Escolar Documentos

Profissional Documentos

Cultura Documentos

Hatch Cover - Hot Spots

Enviado por

Drago DragicDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hatch Cover - Hot Spots

Enviado por

Drago DragicDireitos autorais:

Formatos disponíveis

HATCH COVER HOT SPOTS

Use with North's loss prevention guide - Hatch Cover Maintenance and Operation - and Maker's Manual.

Always refer to hatch cover Makers for specific advice on repairs.

Closure

Bearing pads are in contact and providing correct support and rubber seal compression........................................

Adjacent hatch cover panels in alignment............................................................................................................................

Cross-joint wedge support areas on panel tops in good condition .................................................................................

Cross-joint wedges and fittings in good condition (if fitted) ............................................................................................

All cleats correctly applied......................................................................................................................................................

Sufficient spares onboard (cleats, rubber seal corners, rubber seal linear).................................................................

Coamings

No structural corrosion in coamings or coaming brackets ...............................................................................................

Bearing pads, chocks or support blocks free of wear or damage...................................................................................

Hatch cover panel edges have not worn grooves in coaming tops .................................................................................

Compression bars good condition, undamaged, no corrosion - uniform height and thickness .................................

Edge plate extends to form water channel and in good condition, no damage .............................................................

Water channel clean and not corroded..................................................................................................................................

Inner face no vertical rust staining (water leakage) especially at cross-joints.........................................................

Drains free and non-return valves working .........................................................................................................................

Cleats all in place, rods straight, washer good, surrounding steel work in good condition .......................................

Panels

Panel tops free of corrosion and damage ............................................................................................................................

Panel undersides and internal structure free of corrosion and damage........................................................................

Panel sides (especially edge on coaming) in good condition and free of corrosion ....................................................

Rubber seal retaining channels in good condition and free of corrosion .....................................................................

Cross-joint seal retaining channels in good condition and corrosion free ....................................................................

Cross-joint compression bars in good condition and corrosion free..............................................................................

Secondary drainage channels in good condition and draining into the coaming top water channel.........................

Panel moving parts, fixed parts and any hydraulic system all in good condition......................................................

Side and cross-joints seals in good condition.....................................................................................................................

Compression bar mark in centre of rubber seals (no misalignment) .............................................................................

Rubber seals free of deformation or tipping to one side...................................................................................................

Rubber seal corners fitted with pre-formed inserts not made up of separate pieces .............................................

Sealing

The use of sealing tape or foam at the cross-joints of hatch covers is common, sometimes even being expressly

called for by the shipper or charterer. See chapter 3.8 of North's loss prevention guide Hatch Cover Maintenance

and Operation.

Use of such tapes or foam is acceptable as an additional precaution on well-maintained weathertight

hatch covers, but is not acceptable as an alternative to proper permanent repairs.

Puiblished by North of England P&I Association

Telephone: +44 191 2325221 Fax: +44 191 2610540

E-mail: loss.prevention@nepia.com Website: www.nepia.com

HATCH COVER HOT SPOTSDOS

AND DONTS

Worn out bearing pads cause panel

steel to steel contact and over

compressed rubber seals. Always

check the bearing pads are in contact

and providing correct support and

rubber seal compression.

Bearing pad no support

Bearing pad correct support

Always use the correct materials and

spares as recommended in Maker's

Manual. Are there sufficient spares on

board including spare cleats and

rubber washers, pre-formed rubber

seal corners, and linear rubber seal?

Corner pieces should not be made up

by splicing pieces of linear rubber seal.

Rubber seal corner made up

Rubber seal corner pre-formed

Never use short inserts to make up

gaps in linear rubber seals. In practice

the minimum length of any insert

should be about 1 metre, with an

absolute minimum of 50 centimetres.

Rubber seals short inserts

Rubber seals min. insert 50cm

Do not try to correct permanent set

in rubber seals by inserting another

seal underneath. Always replace with

new when the permanent set reaches

half of the designed compression.

Rubber seals permanent set

Rubber seals good compression

Seized and/or rusty cleats with

damaged rubber washers, more than

one rubber washer, or bent rods

must be replaced. Regularly inspect

the cleats and replace rubber washers

with one correct spare when necessary.

Cleat damaged washer

Cleat washer in good condition

Puiblished by North of England P&I Association

Telephone: +44 191 2325221 Fax: +44 191 2610540

E-mail: loss.prevention@nepia.com Website: www.nepia.com

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Tools Required For Splicing - SEPT2012 - WEB PDFDocumento2 páginasTools Required For Splicing - SEPT2012 - WEB PDFDrago DragicAinda não há avaliações

- Colreg BuoyageDocumento37 páginasColreg BuoyageBen N GwenAinda não há avaliações

- Revised Crew Documents StatusDocumento7 páginasRevised Crew Documents StatusDrago DragicAinda não há avaliações

- StencilDocumento8 páginasStencilDrago DragicAinda não há avaliações

- Gunes ExtensionDocumento1 páginaGunes ExtensionDrago DragicAinda não há avaliações

- Standard Bulk Cargoes-Hold Preparation and CleaningDocumento32 páginasStandard Bulk Cargoes-Hold Preparation and CleaningSoyHan BeLen100% (3)

- Rp12 c1 Eye Splice Aug2012 WebDocumento3 páginasRp12 c1 Eye Splice Aug2012 WebDrago DragicAinda não há avaliações

- Bridge10 - Port Watch ChangeoverDocumento1 páginaBridge10 - Port Watch ChangeoverDrago DragicAinda não há avaliações

- 3strand C1 Rope To Chain AUG2012 WEBDocumento2 páginas3strand C1 Rope To Chain AUG2012 WEBDrago DragicAinda não há avaliações

- Snowdon Noon Voy 77 B Cape Town-PdmDocumento1 páginaSnowdon Noon Voy 77 B Cape Town-PdmDrago DragicAinda não há avaliações

- Bridge Audit Check ListDocumento7 páginasBridge Audit Check ListDrago Dragic100% (1)

- Bruce Blitz - How To Draw Blitz CartoonsDocumento62 páginasBruce Blitz - How To Draw Blitz CartoonsSteven Ice96% (49)

- CvoroviDocumento82 páginasCvoroviAna Lekan100% (2)

- Ffe Lsa 31 May 09Documento1 páginaFfe Lsa 31 May 09Drago DragicAinda não há avaliações

- Revised Crew Documents StatusDocumento7 páginasRevised Crew Documents StatusDrago DragicAinda não há avaliações

- Drills-IsPS Inspections - Cape Kestrel-210609Documento2 páginasDrills-IsPS Inspections - Cape Kestrel-210609Drago DragicAinda não há avaliações

- Ffe Lsa 30 July 09Documento1 páginaFfe Lsa 30 July 09Drago DragicAinda não há avaliações

- Ffe Lsa 30 Apr 09Documento1 páginaFfe Lsa 30 Apr 09Drago DragicAinda não há avaliações

- Ante 2003Documento2 páginasAnte 2003Drago DragicAinda não há avaliações

- Ffe Lsa 30 June 09Documento1 páginaFfe Lsa 30 June 09Drago DragicAinda não há avaliações

- Ffe Lsa 29, Mar.09Documento1 páginaFfe Lsa 29, Mar.09Drago DragicAinda não há avaliações

- Copy (2) of Gunes ExtensionDocumento1 páginaCopy (2) of Gunes ExtensionDrago DragicAinda não há avaliações

- Ffe Lsa 13, Feb.09Documento1 páginaFfe Lsa 13, Feb.09Drago DragicAinda não há avaliações

- NW4000-60 VDR Authority Access Manual V1.4Documento19 páginasNW4000-60 VDR Authority Access Manual V1.4Drago Dragic100% (1)

- List of Antenna: ParaboraDocumento2 páginasList of Antenna: ParaboraDrago DragicAinda não há avaliações

- Drill Schedule MV DuhallowDocumento4 páginasDrill Schedule MV DuhallowDrago Dragic100% (1)

- Safety Bridges Fabricated by FTA Elmaz and BotsevDocumento6 páginasSafety Bridges Fabricated by FTA Elmaz and BotsevDrago DragicAinda não há avaliações

- Imo Fategue Part 1Documento85 páginasImo Fategue Part 1Ali AzouaouAinda não há avaliações

- Drills-IsPS Inspections - Cape Kestrel-210609Documento2 páginasDrills-IsPS Inspections - Cape Kestrel-210609Drago DragicAinda não há avaliações

- Example DrillsDocumento60 páginasExample DrillsDrago Dragic100% (5)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Washer Dryer: Owner'S ManualDocumento29 páginasWasher Dryer: Owner'S ManualThai FuizaiAinda não há avaliações

- 5.2.1 Red AlertsDocumento4 páginas5.2.1 Red AlertsCursedDiamondsAinda não há avaliações

- Selangor-Physics P2-Trial SPM 2009Documento24 páginasSelangor-Physics P2-Trial SPM 2009kamalharmozaAinda não há avaliações

- Bailey HangoutsDocumento477 páginasBailey Hangoutsmemes MendezAinda não há avaliações

- Sphere FitupDocumento103 páginasSphere FitupAnonymous wxLjBEzAinda não há avaliações

- Skim Mik Powder MSDSDocumento6 páginasSkim Mik Powder MSDSVampireSuicideAinda não há avaliações

- 117BH - Ceramic Science and Technology PDFDocumento8 páginas117BH - Ceramic Science and Technology PDFvenkiscribd444Ainda não há avaliações

- Load TablesDocumento3 páginasLoad Tablesidinjan.ashtariAinda não há avaliações

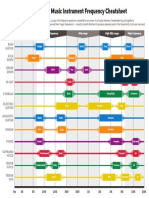

- Music Frequency Cheat SheetDocumento1 páginaMusic Frequency Cheat SheetLeonel Molina AlvaradoAinda não há avaliações

- Manual Daiwa Tanacom 500 PDFDocumento37 páginasManual Daiwa Tanacom 500 PDFHenrique BelliniAinda não há avaliações

- LI Report GuidelineDocumento2 páginasLI Report GuidelineNaavalan Krishnaga Art'wAinda não há avaliações

- FuzzyDocumento75 páginasFuzzyvatsalshah24Ainda não há avaliações

- Design of Queensland Road Infrastructure For High Risk EnvironmentsDocumento7 páginasDesign of Queensland Road Infrastructure For High Risk EnvironmentsAnonymous fS6Znc9Ainda não há avaliações

- Case/Duct System (Automobile)Documento7 páginasCase/Duct System (Automobile)Tran xuan ThuyAinda não há avaliações

- Abrasive Cleaning SystemDocumento4 páginasAbrasive Cleaning SystemSulfikar SalimAinda não há avaliações

- 117position Monitor PDFDocumento2 páginas117position Monitor PDFJacob KalloorAinda não há avaliações

- 0764 Kali LinuxDocumento322 páginas0764 Kali LinuxAnonymous wlDp7UrBam0% (2)

- Course Objective and Outcome FormDocumento2 páginasCourse Objective and Outcome FormSajedur Rahman MishukAinda não há avaliações

- CM-510.9 Crane ChecklistDocumento2 páginasCM-510.9 Crane ChecklistHSE HerygintingAinda não há avaliações

- 1Documento9 páginas1MurtadhaAinda não há avaliações

- Equipment Damage Curves TransformersDocumento8 páginasEquipment Damage Curves TransformersrobertoseniorAinda não há avaliações

- History of UASDocumento44 páginasHistory of UASAswin BalasubramaniamAinda não há avaliações

- TR-7551 Wiring & Typical Connection DiagramDocumento1 páginaTR-7551 Wiring & Typical Connection Diagramlakshitha sandaruwanAinda não há avaliações

- Casting DefectsDocumento22 páginasCasting DefectsDeepakKaushik100% (1)

- B968B968M 10 Standard Test MethodDocumento2 páginasB968B968M 10 Standard Test Methodmarjan banooAinda não há avaliações

- PPC Porcelain Solid Core Post Insulators and Operating RodsDocumento23 páginasPPC Porcelain Solid Core Post Insulators and Operating RodsCHRISTIANAinda não há avaliações

- Steam Its Generation and Use 41st Edition PDFDocumento1.106 páginasSteam Its Generation and Use 41st Edition PDFAlberto Valdivia91% (11)

- Sizing Columns in HysysDocumento4 páginasSizing Columns in HysysemebusamuelAinda não há avaliações

- SANYO UR18650A 2.2ah SpecificationsDocumento18 páginasSANYO UR18650A 2.2ah SpecificationsArpit Agrawal100% (1)

- Weka Lab Record ExperimentsDocumento21 páginasWeka Lab Record ExperimentsTirumala Placement Cell-hydAinda não há avaliações