Escolar Documentos

Profissional Documentos

Cultura Documentos

Slab Formwork Design: Technical Note

Enviado por

Ahmed AjjourTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Slab Formwork Design: Technical Note

Enviado por

Ahmed AjjourDireitos autorais:

Formatos disponíveis

Civil Engineering Dimension, Vol. 8, No.

1, 4754, March 2006

ISSN 1410-9530

Technical Note

SLAB FORMWORK DESIGN

Octavian George Ilinoiu

Technical Manager Alpine S.A., Sos. Vergului no. 18, sector 2, Bucharest, Romania

Email: ilinoiug@utcb.ro

Catatan Redaksi:

Perencanaan bekisting (form work) di Indonesia sering kali dilalaikan dan diserahkan kepada pelaksana/

mandor, padahal kegagalan bekisting akan menimbulkan masalah yang sangat rumit. Bekisting juga

merupakan komponen biaya pelaksanaan struktur beton bertulang yang cukup besar. Makalah ini

memaparkan praktek perencanaan bekisting untuk lantai di Romania, dimana perencanaan bekisting

merupakan salah satu syarat untuk mendapatkan sertifikasi insinyur professional. Makalah ini adalah

kelanjutan dari makalah Wall Formwork Design, yang dimuat dalam Dimensi Teknik Sipil, Vol. 6, no.2,

September 2004.

Note from the Editor:

In Indonesia, although cost of formwork contributes significantly to the total reinforced concrete construction

cost and formwork failure will result in a very complicated construction problem, formwork design is often

neglected and left to the foreman to design. This paper presents slab formwork design practice in Romania,

where formwork design is a requirement to obtain professional engineer certification. This paper is a

continuation of previous paper Wall Formwork Design by the same author published in Dimensi Teknik

Sipil, Vol. 6, no. 2, September 2004.

GENERAL CONSIDERATIONS

Although formwork is temporary in nature, the

methods used in building formwork must adhere to

code specifications [1] that apply to the particular

material being used. Each component of the form

must be able to support its load from two points of

view: (1) strength, based on the physical properties

of the material used, and (2) serviceability, the

ability of the selected sections to resist the

anticipated loads without exceeding deflection

limits.

The usual format of a modular plywood panel,

consists of framed plywood sheet screwed/nailed on

a timber studwork (Figure 1). Plywood is a

sheathing product made of several wood veneers

with their grain lying (normal to one another) at

right angles and firmly glued together under

pressure, producing a panel that has uniform

properties in both directions, an advantage

regarding increased bending, shear, and deflection

properties. [4]

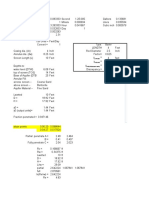

When designing modular formwork for concrete,

there is frequent intermixing of standard size units

that have the following nominal dimensions, as

shown in Table 1.

Note: Discussion is expected before June, 1st 2006. The

proper discussion will be published in Dimensi Teknik

Sipil volume 8, number 2, September 2006.

Table 1. Formwork Panel Nominal Dimensions [3]

Size

Type

of

Length Width

panel (mm)

(mm)

P1

P2

P3

P4

P5

P6

P7

P8

2400

2400

2400

1200

1200

1200

600

600

300

400

600

300

400

600

300

400

Components

No. of

No. of

No. of

traverse

studs

braces

frames

2

2

3

3

2

6

3

2

6

2

2

1

3

2

2

3

2

2

2

2

3

2

-

Thickness

of panel

100 mm

SHORING MEMBERS

Shoring members support formwork and their

contents, bearing loads and limiting their deflections. They can be divided into two major categories

according to type and shape of concrete member

that will be supported:

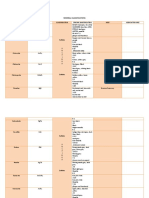

a. Horizontal shores (also known as joists) range

from small units 1,8 m, to large members 9,0 m,

used to carry much heavier loads, usually

manufactured from wood or high-tensile steel,

typical steel joists are illustrated in Figure 2.

They are placed one along side another at

allowable spans as specified in Table 2, and in

accordance with bearing load imposed upon

formwork.

Civil Engineering Dimension

ISSN 1410-9530 print 2007 Thomson GaleTM

http://puslit.petra.ac.id/journals/civil

47

O. G. Ilinoiu / Slab Formwork Design / CED, Vol. 8, No. 1, 4754, March 2006

(a)

(b)

(c)

Figure 2. Typical Steel Telescopic Joists. a. Joist Length

1,8..3,0 m; b. Joist Length 3,0..5,0 m and c. Joist

Length 3,66,0 m [1]

b. Vertical shores (also known as props) support

the horizontal shores (joists) from a firm base

below. They may be manufactured of wood or

steel, with various shapes, depending on the

particular scope, typical adjustable steel pipe

shores are illustrated in Figure 3.

Vertical wood shores may be single wood

posts, with wedges to adjust the height, double wood posts, two-piece adjustable posts, or

T head shores.

Figure 1. Typical Plywood Panel

Caption: 1. Plywood sheathing; 2. Batten (Stud); 3.

Brace; 4. Transverse frame: e = 8; 15 mm, d = 92; 85

mm, c = 48 mm, i = 68 mm, f = 38 mm. [1, 2, 3]

Table 2. Allowable Spans d (m) Between Joists in Accordance With Length and Imposed Load [3]

Load (N/m2)

d (m)

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

2000

2500

3000

2.97

2.77

2.60

2.46

2.34

2.24

2.15

2.07

2.82

2.62

2.46

2.33

2.21

2.12

2.03

1.96

2.69

2.50

2.34

2.21

2.10

2.01

1.93

1.86

Telescopic joist 1,83,0 m

Span of joist D in accordance with d distance between joists

3500 4000 4500 5000

5500

6000

6500 7000

7500

2.58

2.39

2.24

2.12

2.01

1.92

1.84

2.39

2.30

2.15

2.03

1.93

1.84

2.34

2.21

2.07

1.96

1.86

2.31

2.14

2.00

1.89

2.24

2.07

1.94

1.83

8000

8500

9000

2.18

2.01

1.88

2.17

1.96

1.83

2.06

1.91

2.01

1.86

1.96

1.82

1.92

1.80

3.74

3.44

3.21

3.02

3.63

3.34

3.11

3.53

3.25

3.03

3.44

3.17

3.36

3.09

3.28

3.02

3.21

4.62

4.25

3.96

3.72

4.48

4.12

3.84

3.61

4.36

4.01

3.73

4.25

3.91

3.64

4.14

3.81

4.05

3.72

3.96

3.64

Telescopic joist 3,05,0 m

d (m)

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

5.00

4.83

4.51

4.23

4.04

3.85

3.69

3.55

4.93

4.55

4.25

4.01

3.80

3.63

3.47

3.34

4.68

4.32

4.04

3.80

3.61

3.44

3.29

3.16

4.47

4.13

3.85

3.63

3.44

3.28

3.14

4.29

3.96

3.69

3.47

3.29

3.14

4.13

3.80

3.55

3.34

3.17

3.02

3.98

3.67

3.42

3.22

3.05

3.85

3.55

3.31

3.11

Telescopic joist 3,66,0 m

d (m)

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

6.00

5.98

5.59

5.27

4.99

4.76

4.56

4.38

6.00

5.64

5.27

4.96

4.70

4.48

4.29

4.12

5.80

5.35

4.99

4.70

4.46

4.25

4.07

3.91

5.54

5.11

4.76

4.48

4.24

4.05

3.87

3.72

5.31

4.89

4.56

4.29

4.07

3.87

3.71

5.11

4.70

4.38

4.12

3.91

3.72

4.92

4.53

4.23

3.97

3.76

4.76

4.38

4.08

3.84

3.64

48

O. G. Ilinoiu / Slab Formwork Design / CED, Vol. 8, No. 1, 4754, March 2006

Vertical metal shores may be adjustable

pipe shores or shores made up of prefabricated steel tubing. Scaffold-type shoring, is

usually assembled into towers by combining a

number of units into a single shoring

structure.

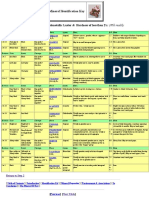

Table 4. Types of Loads According to Weight of

Material or Equipment [1]

Item

Type load

Weight of the

formwork itself

and the scaffold

Weight of fresh

concrete

:c

Uniform

distributed load

of runways for

concrete

transport and

impact loads of

the crowding of

crewmen

Concentrated

one crew member that

load form weight carries loads

of work crews

wheel barrow/ buggies for

and transport

concrete transport

equipment:

Load from the vibrating effect of the concrete

compaction:

Figure 3. Typical Adjustable Steel Pipe Shore (Prop) [3]

Table 3. Allowable Axial Load P (daN) on Shore in

Accordance With Length

Item

name

Hmax (mm)

Hmin (mm)

Steel shore Steel shore

PE 3100 R PE 5100 R

3100

1700

min 20000

Load (N)

max 45000

5100

3100

18000

45000

Light

Steel

Light

Steel

steel

shore

steel

shore

telesco telescopi

with

with

pic

spatial

c shore

spatial

shore PU 1200

base

base

PES 3100 PES 5100 PU 3100

3100

5100

3100

1220

1700

3100

1700

232

2000

18000

6000

3000

45000

45000

12000 45000

Building material,

equipment

lumber in panels

lumber in shoring

elements

plywood

normal weight (heavy)

concrete

lightweight concrete

panel design

horizontal shoring (joists)

of panels

vertical shoring elements

(e.g. props, columns)

Value

7500 N/m3

6000 N/m3

8500 N/m3

plain

24000 N/m3

reinforced

25000 N/m3

700019000N/m3

2500 N/m2

1500 N/m2

1000 N/m2

1300 N

2800 N

1200 N/m2

Table 5. Combination of Loads According to Member Design [1, 3]

Item name

Slab and arch forms and horizontal props

(joists)

Vertical props for slabs

Column forms with the maximum edge of 30

cm and walls of maximum 10 cm width

Column forms and walls with larger values

Lateral faces of forms for beams and arches

Bottom of beams

Centers and scaffolds < 6 m

Centers and scaffolds > 6 m

Combination of loads

Strength

Deflection

a+b+c+d

a+b

a+b+c

a+b

f+g

f

f

a+b+e

a + b + c (e)

a + b + c (e) + h

f

f

a+b

a+b

a+b

FORMWORK PRINCIPLES AND LOADS

ON CONCRETE SLABS

SLAB FORMWORK AND SHORING

SYSTEM DESIGN

The principles behind good formwork are based on

the same basic frame theories used in the design

and construction of structural frames. Formwork

must be able to withstand loads that, in many

respects, can be more severe than those experienced

by the completed structure. It is imperative that

each component of the formwork be erected

according to the formwork drawings to ensure that

all construction loads are safely supported.

Formwork must be checked to ensure that they

withstand bending and shear, and that deflection

will not exceed the specified value according to

surface finishing.

For the design of formwork, the loads on concrete

slabs (Table 4) must be taken into account differently, in combination, according to Table 5.

The design of formwork components will be made

according to the following characteristics: type of

material used, nature of the load, number of reuses,

moisture conditions and deflection limitations.

Evaluation of Loads

1. Weight of 8 (15) mm panel sheathing.

2. Weight of fresh concrete (hslab).

3. Uniform distributed load of runways for concrete

transport and impact loads of the crowding of

crewmembers.

4. Concentrated load weight of work crews and

transport equipment.

5. Load from the vibrating effect of concrete consolidation.

49

O. G. Ilinoiu / Slab Formwork Design / CED, Vol. 8, No. 1, 4754, March 2006

Note 1: The loads on plywood are usually considered as being uniformly distributed over the entire

surface of the plywood. The concentrated load d

can by transformed in a uniform distributed load, by

dividing it to the span l.

Table 6. Properties of form Material

PROPERTIES OF

FORM

Allowable bending

stress (a)

Allowable bending

stress (a)

Note 2: This design recommends three basic span

conditions for computing the uniform load capacity

of plywood panels. The span may be single span,

two-spans or threespan according to the panels

width.

Material

Value

lumber

12 N/mm2

plywood

Allowable bending

stress of steel (a)

Modulus of elasticity lumber

plywood

Plywood Panel Design

Recommended standard thickness of plywood

(panel), 8 or 15 mm. When calculating the allowable

pressure of concrete on plywood as limited by the

allowable unit stress deflection of the plywood, use

the clear span between supports.

When the face grain 13 N/mm2

is parallel to the

span

When the face grain 5 N/mm2

is perpendicular to

the span

210 N/mm2

10.000 N/mm2

7.000 N/mm2

steel

Allowable bending

architectural concrete

deflection limitations

concrete surfaces with finishing

210.000 N/mm2

L maximum clear

span/300

L maximum clear

span/200

Allowable tolerances length and width of panel

thickness of panel

length of diagonals of panel

+ 2 mm

- 5 mm

5 mm

a. For 30 cm width panel:

q (daN/m)

q l/2

l = 25.2 cm

q l/2

Reactions for a simple beam with a uniformly distributed load

q = uniformly distributed load pre unit length (ml) [Nml]

Verification for bending stress:

The calculation is made for a width of b=1m.

q = (a + b + c) x 1.00 + d/l (N/ml)

Where: l = span between supports (25.2 cm)

The maximum bending moment that will occur at the

center of the beam, will be calculated as follows:

M = ql2/8

The applied bending stress must not exceed the

allowable bending design stress:

Verification for deflection:

The calculation is made for a width of b=1m.

q = (a + b) x 1.00 m (N/ml)

For a rectangular beam subjected to bending the applied

deflection f can be calculated form the following equation:

5 qxl 4

fe =

x

384 ExI

The applied deflection must not exceed the allowable design

deflection:

Where:

e = applied bending stress;

Where:

f e = applied deflection;

e a

a = allowable bending design stress;

M = bending moment [Nmm];

I = moment of inertia of the cross section [mm4];

W = section modulus of the cross- section [mm3]

y M

e = M =

a

I W

M = q x l2/8;

W= b x h2/6

h = 8 or 15 mm

fe fa

f a = allowable design deflection;

I = moment of inertia of the cross section [mm4];

E = modulus of elasticity [N/mm2]

fe =

5 qxl 4

l

fa =

x

384 ExI

200

I = bxh3/12 (mm4)

h = 8 or 15 mm

E = 7000 (N/mm2)

50

O. G. Ilinoiu / Slab Formwork Design / CED, Vol. 8, No. 1, 4754, March 2006

b. For 60 cm width panel:

q (daN/m)

l = 27.6 cm

l = 27.6 cm

Reactions for a simple beam with a uniformly distributed load spanning over three or more equally spaced

supports. q = uniformly distributed load pre unit length (ml) [Nml]

Verification for bending stress:

The calculation is made for a width of b=1m.

q = (a + b + c) x 1.00 + d/l (N/ml)

Where: l = span between supports (27,6 cm)

The maximum bending moment that will occur at the

center of the beam, will be calculated as follows:

M = ql2/10

The applied bending stress must not exceed the allowable

bending design stress:

e a

e = applied bending stress;

a = allowable bending design stress;

M = bending moment [Nmm];

I = moment of inertia of the cross section [mm4];

W = section modulus of the cross- section [mm3].

y M

=

a

I W

qxl 4

ExI

The applied deflection must not exceed the allowable design

deflection:

Where:

f e = applied deflection;

f a = allowable design deflection;

I = moment of inertia of the cross section [mm4];

E = modulus of elasticity [N/mm2].

f e = 0.005 x

qxl 4

l

fa =

200

ExI

I = bxh3/12 (mm4)

h = 8 or 15 mm

E = 7000 (N/mm2)

M = q x l2/10;

W= b x h2/6

h = 8 or 15 mm

Horizontal Steel Telescopic Joist Design

q

15

f e = 0.005 x

fe fa

Where:

e = M

Verification for deflection:

The calculation is made for a width of b=1m.

q = (a + b) x 1.00 m (N/ml)

For a rectangular beam subjected to bending the applied

deflection f can be calculated form the following equation:

Joist

Loads: q = a + b (N/m2)

From Table 2, according to the type of joist used, the

load q and the span of the joist D the spacing d

of joists under paneling is given.

q = uniformly distributed load pre unit length (ml)

[Nml]

Technical note: If the value d is not a common

measure of the standard panel length, the joists will

be placed at equidistance, but not more than dmax

for Table 2.

Shore (prop)

Batten (Stud) Design

The design will be made in the most unfavorable

situation; this will be, the design of the central stud

of the 60 cm width plywood panel.

Loads:

15

Figure 4. Typical View of Joist and Prop

Requirement: Spacing of joists under paneling

d (m).

For verification for bending stress:

q = (a + b + c) x l.00 + d/l (N/ml)

For verification of deflection:

q = (a + b) x 1.00 m (N/ml)

51

O. G. Ilinoiu / Slab Formwork Design / CED, Vol. 8, No. 1, 4754, March 2006

a. For panel with L = 1.20 m and spacing between joists d = 1.20 m

P

q (daN/m)

h=85 or 92

L = 1.20 m

b=48

P = concentrated load do to work crews and transport equipment [N]

q = uniformly distributed load pre unit length (ml) [Nml]

Verification for deflection:

Verification for bending stress:

M

e = x a = 12 N/mm2

W

fe =

M = bending moment [Nmm];

W = section modulus of the cross section [mm3]

M=

l

5 qxl 4

fa =

x

384 ExI

200

f e = applied deflection;

f a = allowable design deflection;

I = moment of inertia of the cross section [mm4];

E = modulus of elasticity [N/mm2]

bxh 3 (mm4)

I=

12

b = 48 mm, h = 85 mm

E = 10000 (N/mm2)

qxL2 PxL

+

8

4

bxh 2 4,8x8,5 2

=

6

6

h = thickness of stud 85 or 92 mm

W=

b. For panel with L = 2.40 m and spacing between joists d = 1.20 m

P

P

q (daN/m)

L = 1.20 m

L = 1.20 m

P = concentrated load do to work crews and transport equipment [N]

q = uniformly distributed load pre unit length (ml) [Nml]

Verification for bending stress:

M

e =

a = 12 N/mm2

W

M = bending moment [Nmm];

W = section modulus of the cross section [mm3]

qxL2

PxL

M=

+ 0,203x

8

4

bxh 2 4,8x8,5 2

=

6

6

h = thickness of stud 85 or 92 mm

W=

Verification for deflection:

f e = 0,005 x

qxl 4

l

fa =

ExI

200

f e = applied deflection;

f a = allowable design deflection;

I = moment of inertia of the cross section [mm4];

E = modulus of elasticity [N/mm2]

bxh 3 (mm4)

I=

12

b=48 mm, h = 85 mm

E = 10000 (N/mm2)

52

O. G. Ilinoiu / Slab Formwork Design / CED, Vol. 8, No. 1, 4754, March 2006

Steel Pipe Shore Design

8.

Chudley, R., Building Site Works, Substructure

and Plant, Longman Scientific and Technical,

1988.

9.

Chudley, R., Advanced Construction Technology. Pearson Education Ltd., England, 1999.

10. Ilinoiu, G., Construction Engineering. Conspress, 2003.

11. Ilinoiu, G., Construction Project Engineering.

Conspress, Bucharest 2004.

12. Plesca, A., Manualul Dulgherului, Editura

Tehnica, 1998.

Figure 5. Schematic View of Prop (Shore)

13. Nunnally, S.W., Construction Methods and

Management. Pearson Prentice Hall, 2004.

The design will be made for the most loaded shore.

D

P = (a + b + c )xdx (N)

2

Where:

d = spacing of joists support under the paneling

(m);

D = span of telescopic steel joist (m);

P = concentrated load do to work crews and transport equipment [N]

The type of steel pipe shore will be chosen if:

Pa = Pmax

(P

max

Pmin x (H story H )

(H max H min )

P (N)

REFERENCES

1.

C11-1974, Instructiuni Tehnice Privind Alcatuirea si Folosirea in Constructii a Panourilor

Din Placaj.

2.

Popa, R. and Teodorescu M., Cofraje Modulate

de Lemn, ICB, 1978.

3.

Teodorescu, M., Tsicura, A, Ilinoiu, G., ndru-Mator Pentru Examenul de Licenta la Disciplina Tehnologia Lucrarilor de Constructii,

UTCB, 1998.

4.

Peurifoy, R., and Oberlender G., Formwork for

concrete structure, McGraw-Hill, 1996.

5.

Andres, C., and Smith, R., Principles and Practices of Heavy Construction. Prentice Hall,

1998.

6.

Andres, C., and Smith, R., Principles and Practices of Commercial Construction. Prentice

Hall, 2003.

7.

APA, Concrete forming. Design and Construction Guide, The Engineering Wood Association,

1999

53

Você também pode gostar

- Reinforced Concrete Buildings: Behavior and DesignNo EverandReinforced Concrete Buildings: Behavior and DesignNota: 5 de 5 estrelas5/5 (1)

- 08 Concrete Mix DesignDocumento14 páginas08 Concrete Mix Designyusman foenayAinda não há avaliações

- Deskripsi Dan IdentifikasiDocumento26 páginasDeskripsi Dan IdentifikasiMuhammad Fairuz AgdaAinda não há avaliações

- Fundamentals of Soil Science Practical NotesDocumento61 páginasFundamentals of Soil Science Practical NotesshubhAinda não há avaliações

- National Geographic UK October 2021 PDFDocumento132 páginasNational Geographic UK October 2021 PDFAshan HasanthaAinda não há avaliações

- Clues For The Identification of Rock Forming Minerals: Mirzam ADocumento22 páginasClues For The Identification of Rock Forming Minerals: Mirzam ARosa Fitris SundewiAinda não há avaliações

- Geologist GojjamDocumento5 páginasGeologist GojjamgojjamnhialpalAinda não há avaliações

- 01 Analisa Hidrologi Cemara (Tugas Periode Ulang)Documento34 páginas01 Analisa Hidrologi Cemara (Tugas Periode Ulang)Irfan AlfandaryAinda não há avaliações

- Variogram Fan Inteps - LFDocumento3 páginasVariogram Fan Inteps - LFEfraim HermanAinda não há avaliações

- Geology Minerals Practical 1-3Documento9 páginasGeology Minerals Practical 1-3Simiso GasaAinda não há avaliações

- Analisis Hidrologi: Curah Hujan WilayahDocumento14 páginasAnalisis Hidrologi: Curah Hujan WilayahRisa KristaliaAinda não há avaliações

- DUO For Wall and Column Formwork Poster US1 enDocumento3 páginasDUO For Wall and Column Formwork Poster US1 enJc KrkmoAinda não há avaliações

- Aqt Demo TutorialDocumento45 páginasAqt Demo TutorialAgnesa Resa100% (1)

- Megascopic Identification of Minerals: Physical Properties Quartz Talc Bauxite Biotite Mica Muscovite MicaDocumento3 páginasMegascopic Identification of Minerals: Physical Properties Quartz Talc Bauxite Biotite Mica Muscovite MicaKannanGovindarajanAinda não há avaliações

- Exercise 1 Ore MineralogyDocumento25 páginasExercise 1 Ore MineralogyMaria Luisa B. DichosAinda não há avaliações

- 9761 - Rock Mass DescriptionDocumento14 páginas9761 - Rock Mass DescriptionChris DiantoroAinda não há avaliações

- Appendix B. Soil Classification Guide (Cohesive Soil) : Cohesive Soils (Modified After Ref. D2487-93 and D2488-93)Documento6 páginasAppendix B. Soil Classification Guide (Cohesive Soil) : Cohesive Soils (Modified After Ref. D2487-93 and D2488-93)Edvin Neil Huamanguillas ParavecinoAinda não há avaliações

- BPJS Ajenrem 043Documento7 páginasBPJS Ajenrem 043Bagas SanjayaAinda não há avaliações

- Mine Planning PDFDocumento142 páginasMine Planning PDFgetasewAinda não há avaliações

- Rock Mass Characterization: EM 1110-1-2908 30 Nov 94Documento22 páginasRock Mass Characterization: EM 1110-1-2908 30 Nov 94feiernicoletaAinda não há avaliações

- Time Series Analysis and ForecastingDocumento69 páginasTime Series Analysis and ForecastingSumendra RaghavAinda não há avaliações

- CH 3 Example 1Documento3 páginasCH 3 Example 1Kamel HassounAinda não há avaliações

- Slug Bouwer-Rice EuroExampleDocumento32 páginasSlug Bouwer-Rice EuroExampleJuan MendozaAinda não há avaliações

- Mineral IdDocumento52 páginasMineral Idsamosir123xxxxAinda não há avaliações

- Duo PDFDocumento72 páginasDuo PDFAnubhav MukherjeeAinda não há avaliações

- Field Guide Sheet Description of Soil and Rock 2005Documento2 páginasField Guide Sheet Description of Soil and Rock 2005paramarthasom1974Ainda não há avaliações

- Slug Bouwer-RiceDocumento67 páginasSlug Bouwer-RiceAnonymous PdzpkUAinda não há avaliações

- Geostats - VigarDocumento54 páginasGeostats - VigarSeiji Renan MichishitaAinda não há avaliações

- Chapter 3 Preliminary Information Gathering and Problem DefinitionDocumento15 páginasChapter 3 Preliminary Information Gathering and Problem Definitionnoor marliyahAinda não há avaliações

- Calculation - Pierhead - Jembatan KIT BatangDocumento9 páginasCalculation - Pierhead - Jembatan KIT Batanghanif ahmadAinda não há avaliações

- Commonly Ask MineralsDocumento20 páginasCommonly Ask MineralsJay-R EspinosaAinda não há avaliações

- Perhitungan DrainaseDocumento133 páginasPerhitungan DrainaseFarid HanafiAinda não há avaliações

- 3.1 Manual For Laboratory Investigation PDFDocumento70 páginas3.1 Manual For Laboratory Investigation PDFmanusher sebaAinda não há avaliações

- Check List For Rock DescriptionDocumento2 páginasCheck List For Rock DescriptionsamAinda não há avaliações

- Coal Modelling Tutorial Vision1Documento78 páginasCoal Modelling Tutorial Vision1rusli geologistAinda não há avaliações

- Chapter 1 Introduction To Business ResearchDocumento13 páginasChapter 1 Introduction To Business Researchreda gad100% (1)

- GEO - Checklist For Soil DescriptionDocumento2 páginasGEO - Checklist For Soil Descriptionraidall0% (1)

- LAB 1 - PART B MINERALS - SoilDocumento5 páginasLAB 1 - PART B MINERALS - SoilErica AbelardoAinda não há avaliações

- AquiferTest Pro 10.0 (2020) - User's Manual. Waterloo HydrogeologicDocumento24 páginasAquiferTest Pro 10.0 (2020) - User's Manual. Waterloo Hydrogeologicronle01Ainda não há avaliações

- ForecastingDocumento21 páginasForecastingSyed Umair100% (1)

- Mineral Identification KeyDocumento15 páginasMineral Identification KeyElla Mari ComiaAinda não há avaliações

- Water BalanceDocumento27 páginasWater BalanceglauzierAinda não há avaliações

- Module 3 (Physical and Chemical Properties of Minerals)Documento3 páginasModule 3 (Physical and Chemical Properties of Minerals)AkiAinda não há avaliações

- Book 1Documento496 páginasBook 1SMK AL-HUDA JATIAGUNGAinda não há avaliações

- AquiferTest2016 UsersManual Web PDFDocumento438 páginasAquiferTest2016 UsersManual Web PDFGabriela100% (2)

- Surpac Minex Group Geostatistics in Surp PDFDocumento116 páginasSurpac Minex Group Geostatistics in Surp PDFGardo PrasetyoAinda não há avaliações

- Construction EquipmentDocumento49 páginasConstruction EquipmentDivith B SannakkiAinda não há avaliações

- 07 - Golder AssociatesDocumento8 páginas07 - Golder AssociatesFerdiyan100% (1)

- MS-08Method Statement For Construction of Elevated Rectangular Open CanalDocumento127 páginasMS-08Method Statement For Construction of Elevated Rectangular Open CanalAmila Priyadarshana DissanayakeAinda não há avaliações

- Perhitungan Curah HujanDocumento15 páginasPerhitungan Curah HujanDwi Rina MurniAinda não há avaliações

- Minerals and RocksDocumento6 páginasMinerals and Rocksmarc7victor7salesAinda não há avaliações

- Rock Description PDFDocumento19 páginasRock Description PDFmecanicadesuelos2014Ainda não há avaliações

- 2.3 Mineral Identification SEDocumento8 páginas2.3 Mineral Identification SEWyatt KesterAinda não há avaliações

- (PDF) Geology For Civil Engineers (Second Edition) - NAIYAR IMAM - Academia - EduDocumento182 páginas(PDF) Geology For Civil Engineers (Second Edition) - NAIYAR IMAM - Academia - EduSangin ZandiAinda não há avaliações

- Food & Beverage Service S O PDocumento6 páginasFood & Beverage Service S O PNIRANJAN BERAAinda não há avaliações

- Pumping DistanceDrawdownDocumento16 páginasPumping DistanceDrawdownJuan MendozaAinda não há avaliações

- Variograms ExerciseDocumento13 páginasVariograms ExercisesergiocallauAinda não há avaliações

- Excel LikuifaksiDocumento6 páginasExcel Likuifaksicressytambunan100% (1)

- Lecture Notes Structural Steel DesignDocumento26 páginasLecture Notes Structural Steel DesignPeter Jean-jacques100% (1)

- EC4 DesignOfCompositeColumns PDFDocumento27 páginasEC4 DesignOfCompositeColumns PDFtoliveira80100% (1)

- 150519154926Documento6 páginas150519154926Ahmed AjjourAinda não há avaliações

- Structural Design Methodology For Solar Concentrators Subjected To Wind LoadsDocumento7 páginasStructural Design Methodology For Solar Concentrators Subjected To Wind LoadsAhmed AjjourAinda não há avaliações

- Pvtoolkit 5Documento10 páginasPvtoolkit 5Ahmed AjjourAinda não há avaliações

- 2011 12 Structural Considerations Roof Top Solar PanelsDocumento6 páginas2011 12 Structural Considerations Roof Top Solar PanelsAhmed AjjourAinda não há avaliações

- Which Contractor Selection Methodology?Documento12 páginasWhich Contractor Selection Methodology?Ahmed AjjourAinda não há avaliações

- Typical API 650 TanksDocumento1 páginaTypical API 650 TanksAhmed AjjourAinda não há avaliações

- Retaining Wall3 1Documento1 páginaRetaining Wall3 1Ahmed AjjourAinda não há avaliações

- Top 5 Free WiFi Hotspot Software For Windows PC (XP, 7, 8)Documento18 páginasTop 5 Free WiFi Hotspot Software For Windows PC (XP, 7, 8)Ahmed AjjourAinda não há avaliações

- 1 FloorDesignGuideDocumento18 páginas1 FloorDesignGuidesayedwafiullahAinda não há avaliações

- EM 1110-2-2504 - Design of Sheet Pile Walls 1Documento75 páginasEM 1110-2-2504 - Design of Sheet Pile Walls 1PDHLibrary100% (2)

- Self-Compacting ConcreteDocumento68 páginasSelf-Compacting ConcreteMisgun SamuelAinda não há avaliações

- Sdarticle 2Documento10 páginasSdarticle 2Ahmed AjjourAinda não há avaliações

- GenderDocumento3 páginasGenderAhmed AjjourAinda não há avaliações

- Simulation of Draping, Infiltration and Curing of CompositesDocumento49 páginasSimulation of Draping, Infiltration and Curing of CompositesPeti Kovács100% (1)

- 01CB1S01Documento5 páginas01CB1S01raobabar21Ainda não há avaliações

- Aditya Series Ws 325 350 144 CellsDocumento2 páginasAditya Series Ws 325 350 144 CellsEureka SolarAinda não há avaliações

- Engineering Metallurgy MM207 IIT Bombay Kashyap Sir Dislocation Grains Grain Boundary SlidesDocumento97 páginasEngineering Metallurgy MM207 IIT Bombay Kashyap Sir Dislocation Grains Grain Boundary SlidesPratik BabhulkarAinda não há avaliações

- Linear ScaleDocumento19 páginasLinear ScaleHà ChínhAinda não há avaliações

- DokwegII - Auxiliary - Maintenance Compressed Air SystemDocumento62 páginasDokwegII - Auxiliary - Maintenance Compressed Air SystemCarlin BabuchasAinda não há avaliações

- 3.2 Overexcitation and Overvoltage ProtectionDocumento6 páginas3.2 Overexcitation and Overvoltage Protectionlkt_pestechAinda não há avaliações

- Ces Manual-Ame 513Documento31 páginasCes Manual-Ame 513Anush AntonyAinda não há avaliações

- Entrepreneurship Module 6Documento8 páginasEntrepreneurship Module 6Cync KlayAinda não há avaliações

- IGC Doc 24-08-EDocumento19 páginasIGC Doc 24-08-Elutfirashid87Ainda não há avaliações

- Chemical Composition, Mechanical, Physical and Environmental Properties of SAE 1536, Steel Grades, Carbon SteelDocumento1 páginaChemical Composition, Mechanical, Physical and Environmental Properties of SAE 1536, Steel Grades, Carbon SteelKuldeep SinghAinda não há avaliações

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocumento1 página4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- Galvanized Peeling Vs FlakingDocumento1 páginaGalvanized Peeling Vs FlakingECCAinda não há avaliações

- Elastomeric Bearing Design ExampleDocumento14 páginasElastomeric Bearing Design ExampleTan Nguyen Cong100% (2)

- 500kW BG Specs - Patruus IL6 TWIN PACK Biogas - 2 X 250 BGDocumento7 páginas500kW BG Specs - Patruus IL6 TWIN PACK Biogas - 2 X 250 BGbinstartedAinda não há avaliações

- Aeron Chairs Service InstructionsDocumento182 páginasAeron Chairs Service InstructionsMatt Wang0% (1)

- Junkers Monobloc Planning Guide English PDFDocumento184 páginasJunkers Monobloc Planning Guide English PDFReInvieAinda não há avaliações

- Ductless Fume Hood Brochure - FEB19Documento2 páginasDuctless Fume Hood Brochure - FEB19Musz MusaAinda não há avaliações

- RS-540SH-7520|MABUCHI MOTOR CO., LTD. Product SearchDocumento2 páginasRS-540SH-7520|MABUCHI MOTOR CO., LTD. Product Searchjoroma58Ainda não há avaliações

- BD80 Instructions PDFDocumento24 páginasBD80 Instructions PDFPipe CastilloAinda não há avaliações

- Roper 3611-22 GHB PumpsDocumento1 páginaRoper 3611-22 GHB PumpsDark CenobiteAinda não há avaliações

- Bright Septic TankDocumento1 páginaBright Septic TankNiđe VezeAinda não há avaliações

- Aquaculture Brochure PDFDocumento2 páginasAquaculture Brochure PDFPipe Malo DisconnectedAinda não há avaliações

- Envicool Cabinet Air Conditioner Service ManualDocumento22 páginasEnvicool Cabinet Air Conditioner Service ManualCONSORCIO TECA 2019100% (2)

- G95.desprendimiento CatodicoDocumento4 páginasG95.desprendimiento Catodicofernando magneAinda não há avaliações

- Brochure WEBDocumento6 páginasBrochure WEBManivannanMudhaliarAinda não há avaliações

- Beam Tutorial 1Documento23 páginasBeam Tutorial 1aikalessAinda não há avaliações

- Exercise 4.3Documento3 páginasExercise 4.3Anonymous w7ujq3cH2FAinda não há avaliações

- 01 Introduction To Press ToolsDocumento9 páginas01 Introduction To Press ToolsAngelo De DominicisAinda não há avaliações

- Heat Exchanger With Helical BafflesDocumento8 páginasHeat Exchanger With Helical BaffleshuangjlAinda não há avaliações

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsAinda não há avaliações

- To Engineer Is Human: The Role of Failure in Successful DesignNo EverandTo Engineer Is Human: The Role of Failure in Successful DesignNota: 4 de 5 estrelas4/5 (137)

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresNo EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresNota: 1 de 5 estrelas1/5 (2)

- Structural Cross Sections: Analysis and DesignNo EverandStructural Cross Sections: Analysis and DesignNota: 4.5 de 5 estrelas4.5/5 (19)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsNo EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsAinda não há avaliações

- Pile Design and Construction Rules of ThumbNo EverandPile Design and Construction Rules of ThumbNota: 4.5 de 5 estrelas4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingAinda não há avaliações

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesNo EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraNota: 4.5 de 5 estrelas4.5/5 (4)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsNo EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsNota: 4 de 5 estrelas4/5 (16)

- Engineering for Kids: Building and Construction Fun | Children's Engineering BooksNo EverandEngineering for Kids: Building and Construction Fun | Children's Engineering BooksNota: 3 de 5 estrelas3/5 (2)

- Transmission Pipeline Calculations and Simulations ManualNo EverandTransmission Pipeline Calculations and Simulations ManualNota: 4.5 de 5 estrelas4.5/5 (10)

- Advanced Design Examples of Seismic Retrofit of StructuresNo EverandAdvanced Design Examples of Seismic Retrofit of StructuresNota: 1 de 5 estrelas1/5 (1)