Escolar Documentos

Profissional Documentos

Cultura Documentos

Plane Wall Lecture Week 7 HT

Enviado por

ToMemDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Plane Wall Lecture Week 7 HT

Enviado por

ToMemDireitos autorais:

Formatos disponíveis

One-Dimensional, Steady-State

Conduction without

Thermal Energy Generation

On Plane wall or a slab

And on composite walls

Week 7 VD

Methodology

Methodology of a Conduction Analysis

Specify appropriate form of the heat equation.

Solve for the temperature distribution.

Apply Fouriers Law to determine the heat flux.

Simplest Case: One-Dimensional, Steady-State Conduction with No

Thermal Energy Generation.

Common Geometries:

The Plane Wall: Described in rectangular (x) coordinate. Area

perpendicular to direction of heat transfer is constant

(independent of x).

The Composite Wall:As a combination of different materials in specific

arrangements

The Radial and Spherical structures: Radial conduction through wall.

Plane Wall

The Plane Wall

Consider a plane wall between two fluids of different temperature:

Heat Equation no heat generation

d dT

k

0

dx dx

(3.1a)

Heat Equation with energy generation ?:

d 2T ( x) 1

g ( x) 0

2

dx

k

Implications:

Heat flux qx is independent of x.

Heat rate qx is independent of x.

T 0 Ts ,1, T L Ts,2

Boundary Conditions:

Temperature Distribution for Constant k :

x

T x Ts,1 Ts,2 Ts ,1

L

(3.3)

(3.1b)

Plane Wall (cont.)

Heat Flux and Heat Rate:

dT k

qx k

Ts ,1 Ts,2

dx L

dT kA

q x kA

Ts ,1 Ts ,2

dx

L

T

Thermal Resistances Rt

and Thermal Circuits:

q

L

Rt ,cond

Conduction in a plane wall:

kA

Convection:

Rt ,conv

1

hA

(3.5)

(3.4)

(3.6)

(3.9)

Thermal circuit for plane wall with adjoining fluids:

Rtot

1

L

1

h1 A kA h 2 A

qx

(3.12)

T,1 T,2

Rtot

(3.11)

Plane Wall (cont.)

Thermal Resistance for Unit Surface Area:

L

1

Rt,cond

Rt,conv

k

h

Units: Rt W/K

Rt m 2 K/W

Numerical Problem No. 1

Determine steady state heat flux through a 0.20 m thick brick wall [k = 0.69

W/m0C ] with one surface at 300C and the other at -20 0C.

Ans: 172.5 W/m2

Numerical Problem No. 2

A steel plate of thickness L = 5 cm and thermal conductivity k = 20 W/(m.0C) is

subjected to a uniform heat flux q=600 W/m2 on one of its surfaces and dissipates

heat by convection with a heat transfer coefficient h = 80 W/ (m2. 0C) from the

other surface into the ambient air at T = 25 0C . What is the temperature of

the surface dissipating heat by convection?

Ans : 32.5 0C

Plane Wall (cont.)

Composite Wall with Negligible

Contact Resistance:

qx

Rtot

T,1 T,4

Rtot

(3.14)

1 1 LA LB LC 1 Rtot

A h1 k A k B kC h4

A

Overall Heat Transfer Coefficient (U) :

A modified form of Newtons Law of Cooling to encompass multiple resistances

to heat transfer.

(3.17)

q x UAToverall

Rtot

1

UA

(3.19)

Plane Wall (cont.)

Series Parallel Composite Wall:

Note departure from one-dimensional conditions for k F kG .

Circuits based on assumption of isothermal surfaces normal to x direction or

adiabatic surfaces parallel to x direction provide approximations for q x .

Tube Wall

The Tube Wall

Heat Equation:

1 d dT

(3.23)

kr

0

r dr dr

What does the form of the heat equation tell us about the variation of qr with

r in the wall?

Is the foregoing conclusion consistent with the energy conservation requirement?

How does qr vary with r ?

Temperature Distribution for Constant k :

Ts ,1 Ts,2 r

T r

ln Ts ,2

ln r1 / r2 r2

(3.26)

Tube Wall (Cont.)

Heat Flux and Heat Rate:

dT

k

qr k

Ts,1 Ts,2

dr r ln r2 / r1

qr 2 rqr

2 k

Ts ,1 Ts ,2

ln r2 / r1

qr 2 rLqr

2 Lk

Ts,1 Ts ,2

ln r2 / r1

Conduction Resistance:

ln r2 / r1

Rt ,cond

2 Lk

ln r2 / r1

Rt ,cond

2 k

Units K/W

Units m K/W

Why is it inappropriate to base the thermal resistance on a unit

surface area?

(3.27)

(3.28)

Tube Wall (Cont.)

Composite Wall with

Negligible Contact

Resistance

qr

T,1 T ,4

Rtot

UA T,1 T,4

(3.30)

Note that

UA Rtot 1

is a constant independent of radius.

But, U itself is tied to specification of an interface.

U i Ai Rtot

(3.32)

Spherical Shell

Spherical Shell

Heat Equation

1 d 2 dT

r

2 dr

r

dr

What does the form of the heat equation tell us about the variation of

qr with r ? Is this result consistent with conservation of energy?

How does qr vary with r ?

Temperature Distribution for Constant k :

T r Ts ,1 Ts ,1 Ts ,2

1 r1/ r

1 r1 / r 2

Spherical Shell (cont.)

Heat flux, Heat Rate and Thermal Resistance:

dT

k

2

Ts,1 Ts,2

dr r 1/ r1 1/ r2

4 k

qr 4 r 2 qr

Ts,1 Ts,2

1/

r

1/

r

1 2

qr k

Rt ,cond

1/ r1 1/ r2

4 k

Composite Shell:

T

qr overall UAToverall

Rtot

UA Rtot 1 Constant

U i Ai Rtot

Depends on Ai

(3.35)

(3.36)

Problem: Thermal Barrier Coating

Case Study 1: Assessment of thermal barrier coating (TBC) for protection

of turbine blades. Determine maximum blade temperature

with and without TBC.

Schematic:

ASSUMPTIONS: (1) One-dimensional, steady-state conduction in a composite plane wall, (2) Constant

properties, (3) Negligible radiation.

Problem: Thermal Barrier (Cont.)

ANALYSIS: For a unit area, the total thermal resistance with the TBC is

, w ho1 L k Rt, c L k hi1

Rtot

Zr

In

, w 10

Rtot

3.85 10

10

2 10

2 10

m2 K W =3.6910-3m2 K W

With a heat flux of

qw

T, o T, i

, w

Rtot

1300 K

3.6910-3 m 2 K W

=3.52105 W m 2

the inner and outer surface temperatures of the Inconel are

hi

Ts, i ( w) T, i qw

400 K+ 3.52105 W m2 500 W m 2 K =1104 K

Ts , o( w) T, i 1 hi L k In qw

-3

=400 K+ 210 +210

-4

m K W 3.5210

2

W m

=1174 K

Problem: Thermal Barrier (Cont.)

Without the TBC,

1

Rtot

, wo ho L k In hi

T, o T, i

qwo

-3

3.2010 m K W

, wo 4.06105 W/m2.

Rtot

the inner and outer surface temperatures of the Inconel are

hi 1212 K

Ts,i(wo) T,i q wo

Ts , o ( wo ) T , i

1 hi L

1293 K

k In qwo

Use of the TBC facilitates operation of the Inconel below Tmax = 1250 K.

COMMENTS: Since the durability of the TBC decreases with increasing temperature, which increases

with increasing thickness, limits to its thickness are associated with reliability considerations.

Problem: Radioactive Waste Decay

Case Study 2: Suitability of a composite spherical shell for storing

radioactive wastes in oceanic waters.

SCHEMATIC:

ASSUMPTIONS: (1) One-dimensional conduction, (2) Steady-state conditions, (3) Constant

properties at 300K, (4) Negligible contact resistance.

PROPERTIES: Table A-1, Lead: k = 35.3 W/mK, MP = 601K; St.St.: 15.1 W/mK.

ANALYSIS: From the thermal circuit, it follows that

T T

4

q= 1

q r13

R tot

3

Problem: Radioactive Waste Decay (Cont.)

The thermal resistances are:

1

1

R Pb 1/ 4 35.3 W/m K

0.00150 K/W

0.25m

0.30m

1

1

R St.St. 1/ 4 15.1 W/m K

0.000567 K/W

0.30m 0.31m

R conv 1/ 4 0.312 m 2 500 W/m2 K 0.00166 K/W

R tot 0.00372 K/W.

The heat rate is then

3

q=5 105 W/m 3 4 / 3 0.25m 32, 725 W

and the inner surface temperature is

T1 T R tot q=283K+0.00372K/W 32,725 W 405 K < MP = 601K.

Hence, from the thermal standpoint, the proposal is adequate.

COMMENTS: In fabrication, attention should be given to maintaining a good thermal contact. A

protective outer coating should be applied to prevent long term corrosion of the stainless steel.

Você também pode gostar

- Steady StateDocumento28 páginasSteady StateBoyHahaAinda não há avaliações

- HT Student Notes-Part1Documento72 páginasHT Student Notes-Part1Arvind Rebel75% (4)

- HW 3Documento14 páginasHW 3Mark LutherAinda não há avaliações

- HT 02 ConductionDocumento37 páginasHT 02 ConductionDubistWhiteAinda não há avaliações

- Chapter 2 Conduction AnalysisDocumento16 páginasChapter 2 Conduction AnalysisNurul AsyilahAinda não há avaliações

- Chapter 3 Heat Trasnfer 4001Documento45 páginasChapter 3 Heat Trasnfer 4001Maria Camila De la RosaAinda não há avaliações

- Heat Chap03 039Documento17 páginasHeat Chap03 039Kerem GönceAinda não há avaliações

- Fundamentals of Heat and Mass Transfer Bergman 7th Edition Solutions ManualDocumento22 páginasFundamentals of Heat and Mass Transfer Bergman 7th Edition Solutions Manualcuongviolet1or0zm0% (1)

- Assignment 1Documento7 páginasAssignment 1AdarshpatankarAinda não há avaliações

- HMT Answer 2 & 16 Marks HMTDocumento85 páginasHMT Answer 2 & 16 Marks HMTChandra Sekar100% (3)

- Heat Transfer From Finned SurfacesDocumento81 páginasHeat Transfer From Finned SurfacesIsmail MughalAinda não há avaliações

- Ch3 HeatTransfer 2Documento27 páginasCh3 HeatTransfer 2Fernando EsquivelAinda não há avaliações

- مثال فصل 3Documento10 páginasمثال فصل 3mohammadAinda não há avaliações

- Mech302-Heat Transfer Homework-7 SolutionsDocumento8 páginasMech302-Heat Transfer Homework-7 SolutionsJake OkuyeAinda não há avaliações

- MAE 4171: Principles of Heat Transfer Solution-Assignment #1Documento4 páginasMAE 4171: Principles of Heat Transfer Solution-Assignment #1Bo100% (5)

- Heat and Mass Transfer by S K Mondal T&QDocumento216 páginasHeat and Mass Transfer by S K Mondal T&Qajaykrishna_9983% (6)

- CH 11Documento72 páginasCH 11cameronsidwell0% (2)

- Heat Transfer Chapter 3Documento45 páginasHeat Transfer Chapter 3Gregory Simmon100% (1)

- 03.conduction Part1Documento35 páginas03.conduction Part1rameshaarya99Ainda não há avaliações

- 2marks & 16 Marks HMT PDFDocumento85 páginas2marks & 16 Marks HMT PDFSrini VasanAinda não há avaliações

- Konduksi TunakDocumento27 páginasKonduksi TunakRuryKharismaMuzaqieAinda não há avaliações

- Lecture 5 - May 2014 Heat TrasferDocumento19 páginasLecture 5 - May 2014 Heat TrasferAhmedHassan100% (12)

- Heat Transfer by S K Mondal-3-42Documento40 páginasHeat Transfer by S K Mondal-3-42Arpit Thakur0% (2)

- Tutorial Sheet 3Documento10 páginasTutorial Sheet 3kushalAinda não há avaliações

- Heat Transfer Calculations for Thermal Insulation ProblemsDocumento12 páginasHeat Transfer Calculations for Thermal Insulation ProblemsAdelia CristinaAinda não há avaliações

- Problem 1.1 KNOWN: Heat Rate, Q, Through One-Dimensional Wall of Area A, Thickness L, ThermalDocumento8 páginasProblem 1.1 KNOWN: Heat Rate, Q, Through One-Dimensional Wall of Area A, Thickness L, ThermalMarco Antonio Salcedo HinojosaAinda não há avaliações

- HW 01 SolutionDocumento6 páginasHW 01 SolutionPotatoes123Ainda não há avaliações

- 65687df49621435f859d0f69_45195217850Documento4 páginas65687df49621435f859d0f69_45195217850vitosoltanabadiAinda não há avaliações

- ME311 Assignment 1 ConductionDocumento4 páginasME311 Assignment 1 ConductionPradumn DixitAinda não há avaliações

- PERSAMAAN KONDUKSI PANAS DAN BERBAGAI KASUSDocumento25 páginasPERSAMAAN KONDUKSI PANAS DAN BERBAGAI KASUSArdanAinda não há avaliações

- Modes of Heat Transfer GuideDocumento110 páginasModes of Heat Transfer GuideksAinda não há avaliações

- Chapter - 2 Conduction Heat TransferDocumento41 páginasChapter - 2 Conduction Heat TransferRenu SekaranAinda não há avaliações

- sm3 049Documento2 páginassm3 049Sadie HnatowAinda não há avaliações

- ENG-S17-S18 - Heat Transfer Problems (Modes, Plane Wall, Thermal Resistances)Documento4 páginasENG-S17-S18 - Heat Transfer Problems (Modes, Plane Wall, Thermal Resistances)fAinda não há avaliações

- Critical Thickness PDFDocumento6 páginasCritical Thickness PDFSurya KiranAinda não há avaliações

- Heat transfer through double pane windowDocumento7 páginasHeat transfer through double pane windowKetan RsAinda não há avaliações

- Heat Conservation in Liquid IronDocumento2 páginasHeat Conservation in Liquid Ironarnaldorcr8646Ainda não há avaliações

- HW 1 SolDocumento9 páginasHW 1 SolNatalia AlvaradoAinda não há avaliações

- Week 2 - Assignment 2 - Final Heat TransferDocumento4 páginasWeek 2 - Assignment 2 - Final Heat TransferchandrakiranAinda não há avaliações

- Heat Transfer Qualifying Exam, Fall 2015Documento2 páginasHeat Transfer Qualifying Exam, Fall 2015Yoni Ramirez RoblesAinda não há avaliações

- One-Dimensional, Steady-State Conduction With Thermal Energy GenerationDocumento35 páginasOne-Dimensional, Steady-State Conduction With Thermal Energy GenerationIvan PonceAinda não há avaliações

- EjerciciosDocumento24 páginasEjerciciosMarjorieAinda não há avaliações

- Extended Surface Heat TransferDocumento13 páginasExtended Surface Heat TransferDirkMyburghAinda não há avaliações

- Tutorial 2-1Documento4 páginasTutorial 2-1chandan rajAinda não há avaliações

- Heat and Mass TransferDocumento107 páginasHeat and Mass Transferchandar munisamyAinda não há avaliações

- Lecture Notes For CO2 (Part 2) : 1-D Steady State Heat ConductionDocumento35 páginasLecture Notes For CO2 (Part 2) : 1-D Steady State Heat ConductionhahahaAinda não há avaliações

- Physical Electronics: Handbook of Vacuum PhysicsNo EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckAinda não há avaliações

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1No EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Ainda não há avaliações

- Physical Properties of High-Temperature SuperconductorsNo EverandPhysical Properties of High-Temperature SuperconductorsAinda não há avaliações

- Advances in Magnetohydrodynamics: Proceedings of a Colloquium Organized by the Department of Fuel Technology and Chemical Engineering at Sheffield University, October 1961No EverandAdvances in Magnetohydrodynamics: Proceedings of a Colloquium Organized by the Department of Fuel Technology and Chemical Engineering at Sheffield University, October 1961I. A. McGrathAinda não há avaliações

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterAinda não há avaliações

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresNo EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresNota: 4 de 5 estrelas4/5 (1)

- Electronic Devices and Circuits: In Three VolumesNo EverandElectronic Devices and Circuits: In Three VolumesNota: 3.5 de 5 estrelas3.5/5 (2)

- CHLDocumento1 páginaCHLToMemAinda não há avaliações

- Discussion Reaction EnggDocumento2 páginasDiscussion Reaction EnggToMemAinda não há avaliações

- Energy Audit Mauritian HouseholdDocumento13 páginasEnergy Audit Mauritian HouseholdToMemAinda não há avaliações

- Web Advert 230513Documento6 páginasWeb Advert 230513ToMemAinda não há avaliações

- Reaction rate determination and simulation of hydrogenation processDocumento3 páginasReaction rate determination and simulation of hydrogenation processToMemAinda não há avaliações

- 6.0 Analysis and DiscussionDocumento2 páginas6.0 Analysis and DiscussionToMemAinda não há avaliações

- List of Statistical FormulaeDocumento1 páginaList of Statistical FormulaeToMemAinda não há avaliações

- CHLDocumento1 páginaCHLToMemAinda não há avaliações

- Probability Tutorial ProblemsDocumento3 páginasProbability Tutorial ProblemsToMemAinda não há avaliações

- SPL DiscDocumento3 páginasSPL DiscToMemAinda não há avaliações

- Properties of Coal Classification and AnalysisDocumento7 páginasProperties of Coal Classification and AnalysisJaco KotzeAinda não há avaliações

- Determination of Concentration of Bromine Cyanide and Methyl Bromide and The Rate of Reaction As A Function of TimeDocumento4 páginasDetermination of Concentration of Bromine Cyanide and Methyl Bromide and The Rate of Reaction As A Function of TimeToMemAinda não há avaliações

- Liquid Phase Methyl Bromide Production KineticsDocumento8 páginasLiquid Phase Methyl Bromide Production KineticsToMemAinda não há avaliações

- Che2005y 3 2009 2 PDFDocumento4 páginasChe2005y 3 2009 2 PDFToMemAinda não há avaliações

- Simulation BromideDocumento3 páginasSimulation BromideToMemAinda não há avaliações

- Adsorption M + S . (K, K) - R K C (1 - ) 2. Reaction 3A + M.S T.S + 2H O (K) - R K C 3. Desorption T.S T + S (K, K) - R K - K - (1 - )Documento3 páginasAdsorption M + S . (K, K) - R K C (1 - ) 2. Reaction 3A + M.S T.S + 2H O (K) - R K C 3. Desorption T.S T + S (K, K) - R K - K - (1 - )ToMemAinda não há avaliações

- IndividuallyDocumento2 páginasIndividuallyToMemAinda não há avaliações

- This Practical Is Concerned For All Practical Made, But Then Procrastination AppearedDocumento1 páginaThis Practical Is Concerned For All Practical Made, But Then Procrastination AppearedToMemAinda não há avaliações

- UOM Reaction Engineering ExamDocumento4 páginasUOM Reaction Engineering ExamToMemAinda não há avaliações

- Discussion On Energy BalanceDocumento1 páginaDiscussion On Energy BalanceToMemAinda não há avaliações

- Literature ReviewDocumento2 páginasLiterature ReviewToMem50% (2)

- COSHH Assessment Coomassie ExampleDocumento3 páginasCOSHH Assessment Coomassie ExampleToMemAinda não há avaliações

- Lecture 1-Students NotesDocumento43 páginasLecture 1-Students NotesToMem50% (2)

- Matlab BasicsDocumento18 páginasMatlab BasicsUdhayakumar RathakrishnanAinda não há avaliações

- Liquid Phase Chemical Reactor FinalDocumento38 páginasLiquid Phase Chemical Reactor FinalToMemAinda não há avaliações

- MSS Chemical Engg Laws and Economics 2015-2016Documento6 páginasMSS Chemical Engg Laws and Economics 2015-2016ToMemAinda não há avaliações

- Lecture 1-Students NotesDocumento43 páginasLecture 1-Students NotesToMem50% (2)

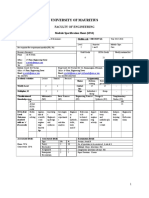

- University of Mauritius Faculty of EngineeringDocumento5 páginasUniversity of Mauritius Faculty of EngineeringToMemAinda não há avaliações

- Length)Documento4 páginasLength)George Godswill AguAinda não há avaliações

- E Hu HV HKGah 9 GFKPZDocumento7 páginasE Hu HV HKGah 9 GFKPZPeri PeriAinda não há avaliações

- PRODUCT INFORMATIONDocumento2 páginasPRODUCT INFORMATIONAdriana GonçalvesAinda não há avaliações

- Forensic ChemistryDocumento53 páginasForensic ChemistryJoana-MariAinda não há avaliações

- App1Documento12 páginasApp1Diastari KusumawatiAinda não há avaliações

- Stainless Steel Molecular Etching PDFDocumento6 páginasStainless Steel Molecular Etching PDFp.designAinda não há avaliações

- Planar Rigid Body Dynamics: Work and EnergyDocumento11 páginasPlanar Rigid Body Dynamics: Work and EnergynguyendaibkaAinda não há avaliações

- Development of Light Weight ConcreteDocumento14 páginasDevelopment of Light Weight ConcreteAmit ChouguleAinda não há avaliações

- Molecular ModelingDocumento22 páginasMolecular ModelingHely PatelAinda não há avaliações

- CaseStudy2 WindmillDocumento8 páginasCaseStudy2 WindmillAnthony BergemannAinda não há avaliações

- Calender IngDocumento12 páginasCalender IngAditi ChakrabortyAinda não há avaliações

- Visible Particles Regulatory and Compendial RequirementsDocumento31 páginasVisible Particles Regulatory and Compendial Requirementsdavincicode888Ainda não há avaliações

- Southern Company/MHI Ltd. Plant Barry CCS DemonstrationDocumento23 páginasSouthern Company/MHI Ltd. Plant Barry CCS Demonstrationrecsco2100% (1)

- Macroetch Testing of Tool Steel Bars: Standard Practice ForDocumento2 páginasMacroetch Testing of Tool Steel Bars: Standard Practice ForAmir AlikhaniAinda não há avaliações

- INSPECTION of Galvanize Product PDFDocumento24 páginasINSPECTION of Galvanize Product PDFNasikhatul AmanahAinda não há avaliações

- Liquid ring vacuum pumps and compressors operating modesDocumento5 páginasLiquid ring vacuum pumps and compressors operating modesSandi AslanAinda não há avaliações

- SR 6898 1 Tevi de Otel PDFDocumento1 páginaSR 6898 1 Tevi de Otel PDFCRISTIAN SILVIU IANUCAinda não há avaliações

- DSM Chemical Resistance TablesDocumento32 páginasDSM Chemical Resistance TablesJacp2Ainda não há avaliações

- Army Public School Bhopal: TOPIC:-" "Documento20 páginasArmy Public School Bhopal: TOPIC:-" "Gourav Pathariya100% (1)

- Design of Machine Elements GateDocumento4 páginasDesign of Machine Elements GateshashankAinda não há avaliações

- Characterisation of Polymer With GCDocumento104 páginasCharacterisation of Polymer With GCAmit KumarAinda não há avaliações

- Hydrometallurgical Process For TheDocumento11 páginasHydrometallurgical Process For ThemanzoorAinda não há avaliações

- Analysis of Driven Pile Setup With Abaqus/Standard 2006Documento1 páginaAnalysis of Driven Pile Setup With Abaqus/Standard 2006SIMULIACorpAinda não há avaliações

- Unit 4 Cell Division and Cell Communication UnitDocumento6 páginasUnit 4 Cell Division and Cell Communication Unitapi-237676607Ainda não há avaliações

- ENGINEERING DESIGN GUIDELINES Fin Fan Air Cooler Rev Web PDFDocumento18 páginasENGINEERING DESIGN GUIDELINES Fin Fan Air Cooler Rev Web PDFeoseos12Ainda não há avaliações

- DyeDocumento12 páginasDyeVeby LamanepaAinda não há avaliações

- ASTM E291 - 09 - Standard Test Methods Forchemical Analysis of Caustic Soda and Caustic Potash (Sodium Hydroxide and Potassium Hydroxide) 1Documento15 páginasASTM E291 - 09 - Standard Test Methods Forchemical Analysis of Caustic Soda and Caustic Potash (Sodium Hydroxide and Potassium Hydroxide) 1Boby WongAinda não há avaliações

- Introduction To Statistical Physics Solution Manual: Kerson HuangDocumento105 páginasIntroduction To Statistical Physics Solution Manual: Kerson Huangsumivrindavan100% (7)

- 05.lecture110120 GGE2012 PrecisionLeveling ByAhn 2pagesDocumento14 páginas05.lecture110120 GGE2012 PrecisionLeveling ByAhn 2pagesGirma FikreAinda não há avaliações

- MRES216 Physical Techniques For The Study of Biological SystemsDocumento10 páginasMRES216 Physical Techniques For The Study of Biological SystemsSaurabh ShineAinda não há avaliações

- Milipore CleanlinessDocumento76 páginasMilipore Cleanlinesswendypost73Ainda não há avaliações