Escolar Documentos

Profissional Documentos

Cultura Documentos

Camworks 2.5-Axis Milling: For Pocketing, Contouring, and Drilling

Enviado por

Axel DominiqueTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Camworks 2.5-Axis Milling: For Pocketing, Contouring, and Drilling

Enviado por

Axel DominiqueDireitos autorais:

Formatos disponíveis

CAMWORKS 2.

5-AXIS MILLING

For Pocketing, Contouring, and Drilling

Automatic Feature Recognition (AFR) automatically

recognizes over 20 types of features on native Solid

Edge part models or on solid models imported via

IGES, STP, SAT, etc. Feature-based machining reduces

programming time by as much as 90% compared to

traditional CAM software.

CIRCULAR BOSS

HOLE

TAPPED HOLE

RECTANGULAR SLOT

CIRCULAR POCKET

OBROUND BOSS

IRREGULAR

POCKETS

MULTI-STEPPED HOLE

CORNER SLOT

FILLETS &

TAPERS

COUNTERSUNK

HOLE

OBROUND

POCKET

RECTANGULAR BOSS

IRREGULAR

SLOT

COUNTER BORE

HOLE

RECTANGULAR POCKET

Interactive Feature Recognition (IFR) provides an

intuitive and easy-to-use wizard interface for inserting

user-dened features

Knowledge-Based Machining allows you to capture

and reuse your programmers and machinists best

programming practices using the patented TechDB

(Technology Database). The TechDB reduces

programming time by as much as 80% and provides a

company-owned database to store employee

knowledge and skill.

Seamless Integration of CAMWorks with Solid Edge

ensures that the design model and CAM model share

a common interface with the same intuitive menus,

toolbars, and view manipulation, thus allowing users

to quickly master the software. The CAM data is

integrated and stored along with the CAD model

automatically in a single le.

2.5-Axis Milling includes automatic roughing,

ocuntouring (nishing), thread milling, hole drilling,

boring, reaming, ant tapping cycles. Machining

algorithms use the latest toolpath and gouge

protection methods to provide fast, error-free

toolpaths

Thread Milling supports bi-directional thread milling

for both single-point and multi-point tools. Thread

mill with ID or OD threads, using climb or conventional

milling. Either top-down or bottom-up cycles can be

employed.

Face Mill generates toolpaths on a face feature to

square or face o the top of a part. Number of passes

can be calculated automatically or can be user

dened. An option is also available to specify one pass

down the middle of the part.

Full Model to Toolpath Associativity automatically

updates the toolpaths and CAM data to design

changes made to the model

4- and 5-Axis Indexing Included! The CAMWorks

2.5-axis module also includes 4- and 5-axis indexing

(pre-positioning) to reduce setups and facilitate the

use of shorter, more rigid tools. Setups and indexing

angles are created and posted automatically.

Drilling Cycles: Canned cycle support for all major

hole types and cycles including drill, pecking,

high-speed

pecking,

v a r i a b l e

pecking, bore, bore w/

dwell,

back

boring,

ne

boring,

counter boring,

ream, ream w/ dwell,

tapping, reverse tapping

www. camworks .com

CAMWORKS 2.5-AXIS MILLING

Roughing Operations remove material by following

the machinable feature shape in standard pattern

strategies. Patterns included are: zigzag, zig, pocket

in/out, spiral in/out, plunge rough, and oset

roughing. High-speed toolpaths can be generated

with no sharp corners.

Countersink and Center Drill Operations include

automatic calculation of machining depth based on

tool size/shape and countersink diameter

Assembly Mode Machining allows you to accurately

model your xtures and clamps using Solid Edge

assemply mode to avoid costly crashes with tools.

Also includes ll xture

oset

and

sub-programming

support for automatic

programming

of

multiple part setups.

CAMWorks Conguration Support for multiple

setups across multiple machines. Programs for each

machining setup can be saved as a separate

conguration, even for multiple machines of dierent

types. Using congurations, all of the programs

required to machine a part cab be stored along

with the CAD model automatically, in a

single le.

CAMWorks VoluMill is an optional

module for creating ultra-high

performance toolpaths, using

the latest technology to

rough mill parts faster

and more eciently

than any other

product available on

the market today

CAMWorks Modules are available in a variety

of bundles or combinations:

Simulation and

Verication allows you

to easily and accurately step

through

or

continuously

simulate toolpaths with speed control and optional

stop capabilities. A model compare feature is also

included, to compare the machined model and the

design model to validate program accuracy, so you can

be sure youll cut it right the rst time

2.5-Axis Mill

3-Axis Mill

Multi-Axis Machining

Mill Turn

2- and 4-Axis Turning

Wire EDM

CAMWorks VoluMill

CAMWorks Virtual Machine

About Geometric

CAMWorks

Geometric is a specialist in the domain of engineering solutions, services and technologies. Its Geometry Technology Solutions

(GTS) business unit develops cutting-edge point productivity solutions that enhance design and improve manufacturing

operations. The end-user products from Geometric include CAMWorks, eDrawings Publisher, DFMPro, GeomCaliper,

3DPaintBrush, CAMWorksXpress and Glovius. The key technologies from Geometric are NestLib, Feature Recognition (FR),

GeomDi and 3DSearchIT. Geometric licenses these technologies to OEM partners and also designs and implements

customized process solutions using these technologies for industrial customers.

To know more about this solution:

email: inquiries@camworks.com

www.camworks.com/solidedge

For further details about Geometrics GTS business unit, please visit www.geometricglobal.com/products

or call 480.367.0132

The copyrights/trademarks of all products referenced herein, are held by their respective companies.

Você também pode gostar

- Camworks 2.5-Axis Milling: For Pocketing, Contouring, and DrillingDocumento2 páginasCamworks 2.5-Axis Milling: For Pocketing, Contouring, and DrillingNisarg MehtaAinda não há avaliações

- Boxford UK Catalossgue WebDocumento58 páginasBoxford UK Catalossgue WebWael BazziAinda não há avaliações

- Cad Cam Destools v2 WebDocumento6 páginasCad Cam Destools v2 Weblaro76Ainda não há avaliações

- Catia v5 Machining BrochureDocumento4 páginasCatia v5 Machining BrochureMiguel PittaAinda não há avaliações

- Data Sheet SolidcamDocumento2 páginasData Sheet SolidcamCrea mundoAinda não há avaliações

- Let's Go Manufacture !Documento2 páginasLet's Go Manufacture !Gustavo HernándezAinda não há avaliações

- Multi-Axis SEDocumento2 páginasMulti-Axis SEVISHNU V SAinda não há avaliações

- MAX-PAC Brochure Concepts NREC WebDocumento8 páginasMAX-PAC Brochure Concepts NREC Websrinivas murthyAinda não há avaliações

- Camworks 2020: Virtual MachiningDocumento18 páginasCamworks 2020: Virtual MachiningIonutNutuAinda não há avaliações

- CATIA AME Advanced Multi Axis Pocket MachiningDocumento2 páginasCATIA AME Advanced Multi Axis Pocket MachiningB.100% (3)

- Computer 2112Documento12 páginasComputer 2112zxcccz100% (2)

- Alphacam For Wood Datasheet-240212Documento2 páginasAlphacam For Wood Datasheet-240212Cristina CardosoAinda não há avaliações

- CATIA SGE Surface MachiningDocumento2 páginasCATIA SGE Surface MachiningB.Ainda não há avaliações

- NC Programming For Molds, Dies, Plates & Discrete ManufacturingDocumento2 páginasNC Programming For Molds, Dies, Plates & Discrete ManufacturingKhang NguyenAinda não há avaliações

- Cimatron NC-Programming Datasheet A4 ENDocumento2 páginasCimatron NC-Programming Datasheet A4 ENmanjunathnd1995Ainda não há avaliações

- Edgecam Production MillingDocumento2 páginasEdgecam Production MillingMarceloPolicastroAinda não há avaliações

- Mastercam X7 Wire PDFDocumento3 páginasMastercam X7 Wire PDFabsalon_jarv0% (1)

- Mold&dieDocumento2 páginasMold&dieTRUNG QUOC LEAinda não há avaliações

- Camworks 3 Axis Milling: Camworks 3 Axis Millingfor 3D Toolpaths, Roughing, and FinishingDocumento2 páginasCamworks 3 Axis Milling: Camworks 3 Axis Millingfor 3D Toolpaths, Roughing, and FinishingsaptagunungAinda não há avaliações

- NX CAD CAM 2 5 Axis Milling FoundationDocumento4 páginasNX CAD CAM 2 5 Axis Milling FoundationEren KayaAinda não há avaliações

- Workflow: Advanced Toolpath AcceleratorDocumento11 páginasWorkflow: Advanced Toolpath AcceleratorPhạm Đăng DiệnAinda não há avaliações

- Hexagon MI EDGECAM Product Brochure A4 Web ENDocumento28 páginasHexagon MI EDGECAM Product Brochure A4 Web ENHoang MaiAinda não há avaliações

- Delcam - PowerMILL 2014 R2 Whats New EN - 2014Documento109 páginasDelcam - PowerMILL 2014 R2 Whats New EN - 2014phạm minh hùngAinda não há avaliações

- ProNest 2012 Data SheetDocumento2 páginasProNest 2012 Data Sheetalejandro777_eAinda não há avaliações

- 5 - PowerMill 2019 BrochureDocumento4 páginas5 - PowerMill 2019 BrochureAhmedBrahamAinda não há avaliações

- Alphacam Router 13032012Documento4 páginasAlphacam Router 13032012Zalkar Kasymov0% (2)

- Alphacam Machinist 2015Documento4 páginasAlphacam Machinist 2015AchmatAfipudinAinda não há avaliações

- Power MILL2013Documento2 páginasPower MILL2013Adrian Saliba VellaAinda não há avaliações

- CATIA PLM Express: CATIA - Lathe & Prismatic MachiningDocumento2 páginasCATIA PLM Express: CATIA - Lathe & Prismatic MachiningjcetmechanicalAinda não há avaliações

- Pronest 2021 LT: Cad/Cam Nesting SoftwareDocumento2 páginasPronest 2021 LT: Cad/Cam Nesting SoftwareBesleaga GabrielAinda não há avaliações

- Top Solid Cam 2006 UsDocumento12 páginasTop Solid Cam 2006 Usapi-3725036100% (2)

- ON Product Design and Manufacturing: Prepared byDocumento25 páginasON Product Design and Manufacturing: Prepared byChinmay BeheraAinda não há avaliações

- Camworks 3-Axis Milling: For 3D Toolpaths, Roughing, and FinishingDocumento2 páginasCamworks 3-Axis Milling: For 3D Toolpaths, Roughing, and Finishingjulio ortegaAinda não há avaliações

- CAMplus BrochureDocumento8 páginasCAMplus BrochureFagner Moura100% (1)

- Delcam - PowerMILL 2012R2 Whats New EN - 2012Documento82 páginasDelcam - PowerMILL 2012R2 Whats New EN - 2012phạm minh hùngAinda não há avaliações

- Production Milling SURFCAMDocumento2 páginasProduction Milling SURFCAMMinou DeathfulAinda não há avaliações

- 300VMCi PC Technical Spec If CationDocumento8 páginas300VMCi PC Technical Spec If CationMohd NursyazwanAinda não há avaliações

- Vericut Brochure 70Documento16 páginasVericut Brochure 70sivakumarsambandamAinda não há avaliações

- Cimatron Mold Handout 2P en Letter WEBDocumento2 páginasCimatron Mold Handout 2P en Letter WEBPaul VeramendiAinda não há avaliações

- ALPHACAM For Wood Datasheet-240212Documento2 páginasALPHACAM For Wood Datasheet-240212José PerezAinda não há avaliações

- Mastercam Mill Is Rich in Features Yet Still Simple and Intuitive To UseDocumento4 páginasMastercam Mill Is Rich in Features Yet Still Simple and Intuitive To UseODEH ABU YAHIAAinda não há avaliações

- Cimatron Mold Handout A4 ENDocumento2 páginasCimatron Mold Handout A4 ENmanjunathnd1995Ainda não há avaliações

- BR Nxcam ExpressDocumento12 páginasBR Nxcam Expressvicks_169Ainda não há avaliações

- WhatsNew CimatronE 9.0 Version HighlightsDocumento3 páginasWhatsNew CimatronE 9.0 Version HighlightsfaizAinda não há avaliações

- 160TCLi PC Technical SpecificationDocumento8 páginas160TCLi PC Technical SpecificationChristina BassAinda não há avaliações

- PowerMILL Blades Blisks ImpellersDocumento1 páginaPowerMILL Blades Blisks ImpellersRelu ChiruAinda não há avaliações

- CAD/CAM Nesting Software: BenefitsDocumento4 páginasCAD/CAM Nesting Software: Benefitsibrahim toptasAinda não há avaliações

- Delcam - PowerMILL 2014 R1 Whats New EN - 2013Documento137 páginasDelcam - PowerMILL 2014 R1 Whats New EN - 2013phạm minh hùngAinda não há avaliações

- Gangam Style 6Documento31 páginasGangam Style 6Light WorkerAinda não há avaliações

- WorkNC DentalDocumento4 páginasWorkNC DentalArul SakthiAinda não há avaliações

- NX Total Machining PDFDocumento5 páginasNX Total Machining PDFHussein ZeinAinda não há avaliações

- DS 895160 R10 PNLT2023Documento4 páginasDS 895160 R10 PNLT2023teera warenasaAinda não há avaliações

- Cadcam2014 Part1 PDFDocumento126 páginasCadcam2014 Part1 PDFA. I. RehmanAinda não há avaliações

- CNC MachineTool Component Web2-5Documento2 páginasCNC MachineTool Component Web2-5Ramon RondoAinda não há avaliações

- Lecture-18 Virtual Prototyping: K.Sivanathan Assistant Professor Dept. of Mechatronics SRM UniversityDocumento8 páginasLecture-18 Virtual Prototyping: K.Sivanathan Assistant Professor Dept. of Mechatronics SRM UniversityRahul AshokAinda não há avaliações

- Delcam - PowerMILL 2012 Whats New EN - 2011Documento100 páginasDelcam - PowerMILL 2012 Whats New EN - 2011phạm minh hùngAinda não há avaliações

- Implementation of CAD/CAM System CATIA V5 in Simulation of CNC Machining ProcessDocumento8 páginasImplementation of CAD/CAM System CATIA V5 in Simulation of CNC Machining ProcessRay SaAinda não há avaliações

- Top Reason Inventor HSM CAMDocumento2 páginasTop Reason Inventor HSM CAMCha YessicaAinda não há avaliações

- AutoCAD Electrical 2020 for Electrical Control Designers, 11th EditionNo EverandAutoCAD Electrical 2020 for Electrical Control Designers, 11th EditionAinda não há avaliações

- Connector DeploymentDocumento7 páginasConnector DeploymentAxel DominiqueAinda não há avaliações

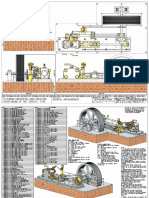

- A Single Cylinder Vertical Steam EngineDocumento3 páginasA Single Cylinder Vertical Steam EngineAxel DominiqueAinda não há avaliações

- Metro MoscuDocumento1 páginaMetro MoscuAxel DominiqueAinda não há avaliações

- F I .The Diam - MM - Dim .: SolidworksDocumento1 páginaF I .The Diam - MM - Dim .: SolidworksAxel DominiqueAinda não há avaliações

- 2 Cylinder Steam Engine To The Bernay DesignDocumento4 páginas2 Cylinder Steam Engine To The Bernay DesignAxel Dominique100% (1)

- 1 Cylinder Horizontal High Pressure Steam Engine of The - Corliss - TypeDocumento8 páginas1 Cylinder Horizontal High Pressure Steam Engine of The - Corliss - TypeAxel DominiqueAinda não há avaliações

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDocumento16 páginasClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyAxel DominiqueAinda não há avaliações

- A Single Cylinder Vertical Steam Engine of The GrasshopperDocumento8 páginasA Single Cylinder Vertical Steam Engine of The GrasshopperAxel DominiqueAinda não há avaliações

- A Simple Small Metalworking ShaperDocumento7 páginasA Simple Small Metalworking ShaperAxel DominiqueAinda não há avaliações

- Maudslay Marine Type Vertical Steam EngineDocumento3 páginasMaudslay Marine Type Vertical Steam EngineAxel DominiqueAinda não há avaliações

- Flame Eating EngineDocumento4 páginasFlame Eating EngineAxel DominiqueAinda não há avaliações

- Hexagon MI MSC Nastran Ebook A4 WEBDocumento46 páginasHexagon MI MSC Nastran Ebook A4 WEBAxel DominiqueAinda não há avaliações

- Z DistributionDocumento2 páginasZ DistributionVahid HelaćAinda não há avaliações

- Hexagon MI MSC Software Adams Ebook A4 WEBDocumento77 páginasHexagon MI MSC Software Adams Ebook A4 WEBAxel Dominique100% (1)

- Mechanical Engineer: EducationDocumento1 páginaMechanical Engineer: EducationAxel DominiqueAinda não há avaliações

- HyperCrash 12.0 User GuideDocumento873 páginasHyperCrash 12.0 User GuideAxel Dominique100% (1)

- Mathematica and SystemModeler KeygenDocumento3 páginasMathematica and SystemModeler KeygenAxel DominiqueAinda não há avaliações

- Cam Rocker Mechanism PDFDocumento6 páginasCam Rocker Mechanism PDFAxel DominiqueAinda não há avaliações

- Legal Statement Year 2002/2003 Releases TermsDocumento4 páginasLegal Statement Year 2002/2003 Releases TermsAxel DominiqueAinda não há avaliações

- asset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Documento42 páginasasset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Axel DominiqueAinda não há avaliações

- BOM Template v2Documento11 páginasBOM Template v2Axel DominiqueAinda não há avaliações

- UCF Athletics: 2016 17 (M) Basketball ScheduleDocumento2 páginasUCF Athletics: 2016 17 (M) Basketball ScheduleAxel DominiqueAinda não há avaliações

- 196 Vestas Case Study WerstDocumento18 páginas196 Vestas Case Study WerstAxel DominiqueAinda não há avaliações

- Models - Acdc.simple ResistorDocumento8 páginasModels - Acdc.simple ResistorAxel DominiqueAinda não há avaliações

- 19BCG1077 - Swarup DebDocumento1 página19BCG1077 - Swarup DebUX ༒CONQUERERAinda não há avaliações

- KeyboardDocumento8 páginasKeyboardaltawanmudzharAinda não há avaliações

- Multi-Crop HarvesterDocumento6 páginasMulti-Crop HarvesterErwinAinda não há avaliações

- Data Flow Diagram Level-0: Health Insurance System Customer InsurerDocumento1 páginaData Flow Diagram Level-0: Health Insurance System Customer InsurerVarun DhimanAinda não há avaliações

- CWCTDocumento5 páginasCWCTtroyel99Ainda não há avaliações

- Strategic Management Term PaperDocumento18 páginasStrategic Management Term PaperOchena RajkonnaAinda não há avaliações

- DesktopauditreportDocumento15 páginasDesktopauditreportapi-385391462Ainda não há avaliações

- Digital BankingDocumento66 páginasDigital BankingshyamAinda não há avaliações

- Joaquín Vélez: 1 HOTEL CENTRAL PARK - NYC - Construction EngineerDocumento2 páginasJoaquín Vélez: 1 HOTEL CENTRAL PARK - NYC - Construction EngineerVaé RiberaAinda não há avaliações

- From The President's Desk: in This IssueDocumento6 páginasFrom The President's Desk: in This IssueJayant ShaligramAinda não há avaliações

- Plantronics Voyager Pro Plus ManualDocumento10 páginasPlantronics Voyager Pro Plus Manualbsd_storesAinda não há avaliações

- Industrial Wiring and Design ProjectDocumento3 páginasIndustrial Wiring and Design ProjectJibril JundiAinda não há avaliações

- Alm-Ims-Prc-Si-013 Welding Inspection FDocumento11 páginasAlm-Ims-Prc-Si-013 Welding Inspection F123netflix542Ainda não há avaliações

- Sony Education Projectors 2019Documento60 páginasSony Education Projectors 2019alanAinda não há avaliações

- AICE Milestone04 03.04.2024Documento15 páginasAICE Milestone04 03.04.2024kevinkiprotichyegonAinda não há avaliações

- Advanced Product Quality Planning (APQP)Documento15 páginasAdvanced Product Quality Planning (APQP)José AlcocerAinda não há avaliações

- Premier League Season Review 2020 - 21Documento9 páginasPremier League Season Review 2020 - 21Iftar KhanAinda não há avaliações

- CHD Candidate Guidebook PDFDocumento20 páginasCHD Candidate Guidebook PDFsyammc0% (1)

- Collaborative Knowledge Networks: Peter Gloor Deloitte ConsultingDocumento15 páginasCollaborative Knowledge Networks: Peter Gloor Deloitte ConsultingJona D'johnAinda não há avaliações

- 1298Documento136 páginas1298Iker BasqueAdventureAinda não há avaliações

- Grades of Reinforcing SteelDocumento15 páginasGrades of Reinforcing Steelshuckss taloAinda não há avaliações

- Instruction Manual: Fundus CameraDocumento37 páginasInstruction Manual: Fundus Camerashakil ahmadAinda não há avaliações

- Company Report FS Work Draft !!!Documento26 páginasCompany Report FS Work Draft !!!tsehay seidAinda não há avaliações

- All Lab WorkDocumento43 páginasAll Lab WorkHarsh ChopraAinda não há avaliações

- Narada 12ndt190sDocumento2 páginasNarada 12ndt190sYANdalfAinda não há avaliações

- Indicative ProfileDocumento5 páginasIndicative ProfileYashveer TakooryAinda não há avaliações

- Amdocs Interview QuestionsDocumento3 páginasAmdocs Interview QuestionsOmkar J Goulay0% (1)

- Base Paper TamDocumento17 páginasBase Paper TamJoseph JohnAinda não há avaliações

- HPE BladeSystem Onboard Administrator Release Notes 4.97-A00112729en - UsDocumento16 páginasHPE BladeSystem Onboard Administrator Release Notes 4.97-A00112729en - Usamit_post2000Ainda não há avaliações

- Cpu - VTT Vcore: Gigabyte TechnologyDocumento35 páginasCpu - VTT Vcore: Gigabyte TechnologyDébo Orellano100% (1)