Escolar Documentos

Profissional Documentos

Cultura Documentos

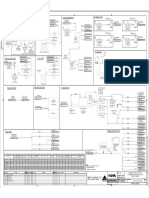

2 m3/h 1 m3/h 3 1: Demineralized Water Potable Water

Enviado por

Edú BrizuelaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

2 m3/h 1 m3/h 3 1: Demineralized Water Potable Water

Enviado por

Edú BrizuelaDireitos autorais:

Formatos disponíveis

3

2 m3/h

3

1 m3/h

DEMINERALIZED WATER

3600-225-FS-0002

POTABLE WATER

3600-225-FS-0002

2325-3600-225-FS-0001

CELL RETURN CIRCUIT G

127

CELL RETURN CIRCUIT H

ANALYZER

3600-5MDC-202

18 m3/h

REJECTS

3500-225-FS-0001

53

EMERGENCY DRAIN TO

OXIDE RAFFINATE POND

1,875 m3/h

-----

127

3700-225-FS-0002

CELL RETURN CIRCUIT E

45

EW - LEAN ELECTROLYTE

TANK

625 m3

3600-5TAA-235

316LSS

FROM COLOSO

LE TO SX PLANT

3700-225-FS-0002

3700-225-FS-0001

CELL RETURN CIRCUIT F

PROVISION FOR FUTURE

ELECTROLYTE COOLING

45

3700-225-FS-0001

GUAR

61

3600-225-FS-0002

112

CoSO4

EW - LEAN ELECTROLYTE

TRANSFER PUMPS

625 m3/h

3600-5PPP-325@328

57

3600-225-FS-0002

FC-1100

58

3600-225-FS-0002

HCL

155

NOTE 2

NOTE 4

RE FROM SX PLANT

3500-225-FS-0001

EMERGENCY DRAIN TO OXIDE

RAFFINATE POND

-----

37

111

111

63

3600-225-FS-0002

HWS

111

CELL RETURN PUMPS

500 m3/h

2 OPER./1 STAND-BY

3600-5PPP-335@337

108

73

OXIDE RICH ELECTROLYTE

HEAT EXCHANGERS

2 EACH 316 SS

5,100 KW EA

3600-5HXP-218/219

OXIDE RICH ELECTROLYTE

TRANSFER PUMPS

300 m3/h

2 OP / 1 STAND BY

3600-5PPP-330@332

113

113

113

113

CELL FEED TO CIRCUIT E

3700-225-FS-0001

39

51

CELL FEED TO CIRCUIT F

3700-225-FS-0001

39

38

EW - RICH ELECTROLYTE

TANK

625 m3

3600-5TAA-236

316LSS

FROM COLOSO

TO OXIDE

TRAIN C / D ER TANK

114

108

CELL FEED PUMPS

1,200 m3/h

4 OPER.

3600-5PPP-315 @ 318

107

108

RICH ELECTROLYTE PUMPS

500 m3/h

FIXED SPEED

3600-5PPP-341@345

41

114

109

TP

114

CELL FEED HEAT EXCHANGERS

4 EACH

4,500 KW EA

AL6XN

3600-5HXP-212/213

3600-5HXP-216/217

CELL FEED TO CIRCUIT G

108

54

OXIDE C / D

LE TANK

3600-225-FS-0002

1,875 m3/h

74

-----

DEMIN WATER OXIDE

59

NOTE 4

111

3600-225-FS-0002

NOTE 4

3700-225-FS-0002

46

CIRCUITS E - F

CELL RETURN TANK

RECIRCULATION TANK

315 m3

1,200 m3

3600-5TAA-241

3600-5TAA-237

316 SS LINED CONCRETE 316 SS LINED CONCRETE

114

CELL FEED TO CIRCUIT H

3700-225-FS-0002

46

HWR

3600-225-FS-0002

64

GUAR

ELECTROLYTE

HEAT EXCHANGERS

4 EACH

8,000 KW EA

316SS

3600-5HXP-210

3600-5HXP-211

3600-5HXP-214

3600-5HXP-215

EXIISTING OXIDE LEAN

ELECTROLYTE PUMPS

420-5PPC-047/048/101

UPRATED

61

52

3600-225-FS-0002

CoSO4

57

3600-225-FS-0002

FC-1100

58

3600-225-FS-0002

HCL

155

126

3600-225-FS-0002

110

CELL RETURN PUMPS

500 m3/h

2 OPER./1 STAND-BY

3600-5PPP-338@340

316SS

CIRCUITS G - H

CELL RETURN TANK RECIRCULATION TANK

315 m3

1,200 m3

3600-5TAA-242

3600-5TAA-238

CELL FEED PUMPS

1,200 m3/h

4 OPER.

3600-5PPP-320 @ 323

TANKFARM & TANKHOUSE

DRAINAGE

OXIDE RAFFINATE POND

3700-225-FS-0001

117

-----

3700-225-FS-0002

Stream Number

37

38

39

41

45

Stream Description

Rich

Electrolyte

from SX

Hot Rich

Electrolyte

Cell Feed to

Tankhouse

Cool Cell

Feed to

Tankhouse

Cell Return

Tankhouse

1,875

1.2

55

1.50

18

157

31

1,875

693

1.2

55

1.50

18

157

44

1,000

2,045

1.2

42.5

1.50

18

176

50

2,400

4,089

1.2

42.5

1.50

18

176

49

4,800

2,043

1.2

40

1.50

18

180

51

2,400

Nominal Flow

SG

Cu Concentration

Fe Concentration

Cl Concentration

Acid Concentration

pH

Temperature

Design Flow

m3/h

g/l

g/l

ppm

g/l

C

m3/h

46

51

52

Cell Feed to Cell Feed HE Cell Return

Tankhouse

Bypass

Electrolyte

2,045

1.2

42.5

1.50

18

176

50

2,400

7,566

1.2

42.5

1.50

18

176

49

9,600

690

1.2

40

1.50

18

180

51

1,000

53

54

57

58

59

61

Lean

Electrolyte

Overland

Electrolyte

HX Bypass

Cobalt

Sulphate

FC-1100

Demin to ER

Tanks

Guar

Solution

HWS

HWR

1,867

1.2

40

1.50

18

180

37

1,875

0

1.2

55.0

1.50

18

157

30

2,000

0.01

1.2

4.0

10-20

0.07

3 L/d

1.23

4.4

10-20

1.0 L/h

0

1.0

5

4.8

15

50

1.4

1.0

5

4.8

15

3

1440

1.0

5

8.5

90

1,440

63

1440

1.0

5

8.5

84

1,440

64

73

74

Lean

Rich

Electrolyte to Electrolyte

from Oxide

Oxide

490

1.2

55

1.50

18

157

44

600

488

1.2

40

1.50

18

180

37

600

107

108

109

110

111

112

113

114

117

126

127

Cool Rich

Electrolyte

Hot Rich

Electrolyte

Hot Rich

Electrolyte

Cool Cell

Feed to

Tankhouse

Cool Lean

Electrolyte

Cool Lean

Electrolyte

HWS

Hot Cell

Feed

EW Sump

Pump

Cell Return

Electrolyte

Cell Return

Tankhouse

HCl

1,385

1.2

55

1.50

18

157

31

2,000

346

1.2

55

1.50

18

157

44

500

693

1.2

55

1.50

18

157

44

1,000

4,089

1.2

42.5

1.50

18

176

49

4,800

345

1.2

40

1.50

18

180

37

500

1,379

1.2

40

1.50

18

180

37

2,000

360

1.0

5

8.5

90

360

153

1.2

42.5

1.50

18

176

62

360

0

1.0-1.2

0.5-40

0.01-1.5

5-30

5-180

20-40

200

690

1.2

40

1.50

18

180

51

1,000

2,043

1.2

40

1.50

18

180

51

2,400

155

1.16

15

50 L/h

EW - TANKFARM AREA

SUMP PUMPS 316SS

100 m3/h

3600-5PPM-313/314

NOTES :

1.- DESIGN VALUES INCORPORATE INITIAL AND SUSTAINING REQUIREMENTS

2.- DEMIN TO ER TANKS FOR FILLING PURPOSE ONLY

3.- TEMPERATURES ARE NOMINAL.

4.- BYPASS.

E. VERA

A

B

0

05-11-2003

ISSUED FOR INTERNAL REVIEW

14-11-2003

ISSUED FOR CLIENT APPROVAL

24-02-2004 ISSUED FOR DESIGN

E.V.

D.C.

R..J..

E.V.

D.C.

R..J..

E.V.

D.C.

R..J..

15-06-2004 RE- ISSUED FOR DESIGN

E.V.

D.C.

R..J..

10-12-2004 RE- ISSUED FOR DESIGN

E.V.

D.C.

R..J..

31-03-2005 ISSUED FOR GENERAL REVIEW

E.V.

D.C.

R..J..

ESCONDIDA SULPHIDE LEACH PROJECT

ELECTROWINNING TANKFARM

PROCESS FLOWSHEET

E. VERA

D. CELMER

J. BERTOIA

C. ASTORGA

R. JAEDECKE

NONE

2325-3600-225-FS-0001

Você também pode gostar

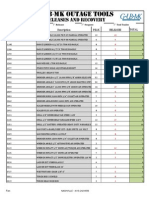

- Guar System Hci System Plant and Instrument Air Air Sparging SystemDocumento1 páginaGuar System Hci System Plant and Instrument Air Air Sparging SystemEdú BrizuelaAinda não há avaliações

- Caldaie Scambiatori Parts ListDocumento37 páginasCaldaie Scambiatori Parts ListJavier Melvin Alvarez MasiasAinda não há avaliações

- Preturi Centrale EolieneDocumento97 páginasPreturi Centrale EolieneRahan`Is`BackAinda não há avaliações

- Preturi Centrale EolieneDocumento97 páginasPreturi Centrale EolieneioandumaAinda não há avaliações

- STP (200kld) - Technical Datasheet 17.02.23Documento150 páginasSTP (200kld) - Technical Datasheet 17.02.23Rajender Chamoli100% (1)

- Costing For SwroDocumento1.021 páginasCosting For Swroganesh100% (2)

- Tool FormDocumento62 páginasTool FormStevenHansardAinda não há avaliações

- Catalogo Perylsa CompletoDocumento221 páginasCatalogo Perylsa CompletoAlvaro Diaz0% (1)

- EPC-4 HT Motor Details and Load ConsumptionDocumento3 páginasEPC-4 HT Motor Details and Load ConsumptionBala MAinda não há avaliações

- 4.ageing 01.01.21Documento4.991 páginas4.ageing 01.01.21Mukesh ManideepAinda não há avaliações

- InvDocumento4 páginasInvJobJobAinda não há avaliações

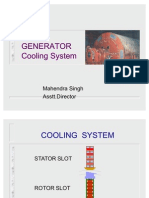

- GENERATOR Cooling System Technical DetailsDocumento54 páginasGENERATOR Cooling System Technical DetailsParvin KumarAinda não há avaliações

- Wall Hung Boiler Spare Parts Price ListDocumento17 páginasWall Hung Boiler Spare Parts Price ListsorinelubadAinda não há avaliações

- StocksSale1 Bha - Com.vnDocumento2 páginasStocksSale1 Bha - Com.vnAnonymous ItzBhUGoiAinda não há avaliações

- Cable Laying Report-1Documento6 páginasCable Laying Report-1Anonymous vcadX45TD7Ainda não há avaliações

- Boiler FundaDocumento37 páginasBoiler FundaTanu SinghAinda não há avaliações

- Catalog Lowara PDFDocumento47 páginasCatalog Lowara PDFMariana VacaruAinda não há avaliações

- Major Equipment List 040618Documento8 páginasMajor Equipment List 040618KoestyomonoAinda não há avaliações

- Cat 3512B Genset System Detection Ground Test ReportDocumento94 páginasCat 3512B Genset System Detection Ground Test Reportbogdanapostol100% (1)

- Pumps - Pumps: Model QC 100 1 X 1 Model QC 100 1 X 1Documento1 páginaPumps - Pumps: Model QC 100 1 X 1 Model QC 100 1 X 1Edgar JimenezAinda não há avaliações

- Conduit Selection On CB SizesDocumento2 páginasConduit Selection On CB SizesSri NathAinda não há avaliações

- Cooling Tower CatalogDocumento16 páginasCooling Tower CatalogKannan VellasamyAinda não há avaliações

- Clint Cha k182p 604p Brochure 0407 enDocumento2 páginasClint Cha k182p 604p Brochure 0407 enManwlis PloimanicAinda não há avaliações

- Esteem Industries PVT Ltd-Pissrulem PLANT & MACHINERY DETAILS - As On 21st September, 2018 SR - No Description CapacityDocumento9 páginasEsteem Industries PVT Ltd-Pissrulem PLANT & MACHINERY DETAILS - As On 21st September, 2018 SR - No Description Capacitysenvy coutinhoAinda não há avaliações

- KST-N Cooling Tower Counterflow Bottle Type FRP StructureDocumento12 páginasKST-N Cooling Tower Counterflow Bottle Type FRP Structurepalitha1902Ainda não há avaliações

- كودات الاجهزة الطبيةDocumento57 páginasكودات الاجهزة الطبيةHussein SultanyAinda não há avaliações

- TVI Motor ListDocumento15 páginasTVI Motor ListjunclarcAinda não há avaliações

- Eepl - Apgenco - 128 - PD - e - Cal - 1029 - r5Documento20 páginasEepl - Apgenco - 128 - PD - e - Cal - 1029 - r5rukmagoudAinda não há avaliações

- Lista Compresores 2 - de - AgostoDocumento11 páginasLista Compresores 2 - de - Agostojuan luis loaiza correaAinda não há avaliações

- E3 Catalog PDFDocumento54 páginasE3 Catalog PDFmjellis68Ainda não há avaliações

- Dab Feka 2500 6000Documento6 páginasDab Feka 2500 6000Cristian CostinAinda não há avaliações

- Referenzliste MRT 03 2016 WebDocumento40 páginasReferenzliste MRT 03 2016 Webjack21abAinda não há avaliações

- 33 & 6.6 kV Cable Laying Report for PDS SystemDocumento6 páginas33 & 6.6 kV Cable Laying Report for PDS SystemAnonymous vcadX45TD7Ainda não há avaliações

- Ra Bill 3 Mesurment SheetDocumento9 páginasRa Bill 3 Mesurment SheetRenu TekumudiAinda não há avaliações

- SP BeringinDocumento1 páginaSP BeringinagusnnnAinda não há avaliações

- Webasto-Blue Line Premium A-C SystemDocumento12 páginasWebasto-Blue Line Premium A-C Systemhayrierenli100% (1)

- Electrical Inventory Min-MaxDocumento11 páginasElectrical Inventory Min-MaxYogendra Kumar SahuAinda não há avaliações

- Aera - Fan Coil ENDocumento20 páginasAera - Fan Coil ENmister_no34Ainda não há avaliações

- Vis Eqp FndlistDocumento8 páginasVis Eqp FndlistsuhaemiAinda não há avaliações

- Toplotna Pumpa Hidria Clint - Eu - Cha K - 182 P 604 P - cls61.7 EngDocumento2 páginasToplotna Pumpa Hidria Clint - Eu - Cha K - 182 P 604 P - cls61.7 EngMuhidin KozicaAinda não há avaliações

- Rotating EquipmentDocumento21 páginasRotating EquipmentpermonoAinda não há avaliações

- Call or email for solar thermal collector and equipment pricingDocumento5 páginasCall or email for solar thermal collector and equipment pricingMuhammad AwaisAinda não há avaliações

- 33 KV Gis CBDocumento12 páginas33 KV Gis CBanurag_jay12464Ainda não há avaliações

- AHP Equipment ListDocumento8 páginasAHP Equipment Listanke6s194100% (1)

- Air Chiller Specifications and Models Comparison ChartDocumento3 páginasAir Chiller Specifications and Models Comparison Chartteddy tavaresAinda não há avaliações

- Rei Vol ViDocumento111 páginasRei Vol ViDineshAinda não há avaliações

- Pricelist OXONE For ResellerDocumento11 páginasPricelist OXONE For ResellerAdiKangdraAinda não há avaliações

- Driconeq Conversions Brochure WebbDocumento92 páginasDriconeq Conversions Brochure WebbSugeng DarmintoAinda não há avaliações

- Provision Stock ListDocumento59 páginasProvision Stock Listapi-234089277Ainda não há avaliações

- Catalogo Bombas DAB KDocumento9 páginasCatalogo Bombas DAB Kalberto_03Ainda não há avaliações

- Canal IsDocumento240 páginasCanal IsTomuta StefanAinda não há avaliações

- 20141203043222547e9256a0bc6Documento17 páginas20141203043222547e9256a0bc6Dielon PatikAinda não há avaliações

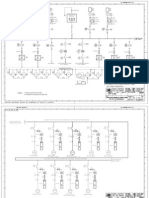

- MCC #3 Elevation: District of Sicamous Mara Lake WTP UpgradeDocumento1 páginaMCC #3 Elevation: District of Sicamous Mara Lake WTP UpgradeSurya Kazu MaruAinda não há avaliações

- Orient Petroleum Surplus Inventory GuideDocumento42 páginasOrient Petroleum Surplus Inventory GuideHANIF AKBARAinda não há avaliações

- Oteco GeneralDocumento16 páginasOteco GeneraldrehergeoAinda não há avaliações

- Electricity for the farm: Light, heat and power by inexpensive methods from the water wheel or farm engineNo EverandElectricity for the farm: Light, heat and power by inexpensive methods from the water wheel or farm engineAinda não há avaliações

- Southern Marine Engineering Desk Reference: Second Edition Volume INo EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IAinda não há avaliações

- Scientific American Supplement, No. 633, February 18, 1888No EverandScientific American Supplement, No. 633, February 18, 1888Ainda não há avaliações

- Survey Based On Reliability Centered Maintenance PDFDocumento114 páginasSurvey Based On Reliability Centered Maintenance PDFEdú BrizuelaAinda não há avaliações

- 4 Standards For AC Motors PDFDocumento37 páginas4 Standards For AC Motors PDFEdú BrizuelaAinda não há avaliações

- Survey Based On Reliability Centered Maintenance PDFDocumento114 páginasSurvey Based On Reliability Centered Maintenance PDFEdú BrizuelaAinda não há avaliações

- Speed Training For TennisDocumento138 páginasSpeed Training For TennisEdú Brizuela67% (3)

- Tiastar Seminar Presentation Es Jun2012Documento73 páginasTiastar Seminar Presentation Es Jun2012Edú BrizuelaAinda não há avaliações

- A Practical Guide For Using MicroStation XMDocumento162 páginasA Practical Guide For Using MicroStation XMnurul_suhariAinda não há avaliações

- Medium Voltage Switchgear AHA: Up To 24 KV, Up To 5000 A, Up To 125 KaDocumento78 páginasMedium Voltage Switchgear AHA: Up To 24 KV, Up To 5000 A, Up To 125 KaEdú Brizuela100% (1)

- Speed Training For TennisDocumento138 páginasSpeed Training For TennisEdú Brizuela67% (3)

- Load Flow Basic Principles DigsilentDocumento17 páginasLoad Flow Basic Principles Digsilentjcrodriguez83100% (2)

- Converting Nature into Electricity: Gilkes Hydropower TurbinesDocumento12 páginasConverting Nature into Electricity: Gilkes Hydropower TurbinesEdú Brizuela100% (1)

- Texas FlangeDocumento76 páginasTexas FlangeggansAinda não há avaliações

- Paper # 107 - Enhanced Liberation in HPGR CircuitsDocumento13 páginasPaper # 107 - Enhanced Liberation in HPGR CircuitsEdú BrizuelaAinda não há avaliações

- Gilkes Hydro Brochure 2011 PDFDocumento20 páginasGilkes Hydro Brochure 2011 PDFEdú BrizuelaAinda não há avaliações

- Generadores MarelliMotoriDocumento18 páginasGeneradores MarelliMotoriEdú Brizuela100% (1)

- Paper # 1 - Simulation As A Tool To Enable World's Best Mill Relining PracticeDocumento10 páginasPaper # 1 - Simulation As A Tool To Enable World's Best Mill Relining PracticeEdú BrizuelaAinda não há avaliações

- Rta 4 2012Documento102 páginasRta 4 2012Edú BrizuelaAinda não há avaliações

- 12WIM Abstract 37 Rev2 - Tendencias en CostosDocumento16 páginas12WIM Abstract 37 Rev2 - Tendencias en CostosEdú BrizuelaAinda não há avaliações

- Rta 3 2012Documento98 páginasRta 3 2012Edú BrizuelaAinda não há avaliações

- Weibull6 TrainingDocumento83 páginasWeibull6 TrainingdanilonevesAinda não há avaliações

- Paper # 143 - A New Baffles System in Sag Mill Trommel at The Shahrebabak Copper ComplexDocumento11 páginasPaper # 143 - A New Baffles System in Sag Mill Trommel at The Shahrebabak Copper ComplexEdú BrizuelaAinda não há avaliações

- Rta 2 2012Documento92 páginasRta 2 2012Edú BrizuelaAinda não há avaliações

- Chap3 PDFDocumento31 páginasChap3 PDFPranveer Singh PariharAinda não há avaliações

- Chap 2Documento70 páginasChap 2Jesuv Cristian CleteAinda não há avaliações

- Traduccion Presente Pasado Participio (E Ido, e Comprado)Documento1 páginaTraduccion Presente Pasado Participio (E Ido, e Comprado)Edú BrizuelaAinda não há avaliações

- Dissolved OxygenDocumento2 páginasDissolved OxygenAnonymous atBeojaAinda não há avaliações

- TI Oxydur PTB 206 - en PDFDocumento5 páginasTI Oxydur PTB 206 - en PDFgonzalogvargas01100% (1)

- Ricoh 301 PARTS CATALOGDocumento68 páginasRicoh 301 PARTS CATALOGbefremdenAinda não há avaliações

- 350q-5 Operation ManualDocumento97 páginas350q-5 Operation ManualCesar Mora100% (2)

- Indian Standards As On 17.01.2004 LatestDocumento19 páginasIndian Standards As On 17.01.2004 LatestSaravana KumarAinda não há avaliações

- Listado Articulos PVPDocumento116 páginasListado Articulos PVPfausto.ca68Ainda não há avaliações

- Under Water WeldingDocumento23 páginasUnder Water WeldingNishanth GowdaAinda não há avaliações

- Trade Skills Assessment GuideDocumento25 páginasTrade Skills Assessment GuideRandz Lampa0% (1)

- As 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisDocumento7 páginasAs 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisSAI Global - APAC0% (1)

- Digital Logic DesignDocumento4 páginasDigital Logic DesignkiranAinda não há avaliações

- Solution 2 AntennaDocumento7 páginasSolution 2 Antennaabdulwahab12100% (1)

- Novajet Refference GuideDocumento74 páginasNovajet Refference GuideoralbnetworkAinda não há avaliações

- KALEKİMDocumento18 páginasKALEKİMqaisalkurdyAinda não há avaliações

- Linthwaite: Conservatio N AreaDocumento26 páginasLinthwaite: Conservatio N Areabill baileyAinda não há avaliações

- Reliance Jio Industry AnalysisDocumento45 páginasReliance Jio Industry AnalysisBhavya BhartiAinda não há avaliações

- Fire Drencher System - Base-Engineer PDFDocumento2 páginasFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- Pressure Regulators (DRV Valve) Suitable ForDocumento4 páginasPressure Regulators (DRV Valve) Suitable ForNOUREDDINE BERCHAOUAAinda não há avaliações

- Spectral Analysis of The ECG SignalDocumento2 páginasSpectral Analysis of The ECG SignalCamilo BenitezAinda não há avaliações

- Pairwise testing: A powerful technique for reducing test casesDocumento26 páginasPairwise testing: A powerful technique for reducing test casesvineeta1234Ainda não há avaliações

- d-Copia3500MF 4500MF 5500MFsmY113351-4Documento1.051 páginasd-Copia3500MF 4500MF 5500MFsmY113351-4ctecisbAinda não há avaliações

- A JIT Lot Splitting Model For Supply Chain Management Enhancing Buyer Supplier Linkage 2003 International Journal of Production EconomicsDocumento10 páginasA JIT Lot Splitting Model For Supply Chain Management Enhancing Buyer Supplier Linkage 2003 International Journal of Production EconomicsDaniel Renaldo SimanjuntakAinda não há avaliações

- Bel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Documento5 páginasBel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Palani AppanAinda não há avaliações

- Calculating The Pressure Tank Size: Where: Q Cut in & Cut OutDocumento1 páginaCalculating The Pressure Tank Size: Where: Q Cut in & Cut OutEdsel Camiguing LoquillanoAinda não há avaliações

- NASA ERAST Program Develops High-Altitude UAVsDocumento17 páginasNASA ERAST Program Develops High-Altitude UAVsEgz AguilarAinda não há avaliações

- Leg Foot Massager 1026 ManualDocumento5 páginasLeg Foot Massager 1026 ManualBhushan BhikeAinda não há avaliações

- Yasnac Mx-3 Fault Finding GuideDocumento70 páginasYasnac Mx-3 Fault Finding Guidechidambaram kasi100% (1)

- Phase Diagrams IntroductionDocumento76 páginasPhase Diagrams IntroductionGikiTopiAinda não há avaliações

- Cryx Necro Energy NecrotiteDocumento2 páginasCryx Necro Energy NecrotitecameronhyndmanAinda não há avaliações

- Zimbabwe Engineer ITDG Small Scale Production of Fired Clay BricksDocumento8 páginasZimbabwe Engineer ITDG Small Scale Production of Fired Clay BricksdkataleAinda não há avaliações

- SHINI Hopper-Loader - SAL-400 SERIES MANUALDocumento38 páginasSHINI Hopper-Loader - SAL-400 SERIES MANUALRick ChenAinda não há avaliações