Escolar Documentos

Profissional Documentos

Cultura Documentos

Data 1TK-2952 Tanque de Isomerado

Enviado por

luismmonDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Data 1TK-2952 Tanque de Isomerado

Enviado por

luismmonDireitos autorais:

Formatos disponíveis

Document No.

DS-P162-CMS-1TK2952

Item No. 1TK-2952

LOW PRESSURE TANK DATA SHEET

Job. No.

P162

Service

TANQUE DE ISOMERADO

Customer YPFB Refinacion S.A.

Project:

NUEVOS TANQUES DE ALMACENAMIENTO

Unit:

ALMACENAMIENTO

Nominal Capacity 10300 BBL NOM.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Date

No. Required:

Size

ONE

18-Jun-14 Rev. E1

1 OF 2

Sheet

By

Chk'd

Apprvd.

48'-0" I.D. X 32'-0" S/S

DESIGN DATA

Code Requirements

API 620

Stamp

YES

Design Pressure

6 PSIG pressure (-)0.5 PSIG vacuum

Design Temperature

120/20 F

Corrosion Allowance

1mm

X-Ray

PER CODE

Physical & Chemical Tests

PER CODE

Impact Tests

PER CODE

Roof Design DOME (Note 1)

Bottom Design DOME

Norm Pressure16 psia @ 100F Temperature

40 to 100oF

Fluid

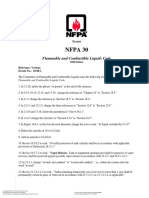

ISOMERADO, True V.P.= 16 PSIA @ 100oF

Specific Gravity

0.620 to 0.652 Flash Point Below 100 oF

Filling Rate 1000 gpm max. Pumpout

600 gpm max.

Corrosion Due To

Insulation Thickness

NONE

Wind Load 80 MPH, ASCE 7-05

Rain Load

15 mm/h

Earthquake Zone

See project design basis

Foundation EARTH (note 8 pg 2)

MATERIALS

CONNECTIONS

Shell

ASTM A285C (PREFERIBLE) or A36 (Note 2)

Roof

ASTM A285C (PREFERIBLE) or ASTM A36 (Note 3)

Bottom ASTM A285C (PREFERIBLE) or ASTM A36 (Note 4)

Gaskets

Flex. Style GC

Couplings

A105

Pipe ASTM A106 GR. B

Flanges

A105

Insulation

NONE

Externals

ASTM A36

Internals

ASTM A36

Surface PreparationCOMSERTEC EQ-100/101

External Paint

COMSERTEC EQ-100/101 (NOTE 5)

Internal Coating

COMSERTEC EQ-100/101 (NOTE 9)

External Bolts & Nuts ASTM A193 Gr.B7 & A194 Gr.2H

Internal Bolts & Nuts ASTM A193 Gr.B6 & A194 Gr.6

Platforms NOTE 6

Ladders

NOTE 6

SPECIAL REQUIREMENTS

Ladder / Platform Clips Req'd

Pipe Supports Req'd YES (for firewater sprays, note 7 pg 2)

Insulation Clips Req'd

NO

Grounding Lugs YES

NACE MR-01-75

NO

Lethal Service

NO

Hardness Test

PER CODE

Ultrasonic Test

PER CODE

Dye penetrant Test

PER CODE

Mark

N-1

N-2

N-3

N-4

N-5

N-6

N-7

N-8

N-9

N-10

N-11

N-12

N-13

N-14

N-15

N-16

Service

No.

INLET

1

OUTLET

1

PUMP OUT

1

LI (note 2 pg. 2)

1

LT (note 4 pg. 2)

1

LS (note 4 pg. 2)

1

1

CONSERVATION VLV.

TI

1

TT

1

PI

1

PT

1

SYPHON DRAIN

1

DRAIN

1

PORTABLE FOAM

1

3

SAMPLE (note 5 pg. 2)

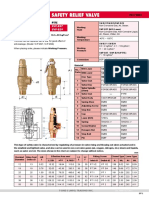

PSV (note 9&10 pg. 2) 2

H-1

M-1

M-2

GAUGING/SAMPLE

ROOF MANWAY

SHELL MANWAY

2

1

2

Size

10"

6"

6"

1"

8"

8"

6"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

3"

3"

6"

1-1/2"

6"

Rating

150#

150#

150#

3000#

150#

150#

125#

150#

150#

150#

150#

150#

150#

150#

150#

125#

Facing

RFWN

RFWN

RFWN

NPT

RFWN

RFWN

FFWN

RFWN

RFWN

RFWN

RFWN

RFWN

RFWN

RFWN

RFWN

FFWN

8" (NOTE 7)

20" API 620 STD (NOTE 8)

30"API 620 STD (NOTE 8)

NOTES

(1) The tank dome roof per API 620.

(2) Minimum shell thickness shall be 5/16" for bottom course and 1/4" for others.

(3) Minimum dome roof thickness shall be 1/4".

(4) Minimum bottom thickness shall be 5/16".

(5) With epoxy zinc rich primer with 2.5 mils min dry thickness. YPFBR will approve the paint manufacturer and color.

(6) Circular stairway. Include walkway and platforms where required to access instruments and roof manway. The stairways,

walkways and platforms shall be painted.

(7) Gauging and sampling device with gastight cover and handles.

(8) One piece cover with gasket and handles.

(9) The tank bottom and first ring shall be painted with a suitable paint for internal corrosion protection. The minimum dry

50 thickness shall be 250 microns. (10) See EI-P158-CMS-003 Requerimientos Tecnicos Para el OSBL y Servicios, for additional

requirements.

Rev/Date

Document No.

DS-P162-CMS-1TK2952

Item No. 1TK-2952

LOW PRESSURE TANK DATA SHEET

Job. No.

Service

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

P162

Customer YPFB Refinacion S.A.

No. Required:

TANQUE DE ISOMERADO

Date

ONE

Sheet

18-Jun-14 Rev. E1

2 OF 2

NOTES & ADDITIONAL REQUIREMENTS

(1) Nozzle N2 with vortex breaker.

(2) Include a Varec Model 2500 or equal level gauge.

(3) Project syphon drain to center of tank and 50 mm from bottom of dome

(4) Nozzles N5 and N6 with slotted 8" Schd 40 S.S. stilling well. Slots per API MPMS Chapter 3 Section 1A. See

sketck DW-P158-CMS-0002 for details.

(5) Nozzles N15 to be projected 250mm inside tank wall. Distribute sample connection strategically top, middle and

bottom of usable liquid level.

(6) Nozzle N14 for portable foam injection with internal elbow. Rotate elbow on plan view.

(7) Include clips and pipe supports as needed for firewater spray for cooling top of roof (outside) and outside surface.

(8) Foundation shall comply with API 620 and drawing CE-P158-CMS-2952.

(9) Contractor to verify capacity of venting devices in accordance with the filling and pumpout rates.

(10) Pressure safety valve to vent 1500mm from top of tank.

TANK SCHEMATIC

Rev/Date

Document No.

DS-P162-CMS-1TK2952

Item No. 1TK-2952

LOW PRESSURE TANK DATA SHEET

Job. No.

Service

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

P162

Customer YPFB Refinacion S.A.

No. Required:

TANQUE DE ISOMERADO

ONE

Date

18-Jun-14 Rev. E1

Sheet

3 OF 3

NOTAS DEL INSPECTOR API 653

Se excluye de aprobacion:

El piso en forma de domo y la fundacion (tierra) de croquis CE-P158-CMS-2952, estamos rediseando

un modelo de piso y fundacion mas seguro acorde a las condiciones del terreno, climaticas y

sismicas de Cochabamba y en cumplimiento a la norma API 620 vigente.

Apruebo el resto de esta hoja de datos

Luis M. Mon Herrera

Metallurgical Engineer. PE No. 84-010-003

API 653 Storage Tank Inspector Certification No. 34989

API 570 Piping Inspector Certification No. 41220

API 510 Pressure Vessel Inspector Certification No. 41793

API 580 Risk Based Inspection, Certification No. 44236

Non Destructive Examiner level II (SNT-TC-1A): UT,PT

Rev/Date

Julio 8, 2014

Você também pode gostar

- ListDocumento12 páginasListashishtaneja30Ainda não há avaliações

- Equipetrol Brochure Hi RsDocumento12 páginasEquipetrol Brochure Hi RsJorge ResendezAinda não há avaliações

- SBC (Safety Break-Away Couplings) v140630Documento16 páginasSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- rs-andes-basin-2020-Sub-Andean Thick and Thin-Skinned Thrust Systems AAPG Memoir117 Chapter02Documento28 páginasrs-andes-basin-2020-Sub-Andean Thick and Thin-Skinned Thrust Systems AAPG Memoir117 Chapter02David PradaAinda não há avaliações

- Forged Steel Flanges PriceListDocumento4 páginasForged Steel Flanges PriceListAdjie HofniAinda não há avaliações

- Siemens Coriolis Flow MeterDocumento69 páginasSiemens Coriolis Flow MeterDavinder Singh100% (1)

- Volvo Canada d13-455 Eco DualDocumento2 páginasVolvo Canada d13-455 Eco DualDIONYBLINK100% (1)

- Asme b16.43 PDFDocumento24 páginasAsme b16.43 PDFMuhammad RidwanAinda não há avaliações

- Incahuasi+Memoir117 Chapter23Documento24 páginasIncahuasi+Memoir117 Chapter23aristi51Ainda não há avaliações

- 1045-BB1-ME-CAL-001 - A ScopeDocumento187 páginas1045-BB1-ME-CAL-001 - A ScopeAlfredo Bautista HernándezAinda não há avaliações

- Oil and Gas Upstream in Bolivia - YPFB (081-180)Documento100 páginasOil and Gas Upstream in Bolivia - YPFB (081-180)Dream-&-CreateAinda não há avaliações

- Tka-209 Manual Worksheet For Standard Permeability MeasurementsDocumento3 páginasTka-209 Manual Worksheet For Standard Permeability MeasurementsCamila Nelida BernabeAinda não há avaliações

- TK02 Rev01Documento7 páginasTK02 Rev01mggz_15Ainda não há avaliações

- Annex H (Summary API 650) : 1. MaterialDocumento6 páginasAnnex H (Summary API 650) : 1. MaterialnjkasdncjkdAinda não há avaliações

- Buoyancy Calculation Report: Tanap Trans Anatolian Natural Gas Pipeline ProjectDocumento31 páginasBuoyancy Calculation Report: Tanap Trans Anatolian Natural Gas Pipeline ProjectbabuAinda não há avaliações

- Datasheet BombaDocumento4 páginasDatasheet BombasaculAinda não há avaliações

- Engrasadora NEUMATICAFLOWSERVERDocumento16 páginasEngrasadora NEUMATICAFLOWSERVERLuis E. Barcelo TovarAinda não há avaliações

- Floboss 104 Flow Manager Fb104 en 132242Documento7 páginasFloboss 104 Flow Manager Fb104 en 132242Marco Antonio TintayaAinda não há avaliações

- Technical Data: Foam Chambers Model FCDocumento5 páginasTechnical Data: Foam Chambers Model FCjhoger2012Ainda não há avaliações

- Medidores Rotativos Série FMRDocumento3 páginasMedidores Rotativos Série FMRmateuAinda não há avaliações

- En 1092-1 PN-10 Steel Pipe Flange - ValviasDocumento5 páginasEn 1092-1 PN-10 Steel Pipe Flange - ValviasHoria ZecheruAinda não há avaliações

- Planilla Calculo PSVDocumento66 páginasPlanilla Calculo PSVPROCESOS PROCESOSAinda não há avaliações

- Norma Astm f2648-13 - SP Tuberia PerforadaDocumento12 páginasNorma Astm f2648-13 - SP Tuberia PerforadaAlcidesRivasMancillaAinda não há avaliações

- JAG Neway Ball Valves PDFDocumento32 páginasJAG Neway Ball Valves PDFprsiva2420034066Ainda não há avaliações

- QT 16Cr PDFDocumento1 páginaQT 16Cr PDFYaroslav RuizAinda não há avaliações

- RLP Topd HDD e 1800 0046 H1 R2Documento10 páginasRLP Topd HDD e 1800 0046 H1 R2fedemochileroAinda não há avaliações

- Act 1 Perforacion DireccionalDocumento7 páginasAct 1 Perforacion Direccionalfabricio cabreraAinda não há avaliações

- Locating Field WeldDocumento8 páginasLocating Field WeldRafeek ShaikhAinda não há avaliações

- Brochure Semi Trailer LPG Tank - R1Documento2 páginasBrochure Semi Trailer LPG Tank - R1miqbalAinda não há avaliações

- API 650 10th Edition ErrataDocumento6 páginasAPI 650 10th Edition ErrataJosé Ramón GutierrezAinda não há avaliações

- Dimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97Documento3 páginasDimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97konazoi100% (1)

- Uwp Model 2030 Os&y Gate Valve 2.5 In.-24 In. SizesDocumento4 páginasUwp Model 2030 Os&y Gate Valve 2.5 In.-24 In. SizesHector Acaro RodriguezAinda não há avaliações

- Amreya Petroleum Refinery Company (Aprc) : Atlas Copco CrepelleDocumento9 páginasAmreya Petroleum Refinery Company (Aprc) : Atlas Copco Crepelleالبريمه المصريهAinda não há avaliações

- Tugas 2 Rekayasa Pipa - Gita Surya Yahya - 04211640000045Documento10 páginasTugas 2 Rekayasa Pipa - Gita Surya Yahya - 04211640000045Gita SuryaAinda não há avaliações

- H 223Documento5 páginasH 223Oscar DorflerAinda não há avaliações

- Fisher Type 667 Diaphragm ActuatorDocumento32 páginasFisher Type 667 Diaphragm Actuatorimran khanAinda não há avaliações

- Weight-Material: Dynamic Sag Test VSST MethodDocumento3 páginasWeight-Material: Dynamic Sag Test VSST MethodLMP2 Mud EngineerAinda não há avaliações

- Manual Medidor Turbina RMG TRZ 03Documento8 páginasManual Medidor Turbina RMG TRZ 03Cleverson BorghezanAinda não há avaliações

- Calentador CataliticoDocumento2 páginasCalentador Cataliticoinstrumentacion.hsrAinda não há avaliações

- Not For Production Use (For Reference Only) : ASTM A778-01Documento1 páginaNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefAinda não há avaliações

- Norma SimonsDocumento24 páginasNorma SimonsJUAN PABLO LUCEROAinda não há avaliações

- Anvil Fig137 U-Bolt PDFDocumento1 páginaAnvil Fig137 U-Bolt PDFAin AzmiAinda não há avaliações

- 26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002Documento33 páginas26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002ogyriskyAinda não há avaliações

- Safety Data Sheet: Deluge ValveDocumento4 páginasSafety Data Sheet: Deluge ValveikramAinda não há avaliações

- Odin Elastopipe Eng Oct 2019 PDFDocumento2 páginasOdin Elastopipe Eng Oct 2019 PDFHafidzManaf100% (1)

- SY Series LEDEEN Actuators: Pneumatic and Hydraulic ActuatorsDocumento8 páginasSY Series LEDEEN Actuators: Pneumatic and Hydraulic ActuatorsCarla FerroAinda não há avaliações

- TB27a ENDocumento4 páginasTB27a ENandy131078Ainda não há avaliações

- Content of Standard 4S-10.02: FRP Pressure Pipe, Fittings and FlangesDocumento24 páginasContent of Standard 4S-10.02: FRP Pressure Pipe, Fittings and FlangesJuan Ayala ValdebenitoAinda não há avaliações

- Bronze Safety Relief Valve: SV-B27 SVP-B27 SV-B29 SVP-B29Documento1 páginaBronze Safety Relief Valve: SV-B27 SVP-B27 SV-B29 SVP-B29Shishan Ahmad100% (1)

- HEAT-TRACE Hoja CalculoDocumento1 páginaHEAT-TRACE Hoja CalculotineohAinda não há avaliações

- BOLIVIADocumento28 páginasBOLIVIAvictor mamaniAinda não há avaliações

- Calculo Espesores ASME B31.4Documento13 páginasCalculo Espesores ASME B31.4Juan YepesAinda não há avaliações

- Aspen 7.2 InstallationDocumento18 páginasAspen 7.2 InstallationSampathkumar Attuluri0% (1)

- Regulador Eska ValveDocumento5 páginasRegulador Eska ValveFercho Mariscal100% (1)

- Bes 800-101Documento25 páginasBes 800-101jfferrog100% (1)

- PPR VerdeDocumento96 páginasPPR VerdeIonut SomneaAinda não há avaliações

- Split Tee CatalogoDocumento3 páginasSplit Tee Catalogobotella berAinda não há avaliações

- Practica # 2 PRV2SIZE PDFDocumento4 páginasPractica # 2 PRV2SIZE PDFCarmen Zurita VeizagaAinda não há avaliações

- Memoria - Tanque N 1° La2326cDocumento98 páginasMemoria - Tanque N 1° La2326cmile457100% (1)

- Tank DatasheetDocumento4 páginasTank DatasheetAlvin Smith60% (5)

- Aws b2.1.1.205Documento25 páginasAws b2.1.1.205Aliakbar Ghaderi100% (2)

- Summary of Changes in 2019Documento82 páginasSummary of Changes in 2019sundarAinda não há avaliações

- 7 App D F Underground PetroleumDocumento6 páginas7 App D F Underground PetroleumluismmonAinda não há avaliações

- Nfpa 30 ErtaDocumento2 páginasNfpa 30 Ertanap_carinoAinda não há avaliações

- RoundnessDocumento35 páginasRoundnesssrinivasansscAinda não há avaliações

- RoundnessDocumento35 páginasRoundnesssrinivasansscAinda não há avaliações

- Invoiceapi 653 MstsDocumento1 páginaInvoiceapi 653 MstsluismmonAinda não há avaliações

- A Pi 510 PV ChecklistDocumento3 páginasA Pi 510 PV ChecklistluismmonAinda não há avaliações

- 1620 E. Richey Rd. Houston, TX 77073 Tel: 281-821-4156, Fax: 281-821-8901 InvoiceDocumento2 páginas1620 E. Richey Rd. Houston, TX 77073 Tel: 281-821-4156, Fax: 281-821-8901 InvoiceluismmonAinda não há avaliações

- FS101 Operation ManualDocumento108 páginasFS101 Operation ManuallyfedancerAinda não há avaliações

- Cgarena Apr12 MagDocumento73 páginasCgarena Apr12 MagBanya TungprasertAinda não há avaliações

- Kathryn Topper, Perseus, The Maiden Medusa, and The Imagery of AbductionDocumento34 páginasKathryn Topper, Perseus, The Maiden Medusa, and The Imagery of AbductionLudwigRossAinda não há avaliações

- SAPScript FormsDocumento65 páginasSAPScript FormswiktroAinda não há avaliações

- History of Photography Timeline AssignmentDocumento14 páginasHistory of Photography Timeline Assignmentapi-442289303Ainda não há avaliações

- CPAR LAS Module 6Documento3 páginasCPAR LAS Module 6Venus AriateAinda não há avaliações

- Allwenn Soul Sword Free PreviewDocumento61 páginasAllwenn Soul Sword Free PreviewsmartelfAinda não há avaliações

- Metal Finishing 2010 PDFDocumento740 páginasMetal Finishing 2010 PDFJuan Ignacio Alvarez Herrera100% (2)

- De Stijl Revised PDFDocumento7 páginasDe Stijl Revised PDFsuresh pv100% (1)

- Jonathan Rosenbaum - David Lynch Twin PeaksDocumento6 páginasJonathan Rosenbaum - David Lynch Twin PeaksalexrgnAinda não há avaliações

- Kim Lighting Landscape Lighting Catalog 1992Documento28 páginasKim Lighting Landscape Lighting Catalog 1992Alan MastersAinda não há avaliações

- Modern and Post Modern Architecture 202, 215, 216Documento64 páginasModern and Post Modern Architecture 202, 215, 216ABHISHEK MAHARJANAinda não há avaliações

- Article By: Hobart M. King, PH.D., RPG: QuartzDocumento9 páginasArticle By: Hobart M. King, PH.D., RPG: QuartzThomaz JudeaAinda não há avaliações

- Riaz Ahmed 12 Ntu 158Documento9 páginasRiaz Ahmed 12 Ntu 158Musarrat HussainAinda não há avaliações

- Kayla Mckay 1/2/2017 1B Renaissance Research PaperDocumento4 páginasKayla Mckay 1/2/2017 1B Renaissance Research Paperapi-360767456Ainda não há avaliações

- Oana Scarlet Caragea - PortfolioDocumento28 páginasOana Scarlet Caragea - PortfolioOana Caragea ScarletAinda não há avaliações

- Villa Project LaunchDocumento13 páginasVilla Project LaunchSrikanth JanardhanAinda não há avaliações

- Lee Miller Picasso Press Release Final (2019!10!18 19-43-51 UTC)Documento5 páginasLee Miller Picasso Press Release Final (2019!10!18 19-43-51 UTC)Zsófia AlbrechtAinda não há avaliações

- American CultureDocumento9 páginasAmerican CultureAlina DanielaAinda não há avaliações

- Art in Renaissance EraDocumento21 páginasArt in Renaissance EraDanny ParaonAinda não há avaliações

- Billie Holiday Research EssayDocumento8 páginasBillie Holiday Research EssayZoe KarpAinda não há avaliações

- Uk Aad Product Catalogue 2015 PDFDocumento109 páginasUk Aad Product Catalogue 2015 PDFWOLFWBEARWAinda não há avaliações

- MetaSynth Tutorials5 PDFDocumento75 páginasMetaSynth Tutorials5 PDFantidogmatiqAinda não há avaliações

- Pointillism PowerPointDocumento9 páginasPointillism PowerPointCarla HoltzhausenAinda não há avaliações

- Phil Collins - Discography - TracklistDocumento12 páginasPhil Collins - Discography - TracklistPuneet SrivastavaAinda não há avaliações

- 601 1111 1 SMDocumento20 páginas601 1111 1 SMАлександр СеровAinda não há avaliações

- Mari KugaDocumento357 páginasMari KugaDavid Bara EganAinda não há avaliações

- Latin PaleographyDocumento78 páginasLatin PaleographyTiago Cândido100% (2)

- Adobe Photoshop CC - Key Terms 2Documento2 páginasAdobe Photoshop CC - Key Terms 2kayla behlerAinda não há avaliações

- Unit 1 Importance Meaning and Assumption of ArtDocumento33 páginasUnit 1 Importance Meaning and Assumption of ArtCedrick AngelesAinda não há avaliações