Escolar Documentos

Profissional Documentos

Cultura Documentos

Escosil 2525 Tds

Enviado por

KifayatullahKalwarDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Escosil 2525 Tds

Enviado por

KifayatullahKalwarDireitos autorais:

Formatos disponíveis

Aquafin Pakistan (Pvt) Ltd.

Steel House West Wharf Road,

Karachi 74000 / Pakistan

phone: +92 21 35361132

fax: +92 21 32310976

email: info@aquafinpakistan.com

web: www.aquafinpakistan.com

INTELLIGENT CONSTRUCTION SYSTEMS

Technical Data Sheet

ESCOSIL 2525

All Weather Silicone sealant

Typical Uses:

Ideal for expansion, connection, perimeter and other

movement joints.

Neutral cure are suitable for use on coated glass,

galvanized steel, masonry and other porous and

non-porous substrate.

Extension compression movement capability up +

50% of the original joint width.

container has been opened and the entire contents

have not been used, extrude 3/8 of material pass

nozzle opening. When ready to use, pull out cured

plug. Sealant is ready to use.

Test Method

Properties

Unit

Specification

Description:

ESCOSIL 2525 is a specified, premium performance

weather sealing product specially designed for general

and weather sealing in curtain wall and building

facades. Excellent weather ability, virtually unaffected

by sunlight, rain, snow, ozone. Excellent rheology, low

string upon gunning.

Lab Test

Color

Visually

Black & White

Lab Test

Appearance

Visually

Homogeneous

paste

ASTM C 679

Skin Over Time

min

Typical Properties:

ASTM C 679

Tack Free Time

min

ASTM D 1475

Specific Gravity

g/cm

6

12

1.35

ASTM D 2240

Hardness

Shore A

35

Colors:

ESCOSIL 2525 is available in Black and White. RAL

colors are available upon request.

Lab Test

Depth Cure

mm/ Day

>2.0

ASTM C 1184-05

Loss of weight

(Shrinkage)

Packing:

ESCOSIL 2525 is available in 300 ml.

ASTM C 639-5

Flow

mm

ASTM 679

Tooling Time

min

12

ASTM C 603

Extrusion Rate

g/min

mi

290 n

Preparation:

The specified sealant bead size should be calculated to

comply with the compression and extension capabilities

of the sealant in relation to the anticipated joint width

due to expansion and contraction. Generally calculation of the width of ESCOSIL 2525 should be computed

on the basis of a maximum +50% compression and

extension capability; minimum bead size should not be

less than 3mm to accommodate movement. Design joint

depth of which ratio width becomes 0.5 to 1.

Suitable joint (Depth vs Width)

Joint size minimum 6mmx6mm

Joint size maximum 30mm.

ASTM D 412

Tensile Strength

MPa

n

0.9 -

ASTM D 412

Elongation

approx

350

ASTM D 412

Young's Modulus

MPa

0.35 g

Storage And Shelf Life:

When stored in original unopened container at or

below 77F (25C), ESCOSIL 2525 has a shelf life of

12 months from date of Manufacturing. Containers

should always be kept sealed when not in use. After a

ASTM D 2238

Solid Contents

ASTM D 6411

Service Temp

ASTM C 679

Application

Temp

ASTM C 1184-05

Shelf Life

Month

10

Non-sag

s

a

> 90 1

-40 up to 200

2

-20 up to 250

12

Note:

*Curing time (Skin over time & Tack Free Time) may

vary depends on climatic condition during application.

*Information on this data sheet is subject to change

without notice and should not be used for writing

specifications.

Users Please Read:

The information and data contained herein is believed

to be accurate and reliable; however, it is the users

responsibility to determine suitability of use. Since the

supplier cannot know all the uses, or the conditions of

use to which these products may be exposed, no

warranties concerning the fitness or suitability for a

particular use or purpose are made.

Caution:

Direct contact of uncured sealant irritates eyes and may

irritate skin. Over exposure to vapor may irritate eyes,

nose and throat. Avoid eye and skincontact. Use with

adequate ventilation. Do not handle contact lenses with

sealant on hands. In case of eye contact, flush eyes

with water for 15 minutes. Obtain medical attention. In

case of skin contact, remove from skin and flush with

water.

Keep out of reach of children

Issued date: February 2016

The information and recommendations above are given in good faith based on our current knowledge and experience of the products when properly stored, handled and applied in accordance

with current best practice, national standards and our recommendations. As we have no control over site conditions or methods of application, no liability can be derived from the contents of

this information sheet, or from any written recommendations, or from any other advice offered. The user of the product is solely responsible for the products suitability for the intended

application and is recommended to test the suitability prior to use. We reserve the right to change the properties of our products without notice. All orders are sold subject to our current terms of

sale and delivery. With the publication of this Technical Information Sheet all previous edition are no longer valid.

Você também pode gostar

- Configuration Guide (Basic) DX100-EnDocumento191 páginasConfiguration Guide (Basic) DX100-Enconmar5mAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Deep BeamDocumento6 páginasDeep BeamHenra HalimAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Renaissance in FranceDocumento23 páginasRenaissance in FranceNihal Singh VermaAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Pitched Roof PergolaDocumento4 páginasPitched Roof PergolaNdahiro Gordon JamesAinda não há avaliações

- KS1000 KingzipDocumento7 páginasKS1000 KingzipmrajansubramanianAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Navicat enDocumento195 páginasNavicat enadyro12Ainda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Complete Beginners Guide To Django - Part 5Documento20 páginasA Complete Beginners Guide To Django - Part 5Michael BaloshAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Program C#Documento5 páginasProgram C#Shanmuga Sundaram ChellamAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Software ReportDocumento21 páginasSoftware Reportapi-326268101Ainda não há avaliações

- TBE006 - Solutions For Remote User Access - OpenTouch R2.2.1 - Ed05dDocumento51 páginasTBE006 - Solutions For Remote User Access - OpenTouch R2.2.1 - Ed05dCamrickAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Barcos de Concreto (Inf)Documento257 páginasBarcos de Concreto (Inf)hectorSTAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Framework For Stormwater Quality Management in SingaporeDocumento8 páginasFramework For Stormwater Quality Management in SingaporeVitor NinaAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Catalogue - Floor Trims GuideDocumento57 páginasCatalogue - Floor Trims GuideFloorkitAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Release Notes GLD Editor V1.51 2Documento3 páginasRelease Notes GLD Editor V1.51 2Papa ConfiAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Business Continuity For EBS Using Oracle 11g Physical Standby DB (Oracle E-Business Suite Technology)Documento7 páginasBusiness Continuity For EBS Using Oracle 11g Physical Standby DB (Oracle E-Business Suite Technology)marwan.saad8461Ainda não há avaliações

- Oid Tuning Configuration Quickreference 01Documento15 páginasOid Tuning Configuration Quickreference 01Ketan PatilAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- 20 Useful Terminal Commands and Tools That You May Need in Ubuntu-Linux MintDocumento7 páginas20 Useful Terminal Commands and Tools That You May Need in Ubuntu-Linux Mintoral_cuAinda não há avaliações

- Unit 3 Tension Members: StructureDocumento28 páginasUnit 3 Tension Members: StructureRaj BakhtaniAinda não há avaliações

- FCL FCL FCL FCL: Model 78 - CortinaDocumento1 páginaFCL FCL FCL FCL: Model 78 - CortinaJeremiahLimAinda não há avaliações

- Catalog Bbs2fr 25Documento1 páginaCatalog Bbs2fr 25SYARULNIZAM ROSLANAinda não há avaliações

- Fibeair® Ip-10G and Ip-10E: 7.2 Release NotesDocumento55 páginasFibeair® Ip-10G and Ip-10E: 7.2 Release NotesKarla VertiAinda não há avaliações

- Permalife Louver VentsDocumento6 páginasPermalife Louver VentsarchitecturalelementAinda não há avaliações

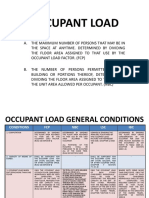

- 02 - Occupant Load General ConditionsDocumento5 páginas02 - Occupant Load General ConditionsLean Liganor100% (1)

- ResumeDocumento7 páginasResumeMA100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Osln PDFDocumento183 páginasOsln PDFAbdallah TebibAinda não há avaliações

- How To Configure VIO LUNs From SAN To Client LPARsDocumento9 páginasHow To Configure VIO LUNs From SAN To Client LPARsTirumala RaoAinda não há avaliações

- Ceilink Detailed Installation GuideDocumento4 páginasCeilink Detailed Installation GuideMetrollDubboAinda não há avaliações

- Rational Performance TesterDocumento48 páginasRational Performance TesterRahul TadakamadlaAinda não há avaliações

- GSHPA Vertical Borehole Standard PDFDocumento45 páginasGSHPA Vertical Borehole Standard PDFSibolga SatuAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Cours de Géographie de L'habitat 2 Année Semestre Quatre Responsable de La Matière: Mme: Tebbi HafidaDocumento22 páginasCours de Géographie de L'habitat 2 Année Semestre Quatre Responsable de La Matière: Mme: Tebbi HafidaAmina AminaAinda não há avaliações