Escolar Documentos

Profissional Documentos

Cultura Documentos

Style PN Flexpro Datasheet

Enviado por

parag7676Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Style PN Flexpro Datasheet

Enviado por

parag7676Direitos autorais:

Formatos disponíveis

FLEXITALLIC

FLEXPRO

Style PN

FLEXITALLIC LIMITED

PO BOX 3 MARSH WORKS DEWSBURY ROAD

CLECKHEATON WEST YORKSHIRE BD19 5BT

TEL: 01274 851273

FAX: 01274 851386

PRODUCT

REFERENCE:

FLEXITALLIC FLEXPRO Style PN

DESCRIPTION:

Flexpro style PN is a high performance semi-metallic gasket designed for use on malefemale and tongue-groove flanged connections. It is comprised of a concentrically

serrated solid metal core with a soft, conformable sealing material bonded to both

faces. The soft material provides low stress gasket seating and the strong metal core

provides rigidity and blowout resistance. The serration profile on the metal core

enhances sealing performance by inducing stress concentrations on the sealing

surfaces.

SERVICE:

Flexpro style PN gaskets have been successfully used for many years and are suitable

for use in a wide range of sealing applications, most notably heat exchangers. They

are capable of providing high integrity seals in most demanding environments, even in

load compromised situations. Gasket metallurgy, serration profile and facing material

selection can be tailored to suit specific applications. Typical applications include HP

and superheated steam, high pressure hydrocarbon and chemical service.

10000C (18300F)*

Maximum recommended temperature:

Maximum recommended pressure:

CONSTRUCTION:

Facing material*:

ASME B16.5 2500#

Flexicarb, Thermiculite, Sigma, Silver.

Serrated metallic core**: Austenitic Stainless steels, High-Temp alloy grades.

*Material combination dependent on application.

**Other, customer specified materials may be available on request.

DESIGN FACTORS:

ASME Y Factor:

ASME m Factor:

PVRC Gb:

PVRC a:

PVRC Gs:

17.2Mpa (2500psi)

2.0

387psi

0.33

14psi

The above design factors are applicable for standard serration profile core faced

with 0.5mm, 1g/cc Flexicarb foil.

Gasket factors to EN13555 for design calculations to EN1591 are available on

request

AVAILABILITY:

Gasket size:

up to 5,000 mm

Thickness range:

2.5mm to 5.0 mm

Other thicknesses may be available on request or may be used when design

constraints dictate.

***Also available in various pass bar configurations to suit partition rib

arrangement on heat exchangers***

PDS 575 10/13

This Data Sheet refers to the material as supplied. The information contained herein is given in good faith, but no liability

will be accepted by the Company in relation to same. We reserve the right to change the details given on this Data Sheet

as additional information is acquired. Customers requiring the latest version of this Data Sheet should contact our

Applications Engineering Department. The information given and, in particular, any parameters, should be used for

guidance purposes only. The Company does not give any warranty that the product will be suitable for the use intended

by the customer.

HEALTH AND SAFETY

Because of the processes which take place during manufacture, the product is believed to present no health

and safety hazard and, under normal handling and use it is unlikely that the product will give rise to

significant levels of exposure to constituent materials.

Flexpro is a semi metallic laminate containing exfoliated graphite reinforced with aserrated metallic core.

Under harsh mechanical treatment (e.g. high speed abrasion) the constituents may give rise to irritant dusts

which, in extreme cases of exposure, could lead to more serious respiratory problems. Occupational

exposure to such dusts should therefore be minimised and kept below relevant national exposure limits.

Good standards of hygiene should be applied during gasket cutting operations and off-cuts should be

disposed of by transfer to a site appropriately licensed to accept industrial materials of this nature.

Graphite is combustible. At elevated temperatures or in a sustained fire, toxic fumes may be produced.

The material is conductive. Graphite debris or dust should not be allowed to penetrate electrical equipment.

The metallic core is selected for the particular application and is machine finished to remove sharp edge or

burr so that ppe are kept to a minimum.

For more detailed information, reference must be made to our Health and Safety Bulletin, Sections 1, 2, 2.11,

3 and 3.2. This will enable you to carry out any necessary assessment of risk which may be required under

national or local legislation.

PDS 575 10/13

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Lecture 25 Design of Stack: Key Words: Stack, Chimney, Draft, Natural Draft What Is Stack EffectDocumento3 páginasLecture 25 Design of Stack: Key Words: Stack, Chimney, Draft, Natural Draft What Is Stack Effectkarthikraja21Ainda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- New Ontario Building Code Highlights: The Corporation of The City of Sarnia Building DepartmentDocumento13 páginasNew Ontario Building Code Highlights: The Corporation of The City of Sarnia Building Departmentparag7676Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- 7 EG-3 Approved Dec 03 Air-Cooled Heat ExchangersDocumento25 páginas7 EG-3 Approved Dec 03 Air-Cooled Heat Exchangersparag7676Ainda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- RailingDocumento11 páginasRailingparag7676Ainda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- 97-269 Safe Working On Roofs Part1Documento36 páginas97-269 Safe Working On Roofs Part1parag7676Ainda não há avaliações

- Lecture 25 Design of Stack: Key Words: Stack, Chimney, Draft, Natural Draft What Is Stack EffectDocumento3 páginasLecture 25 Design of Stack: Key Words: Stack, Chimney, Draft, Natural Draft What Is Stack Effectkarthikraja21Ainda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Seiris Datasheet BolstersDocumento1 páginaSeiris Datasheet Bolstersparag7676Ainda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- 05 GB Simple ConnectionsDocumento11 páginas05 GB Simple Connectionspjustino70Ainda não há avaliações

- BM Europe Expansion Joints Technical CalculationDocumento9 páginasBM Europe Expansion Joints Technical CalculationsahirprojectsAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- 16-21Documento6 páginas16-21parag7676Ainda não há avaliações

- Standard Range: Washer Plates For Use With Holding Down BoltsDocumento1 páginaStandard Range: Washer Plates For Use With Holding Down Boltsparag7676Ainda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- 2 PBDocumento6 páginas2 PBparag7676Ainda não há avaliações

- Beskrivning Av ExpansionsbalgarDocumento25 páginasBeskrivning Av ExpansionsbalgarNopparutAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Design Guide BC1 2012Documento86 páginasDesign Guide BC1 2012Ayingaran Thevathasan100% (1)

- 7 EG-3 Approved Dec 03 Air-Cooled Heat ExchangersDocumento25 páginas7 EG-3 Approved Dec 03 Air-Cooled Heat Exchangersparag7676Ainda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- TMC 704 ReviDocumento19 páginasTMC 704 Reviparag7676Ainda não há avaliações

- Chequer Plate DesignDocumento1 páginaChequer Plate Designmanish_chhuganiAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Chequer Plate DesignDocumento1 páginaChequer Plate Designmanish_chhuganiAinda não há avaliações

- (Preliminary) Exhaust Mating FlangeDocumento1 página(Preliminary) Exhaust Mating Flangeparag7676Ainda não há avaliações

- 1409908607Documento2 páginas1409908607parag7676Ainda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- 1409908607Documento2 páginas1409908607parag7676Ainda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Fastener Tech DetailsDocumento1 páginaFastener Tech DetailsRanganathan SekarAinda não há avaliações

- ML 100500808Documento26 páginasML 100500808Andres Rodriguez HerreraAinda não há avaliações

- 03-Bearing Life PDFDocumento34 páginas03-Bearing Life PDFchanayireAinda não há avaliações

- Stair Treads and Fast NersDocumento1 páginaStair Treads and Fast Nersparag7676Ainda não há avaliações

- 03 Me 2014 PDFDocumento21 páginas03 Me 2014 PDFparag7676Ainda não há avaliações

- ScheduleDocumento1 páginaScheduleparag7676Ainda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 231Documento34 páginas231parag7676Ainda não há avaliações

- Shell Gadus Product Family BrochureDocumento6 páginasShell Gadus Product Family BrochurefahreezAinda não há avaliações

- 03 Me 2014 PDFDocumento21 páginas03 Me 2014 PDFparag7676Ainda não há avaliações

- Caterpillar C10, C12Documento8 páginasCaterpillar C10, C12Вячеслав ШапочкаAinda não há avaliações

- G GTA855A Parts BookDocumento68 páginasG GTA855A Parts BookАндрей Кулешов100% (3)

- Special Flange Joints Used in Floating-Head Shell-And-Tube Heat ExchangersDocumento5 páginasSpecial Flange Joints Used in Floating-Head Shell-And-Tube Heat ExchangersBramJanssen76Ainda não há avaliações

- InventoryDocumento13 páginasInventoryNARAINA DEPOTAinda não há avaliações

- Supplement On Container Inspection and Repair Gray Areas, 2nd Edition (Published 2003) PDFDocumento23 páginasSupplement On Container Inspection and Repair Gray Areas, 2nd Edition (Published 2003) PDFmardika rachmanAinda não há avaliações

- Safety Relief Valve VSEODocumento4 páginasSafety Relief Valve VSEOShashank HAinda não há avaliações

- Chapter 3 Valve and Actuator TypesDocumento23 páginasChapter 3 Valve and Actuator TypesDimas NugrahaAinda não há avaliações

- Air Compressor Spare ListDocumento34 páginasAir Compressor Spare ListPragnesh PrajapatiAinda não há avaliações

- HANS OfficekeoliDocumento503 páginasHANS OfficekeoliSuperintending Engineer IPH Circle SundernagarAinda não há avaliações

- Engineering Manual: Concrete Pressure PipeDocumento176 páginasEngineering Manual: Concrete Pressure Pipeahmad elnggarAinda não há avaliações

- Puertas Anthony Ingles PDFDocumento101 páginasPuertas Anthony Ingles PDFJesus Maria Medina SanchezAinda não há avaliações

- KITZ Carbon Steel E-170-10 - SMSDocumento35 páginasKITZ Carbon Steel E-170-10 - SMSWika GedungAinda não há avaliações

- Road Tank VehiclesDocumento50 páginasRoad Tank VehiclesALONSO GOMEZAinda não há avaliações

- Camperfiladas Asme 16 5Documento8 páginasCamperfiladas Asme 16 5klara23Ainda não há avaliações

- D3E80220B4A-Servicing 6-Speed Manual Gearbox 0B1 Front-Wheel DriveDocumento187 páginasD3E80220B4A-Servicing 6-Speed Manual Gearbox 0B1 Front-Wheel DriveAndrei Stefan DimaAinda não há avaliações

- GE - Frame - 9E - LUBE - OIL - FILTER - LOF11Documento14 páginasGE - Frame - 9E - LUBE - OIL - FILTER - LOF11Abbas AkbarAinda não há avaliações

- Commande MANDocumento8 páginasCommande MANclaudemirAinda não há avaliações

- Spacer Plates C-15Documento13 páginasSpacer Plates C-15MANUTENÇÃO CAVA ENGENHARIAAinda não há avaliações

- Great Parts For Great Engines: Light/Medium Duty Diesel Engine KitsDocumento12 páginasGreat Parts For Great Engines: Light/Medium Duty Diesel Engine KitsTayfun SezişAinda não há avaliações

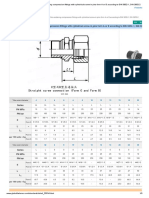

- DIN 2353 - 2013non-Soldering Compression Fittings With Cylindrical Screw-In Pins Form A or B According To DIN 3852-1, DIN 3852-2Documento3 páginasDIN 2353 - 2013non-Soldering Compression Fittings With Cylindrical Screw-In Pins Form A or B According To DIN 3852-1, DIN 3852-2Er.Amritpal SinghAinda não há avaliações

- Superlite: Superlite Asbestos Free Gp-150Documento4 páginasSuperlite: Superlite Asbestos Free Gp-150blahblahAinda não há avaliações

- Delonghi PartsDocumento119 páginasDelonghi PartsOleksAinda não há avaliações

- Vane Type Double Pump (Bomba de Palheta) Vickers EATON V2200-S214Documento5 páginasVane Type Double Pump (Bomba de Palheta) Vickers EATON V2200-S214Lucas CardosoAinda não há avaliações

- PTS-Technical Catalogue 2020Documento51 páginasPTS-Technical Catalogue 2020Commercial MarocAinda não há avaliações

- 6.0 - Motorized Volume Control DamperDocumento5 páginas6.0 - Motorized Volume Control DamperFloizel Anne Cruz - VictorinoAinda não há avaliações

- 3500 MSB80 ENS1 0110 02 - General Material SpecificationDocumento304 páginas3500 MSB80 ENS1 0110 02 - General Material SpecificationJoão Luiz CortatAinda não há avaliações

- KST GasketsDocumento42 páginasKST Gasketsmihir_jha2Ainda não há avaliações

- Piping B.O.Q - BreakupDocumento26 páginasPiping B.O.Q - BreakupBalaji PAinda não há avaliações

- Partbook HM400-3Documento629 páginasPartbook HM400-3lilik100% (2)

- SDG100S 8B1 SDG125S 8B1 SDG150S 8B1Documento33 páginasSDG100S 8B1 SDG125S 8B1 SDG150S 8B1ДмитрийAinda não há avaliações

- To Engineer Is Human: The Role of Failure in Successful DesignNo EverandTo Engineer Is Human: The Role of Failure in Successful DesignNota: 4 de 5 estrelas4/5 (138)

- Waste: One Woman’s Fight Against America’s Dirty SecretNo EverandWaste: One Woman’s Fight Against America’s Dirty SecretNota: 5 de 5 estrelas5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionNo EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionNota: 3 de 5 estrelas3/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsNo EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsAinda não há avaliações