Escolar Documentos

Profissional Documentos

Cultura Documentos

481

Enviado por

Izallmachine0 notas0% acharam este documento útil (0 voto)

76 visualizações4 páginasAURORA

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoAURORA

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

76 visualizações4 páginas481

Enviado por

IzallmachineAURORA

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 4

Horizontal Split Case Pump

AURORA 900 SERIES

Vertical Split Case Pump

SPLIT CASE FIRE PUMPS

Built Per NFPA 20

LISTED

WWW.AURORAPUMP.COM

SPLIT CASE FIRE PUMPS

AURORA 900 SERIES

Split Case Fire Pumps

Horizontal split case pumps are the most common type of fire

pump. These pumps are specifically designed and tested for

fire service applications where reliability of performance is of

vital importance. Split case pumps are characterized by:

Easy access to all working parts;

Rugged construction;

Liberal water passages; and

Efficient operation.

Split case fire pumps are specified when the source of water

is located above the surface of the ground and provides a

positive suction pressure to the pump at any performance point.

Single-stage or multistage pumps are available dependent upon

discharge pressure requirements.

Aurora split case fire pumps are built per the rigid standards of

NFPA 20 and are listed by Underwriters Laboratories (UL) and

approved by Factory Mutual (FM).

Available in a broad range of operating pressures and flows

from a minimum of 250 GPM, Aurora split case pumps can be

driven by either an electric motor or diesel engine. Auroras

UL-Listed, FM-Approved fire pump packages also include the

system controller, with a full range of options and accessories

available to complete the NFPA-compliant fire pump package.

In addition to horizontal split case pumps, Aurora also offers

split case performance in a vertical format. Vertical fire pumps

provide distinct advantages over horizontal pump constructions.

Less floor space is required.

In-line piping arrangement allows piping in any direction

in most cases.

Elevated motor protects against potential flooding if the

pump station is in a low area.

Components are register-fitted to prevent misalignment.

SPLIT CASE FIRE PUMPS

Pump Features

7

2

14

15

16

17

13

10

5

6

12

11

18

Vertical

Split Case

1.

2.

3.

4.

5.

6.

7.

Computer Machined

8.

Integral Bearing Arms

9.

major components with 360 degree registered

fits to assure concentricity of parts.

eliminate bearing misalignment and

simplify maintenance.

Enclosed Impeller Design

provides high efficiency and performance.

Dynamically Balanced Impeller

is keyed to the shaft and secured by adjustable

shaft sleeves.

Double Suction Impeller

balances hydraulic thrust loads.

Cast Iron Drip Rim Base

12.

directs condensation and any stuffing box

leakage to drain.

Short Bearing Span

holds shaft deflection to .002" at face of

stuffing box at maximum load.

WWW.AURORAPUMP.COM

15.

Stuffing Boxes

16.

are extra deep for proper sealing. Split packing

glands simplify packing maintenance.

ball bearing.

and nonsparking neoprene rotating slingers

protect both bearings during pump operation

and washdown.

selected for 50,000 hour minimum life

at maximum load. Average bearing life

5 x minimum.

prevent corrosion of the shaft. This eliminates

the need for stainless steel shafts.

Case Wearing Rings

and throttle bushings protect the

casing from wear and are easily and

inexpensively replaced.

Bronze Shaft Sleeve

17.

simplifies disassembly. The suction and

discharge piping and shaft alignment are

not disturbed.

O-Ring Sealed Shaft Sleeves

Grease Seals

Bearings

13.

Interwoven, Graphite

Impregnated T.F.E.

Double Row Thrust

11.

14.

diagonally cut packing rings seal

the pump shaft.

10.

Split Case Design

Internal Water Seal Passages

between volute and stuffing box cannot

be damaged.

Horizontal

Split Case

prevents shaft wear, is slip fit over the shaft,

keylocked, and extends the entire length

of the seal box.

Certified Performance Test

18.

with Positive Suction Pressure

is provided for each fire pump for customer

approval. Pumps are also hydrostatically tested

per NFPA 20 at no less than 250 psi.

Fire Pump Feature Selector

Standard

Optional

Bronze fitted pump construction

Ductile iron casings (available in selected 481 and 485 models)

Bronze shaft sleeves

Right- or left-hand rotation

Bronze case wearing rings

Impeller wearing rings

Dynamically balanced impellers

Stainless steel shafts

Stainless steel impeller key

Double row ball bearings on inboard side

Carbon steel shaft

External bypass line from casing to stuffing boxes

(optional on Model 480s, standard on Model 490s)

Corrosion-resistant lantern rings*

Bronze stuffing box bushings

Bronze glands

Interwoven graphite-impregnated T.F.E. packing rings

Formed steel drip-rim base (horizontal electric driven units only)

15' Suction lift test to verify performance at 150% of rated flow

Available accessories include valves, headers, main relief valves,

increasers and reducers, waste cones, and more.

Cast integral bearing arms (most models)

Regreaseable ball bearings

Double row thrust bearing (outboard side)

Upper casing lifting lugs

Water slingers and grease seals

Hydrostatic and Certified Performance test**

Coupling guard

Suction and discharge gauges with shutoff cocks

SUCTION

STANDARD

RIGHT-HAND ROTATION

(TOP VIEW HORIZONTAL PUMP)

SUCTION

VERTICAL PUMPS PROVIDE

IN-LINE PIPING IN ANY DIRECTION

(ALSO AVAILABLE RIGHT- OR LEFT-HAND)

OPTIONAL

LEFT-HAND ROTATION

(TOP VIEW HORIZONTAL PUMP)

Automatic air release valve

* Standard on Model 490s; furnished when suction pressure is below 40 psi on Model 480s.

** Test is performed with positive suction pressure.

HY

UT

800 AIRPORT ROAD, NORTH AURORA, ILLINOIS 60542 WWW.AURORAPUMP.COM

Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

AF-02-1033 11/26/12 2012 Pentair Ltd. All Rights Reserved.

ISO 9001

IT

AU

LIC

ST

DR

IN

19 17

ST

EGI

ER E D Q U

TY SYSTEM

ALI

Casing relief valve (electric driven units only)

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Equivalent Length of Pipe PDFDocumento3 páginasEquivalent Length of Pipe PDFSSudhakarAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Package Question List: UPT Periode Exam Code Level Package CodeDocumento5 páginasPackage Question List: UPT Periode Exam Code Level Package CodeYoga Heru NAinda não há avaliações

- K Value of FittingsDocumento4 páginasK Value of FittingsJoydip Misra100% (6)

- Fuel Storage Tanks As Per NFPA 11Documento1 páginaFuel Storage Tanks As Per NFPA 11Adil MominAinda não há avaliações

- Nfpa 221 1997Documento9 páginasNfpa 221 1997Izallmachine100% (1)

- Safety MaterialDocumento40 páginasSafety MaterialAzher AhmedAinda não há avaliações

- 0172 Private Fire Hydrants BrochureDocumento4 páginas0172 Private Fire Hydrants BrochureIzallmachineAinda não há avaliações

- 0172 Private Fire Hydrants BrochureDocumento4 páginas0172 Private Fire Hydrants BrochureIzallmachineAinda não há avaliações

- Tech. Data (Aurora Fire Pump) Relokasi Depot LPG TJ. Priok PDFDocumento51 páginasTech. Data (Aurora Fire Pump) Relokasi Depot LPG TJ. Priok PDFIzallmachine50% (2)

- 4 Performance of A Centrifugal FanDocumento7 páginas4 Performance of A Centrifugal Fanfinix33Ainda não há avaliações

- API 610 Pump Selection and Curve EvaluationDocumento4 páginasAPI 610 Pump Selection and Curve EvaluationbbmokshAinda não há avaliações

- Technical Journal Fire PumpDocumento7 páginasTechnical Journal Fire PumpIzallmachineAinda não há avaliações

- Fire Pump Maintenance ProgramDocumento4 páginasFire Pump Maintenance ProgramIzallmachineAinda não há avaliações

- Fire Pump Maintenance ProgramDocumento4 páginasFire Pump Maintenance ProgramIzallmachineAinda não há avaliações

- Indian OilDocumento71 páginasIndian OilArif Khan50% (2)

- Vibration Monitoring System For Steam TurbineDocumento24 páginasVibration Monitoring System For Steam TurbineRahul Jawda50% (2)

- Bus Chassis 2010Documento13 páginasBus Chassis 2010Philippine Bus Enthusiasts Society100% (1)

- The Understated Benefits of Trolley Assisted HaulageDocumento49 páginasThe Understated Benefits of Trolley Assisted HaulagewalterloliAinda não há avaliações

- ASME PTC 22 Gas Turbine Test Code PDFDocumento46 páginasASME PTC 22 Gas Turbine Test Code PDFDaru CahyoAinda não há avaliações

- Api 610 11th - 2 PDFDocumento218 páginasApi 610 11th - 2 PDFIzallmachineAinda não há avaliações

- 0106 BPUM BR Direct Driven 07-15-150dpi WebDocumento8 páginas0106 BPUM BR Direct Driven 07-15-150dpi WebIzallmachineAinda não há avaliações

- Efficient Driving at Variable Speeds World Pumps Vol 2013 Issue 4 0Documento4 páginasEfficient Driving at Variable Speeds World Pumps Vol 2013 Issue 4 0IzallmachineAinda não há avaliações

- An International Survey of Computer Models For Fire and Smoke by Raymond FriedmanDocumento13 páginasAn International Survey of Computer Models For Fire and Smoke by Raymond FriedmanIzallmachineAinda não há avaliações

- Magma Cover StoryDocumento5 páginasMagma Cover StoryIzallmachineAinda não há avaliações

- Pipe Flow-Friction Factor Calculations With Excel Course Journal PDFDocumento30 páginasPipe Flow-Friction Factor Calculations With Excel Course Journal PDFIzallmachineAinda não há avaliações

- QR 0608 Fire Pumps Suct PipeDocumento1 páginaQR 0608 Fire Pumps Suct PipeIzallmachineAinda não há avaliações

- Basic Pump Manual Feb09Documento52 páginasBasic Pump Manual Feb09IzallmachineAinda não há avaliações

- Fleet SafetyDocumento5 páginasFleet SafetyIzallmachineAinda não há avaliações

- Pump Doctor's Surgery: Looking Beyond The ObviousDocumento2 páginasPump Doctor's Surgery: Looking Beyond The ObviousIzallmachineAinda não há avaliações

- OIl Company ListDocumento16 páginasOIl Company ListIzallmachineAinda não há avaliações

- 481Documento4 páginas481IzallmachineAinda não há avaliações

- Aurora Pump VT (FM) PDFDocumento30 páginasAurora Pump VT (FM) PDFRizalAinda não há avaliações

- Pipe Flow-Friction Factor Calculations With Excel Course Journal PDFDocumento30 páginasPipe Flow-Friction Factor Calculations With Excel Course Journal PDFIzallmachineAinda não há avaliações

- Api 610 11th - 2 PDFDocumento218 páginasApi 610 11th - 2 PDFIzallmachineAinda não há avaliações

- 6 PDFDocumento2 páginas6 PDFIzallmachineAinda não há avaliações

- Fire Pump Supervision JournalDocumento7 páginasFire Pump Supervision JournalIzallmachineAinda não há avaliações

- Performance Data SheetDocumento1 páginaPerformance Data SheetIzallmachineAinda não há avaliações

- 6 PDFDocumento2 páginas6 PDFIzallmachineAinda não há avaliações

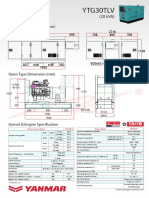

- YTG30TLV 20 kVA Silent Type Genset Dimensions and SpecsDocumento1 páginaYTG30TLV 20 kVA Silent Type Genset Dimensions and Specseric287Ainda não há avaliações

- W201 Wiring Diagram PDFDocumento290 páginasW201 Wiring Diagram PDFNadeem Mohd100% (1)

- QSK95G4Documento2 páginasQSK95G4Mohamed Kamal0% (1)

- Combustion Instability Vortex SheddingDocumento16 páginasCombustion Instability Vortex Sheddingflowh_Ainda não há avaliações

- Linelazer 3000: 308685K Instructions - Parts ListDocumento44 páginasLinelazer 3000: 308685K Instructions - Parts Listraj jangidAinda não há avaliações

- S12H-engine - PDF SPECSDocumento3 páginasS12H-engine - PDF SPECSMarcos Vinicio StizzioliAinda não há avaliações

- A Simple Gamma Type Stirling Engine.: PistonsDocumento3 páginasA Simple Gamma Type Stirling Engine.: PistonssasaAinda não há avaliações

- CIMAC2019 Paper 387Documento11 páginasCIMAC2019 Paper 387sestoubosAinda não há avaliações

- 0 - Lecture Notes FCC Carbon ResidueDocumento6 páginas0 - Lecture Notes FCC Carbon ResidueHarsh BhaktAinda não há avaliações

- Intake and Exhaust Manifolds Emission Control SystemDocumento47 páginasIntake and Exhaust Manifolds Emission Control SystemGreg HannaAinda não há avaliações

- Theories of Combustion in SI EngineDocumento4 páginasTheories of Combustion in SI EngineBALAMBAL RAinda não há avaliações

- Thermo Assignment #6Documento10 páginasThermo Assignment #6mohamedAinda não há avaliações

- A Review of Hydrogen UsageDocumento12 páginasA Review of Hydrogen UsageRonnie GenezAinda não há avaliações

- Basic Engine PrinciplesDocumento31 páginasBasic Engine PrinciplesRayge HarbskyAinda não há avaliações

- TIO-540-AE2A Operator Manual 60297-27Documento74 páginasTIO-540-AE2A Operator Manual 60297-27Andres AnguloAinda não há avaliações

- Manual de Operacion y Funcionamiento Chevrolet S10 Blazer 1991Documento30 páginasManual de Operacion y Funcionamiento Chevrolet S10 Blazer 1991OSCAR SANTIAGO VASQUEZ MADRIDAinda não há avaliações

- TSML Report - ShazDocumento21 páginasTSML Report - ShazUmer AleemAinda não há avaliações

- Operation Stages HDI SIEMENSDocumento9 páginasOperation Stages HDI SIEMENSSergio SambuelliAinda não há avaliações

- 2009FDocumento26 páginas2009FdaimaheshAinda não há avaliações

- TEMPLATE - Fuel Voucher - ExternalDocumento2 páginasTEMPLATE - Fuel Voucher - Externalmodarib26100% (1)

- A Seminar Report On "Camless Engine": Cochin University of Science and TechnologyDocumento26 páginasA Seminar Report On "Camless Engine": Cochin University of Science and TechnologyShivaraj GidaveerAinda não há avaliações