operation And Maintenance Considerations

46 Troubleshooting

Aeration Tank

51 Function

52 How it works

53 Design Criteria

54 Construction And Engineering

55 Operation And Maintenance Considerations

56 Troubleshooting

Secondary Clarifier/Settling Tank

61 Function

62 How It Works

621 Settling tank with air-lift pump

622 Settling tank with direct-suction electric pump

623 Settling tank with buffer sump

624 Mechanized Clarifier Tank

63 Design Criteria

64 Construction And Engineering

65 Operation And Maintenance Considerations

66 Troubleshooting

Sludge Recirculation

71 Function

72 How It Works

73 Design Criteria

74 Construction And Engineering

75 Operation And Maintenance Considerations

76 Troubleshooting

Clarified Water Sump

81 Function

82 Design Criteria

83 Construction And Engineering

84 Operation And Maintenance Considerations

85 Troubleshooting

Filter Feed Pumps (FFP)

91 Function

92 Design Criteria

93 Construction And Engineering

94 Operation And Maintenance Considerations

95 Troubleshooting

Pressure Sand Filter (PSF)

101 Function

102 How It Works

103 Design Criteria

104 Construction And Engineering

105 Operation And Maintenance Considerations

106 Troubleshooting

Activated Carbon Filter (ACF)

111 Function

112 How It Works

113 Design Criteria

114 Construction And Engineering

115 Operation And Maintenance Considerations

116 Troubleshooting

Disinfection Of Treated Water

121 Function

122 Design Criteria

113 Construction And Engineering

124 Operation And Maintenances Considerations

125 Troubleshooting

Excess Sludge Handling

131 Function

Content

6 | The STP Guide Design, Operation and Maintenance |

132 Design Criteria

133 Construction And Engineering

1331 Plate-and-Frame Filter press

1332 Bag-type dewatering

134 Operation And Maintenance Considerations

135 Troubleshooting

Miscellaneous Considerations

Design and Engineering

STP Design Process

Design process overview

Design Criteria for STP

Sewage Quantity (STP Capacity)

Bar Screen Chamber

Equalization Tank

Raw Sewage Lift Pumps

Aeration Tank

Clarifier Tank

Airlift Pump

Electric Pumps for Return Sludge

Sludge-holding sump

Pressure Sand Filter

Activated Carbon Filter

Sodium Hypo Dosing System

Sludge-Handling System

Engineering checks for the STP

Preparation

Bar Screen

Equalization tank

Raw Sewage Lift Pumps

Aeration tank

Secondary settling tank (Hopper-bottom)

Secondary Clarifier tank (mechanized, with rake)

Sludge Recirculation pumps-Airlift

Sludge Recirculation pumps-Electric

Sludge Recirculation system-Direct suction

Sludge Recirculation system- With a buffer sump

Clarified water tank

Filter feed Pumps

Backwash pumps

Pressure Sand Filter

Activated Carbon filter

Disinfection system

Sludge-Handling system

Air Blowers

MISC

Operational checks for the STP

Preparation

Bar Screen Chamber

Equalization tank

Raw Sewage Lift Pumps

Aeration tank

Secondary settling tank (Hopper-bottom)

Content

8 | The STP Guide Design, Operation and Maintenance |9

Secondary Clarifier tank (mechanized, with rake)

Sludge Recirculation pumps-Airlift

Sludge Recirculation pumps-Electric

Sludge Recirculation system-Direct suction

Sludge Recirculation system- With a buffer sump

Clarified water tank

Filter feed Pumps

Backwash pumps

Pressure Sand Filter

Activated Carbon filter

Disinfection system

Sludge-Handling system

Air Blowers

Você também pode gostar

- 8 Dynamic Well SimulationsDocumento24 páginas8 Dynamic Well SimulationsBAGHFAY16Ainda não há avaliações

- Hydroprocessing for Clean Energy: Design, Operation, and OptimizationNo EverandHydroprocessing for Clean Energy: Design, Operation, and OptimizationAinda não há avaliações

- CompressorsDocumento98 páginasCompressorsprabhjotbhangal88% (8)

- UOP Course DescriptionDocumento2 páginasUOP Course DescriptionVictor Esteban CondorAinda não há avaliações

- Constructed Wetlands for Industrial Wastewater TreatmentNo EverandConstructed Wetlands for Industrial Wastewater TreatmentAlexandros I. StefanakisAinda não há avaliações

- Pump Basics-M& PDocumento80 páginasPump Basics-M& Pkapil100% (2)

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsNo Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsNota: 1 de 5 estrelas1/5 (1)

- Refinery Plant OperationsDocumento295 páginasRefinery Plant Operationsluv_y_kush357575% (8)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineNo EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineNota: 5 de 5 estrelas5/5 (1)

- Lab - Utilisation X Effi. 100Documento13 páginasLab - Utilisation X Effi. 100sivareddy143Ainda não há avaliações

- Palm Oil Effluent Treatment SchemeDocumento11 páginasPalm Oil Effluent Treatment SchemebathalapalliAinda não há avaliações

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1No EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Nota: 3.5 de 5 estrelas3.5/5 (3)

- SchuF Valve Guide v6Documento57 páginasSchuF Valve Guide v6Adam Chapin100% (1)

- Marine Diesel Engines: Maintenance, Troubleshooting, and RepairNo EverandMarine Diesel Engines: Maintenance, Troubleshooting, and RepairNota: 4.5 de 5 estrelas4.5/5 (15)

- WBG Formula-Booklet E-F 2009Documento116 páginasWBG Formula-Booklet E-F 2009anna_nemesisAinda não há avaliações

- Voith Turbo BasicsDocumento49 páginasVoith Turbo BasicsSamir Benabdallah100% (1)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisAinda não há avaliações

- Case Studies of Optimizing and Troubleshooting FCC Reactors and RegeneratorsDocumento31 páginasCase Studies of Optimizing and Troubleshooting FCC Reactors and RegeneratorssagarsrinivasAinda não há avaliações

- An Applied Guide to Water and Effluent Treatment Plant DesignNo EverandAn Applied Guide to Water and Effluent Treatment Plant DesignNota: 5 de 5 estrelas5/5 (4)

- Voith Turbo - BasicsDocumento49 páginasVoith Turbo - Basicssenthil031277100% (1)

- Prepared JHA: Attachment V: The Following Samples/pre-Prepared JHA Are Available For Download atDocumento4 páginasPrepared JHA: Attachment V: The Following Samples/pre-Prepared JHA Are Available For Download atprinceoceanAinda não há avaliações

- Petroleum Production Engineering, A Computer-Assisted ApproachNo EverandPetroleum Production Engineering, A Computer-Assisted ApproachNota: 4.5 de 5 estrelas4.5/5 (11)

- Alfa Laval Pump Handbook PDFDocumento257 páginasAlfa Laval Pump Handbook PDFkashifwarsiAinda não há avaliações

- Mechanical Engineering ContentDocumento1 páginaMechanical Engineering ContentMowaten MasryAinda não há avaliações

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantAinda não há avaliações

- Alfa Laval Pump HandbookDocumento257 páginasAlfa Laval Pump Handbooksen_subhasis_58100% (2)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesNo EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesNota: 1 de 5 estrelas1/5 (2)

- JV 2018.03.08 - Mep MomDocumento2 páginasJV 2018.03.08 - Mep MomBenadict JoshuaAinda não há avaliações

- Assignments Abroad Times - India's Exclusive BI-Weekly Newspaper For Global Job OpportunitiesDocumento2 páginasAssignments Abroad Times - India's Exclusive BI-Weekly Newspaper For Global Job OpportunitiesBenadict Joshua50% (2)

- Daily Progress Report: M/s Shapoorji Pallonji Real Estate M/s Shapoorji Pallonji Engineering & ConstructionDocumento24 páginasDaily Progress Report: M/s Shapoorji Pallonji Real Estate M/s Shapoorji Pallonji Engineering & ConstructionBenadict JoshuaAinda não há avaliações

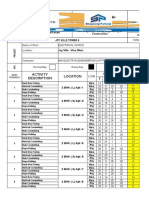

- Site Conditions: Location Qty T C B Activity DescriptionDocumento10 páginasSite Conditions: Location Qty T C B Activity DescriptionBenadict JoshuaAinda não há avaliações

- Rent ReceiptDocumento1 páginaRent ReceiptBenadict JoshuaAinda não há avaliações

- Understanding Process Equipment for Operators and EngineersNo EverandUnderstanding Process Equipment for Operators and EngineersNota: 4.5 de 5 estrelas4.5/5 (3)

- Format Material Transmital TDSDocumento3 páginasFormat Material Transmital TDSBenadict JoshuaAinda não há avaliações

- MK Giridharan Latest EditionDocumento2 páginasMK Giridharan Latest EditionBenadict JoshuaAinda não há avaliações

- Apartment 1 To 6Documento7 páginasApartment 1 To 6Benadict JoshuaAinda não há avaliações

- HT. FROM FFL. Horozontal Ht. From Ffl. Horozontal SN COLOMN NO Location SB No. MODULE (Bottom of SB) LHS RHS (Bottom of SB) LHS RHS 2.5 BHK, Appt-1Documento7 páginasHT. FROM FFL. Horozontal Ht. From Ffl. Horozontal SN COLOMN NO Location SB No. MODULE (Bottom of SB) LHS RHS (Bottom of SB) LHS RHS 2.5 BHK, Appt-1Benadict JoshuaAinda não há avaliações

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentAinda não há avaliações

- S C E T C: Application ID: DEN17317913 Version No: 1Documento1 páginaS C E T C: Application ID: DEN17317913 Version No: 1Benadict JoshuaAinda não há avaliações

- SDFSDFSDFHJKHJKHDocumento2 páginasSDFSDFSDFHJKHJKHBenadict JoshuaAinda não há avaliações

- Distillation Design and Control Using Aspen SimulationNo EverandDistillation Design and Control Using Aspen SimulationNota: 5 de 5 estrelas5/5 (2)

- Lkasdfjasdkf LkasdflkjhaslkdfDocumento2 páginasLkasdfjasdkf LkasdflkjhaslkdfBenadict JoshuaAinda não há avaliações

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNo EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsAinda não há avaliações

- Daily Manpower Report 10..7.2017 - MEPDocumento1 páginaDaily Manpower Report 10..7.2017 - MEPBenadict JoshuaAinda não há avaliações

- Plumbing and Piping Systems Inspection Notes: Up to CodeNo EverandPlumbing and Piping Systems Inspection Notes: Up to CodeNota: 3 de 5 estrelas3/5 (2)

- Daily Manpower Report 8.7.2017 - MEPDocumento16 páginasDaily Manpower Report 8.7.2017 - MEPBenadict JoshuaAinda não há avaliações

- RnthntyjhDocumento1 páginaRnthntyjhBenadict JoshuaAinda não há avaliações

- TIcket Mumbai To ChennaiDocumento3 páginasTIcket Mumbai To ChennaiBenadict JoshuaAinda não há avaliações

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesNo EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesNota: 5 de 5 estrelas5/5 (7)

- SDFSDFSDFHJKHJKHDocumento2 páginasSDFSDFSDFHJKHJKHBenadict JoshuaAinda não há avaliações

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionNo EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionNota: 4.5 de 5 estrelas4.5/5 (16)

- AsdfasdfDocumento2 páginasAsdfasdfBenadict JoshuaAinda não há avaliações

- Multivariable Predictive Control: Applications in IndustryNo EverandMultivariable Predictive Control: Applications in IndustryAinda não há avaliações

- Sullair 185 CFM Compressor Operation & Maintenance & Parts ListDocumento131 páginasSullair 185 CFM Compressor Operation & Maintenance & Parts Listjheinerperez94% (16)

- 9.16. Prepare A Plot of Work Per Pound Mole Versus The Pressue Ratio PDocumento6 páginas9.16. Prepare A Plot of Work Per Pound Mole Versus The Pressue Ratio PttussenoAinda não há avaliações

- Power Electronics and Electric Drives for Traction ApplicationsNo EverandPower Electronics and Electric Drives for Traction ApplicationsAinda não há avaliações

- 11 - Exhibit E - 15 April 07Documento7 páginas11 - Exhibit E - 15 April 07Ahmad Abd RabouAinda não há avaliações

- Chemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningNo EverandChemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningAinda não há avaliações

- MSG® TURBO-AIR® 2000 Centrifugal Air Compressor: FeaturesDocumento3 páginasMSG® TURBO-AIR® 2000 Centrifugal Air Compressor: FeaturesAhmet SaygılıAinda não há avaliações

- HRSG Steam Blow (Load 20 MW) PDFDocumento2 páginasHRSG Steam Blow (Load 20 MW) PDFKanzanah PettaraniAinda não há avaliações

- Flat Panel Display ManufacturingNo EverandFlat Panel Display ManufacturingJun SoukAinda não há avaliações

- Animation Dryer HREDocumento7 páginasAnimation Dryer HREHendri KurniawanAinda não há avaliações

- Natural Gas Processing: Technology and Engineering DesignNo EverandNatural Gas Processing: Technology and Engineering DesignNota: 5 de 5 estrelas5/5 (8)

- Introduction To Steam Seal System of 800Mw Kudgi TurbineDocumento10 páginasIntroduction To Steam Seal System of 800Mw Kudgi TurbineSCEKUDGI 800Ainda não há avaliações

- Oil and Gas Pipelines: Integrity and Safety HandbookNo EverandOil and Gas Pipelines: Integrity and Safety HandbookAinda não há avaliações

- DPM CHECKLISTDocumento1 páginaDPM CHECKLISTShiftinchargeengineer dadri coalAinda não há avaliações

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceAinda não há avaliações

- 8.1 MOBILAIR Portable Compressors "Current Models": Genuine KAESER Maintenance PartsDocumento4 páginas8.1 MOBILAIR Portable Compressors "Current Models": Genuine KAESER Maintenance PartsAnne S. Sokolovska100% (1)

- Process Plant Equipment: Operation, Control, and ReliabilityNo EverandProcess Plant Equipment: Operation, Control, and ReliabilityNota: 5 de 5 estrelas5/5 (1)

- Main Equipment List ISBLDocumento4 páginasMain Equipment List ISBLPaula Vargas AAinda não há avaliações

- Typical HVAC System Installation PDFDocumento1 páginaTypical HVAC System Installation PDFbrodtmtAinda não há avaliações

- SET B With Answer Key Quiz 2 Fluid Machineries (Prof. Enh. 2)Documento4 páginasSET B With Answer Key Quiz 2 Fluid Machineries (Prof. Enh. 2)Famela GadAinda não há avaliações

- Long Tube Vertical EvaporatorDocumento6 páginasLong Tube Vertical EvaporatorKyle HartlerAinda não há avaliações

- Alfa Laval Heating and Cooling Hub Air-Conditioning and Chillers BrochureDocumento6 páginasAlfa Laval Heating and Cooling Hub Air-Conditioning and Chillers BrochureEmmaAinda não há avaliações

- Compressive Fan BlowerDocumento58 páginasCompressive Fan BlowerKiraAinda não há avaliações

- Sample Calculations of Boiler Pumps and IDDocumento5 páginasSample Calculations of Boiler Pumps and IDMelvinDapitanonAinda não há avaliações

- Flowsheet Sistem Utilitas Water Treatment KEL 1Documento1 páginaFlowsheet Sistem Utilitas Water Treatment KEL 1Febri5awalsyahAinda não há avaliações

- BoilersDocumento5 páginasBoilersNisarg ModiAinda não há avaliações

- Me206 QPDocumento2 páginasMe206 QPMohammed Jihad PmAinda não há avaliações

- Compressed Air System: by Raj PrabhakarDocumento21 páginasCompressed Air System: by Raj PrabhakarNabilBouabanaAinda não há avaliações

- Soalan LojiDocumento5 páginasSoalan LojiSilver GrayAinda não há avaliações

- Ebara MLH - 0122Documento6 páginasEbara MLH - 0122DMA ASIAAinda não há avaliações

- Stage 2 SchemeDocumento84 páginasStage 2 Scheme008911Ainda não há avaliações

- Pressure Drop Calculation - Primary Pump & Secondary PumpDocumento6 páginasPressure Drop Calculation - Primary Pump & Secondary PumpAzher AAinda não há avaliações

- Fluid Machinery Problem SetDocumento4 páginasFluid Machinery Problem SetJohn Vincent EslaoAinda não há avaliações

- 2012 Flyer BHS Transporter GBDocumento22 páginas2012 Flyer BHS Transporter GBMona MonicaAinda não há avaliações

- Ash Handling SystemDocumento7 páginasAsh Handling Systemrbdubey2020Ainda não há avaliações

- Jenis BlowerDocumento3 páginasJenis BlowerMuhammad Ridwan TanjungAinda não há avaliações

- Harga Filter & Oli Excavator Kobelco: 1. Preventive Maintenance Sk50P-6Documento1 páginaHarga Filter & Oli Excavator Kobelco: 1. Preventive Maintenance Sk50P-6argya AwangAinda não há avaliações

- Ingersoll Rand Compressors - Consumables For 40-50hpDocumento1 páginaIngersoll Rand Compressors - Consumables For 40-50hpJAinda não há avaliações