Escolar Documentos

Profissional Documentos

Cultura Documentos

WPC Eqp1

Enviado por

Arcenio Jimenez MorganTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

WPC Eqp1

Enviado por

Arcenio Jimenez MorganDireitos autorais:

Formatos disponíveis

Wireline Operations

Quick Union Cross-reference Table

Wireline Pressure Control Equipment

Type B Acme

Thread

Seal Dia

Bore

Pressure

Service

4 3/4"-4

3.750

2.50

10,000

STD

4 3/4"-4

3.750

2.50

5,000

H2S

4 3/4"-4

3.750

3.00

5,000

STD

4 3/4"-4 x 2

3.750

3.00

10,000

H2S

5 1/2"-4 x 2

4.375

3.00

5,000

H2S

5 1/2"-4 x 2

4.375

3.00

10,000

STD

6"-4 x 2

4.875

3.00

5,000

H2S

6 5/16"-4

4.375

2.50/3.00

10,000

H2S

6 5/16"-4

3.750

2.50

15,000

H2S

6 5/16"-4

4.375

3.00

10,000

H2S

7"-5 SA

5.250

4.00

5,000

H2S

8 1/4"-4 x 2

6.000

4.00

10,000

H2S

8 1/4"-4 x 2

6.750

5.00

5,000

H2S

8 7/8"-4 x 2

6.500

5.00

10,000

H2S

9 7/8"-4 x 2

8.000

6.38

5,000

H2S

13"-4

9.500

6.37/7.37

10,000

H2S

13 1/2"-4

10.000

7.37

10,000

H2S

Type B Acme

Type O Acme

Seal Dia

Bore

Pressure

Service

5"-4

3.500

2.50/2.92

10,000

STD

5"-4

3.500

2.50/2.92

5,000

H2S

5"-4

3.500

2.50/3.00

10,000

STD

5"-4

3.500

2.50/3.00

5,000

H2S

5"-4

3.500

2.50

15,000

H2S

5 3/4"-4

4.000

3.00

10,000

H2S

6"-4

4.875

4.00

5,000

STD

6 1/4"-4

4.000

2.50

15,000

H2S

6 1/2"-4

4.750

3.00

10,000

H2S

6 1/2"-4

4.750

4.00

5,000

H2S

6 1/2"-4

5.188

4.00

5,000

H2S

6 1/2"-4

5.250

4.00

5,000

H2S

7 1/2"-4

5.500

3.00

15,000

H2S

8 1/4"-4

6.188

5.00

10,000

STD

8 1/4"-4

6.188

5.00

5,000

H2S

8 3/8"-4

5.250

4.00

10,000

H2S

9"-4

6.750

5.00

10,000

H2S

9 1/2"-4

8.000

6.38

5,000

H2S

9 1/2"-4

6.250

4.00

15,000

H2S

11 1/2"-4

8.250

6.38

10,000

H2S

12"-4

10.313

9.00

5,000

H2S

12 1/4"-4

7.000

5.12

15,000

H2S

www.cromar.com

Wireline Operations

Type O Acme

Thread

Wireline Operations

Wellhead Flange Adapters (Tree Cap)

Product code: 243

Adapter assemblies are available with a choice of:

Material:

Alloy steel, stainless steel and nickel alloys

Inlays and cladding can also be provided

Wellhead Adapter Assembly

Connection:

Standard API and non standard flanges

Type B, O & C Acme Quick Union connections

Working Pressure Rating:

Up to 15,000psi

Size:

From 2 1/16 ID upwards

Service:

H2S, Standard

Wireline Pressure Control Equipment

The Cromar wellhead flange adapter (tree cap)

assembly consists of an API flange by quick union box

adapter, a blanking cap with bleed port (larger sizes

can be provided with lifting eyes) and a quick union

collar. Positioned on top of an API wellhead, the

adapter is designed to provide a positive connection

between the wellhead and surface pressure control

equipment during well intervention operations.

Please refer to relevant section for blanking cap

and lift test cap information.

Flanged Lift Test Cap Assembly

API Flange by Quick Union Pin Adapter

API Flange by Quick Union Box Adapter

www.cromar.com

Wireline Operations

Cromar flange by quick union adapters are available

in all combinations for deployment of pressure control

equipment, including quick union pin and collar

connections besides those specified above.

Wireline Operations

Single Manual Wireline Valves

Product code: 510

Cromar single manual wireline valve assemblies are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 5,000psi

Size:

From 2.5 ID upwards

Wireline Pressure Control Equipment

The Cromar single manual wireline valve is positioned on top of the wellhead; it is designed to provide a

positive seal and contain well pressure around stationary wireline or braided cable during well intervention

operations.

Manually operated stems are used to actuate rams into the bore of the valve and seal around the wireline or

braided cable. The ram bodies are fitted with guides to align the wire/cable into the inner seals. Guides and

inner seals are dressed to suit the wire or cable being deployed. Ram bodies also include outer seals which

seal between the ram body and the bore above. Grease and well pressure behind the rams, acting on these

seals, assist in keeping the rams shut against the wire/cable. When the rams are positively closed, pressure

is bled off above them, allowing safe access to the wire above for fishing operations or to carry out repairs

to the pressure control equipment above the valve. After the task has been completed and the integrity of

the pressure control equipment has been confirmed, an equaliser valve, situated in the wireline valve body,

is used to equalise the pressure across the rams allowing them to be opened manually.

Manual wireline valves are recommended for well pressures of 5,000psi or less, and are not recommended

for H2S or high temperature applications.

Service:

Standard

Wireline Operations

Single Manual Wireline Valve

www.cromar.com

Wireline Operations

Dual Manual Wireline Valves

Product code: 510

Cromar dual manual wireline valve assemblies are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

5,000psi

Size:

From 2.5" ID upwards

Wireline Pressure Control Equipment

The Cromar dual manual wireline valve is positioned on top of the wellhead; it is designed to provide a positive

seal and contain well pressure around stationary wireline or braided cable during well intervention operations.

Manually operated stems are used to actuate the rams into the bore of the valve and seal around the wireline

or braided cable. The ram bodies are fitted with guides to align the wire/cable into the inner seals. Guides

and inner seals are dressed to suit the wire or cable being deployed. The ram bodies also include outer seals,

which seal between the ram body and the bore above or below (when the lower ram set is inverted). A grease

injection port is provided in the cavity between the ram bodies. Grease is injected into this volume to achieve

a seal around a braided cable. Grease and well pressure behind the rams, acting on these seals, assist in

keeping the rams shut against the wire/cable. When the rams have been positively closed, well pressure is

bled off above them. This procedure allows safe access to the wire/cable for fishing operations or to carry

out repairs to the pressure control equipment above the valve. After the task has been completed and the

integrity of the pressure control equipment has been confirmed, equaliser valves, situated in the wireline

valve body, are used to equalise the pressure across both sets of rams.

Manual valves are recommended for well pressures of 5,000psi or less, and are not recommended for H2S or

high temperature applications.

Service:

Standard

Wireline Operations

Dual Manual Wireline Valve

www.cromar.com

Wireline Operations

Single Hydraulic Conventional Wireline Valves

Product code: 511

Cromar hydraulic single conventional wireline valve assemblies are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 5,000psi

Size:

From 2.5 ID upwards

Service:

H2S, Standard

Wireline Pressure Control Equipment

The Cromar single hydraulic conventional wireline valve is positioned on top of the wellhead; it is designed

to provide a positive seal and contain well pressure around a stationary wireline or braided cable during well

intervention operations.

Hydraulically operated cylinder pistons with manual back up are used to actuate the rams into the bore of

the valve and seal around the wireline or braided cable. The ram bodies are fitted with guides to align the

wire/cable into the inner seals. Guides and inner seals are dressed to suit the wireline or cable being deployed.

The ram bodies also include outer seals which seal between the ram body and the bore above. Well pressure

behind the rams, acting on these seals, assists in keeping the rams shut against the wire/cable. When the rams

have been positively closed and the manual back-up stems functioned, pressure is bled off above them, allowing

safe access to the wire above for fishing operations or to carry out repairs to the pressure control equipment

above the valve. After the task has been completed and the integrity of the pressure control equipment has

been confirmed, an equaliser valve, situated in the wireline valve body, is used is used to equalise the pressure

across the rams. The manual back-up stems are then retracted, allowing the rams to be opened hydraulically.

Options include:

Shear/seal rams for cutting wire and cable

Wireline Operations

Single Hydraulic Conventional Wireline Valve

www.cromar.com

Wireline Operations

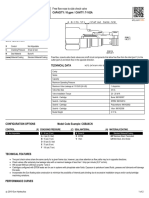

Single Monoblock Wireline Valves

Product code: 512

Special Features Include: Monoblock construction

Quick release hydraulic cylinders

Hydraulic cylinder support rods

Wireline Pressure Control Equipment

The Cromar hydraulic single monoblock wireline valves is positioned on top of the wellhead; it is designed to

provide a positive seal and contain well pressure around a stationary wireline or braided cable during well

intervention operations.

Hydraulically operated cylinder pistons with manual back-up stems are used to actuate the rams into the bore

of the valve and seal around the wireline or braided cable. The ram bodies are fitted with guides to align the

wire/cable into the inner seals. Guides and Inner seals are dressed to suit the wire or cable being deployed.

The ram bodies also include outer seals, which seal between the ram body and the bore above. Well pressure

behind the rams, acting on these seals, assist in keeping the rams shut against the wire/cable. When the rams

have been positively closed and the manual back-up stems functioned, well pressure is bled off above them,

allowing safe access to the wire above for fishing operations or to carry out repairs to the pressure control

equipment above the valve. After the task has been completed and the integrity of the pressure control

equipment has been confirmed, an equaliser valve, situated in the wireline valve body, is used to equalise

the pressure across the rams. The manual back-up stems are then retracted, allowing the rams to be opened

hydraulically.

Non-rising manual stems

Keyless ram bodies

Integral equalisation valve

Options include:

Galvanised steel hollow section

crash frames with fold down

stabbing platforms

Shear/seal rams for cutting wireline and braided cable

Single Monoblock Wireline Valve

Cromar single hydraulic monoblock wireline valve assemblies are available with

a choice of:

Connection:

Type B, O & C Acme Quick Union and standard API Bolt through flanges

Working Pressure Rating:

Up to 15,000psi

Size:

From 2.5 ID upwards

Service:

H2S, Standard

Equalising Valve Detail

www.cromar.com

Wireline Operations

Hydraulic piston position indicators

Wireline Operations

Dual Monoblock Wireline Valves

Product code: 514

Special Features Include: Monoblock construction

Quick release hydraulic cylinders

Hydraulic cylinder support rods

Non-rising manual stems

Keyless ram bodies

Dual Monoblock Wireline Valve

Integral equalisation valves

Integral grease injection port

Options include:

Galvanised steel hollow section crash frames

with fold down stabbing platforms

Shear/seal rams for cutting wire and cable

Cromar dual hydraulic monoblock wireline valve assemblies are available with a

choice of:

Connection:

Type B, O & C Acme Quick Union and standard API bolt through flanges

Working Pressure Rating:

Up to 15,000psi

Size:

From 2.5" ID upwards

Service:

H2S, Standard

Equalising Valve Detail

www.cromar.com

Wireline Operations

Hydraulic piston position indicators

Wireline Pressure Control Equipment

The Cromar dual hydraulic monoblock wireline valve is positioned on top of the wellhead; it is designed to provide

a positive seal and contain well pressure around wireline or braided cable during well intervention operations.

Hydraulically operated cylinder pistons with manual back-up stems are used to actuate the rams into the bore

of the valve and seal around the wireline or braided cable. The ram bodies are fitted with guides to align the

wire/cable into the inner seals. Guides and Inner seals are dressed to suit the wire or cable being deployed.

The ram bodies also include outer seals, which seal between the ram body and the bore above or below (when

the lower ram set is inverted). A grease injection port is provided in the cavity between the ram bodies. Grease

is injected into this area to achieve a seal around a braided cable. Grease and well pressure behind the rams,

acting on these seals, assist in keeping the rams shut against the wire/cable. When the rams have been positively

closed and the manual back-up stems functioned, well pressure is bled off above them. This procedure allows

safe access to the wire/cable for fishing operations or to carry out repairs to the pressure control equipment

above the valve. After the task has been completed and the integrity of the pressure control equipment has

been confirmed, equaliser valves, situated in the wireline valve body, are used to equalise the pressure across

both sets of rams. The manual back-up stems are then retracted, allowing the rams to be opened hydraulically.

Wireline Operations

Triple Monoblock Wireline Valves

Product code: 516

Special features include:

Monoblock construction

Quick release hydraulic cylinders

Hydraulic cylinder

support rods

Wireline Pressure Control Equipment

The Cromar triple hydraulic monoblock wireline valve is positioned on top of the wellhead; it is designed to

provide a positive seal and contain well pressure around stationary wireline or braided cable during well

intervention operations. Triple valves are predominately used during high pressure operations or during fishing

operations where a set of shear and seal rams are installed.

Hydraulically operated cylinder pistons with manual back-up stems are used to actuate the rams into the bore

of the valve and seal around the wireline or braided cable. The ram bodies are fitted with guides to align the

wire/cable into the inner seals. Guides and Inner seals are dressed to suit the wire or cable being deployed.

The ram bodies also include outer seals, which seal between the ram body and the bore above or below (when

the lower ram set is inverted). Grease injection ports are provided in the cavities between the ram bodies.

Grease is injected into these volumes to achieve a seal around a braided cable. Grease and well pressure

behind the rams, acting on these seals, assist in keeping the rams shut against the wire/cable. When the rams

have been positively closed and the manual back-up stems functioned, well pressure is bled off above them.

This procedure allows safe access to the wire/cable for fishing operations or to carry out repairs to the pressure

control equipment above the valve. After the task has been completed and the integrity of the pressure control

equipment has been confirmed, equaliser valves, situated in the wireline valve body, are used to equalise the

pressure across the three sets of rams. The manual back-up stems are then retracted, allowing the rams to

be opened hydraulically.

Non-rising manual stems

Hydraulic piston position indicators

Keyless ram bodies

Integral equalisation

valves

Options include:

Galvanised steel

hollow section crash frames

with fold down stabbing platforms

Shear/seal rams for cutting wire and cable

Triple Monoblock Wireline Valve

Cromar triple hydraulic monoblock wireline valve assemblies

are available with a choice of:

Connection:

Type B, O & C Acme Quick Union and standard API

bolt through flanges

Working Pressure Rating:

Up to 15,000psi

Size:

From 2.5" ID upwards

Service:

H2S, Standard

Equalising Valve Detail

www.cromar.com

Wireline Operations

Integral grease

injection ports

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- 735, 740 and 740E Electrical System Articulated Truck: Machine Harness Connector and Component LocationsDocumento2 páginas735, 740 and 740E Electrical System Articulated Truck: Machine Harness Connector and Component LocationsMiguel Bustamante100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Manual Operador 1350SJPDocumento110 páginasManual Operador 1350SJPDawn HallAinda não há avaliações

- 350X2 Manual de ServicioDocumento1.154 páginas350X2 Manual de ServicioJuan David Gomez Avella100% (1)

- 8 HP45 Hi SSWDocumento37 páginas8 HP45 Hi SSWВиталий ЧерненкоAinda não há avaliações

- Drill Pipe Spec's SheetDocumento10 páginasDrill Pipe Spec's SheetAhmed BakrAinda não há avaliações

- Mazda Protege 1996Documento36 páginasMazda Protege 1996ErasmoNieves100% (4)

- An Introduction To Directional DrillingDocumento86 páginasAn Introduction To Directional DrillingSerag Gamal80% (15)

- CatioLift Technical InformationDocumento9 páginasCatioLift Technical InformationNazihCosmetics0% (1)

- Dictionary of Oil Industry TerminologyDocumento79 páginasDictionary of Oil Industry Terminologyniksharris100% (22)

- H16-22XM-12EC Empty Container Handlers Offer Class-Leading PerformanceDocumento24 páginasH16-22XM-12EC Empty Container Handlers Offer Class-Leading PerformanceEjaz EjazAinda não há avaliações

- Key Issues in Multilateral Technology: Steve BosworthDocumento15 páginasKey Issues in Multilateral Technology: Steve BosworthArcenio Jimenez MorganAinda não há avaliações

- FSH ToolDocumento9 páginasFSH ToolArcenio Jimenez Morgan100% (1)

- B35D B40D PIN 7.5 It4 TIER 3B ADT RevADocumento935 páginasB35D B40D PIN 7.5 It4 TIER 3B ADT RevAPieter BothaAinda não há avaliações

- Aerial Bunch CableDocumento2 páginasAerial Bunch CablePrashant Jha100% (1)

- 7745858w D2-55, D2-75 OPERATOR'S MANUALDocumento64 páginas7745858w D2-55, D2-75 OPERATOR'S MANUALm.kelleci72480% (1)

- ESP Canadian AdvancedDocumento12 páginasESP Canadian Advancedcamillo010Ainda não há avaliações

- Mms Faja Multilateral DrillDocumento26 páginasMms Faja Multilateral DrillArcenio Jimenez MorganAinda não há avaliações

- GP Torsional Tensile Value For Tool Joints PDFDocumento12 páginasGP Torsional Tensile Value For Tool Joints PDFRobertok1234Ainda não há avaliações

- Modern Petroleum Refinery Engineering Bhaskar RaoDocumento208 páginasModern Petroleum Refinery Engineering Bhaskar RaoAman Dhanani71% (21)

- SeismicRefraction PDFDocumento10 páginasSeismicRefraction PDFMaliha N. AhmedAinda não há avaliações

- Resistivity: ON Onductive OmponentsDocumento5 páginasResistivity: ON Onductive OmponentsArcenio Jimenez MorganAinda não há avaliações

- MojabilidadDocumento2 páginasMojabilidadArcenio Jimenez MorganAinda não há avaliações

- Symbols 2Documento1 páginaSymbols 2Arcenio Jimenez MorganAinda não há avaliações

- Symbols 1Documento1 páginaSymbols 1Arcenio Jimenez MorganAinda não há avaliações

- Overview of The Oil and Gas ExplorationDocumento7 páginasOverview of The Oil and Gas ExplorationArcenio Jimenez MorganAinda não há avaliações

- L15 SeismicReflectionIIDocumento13 páginasL15 SeismicReflectionIIadobiAinda não há avaliações

- L10 SeismicRefractionDocumento11 páginasL10 SeismicRefractionDwi HerlinaAinda não há avaliações

- Sed Rocks 1 PDFDocumento11 páginasSed Rocks 1 PDFArcenio Jimenez MorganAinda não há avaliações

- Plate MotionsDocumento11 páginasPlate MotionsArcenio Jimenez MorganAinda não há avaliações

- 08 Sedimentary1Documento10 páginas08 Sedimentary1Ricardo CesarAinda não há avaliações

- Plate Tectonics-A Historical ReviewDocumento15 páginasPlate Tectonics-A Historical ReviewArcenio Jimenez MorganAinda não há avaliações

- Seismic ReflectionDocumento12 páginasSeismic ReflectionArcenio Jimenez MorganAinda não há avaliações

- Sed Rocks 4 PDFDocumento4 páginasSed Rocks 4 PDFArcenio Jimenez MorganAinda não há avaliações

- Overview of The Oil and Gas ExplorationDocumento7 páginasOverview of The Oil and Gas ExplorationArcenio Jimenez MorganAinda não há avaliações

- Geothermal Chart of MexicoDocumento4 páginasGeothermal Chart of MexicoLu GonzalezAinda não há avaliações

- Marine Sed 1 PDFDocumento12 páginasMarine Sed 1 PDFArcenio Jimenez MorganAinda não há avaliações

- JK Flip Flop With CD4027 Circuit DiagramDocumento2 páginasJK Flip Flop With CD4027 Circuit DiagramHARRYAinda não há avaliações

- Honeywell IS2535 Install GuideDocumento2 páginasHoneywell IS2535 Install GuideAlarm Grid Home Security and Alarm MonitoringAinda não há avaliações

- Electric Submersible Pumps GuideDocumento22 páginasElectric Submersible Pumps GuideDanteAinda não há avaliações

- Free-flow nose-to-side check valve technical detailsDocumento2 páginasFree-flow nose-to-side check valve technical detailssnsnagarajanAinda não há avaliações

- ATRT-01 S3/ATRT-01B S3: Transformer Turns Ratio TestersDocumento4 páginasATRT-01 S3/ATRT-01B S3: Transformer Turns Ratio TestersedgarcooAinda não há avaliações

- Catalogo l375 20 So30002Documento12 páginasCatalogo l375 20 So30002Alexis SanchezAinda não há avaliações

- Development of An Adaptive Steering Controlled Headlight For Low Cost VehiclesDocumento5 páginasDevelopment of An Adaptive Steering Controlled Headlight For Low Cost Vehiclesankush belkarAinda não há avaliações

- 70 Series line monitoring relaysDocumento10 páginas70 Series line monitoring relaysovidiuAinda não há avaliações

- Basic Principles V2Documento20 páginasBasic Principles V2Gautam PkAinda não há avaliações

- HVAC Dampers Installation Method StatementDocumento3 páginasHVAC Dampers Installation Method StatementDong VanraAinda não há avaliações

- CDHD2 ECT CAN fw2.15.x Rev.1.0 PDFDocumento499 páginasCDHD2 ECT CAN fw2.15.x Rev.1.0 PDFDon BozarthAinda não há avaliações

- Department of Electrical Engineering: UART - Libraries and Servo ObjectivesDocumento3 páginasDepartment of Electrical Engineering: UART - Libraries and Servo ObjectivesJohn Louie TapecAinda não há avaliações

- Hyundai VENUE SUV BrochureDocumento8 páginasHyundai VENUE SUV BrochurecdcdscdsAinda não há avaliações

- Measuring Output Ripple An-1144Documento8 páginasMeasuring Output Ripple An-1144anon_444314615Ainda não há avaliações

- ARM ProcessorsDocumento20 páginasARM Processorsrajkumar_jain4855Ainda não há avaliações

- PS90 Diagnosis System GuideDocumento31 páginasPS90 Diagnosis System GuideskyAinda não há avaliações

- Band Saw G5018WA: Features of Metal Band Sawing Machine From Hoton MachineryDocumento1 páginaBand Saw G5018WA: Features of Metal Band Sawing Machine From Hoton MachineryMantención FastpackAinda não há avaliações

- ELE3-18 MostUpdated 04052022Documento43 páginasELE3-18 MostUpdated 04052022葉朗Ainda não há avaliações

- P Series Strain GaugesDocumento1 páginaP Series Strain Gaugesjbmune6683Ainda não há avaliações

- Hydraulic/Hydrostatic Schematic: S175 (S/N A3L520001 AND ABOVE)Documento2 páginasHydraulic/Hydrostatic Schematic: S175 (S/N A3L520001 AND ABOVE)alexandrAinda não há avaliações