Escolar Documentos

Profissional Documentos

Cultura Documentos

TDC Fasteners TDC 5 166 Nuts

Enviado por

GohilaRajTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

TDC Fasteners TDC 5 166 Nuts

Enviado por

GohilaRajDireitos autorais:

Formatos disponíveis

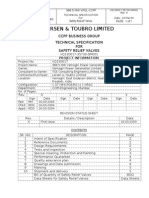

BHEL, Tiruchirappalli 620 014.

Quality Assurance

Technical Delivery Conditions

Product: CARBON & ALLOY STEEL NUTS TO SPECN. SA194 Gr. 2H/2HM/Gr.4/Gr.7 FOR

VALVES, OIL FIELD EQUIPMENTS AND OTHER APPLICATIONS.

Document No.; TDC:5:166

Rev.No.:04

Effective Date: 13/01/1999

Page: 1

1.0

MATERIAL SPECIFICATION

2.0

GENERAL

3.0

- SA 194 Gr2H/Gr2HM/Gr4/Gr7 {latest on date of Purchase Order (P.O)}

This TDC is applicable for API 6A applications including NACE MR-01-75 cl.II & cl.III also.

Shall be manufactured to the relevant drawing and P.O. requirements.

Nuts shall be hot/cold forged or manufactured from hot rolled/cold drawn bars. If made from hexagonal

bars, 100% MT is to be done on bars. If made from round bars, the bars shall be machined to remove 2mm

from surface, (ie 4mm in dia) to remove all surface defects. Atleast 10% of the machined bars shall be MT

tested to ensure that the surface defects are fully removed.

Nuts shall be heat treated to meet the requirements of SA194 only in a salt bath, or controlled

atmosphere furnace. After HT the threads shall be thoroughly cleaned to remove all deposits. When acid

pickling is done for cleaning it shall be done as per Cl 7.3.

Cadmium plating as per (Cl 7.1) if specified in drg/P.O. or rust preventive fluid coating as per ( Cl 7.2)

shall be done.

CHEMICAL & MECHANICAL PROPERTIES

Mill certificate for chemical composition from steel manufacturer for conformance to the specification

heat-wise. Additionally, product analysis shall be done for one piece/heat by the nut manufacturer.

HARDNESS

4.0

5.0

6.0

7.0

For SA194 2H, Gr4, & Gr7

Hardness check on finished nut as per SA194, using sampling plan (Cl.7.4).Hardness in the finished nut

shall be 24 to 35 HRC or 248 to 352 BHN.

For SA194 Gr2HM:

Hardness check on 100% of nuts.Hardness must be within 159 to 237 BHN.

Proof load test shall be done as per SA194 for all grades.

After final heat treatment, sample nuts shall be heat treated as below and meet the corresponding

hardness requirements.

-------------------------------------------------------------------Grade

Temp

TimeCooling

Hardness at room temp.

2H

540C

24Hrs

Slow cool 179 BHN (min)

2HM

540C

-doSlow cool 159 BHN (min)

Gr4/Gr7

590C

-doSlow cool 201 BHN (min)

-------------------------------------------------------------------CONE STRIPPING TEST: This test shall be performed as per SA194 in case of visible surface

discontinuities.On such cases Proof load shall be as per ASTM A194 (latest std).

FINAL INSPECTION

All inspection shall be as per drawing and SA194.

The threads shall be checked with calibrated plug gauge in the final heat-treated condition for black variety

and in final plated condition for the plated variety.

Visual and Dimensional checks in the finished nuts and their acceptance shall be as per IS 2614 TableI(latest).

MARKING & PACKING

Punch/emboss each finished nuts with material grade (2H/2HM/Gr4/Gr7); supplier's emblem.

Punch/emboss Sl.no also in 2HM nuts in addition to the above to co-relate with hardness. In addition,

the grade symbol shall be underlined.

Pack in wooden box of convenient size for easy handling & transportation.Mark quantity in each box.

CERTIFICATION

The manufacturer shall provide TC (ref. page 3) duly countersigned by the Authorised Inspecting

Authority nominated by BHEL in P.O. (if specified) along with Raw Material TC from Steel Maker.

Manufacturer's TC shall contain P.O.No.heat no., Chem & Mech properties,HT parameters,surface coating

with coating thickness, baking details and certify soundness & confirmation to P.O. requirements.

SPECIAL REQUIREMENTS

BHEL, Tiruchirappalli 620 014.

Quality Assurance

Technical Delivery Conditions

Product: CARBON & ALLOY STEEL NUTS TO SPECN. SA194 Gr. 2H/2HM/Gr.4/Gr.7 FOR

VALVES, OIL FIELD EQUIPMENTS AND OTHER APPLICATIONS.

Document No.; TDC:5:166

Rev.No.:04

Effective Date: 13/01/1999

Page: 2

7.1CADMIUM PLATING REQUIREMENTS

Clean the nuts to make it free from rust, grease, oil, scale, etc.,before plating.

When pickling is considered essential, it shall be done as per Cl 7.3.

Apply Cadmium Plating to the specified thickness on specified areas.

After plating, Bake the parts at 175 Deg.C to 205 Deg.C for a minimum period of 3 hours. The

elapsed time between plating and baking shall not exceed 8 hours.

Apply a Chromate Conversion coating after plating and baking.

7.2 RUST PREVENTIVE COATING REQUIREMENTS

Clean the nuts to make it free from rust, grease, oil, scale, etc., before applying protective coating.

When pickling is considered essential it shall be done as per Cl 7.3.

One coat of rust preventive fluid of any of the following vendors shall be applied.

CHEMICAL

VENDOR

1. BONITA-RPF

M/s Bonita Chemicals, 64, Industrial Estate, Nunhai, Agra-282 006.

2. CHAMPION-RPF

M/s Guardian Chemicals, 8, Rajaji IInd st, West Lake Area,

Nungambakkam, Madras-600 034

3. ECONOL RPF

M/s Process Aids, Bangalore

(non-drying type)

4. TECTYL 506

M/s Plastipeel Chemicals and Plastics (P) Ltd, Thane-400 604

5. TRPF

M/s Sundaram Paints Pvt. Ltd., Thanjavur-613 004

6. TRPF

M/s Solar Paints, Pudukkotai.

7. WICOR-P

M/s Western India Paint and Color Co P. Ltd, Madras-600 017

7.3 ACID PICKLING

When pickling is considered essential for cleaning, it shall be done using Hydrochloric acid of 5 to

10% acid concentration at 50 deg C with inhibitor.

The concentration and type of inhibitors shall be as recommended by any of the following vendors.

1) M/s Agromore Ltd. Bangalore. 2) M/s Prosol Corporation, Hyderabad. 3) M/s Guardian

Anticorrosives, Madras. 4) M/s Mascat Chemicals, Bombay.

After pickling thorough rinsing shall be carried out with water to remove acid residues.

Immediately after pickling, the components shall be dried and baked at 175 to 205 deg C for 3hours

before taking up the next operation.

7.4 SAMPLING PLAN FOR HARDNESS CHECK AFTER HT

The following double sampling plan shall be used.Hardness values shall be 25 to 34 HRC after HT.

IS 2500 (Double Sampling) Normal Inspection,Level 2.

-------------------------------------------------------------------------------------No. of

Acceptable Quality Level (2.5%)

Pieces

------------------------------------------------------------------in the

First Acceptance Reject Second Combined Acceptance Rejection

lot

samplenumber

numbersample sample

number

number

(n1) (Ac)

(Rc) (n2)

(n1+n2)

(Ac)

------------------------------------------------------------------------------------0 - 500

32

1

4

32

64

4

5

501 - 1200

50

2

5

50

100

6

7

1201 - 3200

80

3

7

80

100

8

9

3201 -10000

125 5

9

125

250

12

13

10001-35000

200 7

11

200

400

18

19

-----------------------------------------------------------------------------------------------------------------------------------------------------------

Ac:-Acceptance number: Max. no. of defectives allowed in the sample for the acceptance of the lot.

Rc:-Rejection number: Min.no. of defectives in the sample resulting in the lot's rejection.

PROCEDURE FOR OPERATING THIS PLAN : Suppose the lot size is 1,000. From table chose the class,

which includes 1,000 viz 501 - 1200. Hence, use the sampling plan given against this class.Take a

sample of 50 pieces and test for hardness.

BHEL, Tiruchirappalli 620 014.

Quality Assurance

Technical Delivery Conditions

Product: CARBON & ALLOY STEEL NUTS TO SPECN. SA194 Gr. 2H/2HM/Gr.4/Gr.7 FOR

VALVES, OIL FIELD EQUIPMENTS AND OTHER APPLICATIONS.

Document No.; TDC:5:166

Rev.No.:04

Effective Date: 13/01/1999

Page: 3

------------------------------------------------------------------------Revision record:

Rev:00/11.04.90 : First issue

Rev:01/21.06.90 : Editorial corrections

Rev:02/21.04.91 : TC for nuts added

Rev:03/20.10.96 : NDT,Acid pickling added & rewritten

Rev:04/13/01/99 : Studs/bolts changed as nuts in Cl.5,7.1,7.2

-------------------------------------------------------

R.Rajasekar

Qual. Assurance

Prepared by

K.Nagarajan

Engg/Valves

Haridoss

G.Mathivanan

Purchase/Valves

Quality Control

Reviewed by

P.Vasudevan

Quality assurance

K.Rengachari

Qual Assurance

Approved by

BHEL, Tiruchirappalli 620 014.

Quality Assurance

Technical Delivery Conditions

Product: CARBON & ALLOY STEEL NUTS TO SPECN. SA194 Gr. 2H/2HM/Gr.4/Gr.7 FOR

VALVES, OIL FIELD EQUIPMENTS AND OTHER APPLICATIONS.

Document No.; TDC:5:166

Rev.No.:04

Effective Date: 13/01/1999

Page: 4

TEST CERTIFICATE FOR NUTS - SAMPLE FORMAT

TC NO:

DATE:

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------CUSTOMER

:

P.O.NO:

Dt:

D.C.NO:

Dt:

PRODUCT

:

Specn :

SIZE OF BAR USED:

RAW MATL TC NO:

TDC NO:

HEAT NO.:

DRG NO:

LOT NO:

Thread specn:

QUANTITY:

----------------------------------------------------------------------------------------------CHEMICAL COMPOSITION(%):

----------------------------------------------------------------------------------------------C

Si

Mn

P

S

Cr

Ni

Others

----------------------------------------------------------------------------------------------|

|

|

|

|

|

|

|

----------------------------------------------------------------------------------------------HEAT TREATMENT:

----------------------------------------------------------------------------------------------HARDENING: TEMP:

Deg.C;SOAKING TIME:

Minutes; COOLING MEDIUM:

TEMPERING: TEMP:

Deg.C.SOAKING TIME:

Minutes; COOLING MEDIUM:

BAKING TEMP

:

Deg.CBAKING TIME:

Minutess.

---------------------------------------------------------------------------------------------MECHANICAL TESTING:

----------------------------------------------------------------------------------------------HARDNESS AFTER HT (MIN & MAX) :

BHN NO OF SAMPLES TESTED :

HARDNESS AFTER 24 HRS TEMPERING ON SAMPLE NUT :

BHN

PROOF LOAD APPLIED :

Kgf

CONE PROOF LOAD TEST :

LOAD APPLIED:

----------------------------------------------------------------------------------------------MAGNETIC TESTING (IN PROCESS):

FINAL INSPECTION (VISUAL):

----------------------------------------------------------------------------------------------SURFACE COATING :

COATING THICKNESS :

Microns

IDENTIFICATION :

----------------------------------------------------------------------------------------------It is certified that the above results are correct and the parts are as per specification & P.O. requirements.

Você também pode gostar

- AWWASTDSDocumento5 páginasAWWASTDSchavico113Ainda não há avaliações

- ITP Structural SteelDocumento14 páginasITP Structural SteelNavneet SinghAinda não há avaliações

- Grinding MIL STD 866Documento11 páginasGrinding MIL STD 866Dimitris GrimanelisAinda não há avaliações

- Rubber Lining ProcedureDocumento38 páginasRubber Lining ProcedureKumar Jbs83% (18)

- Job Procedure - PWHTDocumento11 páginasJob Procedure - PWHTDebashish ChatterjeeAinda não há avaliações

- Thermocouples Specification and Data SheetsDocumento8 páginasThermocouples Specification and Data SheetsRakesh NayakAinda não há avaliações

- Steel Framed House - EedosteelDocumento36 páginasSteel Framed House - Eedosteelwoongrae100% (1)

- Specification For 3 Layer Polyethylene CoatingDocumento34 páginasSpecification For 3 Layer Polyethylene CoatingYogesh BaraskarAinda não há avaliações

- Pressure Vessel Design Safety: Suryakant RanderiDocumento46 páginasPressure Vessel Design Safety: Suryakant Randericonny julandaAinda não há avaliações

- Ford M2C938-ADocumento7 páginasFord M2C938-Acolive.ptAinda não há avaliações

- TDC QapDocumento69 páginasTDC QapKuppuraj ParamsivamAinda não há avaliações

- Eco Flo Leathercraft Dyeing Finishing GuideDocumento8 páginasEco Flo Leathercraft Dyeing Finishing GuideAna Maria GruiaAinda não há avaliações

- Specification of GasketDocumento5 páginasSpecification of GasketRamana NatesanAinda não há avaliações

- Tender9 Vol II o II Pig Launcher and Receiver by MeconDocumento31 páginasTender9 Vol II o II Pig Launcher and Receiver by MeconVeena S VAinda não há avaliações

- Asme Section II A Sa-278Documento6 páginasAsme Section II A Sa-278Anonymous GhPzn1xAinda não há avaliações

- Bharat Heavy Electricals Limited: (High Pressure Boiler Plant)Documento26 páginasBharat Heavy Electricals Limited: (High Pressure Boiler Plant)MATHEENAinda não há avaliações

- 6-15-0072 Rev 2Documento8 páginas6-15-0072 Rev 2cynideAinda não há avaliações

- D. Specs For Field & Shop PaintingDocumento10 páginasD. Specs For Field & Shop PaintingrajeshAinda não há avaliações

- AAR Manual Steel Casting StandardsDocumento10 páginasAAR Manual Steel Casting StandardsfeelingsudoAinda não há avaliações

- Pocket Guide to Preventing Process Plant Materials Mix-upsNo EverandPocket Guide to Preventing Process Plant Materials Mix-upsAinda não há avaliações

- Inspection Check List 2Documento34 páginasInspection Check List 2r.devendranAinda não há avaliações

- Pumice As SandDocumento36 páginasPumice As SandArbie FerrerAinda não há avaliações

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesNo EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesNota: 3.5 de 5 estrelas3.5/5 (3)

- Hindustan Petroleum Corporation LTD.,: Specification For Coating & Wrapping of Underground PipesDocumento9 páginasHindustan Petroleum Corporation LTD.,: Specification For Coating & Wrapping of Underground PipesBrant AkkanAinda não há avaliações

- Irst 19Documento12 páginasIrst 19krischaeverAinda não há avaliações

- Synthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Documento9 páginasSynthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Ved PrakashAinda não há avaliações

- Type - 4 Cascade TenderDocumento24 páginasType - 4 Cascade TenderrajAinda não há avaliações

- Research Designs & Standards OrganisationDocumento12 páginasResearch Designs & Standards OrganisationHarshavardhan KulkarniAinda não há avaliações

- Is 11513 1999Documento11 páginasIs 11513 1999kishor150688Ainda não há avaliações

- QAP1Documento33 páginasQAP1sanjiv66669Ainda não há avaliações

- Request For Quotation: Collective RFQ Number/ Purchase GroupDocumento47 páginasRequest For Quotation: Collective RFQ Number/ Purchase GroupanmolAinda não há avaliações

- TS-Compressed Air SystemDocumento40 páginasTS-Compressed Air SystemmishtinilAinda não há avaliações

- Irs T19-1994Documento24 páginasIrs T19-1994vpmohammed0% (1)

- STR For Composite GRSP No TDG 0034 Rev 1Documento14 páginasSTR For Composite GRSP No TDG 0034 Rev 1Preeti goswamiAinda não há avaliações

- PERFECT INTERNATIONAL (FZC) - Pressure Vessel ManufacturerDocumento2 páginasPERFECT INTERNATIONAL (FZC) - Pressure Vessel ManufacturerKarthik AnandanAinda não há avaliações

- RFB Type 4Documento5 páginasRFB Type 4Manoj ChitreAinda não há avaliações

- C3. Paint Specification (WSS-M64J39-A1) v1Documento7 páginasC3. Paint Specification (WSS-M64J39-A1) v1Chandrajeet ShelkeAinda não há avaliações

- Is-903 Couplings, Branch Pipe, NozzlesDocumento13 páginasIs-903 Couplings, Branch Pipe, NozzlesCharls JamesAinda não há avaliações

- PROCEDURE -3LPE -MSL-REV.00Documento15 páginasPROCEDURE -3LPE -MSL-REV.00Suresh KrishnanAinda não há avaliações

- OPSS - PROV 1101 - Nov 2020Documento9 páginasOPSS - PROV 1101 - Nov 2020Samantha McLachlinAinda não há avaliações

- 3 Ibr DescriptionDocumento2 páginas3 Ibr DescriptionThiruThirunavukkarasuAinda não há avaliações

- Vertical Pyrolysis Plant OfferDocumento5 páginasVertical Pyrolysis Plant OfferGaurav BihaniAinda não há avaliações

- STR of NCR GRSP TDG 0037 Rev 0 Dated 18-08-2021Documento16 páginasSTR of NCR GRSP TDG 0037 Rev 0 Dated 18-08-2021Preeti goswamiAinda não há avaliações

- PM Is 7904Documento10 páginasPM Is 7904S RamakrishnaAinda não há avaliações

- Asme Section II A Sa-181 Sa-181mDocumento4 páginasAsme Section II A Sa-181 Sa-181mAnonymous GhPzn1xAinda não há avaliações

- PROCEDURE - 3LPE -MSL-REV.01Documento15 páginasPROCEDURE - 3LPE -MSL-REV.01Suresh KrishnanAinda não há avaliações

- Detail Engineering Services For Engen Tank X368 RebuildDocumento9 páginasDetail Engineering Services For Engen Tank X368 RebuildpavanAinda não há avaliações

- SM 001 SRV SpecDocumento5 páginasSM 001 SRV Specvardan_vardanAinda não há avaliações

- Technical Spec. HRC Procurement API 5L Gr. L450MO PSL 2 Rev. 0Documento9 páginasTechnical Spec. HRC Procurement API 5L Gr. L450MO PSL 2 Rev. 0FerryAinda não há avaliações

- CarboDocumento7 páginasCarboBajrang SwarnkarAinda não há avaliações

- Technical DetailsDocumento3 páginasTechnical DetailsRushikesh ChikteAinda não há avaliações

- Heat Transfer Cement: NIOEC-SP-80-03Documento8 páginasHeat Transfer Cement: NIOEC-SP-80-03amin100% (1)

- FOAM TANK KEAMARI (14200 Litres) : 1.0 GeneralDocumento3 páginasFOAM TANK KEAMARI (14200 Litres) : 1.0 GeneralirfanlarikhotmailcomAinda não há avaliações

- Inspection & Testing of Elastic Rail Clips PDFDocumento5 páginasInspection & Testing of Elastic Rail Clips PDFfiemsabyasachi0% (1)

- 16 CR 5 NiDocumento11 páginas16 CR 5 NiNikhil VermaAinda não há avaliações

- 44AC9100-000-V.02-0113-A4 - Rev B - GENERAL SPECIFICATION FOR BQ PLATESDocumento5 páginas44AC9100-000-V.02-0113-A4 - Rev B - GENERAL SPECIFICATION FOR BQ PLATESAvinash ShuklaAinda não há avaliações

- Manufacture ProcessDocumento3 páginasManufacture ProcessEnd LabAinda não há avaliações

- TDC 6 388Documento3 páginasTDC 6 388sonnu151Ainda não há avaliações

- CW6 Part 2Documento34 páginasCW6 Part 2Steve CowanAinda não há avaliações

- 0526 16 2004 07 en - enDocumento6 páginas0526 16 2004 07 en - envtsusr fvAinda não há avaliações

- 3PS Gaw 002Documento6 páginas3PS Gaw 002ravi00098Ainda não há avaliações

- Tender No. & Date: DFD9449L11/06 15.09.2010: Oil India LimitedDocumento23 páginasTender No. & Date: DFD9449L11/06 15.09.2010: Oil India LimitedpvlenggAinda não há avaliações

- Longwall Mining at Shallow Depth of Cover in IndiaNo EverandLongwall Mining at Shallow Depth of Cover in IndiaAinda não há avaliações

- KG Engg Profile 21112017Documento3 páginasKG Engg Profile 21112017GohilaRajAinda não há avaliações

- Extraction of Mango Seed Oil From Mango Kernel: Dr.B.Karunanithi, K.Bogeshwaran, Manasa Tripuraneni, S.Krishna ReddyDocumento10 páginasExtraction of Mango Seed Oil From Mango Kernel: Dr.B.Karunanithi, K.Bogeshwaran, Manasa Tripuraneni, S.Krishna ReddyGohilaRajAinda não há avaliações

- BPS 419026Documento3 páginasBPS 419026GohilaRajAinda não há avaliações

- ASNT Radiography Level I IIDocumento138 páginasASNT Radiography Level I IIGohilaRaj100% (2)

- New Supplierregn LatestDocumento16 páginasNew Supplierregn LatestGohilaRajAinda não há avaliações

- Third Party Inspection Qualification Schedule: AvailableDocumento2 páginasThird Party Inspection Qualification Schedule: AvailableGohilaRajAinda não há avaliações

- Lowest quotation for plasma welding machineDocumento2 páginasLowest quotation for plasma welding machineGohilaRajAinda não há avaliações

- Baker Air Gauges Pricelist 2017Documento30 páginasBaker Air Gauges Pricelist 2017GohilaRajAinda não há avaliações

- Lowest quotation for plasma welding machineDocumento2 páginasLowest quotation for plasma welding machineGohilaRajAinda não há avaliações

- Wps FormatDocumento2 páginasWps FormatGohilaRajAinda não há avaliações

- Weld Proj Action PlanDocumento5 páginasWeld Proj Action PlanGohilaRajAinda não há avaliações

- PROJECT PROFILE ON PRINTED JUTE BAG MANUFACTURINGDocumento9 páginasPROJECT PROFILE ON PRINTED JUTE BAG MANUFACTURINGafham84Ainda não há avaliações

- Power Technologies: No.3/1, Kamadenu Nagar 2 Street, Seikmaniam Porur, Chennai - 116. TIN NO:33021390915Documento2 páginasPower Technologies: No.3/1, Kamadenu Nagar 2 Street, Seikmaniam Porur, Chennai - 116. TIN NO:33021390915GohilaRajAinda não há avaliações

- Weld Proj 5Documento2 páginasWeld Proj 5GohilaRajAinda não há avaliações

- 5MINICNCDocumento16 páginas5MINICNCGohilaRajAinda não há avaliações

- BallDocumento7 páginasBallGohilaRajAinda não há avaliações

- T ToothpasteDocumento4 páginasT ToothpasteGohilaRajAinda não há avaliações

- Eoi 1467609559Documento3 páginasEoi 1467609559GohilaRajAinda não há avaliações

- Ms Me Autonomous in SDocumento3 páginasMs Me Autonomous in SGohilaRajAinda não há avaliações

- Company Brochur PDFDocumento8 páginasCompany Brochur PDFGohilaRajAinda não há avaliações

- Integral-Bonnet Needle Valves: O, 1, 18, 20, and 26 SeriesDocumento9 páginasIntegral-Bonnet Needle Valves: O, 1, 18, 20, and 26 SeriesGohilaRajAinda não há avaliações

- Eoi 1467609559Documento3 páginasEoi 1467609559GohilaRajAinda não há avaliações

- Solderingwire PDFDocumento14 páginasSolderingwire PDFNarendra BholeAinda não há avaliações

- Spec SB 012 Rev02Documento1 páginaSpec SB 012 Rev02GohilaRajAinda não há avaliações

- TDC Fasteners TDC 5 166 NutsDocumento4 páginasTDC Fasteners TDC 5 166 NutsGohilaRajAinda não há avaliações

- Paper Made Carry BagDocumento3 páginasPaper Made Carry BagLokanath Naidu EdamalapatiAinda não há avaliações

- Floor Mopping: Smartcolor Coding SystemDocumento6 páginasFloor Mopping: Smartcolor Coding SystemGohilaRajAinda não há avaliações

- PROF. NO.25 Project Profile On Phenol Manufacturing UnitDocumento7 páginasPROF. NO.25 Project Profile On Phenol Manufacturing UnitVikram UllalAinda não há avaliações

- Project Profile On Cleaning PowderDocumento2 páginasProject Profile On Cleaning PowderGohilaRajAinda não há avaliações

- Glass-Mat Mold-Tough VHI Firecode X PanelsDocumento4 páginasGlass-Mat Mold-Tough VHI Firecode X PanelsDavide GiannuzziAinda não há avaliações

- Erapol EHP95ADocumento2 páginasErapol EHP95AMohammad Doost MohammadiAinda não há avaliações

- Apex Duracast SwirlTexDocumento2 páginasApex Duracast SwirlTexAsian PaintsAinda não há avaliações

- Effects of Stacking Sequence and Clamping Forceon The Bearing Strength of Mechanically Fastened Joints in Composite LaminatesDocumento9 páginasEffects of Stacking Sequence and Clamping Forceon The Bearing Strength of Mechanically Fastened Joints in Composite Laminateskhudhayer1970Ainda não há avaliações

- PSR Puducherry 2011 12Documento1.020 páginasPSR Puducherry 2011 12Anil BishtAinda não há avaliações

- Earthquake Collapse PatternDocumento16 páginasEarthquake Collapse Patterngaurav jagtap0% (1)

- Concrete Materials, Properties, Uses and Production GuideDocumento6 páginasConcrete Materials, Properties, Uses and Production GuideShah KhanAinda não há avaliações

- Harga Bahan Binaan Johor Jan-Nov13Documento6 páginasHarga Bahan Binaan Johor Jan-Nov13Husna HumairaAinda não há avaliações

- Technopanel en 20141023Documento39 páginasTechnopanel en 20141023GeorgiStoyanovAinda não há avaliações

- B37Documento2 páginasB37wpwmhatAinda não há avaliações

- Khadi Extended DocumentationDocumento14 páginasKhadi Extended DocumentationarchaggAinda não há avaliações

- Ishu Kumar PPT UsmDocumento16 páginasIshu Kumar PPT UsmIshu BassanAinda não há avaliações

- The Scraper: A Most Versatile ToolDocumento3 páginasThe Scraper: A Most Versatile ToolAdrian Cocis100% (2)

- Concrete - RevisedDocumento111 páginasConcrete - RevisedmanuvthampyAinda não há avaliações

- Aalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144Documento2 páginasAalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144anilbabu4Ainda não há avaliações

- Mapegrid G 120 PDFDocumento2 páginasMapegrid G 120 PDFdraganugAinda não há avaliações

- GIB Fire Rated Systems 2012Documento84 páginasGIB Fire Rated Systems 2012Hrvoje Placko MacekAinda não há avaliações

- FluOro GuideDocumento21 páginasFluOro GuidegautamahujaAinda não há avaliações

- Tile AdhesiveDocumento1 páginaTile AdhesiveFrank AgabaAinda não há avaliações

- Catalog VitraDocumento218 páginasCatalog VitraAlina SavinAinda não há avaliações

- Fiberglass Reinforced Plastic Fence SystemDocumento1 páginaFiberglass Reinforced Plastic Fence SystemLabeedAbdulrehmanAinda não há avaliações

- HRD C Frame Anchor TDSDocumento18 páginasHRD C Frame Anchor TDSronyAinda não há avaliações

- SG Iron ProductionDocumento20 páginasSG Iron ProductionShreyashri Nayak100% (1)

- AES Pharma Wall SystemDocumento10 páginasAES Pharma Wall Systemjonh3660% (1)

- Burn Test: Identify Fabrics by How They Burn and Leave AshesDocumento1 páginaBurn Test: Identify Fabrics by How They Burn and Leave AshesElrina Erasmus100% (1)

- Two Component Aliphatic Polyurea Coatings For High Productivity ApplicationsDocumento6 páginasTwo Component Aliphatic Polyurea Coatings For High Productivity ApplicationsszafakAinda não há avaliações