Escolar Documentos

Profissional Documentos

Cultura Documentos

160-03 e

Enviado por

Achariya ParpromTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

160-03 e

Enviado por

Achariya ParpromDireitos autorais:

Formatos disponíveis

Technical Paper

Development of 4D95 Engine Series Meeting Tier3

Masaki Tanaka

Keisuke Inoo

Jun Oshima

Masaki Shinohara

The ecot3 engine has been developed and sold on the market as a Komatsu engine series that complies with

the Tier3 exhaust gas regulation. Komatsu has recently completed the development and market entry of its

4D95 engine series as the anchor engines in the series. Not only exhaust gas regulation, but also low noise

and a high fuel consumption efficiency are the important missions in engine development as social demands.

The 4D95 engine series accomplishes these missions and features a good balance without sacrificing the

engine placement property in the vehicle and versatility, which are other missions of the small engine, by

incorporating the state-of-the-art technology to clear the exhaust gas regulation.

Four models in the 4D95 engine series are overviewed and their technical features are introduced.

Key Words: Diesel engine, environmentally friendly, Tier3, electronic control, common rail system, swirl

current chamber system

1. Background

Komatsu has successively developed and commercialized its

engine ecot3 complying with the Tier3 exhaust gas regulations.

The production of an engine series with a piston displacement

of 4.5 to 23 liters covering an output range of 75 to 560kW had

been completed by early 2006. Subsequent to the production

of this engine series, the production of the 4D95 engine series

(piston displacement of 3.3 liters) representing the smallest

piston displacement in the engine series of Komatsu has recently been completed.

The 4D95 engine series complying with the Tier2 exhaust

gas regulation has covered the output range of 40 to 75kW by a

combination of three aspirations (NA [naturally aspirated

engine], T [with turbo] and TAA [with turbo and air-cooled

aftercooler]) and a mechanical fuel injection pump. To comply with the stricter Tier3 exhaust gas regulation, however, a

specification to equip an electronically controlled high-pres-

2007 VOL. 53 NO.160

sure injection system (common rail system) has been added, to

cover the output range of 82kW maximum. Taking the installability and versatility into consideration, the specification

that covers the same output range as that of the Tier2 exhaust

gas regulation continuously uses the mechanical fuel injection

pump. To comply with the emission regulation, the combustion system of the NA and T specifications has been changed to

the swirl current chamber system (IDI - indirect injection).

This paper overviews the 4D95 series, which is regarded as

the anchor engines in the Komatsu ecot3 series, and describes

its technical features.

Development of 4D95 Engine Series Meeting Tier3

1

2. Trends of Emission Regulation for

Construction Machinery Engines

3. Overview of 4D95 Engine Series

As mentioned above, the emission regulations on diesel

engines for construction machinery include the so-called Tier3

exhaust gas regulation centered in Europe and the United

States and on/off-load Tier3 exhaust gas regulation of Japan for

construction machinery.

Figure 1 plots changes in the regulation values for NOx +

NMHC and PM emissions under Tier1, Tier2, Tier3 and Tier4

exhaust gas regulations corresponding to 56kW - 75kW in the

4D95 series using the EPA regulation of the United States as an

example. Macroscopically, principal regulation values such

as for NOx and PM are required to be gradually reduced by a

level of about 30%. Comparing the EPA Tier1 regulation

level of the United States enforced at the beginning of 1996

and EPA Tier3 regulation started in 2007 or 2008 spanning a

period of about ten years, exhaust gas emissions are reduced to

about one half. In the span of about 20 years to 2015 when

Tier4 will be enforced, the emission level will be reduced to

about 1/20.

The 4D95 engine series comprises engines that have four

cylinders, a bore diameter of 95mm, stroke of 115mm and total

piston displacement of 3.3 liters, or the smallest in piston

displacement in the ecot3 engine series of Komatsu. Figure 2

plots the relationship between total piston displacement and the

rated output range of the Komatsu ecot3 engine series. The

principal specification of the 4D95 engine series is summarized

in Table 1.

23.2L

15.2L

11.0L

8.3L

6.7L

4.5L

4D95

4D95 engine series

3.3L

0

100

200

300

400

Fig. 2 Komatsu ecot3 engine series

0.8

Emission Regulations

U.S.EPA (56kw - 75kw)

0.7

Tier1

8mode PM (g/kWh)

0.6

0.5

Tier3

0.4

Tier2

0.3

0.2

0.1

Tier4

0.0

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

8mode NOx+NMHC (g/kWh) (Tier1NOx

(Tier1 regulates only NOx.

10.0

Tier4NOx,THC

In Tier4, NOx and THC will be regulated

independently. The figures in the

diagram show their addition amounts.)

Fig. 1 History of NOx + NMHC and PM emission levels

Table 1 Principal specification of 4D95 engine series

Model

Cylinders

Bore diameter stroke

Piston displacement

Output range

Air intake system

Combustion system

Combustion chamber

unit

mm

L

kW

4D95LE-5

S4D95LE-5

4048

NA

IDI

MPa

Distributor type

pump

30

21.0

Turbo charger

Not provided

Pressure ratio

Control

EGR

Mechanical

Not provided

Fuel injection system

Max. injection pressure

Compression ratio

2007 VOL. 53 NO.160

SAA4D95LEM-5

SAA4D95LE-5

4

95115

3.3

4255

5663

5082

T

TAA (CAC)

TAA (CAC)

IDI

DI

DI

2-stage combustion 2-stage combustion

chamber

chamber

Distributor type

Distributor type

Common rail

pump

pump

system

30

65

110

20.8

19.0

17.3

High pressure ratio High pressure ratio

Standard turbo

turbo

turbo

1.4

2.4

2.4

Mechanical

Mechanical

Electronic control

Not provided

Not provided

Not provided

Development of 4D95 Engine Series Meeting Tier3

2

500

600

kW

3.1

Overview of SAA4D95LE-5 engine

The SAA4D95LE-5 engines cover the high output range in

the 4D95 engine series. As in the medium and large engine

series, the SAA4D95LE-5 engine employs the electronic

control and high-pressure common rail system (HPCR). On

the other hand, aiming at complying with the Tier3 exhaust gas

regulation that does not require EGR, the regulation is

complied by equipment of an air-cooled aftercooler and by

improving combustion mainly by modifying the shape of the

combustion chamber. Figure 3 shows an appearance of the

SAA4D95LE-5 engine. The technologies incorporated in the

engine are described.

The engine will be equipped in the PC138-8 and other construction machines of Komatsu.

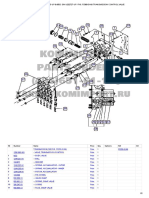

Injector

Rail

Supply

Pump

Fig. 4 Full view of small common rail system

3.1.2

Supercharger and air-to-air air-intake

cooling system

The SAA4D95LE-5 engine incorporates Komatsus key

technology of the Komatsu ecot3 engine series, the air-to-air

air-intake cooling system. The system is designed to increase

the weight flow of intake air into the engine cylinders and to

lower the intake air temperature. The system cools air, which

is heated by supercharging by a turbocharger, by heat exchanging with outside air. This allows lowering of the combustion

temperature; that is, reducing NOx while maintaining high performance.

The turbocharger features a high-pressure ratio and high efficiency by optimizing the shape of the compressor blades and

modifying the air intake port.

Fig. 3 Appearance of SAA4D95LE-5 engine

3.1.1 Common rail system

The common rail system has the highest potentials among

the various injection systems, featuring high-pressure injection

and a high degree of freedom of injection time. Komatsu

quickly equipped the common rail injection system in its

medium and large diesel engines for construction machines.

Quality verification required for construction machinery was

conducted and modification was incorporated in every detail of

the common rail system, to be built with high reliability and

durability.

A small common rail system has been developed in the

SAA4D95LE-5 engine by further modifying it for small engines.

An appearance of the new small common rail system is

shown in Figure 4.

2007 VOL. 53 NO.160

Development of 4D95 Engine Series Meeting Tier3

3

3.1.3 New combustion system

The SAA4D95LE-5 engine has a new combustion system

mainly aimed at improving combustion. The piston has one

large cavity and one small cavity, contributing to the reduction

of NOx in the early stage of combustion and PM, in the latter

part of it. As a result, emissions could be reduced without

drastically increasing the combustion time. Figure 5 shows

an appearance of the combustion chamber of the new combustion system.

Noise

(db-A)

Noise (dB-A)

90

+10

+10

FullLoad

Full

Load

Installed with

Tie common

r3

rail that

complies with Tier3

85

Installed

with conventional Tier2

Tier2

mechanical

fuel injection pump

NoLoad

No Load

80

800

2600

min-1

Engine

revolution speed

Fig. 7 Noise of SAA4D95LE-5 engine body

Fig. 5 Shape of combustion chamber for SAA4D95LE-5 engine

The emission performance and engine body noise of the

SAA4D95LE-5 engine are plotted in Figures 6 and 7. The

NOx + NMHC and PM levels of the Tier3 exhaust gas regulation have been complied with an ample margin. A similar

fuel consumption ratio as that of an engine that complies with

the Tier2 exhaust gas regulation has been secured.

A noise level about 1 to 2dB(A) lower in all the operation

speed range could be achieved compared with engines that

complies with the Tier2 exhaust gas regulation utilizing the

characteristics of the common rail system by multi-injection

and other means.

The new combustion system complies with the Tier3 exhaust

gas regulation without the help of the EGR (exhaust gas

recirculation) technology that is already used in medium and

large engines. Compared with the ECM (engine control module) for medium and large engines that equips the EGR

technology, the ECM for the SAA4D95LE-5 engine has been

simplified by omitting the EGR drive part, thereby contributing

to cost competitiveness, which is an important factor for small

engines.

3.2

SAA4D95LEM-5 engine

The basic design of the SAA4D95LEM-5 engine is the same

as that of the SAA4D95LE-5 engine mentioned in section 3.1

and covers the output range of 56 to 63kW equipped with a

mechanical fuel injection pump. The mechanical fuel injection pump does not offer high-pressure injection, multiple

injection and a high degree of freedom of injection time. The

Tier3 exhaust gas regulation could be complied therefore by

tuning the combustion chamber compared with the new combustion system for the SAA4D95LE-5 engine.

EPATier3 Emission

0.5

8mode PM (g/kWh)

Regulation value

Installed with

conventional Tier2

Tier2fuel

mechanical

injection pump

Installed

with

Tier3

common

rail

that complies

with Tier3

0.0

3.0

6.5

8mode NOx+NMHC (g/kWh)

Fig. 6 Emission performance of SAA4D95LE-5 engine

2007 VOL. 53 NO.160

Development of 4D95 Engine Series Meeting Tier3

4

3.3

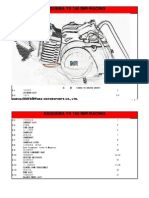

S4D95LWE-5 and 4D95LWE-5 engines

The S4D95LWE-5 and 4D95LWE-5 engines are swirl

current chamber system (IDI) engines that cover the output

ranges of 48 to 55kW and 40 to 48kW, respectively. The IDI

engine has two combustion chambers, namely, a sub-chamber

called a swirl chamber and a main chamber. The generation

of NOx is controlled by low-temperature combustion in the

sub-chamber and the combustion gas emitted by the sub-chamber is again combusted in the main chamber, to curb the generation of PM. Figure 8 shows an appearance of the

4D95LWE-5 engine. The technologies incorporated in this

engine are described below.

The combustion of the IDI engine consists of the following

two combustion modes. The first combustion mode is primary combustion caused by mixing of a tumble current (vertical swirl) that is generated when air in the cylinder is fed to

the sub-chamber during the compression process and fuel

injected by the injector. The second combustion mode is secondary combustion in the main chamber when the combustion

gas in the sub-chamber is injected from the throat part of the

hot plug as the piston lowers.

The S4D95LWE-5 and 4D95LWE-5 engines improved combustion to be compliant with the Tier3 exhaust gas regulation

by tuning the shape of the throat part (combustion gas outflow

part) of the part that constitutes the sub-chamber called a hot

plug and shape of the piston combustion chamber. More

specifically, the foregoing shapes were 3D modeled and flows

of air and combustion gas were simulated. Figure 10 shows

part of the simulation results.

Base TDC

Fig. 8 Appearance of 4D95LWE-5 engine

3.3.1

Final level TDC

Base ATDC15

Final level ATDC15

Base ATDC45

Final level ATDC45

Base ATDC75

Final level ATDC75

Combustion chamber for IDI (Indirect

injection)

The cross section of the combustion chamber for the IDI

engine is illustrated in Figure 9.

4D95LE-3 (Tier2)

(Natural aspiration,

4D95LE-3

(Tier2)

direct

injection system)

()

4D95LEW-5 (Tier3)

(Natural aspiration,

4D95LEW-5

(Tier3)

()

swirl

chamber system)

Glow

Plug

Glow

Plug

InjInjector

ector

Fig. 10 Simulation results of air and combustion gas

Swirl

Swirl Chamber

Chamber

HotPlug

Plug

Hot

Fig. 9

Cross section of combustion chamber for IDI engine

2007 VOL. 53 NO.160

Development of 4D95 Engine Series Meeting Tier3

5

Fuel feed ratio (mm3/deg)

A NOx reduction was forecasted by reducing the tumble

current (vertical swirl) of air generated in the sub-chamber to

curb the mixture of a fuel and air as the simulation result of the

final level shows. A reduction in black smoke and PM

emission was forecasted possible by optimizing the throat

shape to increase the combustion gas injection speed from the

sub-chamber and to increase the air utilization factor in second

diffusion combustion. A design was made based on this

simulation and emission performance was improved as shown

in Figure 11.

Cam angle (deg)

0.5

8mode PM [g/kwh]

Fuel feed ratio of 2-stage cam

Regulation

value

Optimization of shape

combustion chamber

of

including throat part

tip of piston

and

Fig. 12 Fuel feed ratios of fuel injection pumps

Final level

Base

0.0

3

6

8mode NOx+NMHC [g/kwh]

Fig. 11 Emission performance of 4D95LE-5 engine

3.3.2

Characteristics of mechanical fuel

injection pump for IDI engine

1) 2-stage cam shaft

Figure 12 compares fuel feed ratios of mechanical fuel

injection pumps. The fuel feed ratio reaches maximum on the

start of fuel compression with ordinary fuel injection pumps,

whereas the fuel injection pump for IDI curbs the fuel feed

ratio on the start of fuel compression through a 2-stage cam.

This controls radical mixing of a fuel and air in the initial stage

to curb the combustion temperature and to reduce NOx

emissions. The fuel feed ratio is increased in the second half

of the combustion to increase the flow rate of the combustion

gas that is jetted from the sub-chamber to the main chamber.

This accelerates the second-half diffusion combustion and

reduces the emission of black smoke and PM.

2) CSD (Cold start device) - Starting timing control device

When the injection time is delayed to reduce NOx emissions,

the spark advance quantity necessary for starting at a low temperature and for the control of white smoke cannot be achieved

with mechanical fuel injection pumps whose degree of freedom

of injection timing is low. This problem was solved by installing a device (cold start device [CSD]), which advances the

injection timing only when the temperature is low, on the fuel

injection pump. An appearance of this device is shown in

Figure 13. The CSD advances the injection timing at a low

temperature by linking the piston that is sealed with wax,

which expands or contracts depending on the cooling water

temperature, and timing control device of the injection pump.

The injection timing could be advanced a maximum 10 CA at

a low temperature, accomplishing a good startability and

reduction in white smoke also.

CSD device

CSD

Water

Water

Fig. 13 Full view of CSD

2007 VOL. 53 NO.160

Development of 4D95 Engine Series Meeting Tier3

6

3.3.2

Performance of 4D95LWE-5 engine

1) Emission performance

A regulation value in Option1 (Opt1) or in Option2 (Opt2)

can be selected for the output range of 37kW to 56kW in US

EPA Tier3 regulation. Table 2 shows the regulation values

and starting years for Tentative Tier4.

2) Engine noise performance

Figure 15 plots noise performance of the 4D95LWE-5 engine as a representative. The 4D95LE-5 engine lowered noise

by about 3 or 4dB (A) in all operating speed ranges compared

with engines of the direct injection type that complies with the

Tier2 exhaust gas regulation.

Table 2 US EPA regulation values (37kW to 56kW)

Regulation value (g/kWh)

NOx+NMHC

PM

4.7

0.3

4.7

0.4

96

+20

Starting year for

Tentative Tier4

2013

2012

FullLoad

Full Load

Tier2

Tier2

(DI)

DI

The selection of Opt1 offers the following advantages.

The starting year for Tentative Tier4 for European EU

regulation and US EPA regulation will be the same, 2013,

and engines complying with these regulations can be

introduced at the same time.

Tentative Tier4 may require an after treatment device such

as DPF and a cost increase due to installation of such

device will be unavoidable.

However, economical

Tier3-compatible engines can be supplied one year

longer.

Taking these advantages into consideration, Opt1 was selected for the 4D95LWE-5 and S4D95LWE-5 engines that

cover this output range and the engines complied with these

regulations. As a representative, the emission performance of

4D95WE-5 is shown in Figure 14.

Noisedb(A)

Noise

dB (A)

EPA Tier3

regulation EPA

Opt.1

Opt.2

86

Tier3

Ti er3

(IDI)

I DI

No Load

NoLoad

76

800

3000

Engine rpm min-1

min-1

Fig. 15 Noise performance of 4D95LWE-5 engine

Values accomplished by 4D95LWE-5 engine

4D95LWE-5_

0.5

Regulation

value (Opt2)

(Opt.2)

8mode PM [g/kwh]

Regulation

value (Opt1)

(Opt.1)

0.0

3.0

5.0

8mode NOx+NMHC [g/kwh]

Fig. 14 Emission performance of 4D95LWE-5 engine

2007 VOL. 53 NO.160

Development of 4D95 Engine Series Meeting Tier3

7

7. Conclusion

Introduction of the writers

The features and emission reduction technologies of the

4D95 engine series, which is the anchor of the Komatsu ecot3

engine series are described. Among the accomplishments of

this development is the new development of a specification incorporating an air-cooled aftercooler and common rail system.

The potentials of the common rail system are very high. The

SAA4D95LE-5 engine demonstrated excellent performance

while complying with the Tier3 exhaust gas regulation,

accomplishing a high output of 82kW in rated output also.

The question is can the same means be applied to the

4D95LWE-5 engines (natural aspiration) of 48kW in rated

output? The answer is no. A balance between cost and

means to comply with the exhaust gas regulation commensurate with the output is difficult to achieve in design to

comply with the exhaust gas regulation for small engines. A

high output specification allows setting of a price commensurate with high performance by supplying high performance

even if state-of-the-art technology of high functions is incorporated. When this principle is applied to engines of low

output, the price per output significantly increases and engines

will no longer be competitive in the market. The development of the 4D95 engine series complying with the Tier3

exhaust gas regulation has been accomplished by setting three

aspirations, namely, TAA, T and NA, and two fuel injection

systems, namely, the common rail system and a mechanical

fuel injection pump. In a nutshell, the 4D95 engine series

could be realized by the development of indeed four different

engines.

The emission regulation will continue to become stricter.

Two questions for small engines will be the keys to survival.

How to neutralize cost increases that will be necessitated

when EGR, DPF and other emission reduction technologies

that are still high priced are incorporated to comply with

stricter regulation and how technologies to reduce emissions to

cover low output ranges in the same engine series can be made

simple and low cost?

Reference:

1) ENGINE TECHNOLOGY April 2006,

Technology of Komatsu ecot3 Engine.

2007 VOL. 53 NO.160

Masaki Tanaka

Entered Komatsu in 1992.

Currently assigned to the Engine

Development Group, IPA Co., Inc.

Keisuke Inoo

Entered Komatsu in 1988.

Currently assigned to the Engine

Development Group, IPA Co., Inc.

Jun Oshima

Entered Komatsu in 1982.

Currently assigned to the Engine

Development Group, IPA Co., Inc.

Masaki Shinohara

Entered Komatsu in 1991.

Currently assigned to the Combustion and

Fuel System Group, IPA Co., Inc.

[A few words from the authors]

The development of engines to comply with the Tier3 exhaust

gas regulation has been completed and the future task will be to

develop engines that will comply with the Tier4 regulation. As

mentioned above, complying with the Tier4 regulation may require

the installation of devices such as EGR and DPF. Efforts will

continually be made to develop and sell engines that will be

competitive in all aspects by modifying the basic performance of

the engine body so that the installation of these additional devices

will not impair the characteristics requirements demanded for

small diesel engines such as compactness and cost competitiveness.

State-of-the-art

Development of 4D95 Engine Series Meeting Tier3

8

Você também pode gostar

- CV300 2Documento13 páginasCV300 2Achariya ParpromAinda não há avaliações

- Specifications: INI Ydraulic XcavatorDocumento2 páginasSpecifications: INI Ydraulic XcavatorAchariya ParpromAinda não há avaliações

- ทำอย่างไรเมื่อต้องตรวจสอบหลักทรัพย์Documento6 páginasทำอย่างไรเมื่อต้องตรวจสอบหลักทรัพย์Achariya ParpromAinda não há avaliações

- Caterpillar - Basic ElectricityDocumento249 páginasCaterpillar - Basic ElectricityRolando DaclanAinda não há avaliações

- HG CaterpillarPartsListing WebDocumento66 páginasHG CaterpillarPartsListing WebAchariya Parprom100% (1)

- Steering950g 962g SDocumento4 páginasSteering950g 962g SAchariya Parprom100% (4)

- Material Caterpillar 320b 330b Hydraulic Excavators Pilot System Components Diagrams SchematicsDocumento10 páginasMaterial Caterpillar 320b 330b Hydraulic Excavators Pilot System Components Diagrams SchematicsImam Java92% (38)

- จูน 320b-330bDocumento10 páginasจูน 320b-330bAchariya Parprom100% (3)

- 320b 330bDocumento20 páginas320b 330bAchariya Parprom67% (3)

- Acdsee Ultimate 9 End User License AgreementDocumento8 páginasAcdsee Ultimate 9 End User License AgreementAchariya ParpromAinda não há avaliações

- Number Name Price Qty Options Ref Alt 1 1 1 1 1 1 1 1 1 1 1 1 1Documento2 páginasNumber Name Price Qty Options Ref Alt 1 1 1 1 1 1 1 1 1 1 1 1 1Achariya ParpromAinda não há avaliações

- Number Name Price Qty Options Ref Alt 1 1 1 1 1 1 1 1 1 1 1 1 1Documento2 páginasNumber Name Price Qty Options Ref Alt 1 1 1 1 1 1 1 1 1 1 1 1 1Achariya ParpromAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Gear Shift Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocumento20 páginasGear Shift Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoAinda não há avaliações

- Trouble Diagnosis ECM Harness Connector Terminal Layout: PreparationDocumento8 páginasTrouble Diagnosis ECM Harness Connector Terminal Layout: PreparationNelson Cacahuate PowerDanceeAinda não há avaliações

- Chain Saw GuideDocumento22 páginasChain Saw GuideJoanne MowatAinda não há avaliações

- ECM PINOUT Chevrolet Sail PDFDocumento2 páginasECM PINOUT Chevrolet Sail PDFRodrigo Salas100% (4)

- Ju6h Ufg8 Usa PDFDocumento13 páginasJu6h Ufg8 Usa PDFceciliagaitanAinda não há avaliações

- Valve and Injector Adjustment With EPG D12, D12A, D12B, D12CDocumento9 páginasValve and Injector Adjustment With EPG D12, D12A, D12B, D12CRioga Rioga100% (1)

- Deni̇zci̇li̇k İngi̇li̇zcesi̇Documento27 páginasDeni̇zci̇li̇k İngi̇li̇zcesi̇Ramazan MalkocAinda não há avaliações

- Despiece 150 YxDocumento29 páginasDespiece 150 YxDerek Young100% (1)

- 74436GDocumento454 páginas74436Gnosuvito100% (1)

- Liberty Engine History (1918)Documento162 páginasLiberty Engine History (1918)CAP History Library100% (6)

- PCM Programming and Information For Gen IV Vortec 4.8 5.3 6.0 6.2Documento1 páginaPCM Programming and Information For Gen IV Vortec 4.8 5.3 6.0 6.2ehabb3Ainda não há avaliações

- Stability and Performance Analysis of A Two Spool Gas Turbine Aero-EngineDocumento4 páginasStability and Performance Analysis of A Two Spool Gas Turbine Aero-EngineArun KumarAinda não há avaliações

- Engine Expt 4Documento8 páginasEngine Expt 4aashiquear100% (3)

- Muh 24 2 2 98073 PDFDocumento11 páginasMuh 24 2 2 98073 PDFﺃﻧﺲﺻﺪﻳﻖAinda não há avaliações

- Overall Arrangement: Description of The Salient PartsDocumento6 páginasOverall Arrangement: Description of The Salient PartsJitendra KumarAinda não há avaliações

- Unit I Synchronous Generator: Electrical Machines Ii NotesDocumento48 páginasUnit I Synchronous Generator: Electrical Machines Ii NotessakthisrinivassAinda não há avaliações

- Sensors and Electrical Connectors: TroubleshootingDocumento7 páginasSensors and Electrical Connectors: TroubleshootingManuel Ruiz CayunAinda não há avaliações

- Td-25m Extra SN 75001 and UpDocumento2 páginasTd-25m Extra SN 75001 and UpDraganAinda não há avaliações

- Cat C15 SDP Testing and Adjusting Manual 2 PDFDocumento138 páginasCat C15 SDP Testing and Adjusting Manual 2 PDFDragan Krsmanovic100% (1)

- Wartsila 2007Documento120 páginasWartsila 2007Atandho Gama MagwasyarAinda não há avaliações

- Induction MotorsDocumento25 páginasInduction Motorsapi-3827132100% (2)

- CAT C32 Marine Parts BookDocumento685 páginasCAT C32 Marine Parts BookDidik100% (2)

- Squish and Swirl-Squish I+++++++++Documento8 páginasSquish and Swirl-Squish I+++++++++Amal GargouriAinda não há avaliações

- Approved Engines ListDocumento9 páginasApproved Engines ListSAMUEL OLIVEIRAAinda não há avaliações

- Deutz Allis Engine Service ManualDocumento7 páginasDeutz Allis Engine Service ManualLucas Valente0% (1)

- AGT1500 Turbine TechnologyDocumento2 páginasAGT1500 Turbine TechnologySehun CheonAinda não há avaliações

- ServiceSchedule MD22Documento3 páginasServiceSchedule MD22theo_swaranAinda não há avaliações

- F01 PowertrainDocumento39 páginasF01 PowertrainPhan VănAinda não há avaliações

- Catalog Motoare NavaleDocumento164 páginasCatalog Motoare NavaleOvidiu Papuc100% (1)

- Ajax Product Overview BHGE (Sept2017)Documento29 páginasAjax Product Overview BHGE (Sept2017)Odlanier José MendozaAinda não há avaliações