Escolar Documentos

Profissional Documentos

Cultura Documentos

United States Patent (191

Enviado por

pradip panthaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

United States Patent (191

Enviado por

pradip panthaDireitos autorais:

Formatos disponíveis

United States Patent [191

[11]

[45]

King

[54] VALVE POSITION INDICATOR AND

METHOD

[75] Inventor:

[73] Assignee:

[57]

Patent Number:

Date of Patent:

4,545,406

Oct. 8, 1985

ABSTRACT

Disclosed is a method and apparatus for indicating the

Patrick D. King, Rantoul, Ill.

Flo-Con Systems, Inc., Champaign,

Ill.

position of a hydraulically actuated device by measur

ing the volume of hydraulic ?uid flow in and out of the

hydraulic actuator together with separate measurement

corrections to compensate for the hydraulic system

elasticity and transient ?ows and for the mechanical

[21] Appl. No.: 482,496

[22] Filed:

Apr. 6, 1983

clearance or slop in the linkage between the actuator

and the device. In a preferred embodiment of the

[63]

Related US. Application Data

Continuation-impart of Ser. No. 221,933, Dec. 31,

1980, abandoned.

[51]

Int. Cl.4 ............................................ .. F16K 37/00

[52]

US. Cl. ........................................ .. 137/553; 91/1;

[58]

Field of Search ................ .. 137/553, 554; 251/62;

[56]

91/1; 73/708, 37.5; 364/509, 510, 571

References Cited

364/510; 364/571

method, the compensation for hydraulic system elastic

ity and transient flows is preferably made by measuring

the relaxation reverse ?ow when the actuator is depres

surized and using this measurement to offset an equal

amount of the measured forward ?ow when the actua

tor is repressurized in the same direction. Further, the

compensation for mechanical clearance in the linkage

between the actuator and the device is applied only

when the actuator direction is reversed; the amount of

such compensation is empirically determined and may

increase with wear and tear on the linkage. This com

U.S. PATENT DOCUMENTS

pensated hydraulic ?uid ?ow measurement as a position

2,802,483

8/1957

Davis ................................ .. 137/553

indicator is especially advantageous in indicating the

3,081,942

3/1963

Maclay ..

position of a sliding gate valve used for teeming molten

steel. The high temperature and corrosive environment

about such a sliding gate valve preclude use of prior-art

valve position indicators. However, the present inven

tion permits the entire measurement apparatus to be

....... .. 91/1

3,768,510 10/1973 Reves

137/553

3,822,377

364/510

7/1974

Beck ........ ..

4,120,032 10/1978

Mirdadian .

364/510

4,253,156

2/1981

Lisle et al.

364/510

4,404,638

9/1983

Yada et al. ........................ .. 364/571

Primary ExaminerAlan Cohan

Assistant Examiner-John A, Rivell

Attorney, Agent, or Firm-Jack E. Dominik

located at a distance from the sliding gate valve.

2 Claims, 8 Drawing Figures

U.S. Patent

0m. 8, 1985 ,

Sheetl 0f8

4,545,406

US. Patent Oct. 8, 1985

Sheet4 0f8

4,545,406

EMN K I

nm@E

_

_

mP3o><i|_

8%l

_m_~m\ may59:3

m+

_Muam.no_d|.i W0398E. T:O8M;E

_

_

_

N

_

.

:14

rub}Wn.1.

m

_

r

_

__

H

AWE.6Tml.HMW"

HA

L.

A

4A5.:3wzo

M"u"102402

:_v

m:

Y9

5,

_

w

_m_

B:191

m:m2_m_

mmT?/g

mm_8.

US. Patent Oct. 8, 1985

15.230

mkznOu

Sheet7of8

4,545,406

US. Patent 0a. 8, 1985

Sheet80f8

4,545,406

4,545,406

VALVE POSITION INDICATOR AND METHOD

only when the actuator direction is reversed; the

amount of such compensation is empirically determined

and may increase with wear and tear on the linkage.

CROSS-REFERENCE TO RELATED

APPLICATIONS

These compensations solve the problems of the prior

art in that even after repeated pressurizations and de

This application is a continuation-in-part of applica

tion Ser. No. 221,933, ?led Dec. 31, 1980 now aban

doned.

BACKGROUND OF THE INVENTION

1. Field of the Invention

'

The present invention pertains to the control arts, and

more particularly the indication of the position of a

hydraulically actuated valve.

2. Description of the Prior Art

In the teeming of molten steel, refractory lined sliding

gate valves are used to control the ?ow. Such sliding

gate valves are typically hydraulically actuated, and the

operator normally monitors the ?ow by simply watch

ing the stream of molten steel. However, in such high

temperature and corrosive environments, the accuracy

of such visual inspection of ?ow will depend heavily in

pressurizations of the actuator in both directions, the

position of the device is still accurately indicated by the

?ow measurement. This compensated hydraulic ?uid

?ow measurement as a position indicator is especially

advantageous in indicating the position of a sliding gate

valve used for teeming molten steel. The high tempera

ture and corrosive environment about such a sliding

gate valve preclude use of prior-art valve position indi

cators. However, the present invention permits the

entire measurement apparatus to be located at a distance

from the sliding gate valve.

The present invention also provides an apparatus for

use with the method. A preferred embodiment of the

apparatus includes a slave hydraulic actuator which is

inserted in the hydraulic line to the device actuator;

such slave hydraulic actuator drives a shaft encoder

which provides a pair of electrical signals correspond

the skill and experience of the operator, and even with

ing to movement and direction of such slave actuator.

the most skillful operator the accuracy and repeatability

The pair of electrical signals is decoded to create a

of a sliding gate valve position is limited. Thus it is a 25 direction signal and a clock signal; the clock signal

problem with the prior art to accurately and repeatedly

pulses are counted to indicate device position. The com

set the position of a sliding gate valve used for teeming

pensations for hydraulic system elasticity and for me

molten steel.

chanical

clearance are achieved by precluding the

The prior art also includes Davis U.S. Pat. No.

counting

of

a set number of clock pulses. Compensation

2,802,483 which discloses a mechanical valve position

for

transients

is made by counting clock pulses corre

indicator for a hydraulically actuated gate valve. The

position indicator is merely a pointer worm-geared to

sponding to hydraulic ?uid ?ow during times that the

gedness, warpage, and mechanical clearance between

moving parts which limits accuracy and repeatability.

The prior art also includes Maclay U.S. Pat. No.

is activated.

ing the position of a hydraulically actuated device by

teeming is controlled by sliding gate valve 17 which

actuator is not activated and storing this count in an

the valve stem. Such a mechanical valve position indi

auxiliary counter. This count in the auxiliary counter is

cator has the usual problems with mechanical devices in

high temperature and corrosive environments of rug 35 then used to subtract from the count when the actuator

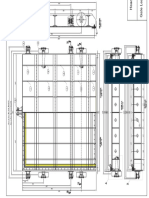

BRIEF DESCRIPTION OF THE DRAWINGS

FIG.

1 diagrammatically shows a preferred embodi

3,081,942 which discloses an electronic measurement of

hydraulic control ?uid ?ow as part of a digital-to 40 ment of the inventive apparatus in place for use with a

sliding gate valve;

analog control device. The electronic measurement is

FIG. 2 is a partial block diagram showing the ?ow of

made by counting pulses generated as the control ?uid

hydraulic ?uid and the electronic components of a pre

flow drives a pair of meshing gears which rotate past a

ferred embodiment of the inventive apparatus; and

magnetic transducer. However, Maclay fails to disclose

FIGS. 3a-3f are schematic diagrams of a portion of a

any corrections to the ?uid ?ow measurement to com 45

preferred embodiment of the inventive apparatus.

pensate for transients occurring when the ?uid ?ow is

stopped and restarted and to compensate for elimination

DESCRIPTION OF THE PREFERRED

and creation of mechanical clearances in the control

EMBODIMENTS

member. Indeed, Maclay fails to even note the existence

FIG.

1

illustrates

a set-up with which preferred em

of such measurement problems.

50

bodiments of both the method and apparatus may be

SUMMARY

used. In particular, tundish 11 is shown ?lled with mol

ten steel 13 which is teemed through nozzle 15. The

The present invention provides a method for indicat

measuring the volume of hydraulic ?uid ?ow in and out 55 includes sliding gate 19 and hydraulic actuator 21 for

pushing and pulling gate 19in valve 17. Hydraulic actu

of the hydraulic actuator together with separate mea

ator 21 is driven by hydraulic pump 23 which pumps

surement corrections to compensate for the hydraulic

hydraulic ?uid out of reservoir 25 and through bi-direc

system elasticity and transient ?ows and for the me~

tion valve 27. All of the items in FIG. 1, except actuator

chanical clearance or slop in the linkage between the

actuator and the device. In a preferred embodiment of 60 21, may be located away from the hostile environment

about valve 17.

the method, the compensation for hydraulic system

elasticity and transient ?ows is preferably made by

Slave hydraulic cylinder 31 is used to measure the

measuring the relaxation reverse ?ow when the actua

?ow of hydraulic ?uid into and out of actuator 21 as is

tor is depressurized and using this measurement to offset

described below. Note that for use in teeming molten

an equal amount of the measured forward ?ow when 65 steel a typical size for actuator 21 is a 3% inch bore and

the actuator is repressurized in the same direction. Fur

capable of a'3 inch stroke in two seconds which trans

ther, the compensation for mechanical clearance in the

lates to approximately 29 cubic inches of hydraulic ?uid

linkage between the actuator and the device is applied

?ow at 14% cubic inches per second.

4,545,406

With valve 27 set to direct the output of pump 23 into

hydraulic line 33, actuator 21 pushes sliding gate 19 into

valve 17 and thereby decreases the opening in valve 17.

ponents (especially the hydraulic lines) relax and con

tract and the previously-compressed hydraulic ?uid

expands.

If the teeming rate is too low, directional valve 27 is

Conversely, if valve 27 is set to direct the output of

pump 23 into hydraulic line 35, then actuator 21 pulls 5 set by energizing solenoid 41 so that pump 23 pressur

izes line 35 (and thereby through slave cylinder 31 pres

gate 19 out of valve 17 and thereby increases the open

surizes line 37) and activates actuator 21 to pull sliding

ing of valve 17. The inclusion of slave hydraulic cylin

gate 19 out of valve 17 and increase the valve opening.

der 31 does not disrupt this operation because ?uid

?owing from valve 27 along line 35 into cylinder 31

causes the piston in cylinder 31 to move and thereby

discharge an equal volume of ?uid at an equal pressure

into line 37 in thence into actuator 21. If valve 27 is set

to disconnect the output of pump 23 from both lines 33

and 35, then actuator 21 is depressurized. Valve 27 is

operated by two electrical solenoids, one for directing

the output of pump 23 into line 33 and the other for

directing the output of pump 23 into line 35. Solenoid 41

is shown mounted on the housing of valve 27. These

two solenoids are wired so that they cannot be simulta

Again, the initial portion of the pull eliminates mechani

cal clearances (in the opposite direction of the initial

push). After a satisfactory teeming rate is obtained slid

ing gate 19 is stopped as before by deenergizing sole

noid 41 and thereby setting valve 27 to cutoff pump 23,

and again a transient hydraulic ?uid ?ow occurs during

relaxation.

Further, the teeming rate may desirably be decreased

(or increased) in a series of pushes (or pulls) of sliding

gate 19. During such a series of pushes, the pressuriza

tion/relaxation cycle just described is repeated many

neously activated, and when they are both deactivated 20 times, but the elimination of mechanical clearances only

occurs on the initial push which is a change in direction.

valve 27 disconnects the output of pump 23 from both

lines 33 and 35.

The position of gate 19 in valve 17 (i.e., the amount

The motion of the piston in slave cylinder 31 corre

that valve 17 is open) at any given time is determined by

an analysis of the hydraulic ?uid ?ows to and from

sponds, after compensation, to the motion of the piston

in actuator 21 and gate 19, so selecting actuator 21 and 25 actuator 21 from a known initial starting point of gate 19

slave cylinder 31 to be identical hydraulic cylinders

up to the time of determination. The measurement of

yields virtually identical piston motions, although this

these ?ows and the corrections in the measurement to

certainly is not necessary. Indeed, slave cylinder 31

compensate for hydraulic system elasticity and mechan

could be replaced with a hydraulic motor as a means for

ical clearance in the linkage between actuator 21 and

measuring the hydraulic ?uid ?ow in lines 35 and 37.

The motion of the piston in slave cylinder 31 drives

shaft encoder 45 whose electrical signal output is pro

cessed in box 51 and the sliding gate displayed as de

scribed below. This signal processing includes use of

gate 19 is shown in block diagram form in FIG. 2. In

particular the output of encoder 45 on lines 61 and 63 is

processed in direction differentiation block 52 which

outputs two signals a Direction signal indicating the

direction that encoder 45 is rotating and a Clock signal

information on the status of the two valve 27 solenoids 35 which consists of a series of pulses corresponding to the

and is indicated by the wires from box 51 to the sole

rotation. The Clock pulses will be counted in position

count block 53 to determine the position of gate 19, but

noids. The signal processing may be done by hardware,

first the Clock pulses pass through relax count block 54

software, or a combination.

FIG. 2 provides a diagrammatic view of the set-up of

which compensates for the relaxation ?ows by prevent

FIG. 1 and also breaks the electronic circuitry in box 51

ing passage of a certain number of Clock pulses. Then

the Clock pulses pass through skip count block 55

down into its functional blocks for a preferred embodi

which compensates for the mechanical clearance elimi

ment of the apparatus. The functioning of this elec

nation by preventing a certain number of Clock pulses

tronic circuitry will be explained below and in conjunc

tion with FIG. 3.

from passing through. Lastly, the Clock pulses passing

Control of the teeming rates of molten steel 13 45 through both blocks 54 and 55 are counted in block 53

and the count data is processed by microprocessor 56,

through sliding gate valve 17 is accomplished as fol

lows:

and the processed data display in display 57. The Direc

If the teeming rate is satisfactory, directional valve 27

tion signal determines whether block 53 is adding or

is set to cut off pump 23 from hydraulic lines 33 and 35

subtracting as it counts the Clock pulses, and the Direc

tion signal plus the status of solenoids 41 and 47 are used

(as in FIG. 2) and thereby depressurize lines 33, 35 and

to perform the compensation in block 54, and the sole

37, deactivate actuator 21, and keep sliding gate 19

stationary in valve 17.

noid status is also used to perform the mechanical clear

If the teeming rate is too high, directional valve 27 is

ance compensation in block 55. Microprocessor 56 may

be in communication with blocks 54 and 55 for setting

set by energizing solenoid 47 so that pump 23 pressur

izes line 33 and activates actuator 21 to push sliding gate

initial data, etc. The output of microprocessor 56 may

19 into valve 17 to decrease the valve opening. The

also be used to control the position of gate 19 as part of

push by actuator 21 ?rst eliminates mechanical clear

an automated valve.

ances and only then does it move sliding gate 19. This

To illustrate how the need for compensations in the

pushing forces hydraulic ?uid out of actuator 21 into

measurement of hydraulic ?uid ?ow arise, consider the

line 37 and into and out of slave cylinder 31, through

sequence of events starting with the system in a relaxed

line 35, through directional valve 27 and back into res

state (pump 23 not connected to either line 33 or line 35)

ervoir 25. Once the valve 17 opening has decreased

and then progressing through activation of valve 27 to

enough to bring the teeming rate down to satisfactory,

drive actuator 21 to pull gate 19 partially out of valve 17

directional valve 27 is set by deenergizing solenoid 47 to

followed by valve 27 deactivating actuator 21 and the

cut off pump 23, and thereby deactivate actuator 21, 65 system returning to a relaxed state.

and depressurize hydraulic lines 33, 35 and 37. The

Initially pump 23 is operating but its output is blocked

depressurization causes a transient hydraulic ?uid ?ow

by valve 27; hydraulic lines 33, 35, and 37 are unpressur

in lines 33, 35 and 37 as the previously-pressurized com

ized and the pistons in actuator 21 and slave cylinder 31

4,545,406

are not moving. To initiate the pulling of gate 19, sole

noid 41 is energized by closing switch 43 (see FIG. 2);

cal clearance in the linkage between the piston of actua

tor 21 and gate 19 must be empirically determined and

the activation of solenoid 41 causes valve 27 to switch

so that the output of pump 23 is directed into line 35.

used as the second compensation.

For a pushing of gate 19, the effects are analogous,

Thus line 35 is pressurized and this causes the piston in

slave cylinder 31 to move to the left in FIG. 2 and force

although the elasticity compensation will likely be

much smaller because line 33 and not lines 35 and 37 is

connected to the output of pump 23 and the elasticity

hydraulic ?uid out into and thereby pressurizing line 37.

Pressurized line 37 drives the piston in actuator 21

contraction will not cause substantial ?ow through

slave cylinder 31. In FIG. 2 activating switch 49 ener~

into line 33 and thence back into reservoir 25. The mo 0 gizes solenoid 47 and shifts valve 27 so that pump 23

tion of gate 19 corresponds to the ?ow in lines 33, 35, or

pressurizes line 33 and leads to a pushing of gate 19.

which, in turn, pulls gate 19 and forces hydraulic ?uid

37 (these three flows being substantially equal) and to

the motion of the pistons in actuator 21 and slave cylin

der 31. The motion of the piston and slave cylinder 31 is

translated into electrical pulses by rotary optical shaft

Encoder 45 may be a model no. 52-A-ACF-200-A-0

00 as manufactured by Dynapar Corp. which generates

two electrical signals, called the First Phase and the

Second Phase. The First Phase and the Second Phase

encoder 45.

each consists of two hundred square wave pulses per

revolution of encoder 45, and the First Phase and the

Second Phase are generated 90 out of phase; the First

elasticity in the hydraulic system, particularly line 37,

Phase leads the Second Phase when encoder 45 is ro

and the second for mechanical clearance in the linkage 20 tated in a ?rst direction, and the First Phase lags the

from actuator 21 to gate 19. The ?rst compensation

Second Phase when encoder 45 is rotated in the oppo

accounts for ?ows such as that due to the piston of

site direction. Consequently, the direction of rotation of

cylinder 31 moving and forcing hydraulic ?uid into line

encoder 45, and thus the direction of movement of the

Two compensations to the measurement of ?ow by

encoder 45 must be made: the ?rst compensation for the

37, which elastically expands, but without moving the

piston of slave cylinder 31, may be detected from a

piston of actuator 21. This ?ow occurs each time the 25 relative phase of the First Phase and Second Phase

signals.

system is pressurized for a pulling of gate 19. Because

the piston of slave cylinder 31 moves without any corre

FIG. 3, in conjunction with FIG. 2, shows how these

sponding movement of the piston of actuator 21, this

two compensations to correct the ?ow measurement

?ow yields spurious valve position indication. How

are made in the preferred embodiment of the inventive

ever, upon depressurization of the system after the de 30 apparatus. Encoder 45 outputs First Phase on line 61

sired pull of gate 19 has been accomplished, the situa

and Second Phase on line 63 are ?rst passed through

tion is reversed and the elastic contraction of line 37

opto-isolators 65 and 67, respectively, and then through

leads to a ?ow into slave cylinder 31 and piston move

inverting Schmitt triggers 71 and 73, respectively. Thus

ment in the direction opposite that of pressurization.

the First Phase and the Second Phase have been electri

This causes encoder 45 to rotate in the opposite direc

tion. Note that the piston in actuator 21 is presumed not

to move during this elastic contraction by line 37; such

cally isolated and squared up. Opto-isolators 65 and 67

may be of type I-IPCL-2602 as manufactured by Hewl

ett Packard. Inverting Schmitt triggers 71 and 73 may

presumption being based primarily on the friction of

be of type 4584. First Phase and Second Phase are ex

gate 19 in valve 17 greatly exceeding that of the cou

clusively ORed in gate 75, and First Phase and a de

pling of the piston of slave cylinder 31 to encoder 45 40 layed Second Phase are exclusively ORed in gate 79;

together with the tensioned linkage between gate 19

the delay of Second Phase is accomplished by resistor

and actuator 21s piston. In general, the pressurization

77 and the chip capacitance at the inputs pins to gate 79.

of the system at the beginning of the pull includes ?ows

The output of gate 75 is delayed by resistor 81 and the

due to the storing of strain energy, and at the end of the

chip input capacitance of gate 83, and this delayed ver

pull this strain energy is released to yield reverse direc 45 sion of the output of gate 75 is exclusively ORed with

tion ?ows. Thus the size of such pressurization ?ows is

the output of gate 75 by gate 85. The delay by resistor

not crucial, but rather the compensation to the total

81 and gate 83 is set to be much shorter than the delay

?ow by the reverse ?ow is.

by resistor 77 and gate 79, such as by choosing the

The second compensation arises from the initial

resistor 77 to be larger than resistor 81 by an order of

movement of the piston in actuator 21 which yields a

magnitude. The output of gate 85 is then used to clock

tensioning of the linkage between the piston and gate 19

the output of gate 79 as data into D ?ip-?op 87. Thus in

prior to any movement of gate 19. This tightening of the

effect First Phase is compared with the earlier Second

linkage only occurs when the direction of movement of

Phase (delayed) to indicate the momentary direction of

gate 19 reverses; that is, if gate 19 has been just previ

rotation of encoder 45. Gates 75, 79, 83, and 85 may be

ously pushed in valve 17, then the initial movement of 55 of type 4070, and ?ip-?op 87 of type 4013.

the piston in actuator 21 for a pulling of gate 19 (prior to

The Q output of ?ip-?op 87 is high when First Phase

the linkage being uncompressed and tensioned) will be

leads Second Phase and is low when First Phase lags

measured because the piston of slave cylinder 31 will

Second Phase, and thus it will be called the Direction

make a corresponding movement. However, note that if

signal.

gate 19 had previously been pulled, then pressurization

60

The output of gate 85 is also passed through resistor

of the system for another pull will not require move

ment of the piston of actuator 21 to decompress the

delay in conjunction with the capacitance of the input

linkage and tension it because it had been previously

to inverter 91. The output of inverter 95 is a series of

tensioned. In short, a compensation for the mechanical

clearance in the linkage between the piston of actuator

21 and gate 19 is made only when the direction of move

ment of gate 19 is reversed. In contrast to the elasticity

compensation, the size of the ?ow due to the mechani

pulses are counted to determine the rotation of encoder

45; note that for each pulse of First Phase or Second

Phase there will be two Clock pulses. Of course, the

two compensations discussed above will be corrections

89 and inverters 91, 93 and 95; resistor 89 providing a

low going pulses called the Clock, and the Clock

4,545,406

AND-gate 141 are the output of latch 121 after inver

in the total of Clock pulses counted and thereby convert

the total to an indication of position of gate 19 in valve

17. Note that resistor 89 delays the Clock pulses so that

Direction signal sets up before the Clock triggers a

sion by inverter 149, and thus high, and the output of

ORgate 151. The output of OR-gate 151 is high if and

only if the output of counters 153 and 155 are both not

zero because the outputs are ORed together by OR

gates 157 and 159. Counters 153 and 155 may be of type

4516 and are 4-bit up/down counters; the overflow of

counter 153 carrying into counter 155. How counters

153 and 155 acquire a non-zero output will be explained

below, so presuming a non-zero output the counting of

the Clock pulses proceeds as follows. The Not Direc

count. Direction differentiation block 52 contains the

foregoing circuitry.

As illustrated in FIG. 2, if neither solenoid 41 nor 47

is energized, then lines 101 and 103 each carry a high

signal into opto-isolator 105 (see FIG. 3). Optoisolator

105 may be of type HPCL 2630. The corresponding

outputs of opto-isolator 105 are passed through Schmitt

triggers 111/113 and 115/117, respectively, and then

into the Not Reset inputs of latches 121 and 123, respec

tively. Schmitt triggers 111, 113, 115 and 117 may be of

essentially Not Clock, is inputted into NAND-gates 131

type 4584 and latches 121 and 123 may be of type 4044.

5 and 133. The Not Direction signal and the output of

Closing switch 43 and thereby energizing pull solenoid

and 117, and resets latch 123. Latch 121 is set by the

latch 123 are also inputted into NAND-gate 131, but

Not Direction is low so the output of NAND-gate 131

is high. The inputs of NAND-gate 133, in addition to

Not Clock, are the Direction signal (which is high), the

inverted output of latch 121 (also high), and the output

of OR-gate 151 (which is high for as long as the output

of counters 153 and 155 is non-zero). Thus the Not

Clock pulses pass through NAND-gate 133 with inver

Direction signal changing from the pull direction to the

push direction; and latch 123 is set by the Direction

sion until the output of counters 153 and 155 is zero.

Thus the inputs to AND-gate 135 are the high from

tion signal is low so counters 153 and 155 are in the

count down mode. The output of inverter 93, which is

41 causes the signal on line 101 to go low. This low

signal passes through opto-isolator 105, Schmitt triggers

111 and 113, and resets latch 121 (i.e. the Q output goes

low). Similarly, if switch 49 is closed to activate push

solenoid 47, then the signal on line 103 goes low and this

passes through optoisolator 105, Schmitt triggers 115

signal changing from the push direction to the pull

NAND-gate 131 and the Clock from NAND-gate 133,

direction. Consequently, the output of both latch 121

and latch 123 does not change when the corresponding

solenoid is de-energized, but rather only when the di

rection of flow changes; this compensates for the fact

that solenoids 41 and 47 do not instantaneously change

the setting of valve 27 upon de-energization.

so the output of AND-gate 135 is essentially the Clock

signal which is fed into counters 153 and 155 count

The hydraulic system elasticity compensation is made

by two relaxation counters (in relax count block 54),

one for gate 19 pushes and one pulls. Each relaxation

counter counts the Clock pulses due to the correspond

input. Thus the Clock pulses are used to count down

until counters 153 and 155 are zero, and this zero drives

OR-gate 151 low so that the counting down is blocked

at NAND-gate 133. Consequently, AND-gate 141 goes

low to unblock the Clock pulses from passing through

OR-gate 125.

pulses generated during the corresponding pressuriza

Counters 153 and 155 may acquire a positive output

in two ways: first the counters may be loaded with the

data on 8-bit bus 161 by applying a load signal on line

163; this may be used to initialize counters 153 and 155.

But more importantly, counters 153 and 155 count up

tion. These relaxation counters operate as follows for a 40

the Clock pulses during the hydraulic system elasticity

pulling of gate 19.

relaxation flow as will now be described. Presume that

ing elastic contraction relaxation flow and uses this sum

to block the counting of an equal number of Clock

First pull solenoid 41 is energized and this causes a

low signal on line 101 which resets latch 121. Energiz

ing pull solenoid 41 also shifts valve 27 to begin (after

perhaps some inertial delay) moving the piston in slave

cylinder 31 in the pull direction (to the left in FIG. 2)

and thus also the piston in actuator 21 to begin tension

ing the linkage to gate 19 and thereafter to pull gate 19

in valve 17. This movement of the piston in slave cylin

der 31 causes encoder 45 to rotate in the pulling direc

tion and generate First Phase and Second Phase pulses

which, as previously explained, lead to the Direction

signal (Q output of ?ip-?op 87) going high and Clock

(output of inverter 95) low going pulses to be generated

pull solenoid 41 is de-energized, that is, the pulling of

gate 19 is to be stopped or reversed to a pushing. De

energizing pull solenoid 41 causes, after some inertial

deay, valve 27 to cut off pump 23 and depressurize line

35. As described above, this also results in line 37 being

depressurized and the piston of slave cylinder 31 mov

ing in the push direction and rotating encoder 45 coun

terclockwise in FIG. 2. This is the pull relaxation flow.

Once encoder 45 rotates in the counterclockwise direc

tion, the Direction signal goes low and this causes the

output of latch 121 to go high; note that the output of

latch 123 remains high until push solenoid 47 is ener

gized. Consequently, both inputs to AND-gate 143 are

corresponding to the motion of encoder 45. The Direc 55 now high and this blocks Clock pulses from passing

tion signal going high implies that Not Direction (the

OR-gate 125. This change in the Direction signal and

Not Q output of ?ip-?op 87) goes low and sets latch

the output of latch 121 causes NAND-gate 133 to block

the Not Clock even if counters 153 and 155 become

non-zero, and NAND-gate 131 to pass with inversion

123.

The relaxation compensation occurs at OR-gate 125

which blocks the low going Clock pulses if and only if

the Not Clock pulses. Thus AND-gate 135 passes the

the output of any of AND-gates 141, 143 and 145 is

Clock pulses which are then fed into the count input of

high. As discussed above, during the pulling of gate 19

counters 153 and 155; however, because the Not Direc

the output of latch 121 is low, thus making the output of

tion signal has gone high counters 153 and 155 are in the

AND-gate 143 low, and the output of latch 123 is high

up count mode. Thus the Clock pulses generated during

but this is inverted by inverter 147, thus making the 65 the pull relaxation flow are all counted and stored in

output of AND-gate 145 also low. Consequently, the

counters 153 and 155. Consequently, the number of

output of AND-gate 141 determines whether Clock

Clock pulses which were blocked by OR-gate 125 while

pulses are passed through OR-gate 125. The inputs to

counters 153 and 155 count down during the pulling, as

4,545,406

10

described above, just equal the number of Clock pulses

passes through AND-gate 219, the delayed version of

generated and stored in counters 153 and 155 during the

pull relaxation reverse ?ow.

this pulse will not clock ?ip-?op 225 because the set

input to ?ip-?op 225 is still high.

The blocking of Clock pulses at OR-gate 125 during

Clock pulses now count down loaded counters 203

a pushing of gate 19 and the push relaxation flow are

and 205 because the carry-in input to counter 203 is low,

analogous and to the just-described pulling and pull

as follows: The setting of ?ip-?op 225 (i.e. the Not Q

output low) which is inputted to AND-gate 243 and

relaxation with counters 171 and 173 corresponding to

counters 153 and 155, OR~gates 175, 177 and 179 corre

sponding to OR-gates 151, 157 and 159, NAND-gates

181 and 183 corresponding to NAND-gates 131 and

133, and AND-gate 185 corresponding to AND-gate

135. Similarly, AND-gate 145 corresponds to AND

gate 141.

Buffer and line drivers 191 and 193 permit communi

cation with the outputs of counters 153, 155, 171 and

173 through eight-bit bus line 161, as described in more

detail below.

After relaxation compensation has been made at OR

thus AND-gate 243 outputs a low into OR-gate 245.

And as seen before, with counters 203 and 205 not zero

the output of inverter 237 is low and this drives the

output of AND-gate 247 low which is the other input to

OR-gate 245. Consequently, the output of OR-gate 245

is low and is the carry-in input for counter 203.

The low output of OR-gate 245 is inverted by in

verter 249 and thus is a high input to OR-gate 201 and

thereby blocks the Clock pulses which are low going.

Once the Clock pulses have counted counters 203 and

205 down to zero, then the output of inverter 237 goes

gate 125, Clock pulses proceed to OR-gate 201 at which

high and the output of AND-gate 247 also goes high

mechanical deflection compensation is made by block 20 because its other input is the low Not Q output of flip

ing a set number of pulses; the set number of pulses

flop 225 after inversion by inverter 251. This high out

being previously loaded into counters 203 and 205, and

put of AND-gate 247 passes through OR-gate 245 and is

the blocking achieved by counting down counters 203

inverted to low by inverter 249, thus the Clock pulses

and 205 to zero upon a change from pushing to pulling

passes through opto-isolator 105, Schmitt inverters 111

are no longer blocked at OR-gate 201.

If a second change of direction of gate 19 is made

after a ?rst change of direction but before counters 203

and 205 have been counted down to zero, then the pulse

generated by one of one~shots 213 and 215 passes

and 113, and then sets the output of latch 211 high.

Latch 211 may be of type 4044. (Analogously, a change

from pulling to pushing causes the signal on line 103 to

because the other input is low re?ecting the non-zero

state of counters 203 and 205. However, the OR-gate

go low which passes through opto-isolator 105, Schmitt

217 output pulse passing through the delay of resistor

or vice versa, as will now be described in detail. Upon

a change from pushing gate 19 to pulling gate 19 the

signal on line 101 goes from high to low, and this signal

through OR-gate 217 but is blocked at AND-gate 219

inverters 115 and 117 and then resets latch 211 output

low.) The transition of latch 211 output from low to

221 and capacitor 223 does clock ?ip-?op 225 because

the output of AND-gate 219 is low. This clocking of

high triggers one-shot 213; similarly, the transition of 35 ?ip-?op 225 causes the Not Q output to go high because

latch 211 output from high to low triggers one-shot 215.

the D input was low. The Not Q output of ?ip-?op 225

One-shots 213 and 215 may be of type 4528. An output

going high shifts counters 203 and 205 into the up count

pulse from either one-shot 213 or one-shot 215 passes

mode and further provides a high input to AND-gate

through OR-gate 217 and is inputted to AND-gate 219

243 and a low input to AND-gate 247. With counters

and also, after a delay by resistor 221 and capacitor 223

203 and 205 in the up count mode, Clock pulses cause

inputted to the clock input of the flip-?op 225. Flip-?op

the counters to count up until they reach the initial total

225 may be of type 4013. If the output of counters 203

loaded from latch 241. At this point comparators 253

and 205 is zero, then a low is passed through OR~gates

and 255 are triggered to output a high to ANDgate

231, 233 and 235, and inverted by inverter 237 to pro

vide a high input to AND-gate 219; this allows the

previously noted pulse output from OR-gate 217 to pass

through AND-gate 219. However, if counters 203 and

205 output is non-zero, then AND-gate 219 blocks this

output pulse from OR-gate 217 by the same OR-gates

243. Thus the output of AND-gate 243 goes high and

this passes through OR-gate 245 and is inverted by 249

231, 233 and 235 and inverter 237, Counters 203 and 205

may be type 4516.

Thus presuming that counters 203 and 205 output is

zero, the output pulse from OR-gate 217 due to the

to a low so that OR-gate 201 no longer blocks the Clock

pulses. Also, the high output of OR-gate 245 provides a

high carry-in to counter 203 so that further Clock pulses

do not change the total stored in counters 203 and 205.

In effect, the ?rst reversal of direction of gate 19 began

an elimination of mechanical clearance but prior to

completion of this elimination the direction was re

versed again and the partial elimination undone which

should have generated an equal number of Clock pulses

and both sets ?ip-?op 225 and loads counters 203 and 55 as the original partial elimination. Thus the number of

205 with the data held by latch 241. Data is entered into

Clock pulses not counted during the up count in count

latch 241 from eight-bit bus 161. Latch 241 may be of

ers 203 and 205 equals the number of Clock pulses not

type 4508. The setting of ?ip-?op 225 causes its Not Q

counted in the down count. Buffer and line driver 257

change from push to pull passes through'AND-gate 219

output to go low and this puts counters 203 and 205 into

provides communication with the output of counters "

the down count mode. The loading of counters 203 and 60 203 and 205 by 8-bit bus 161.

205 provides a high output on OR-gate 235 and thus a

Clock pulses, after relaxation compensation at OR

low input to AND-gate 219, thereby blocking any fur

gate 125 and mechanical clearance compensations at

ther pulses from OR-gate 217 until counters 203 and 205

OR-gate 201, are counted in position counters 261, 263,

have been counted down to zero. The delay by resistor

265 and 267; all of which counters may be 4-bit up/

221 and capacitor 223 is set to be less than the time for 65 down counters of type 4516. The Direction signal deter

the loading of counters 203 and 205 to ripple through

mines whether the counting is up (for pulling gate 19) or

OR-gates 231, 233 and 235 and inverter 237 and AND

down (for pushing gate 19). The outputs of counters 261

gate 219 so that for an OR-gate 217 output pulse which

through 267 is available on 8-bit bus 161 through buffer

11

4,545,406

12

microprocessor 56 (see FIG. 2) which then may convert

processor along with the pull solenoid and push sole

noid signals, and all of the processing done by software.

Similarly, the Clock and Direction signals could be used

the raw count into engineering units so that the position

in place of the First Phase and Second Phase, and rest of

of gate 19 may be displayed in display 57 in familiar

the processing being done by software.

and line drivers 269 and 271. Thus the position count

from counters 261 through 267 is read off of bus 161 by

terms. Similarly, microprocessor 56 can load the initial

count in both the pull relaxation counters 153 and 155

and the push relaxation counters 171 and 173, as previ

ously described, and may read the output of such count

ers from bus 161 through buffer and line drivers 191 and

193.

What is claimed is:

1. A method for continuously monitoring the position

, of a device driven by a hydraulic system in which there

is ?exibility in expansion and contraction of the hydrau

lic system when it is pressurized and when the pressure

is relaxed and also in which lost motion is inherent due

to mechanical clearances, comprising the steps of:

For diagnostic purposes switches 281, 283 and 285

(a) continuously measuring the volume and direction of

flow of the driving hydraulic fluid,

are included and operate as follows. During normal

operation switch 281 is closed so that Clock pulses pass

through it and into position counters 261 through 267.

Opening switch 281 and closing switch 283 permits the

15 (b) continuously computing a net uncorrected volume

of ?ow by subtracting the volume of flow in a ?rst

direction from the volume of flow in the opposite

Not Clock pulses from inverter 93 to bypass the relax

ation compensation and the mechanical clearance com

pensation and be directly counted in counters 261

through 267. Flip-?op 287 controls switches 281 and

direction,

(c) continuously computing a ?rst corrected volume of

flow by correcting the net uncorrected volume of

flow for flows clue to the expansion of the hydraulic

283 which are toggled by write pulses clocking ?ip-?op

system,

287. Determination of which of switches 281 and 283 is

(d) continuously computing a second corrected volume

closed may be read by pulsing inverter 289 which closes

of ?ow by correcting the ?rst corrected volume of

switch 285 and reading the result on the ?rst bit of 8-bit

?ow for flows due to the relaxation of the hydraulic

bus line 161. Switches 281-285 may be of type 4066, and 25

system,

flip-?op 287 of type 4013.

(e) continuously computing a ?nal corrected volume of

Control by a central microprocessor may be accom

?ow correcting the second corrected volume of ?ow

plished as shown in the addressing circuit in FIG. 3 as

for flows due to lost motion elimination of mechani

follows. Presuming a microprocessor with 8-bit data

cal clearances in the system and device, and

and l6-bit address ports, the 8-bit data port is connected

(t) continuously converting the ?nal corrected volume

to 23-bit bus 161, and the l6-bit addresses broken down

of flow to a signal for the position of the device.

into bits A0-A2 for selection of the function to be per

2. Apparatus for monitoring the position of a device

formed and bits A3-A15 for addressing a particular

driven by a hydraulic system in which there is flexiblity

sliding gate valve 17. The valve address is set by

switches 301, 303 and 305, each being a four indepen 35 in expansion and contraction of the hydraulic system

when it is pressurized and when the pressure is relaxed

dent pole switch, The pattern of off/ons set by switches

and also in which lost motion is inherent due to mechan

301-305 is compared to the signals on address lines

ical clearances, comprising:

A3-A13 by comparators 307, 309 and 311, which may

means for measuring the volume and direction of ?ow

be of type 4585. If all three comparators show that the

of the driving hydraulic ?uid,

switch pattern equals the address pattern, then NAND 40

means for computing a net uncorrected volume of flow

gate 313 provides a low pulse to one of the enable inputs

by subtracting the volume of flow in a ?rst direction

of decoders 315 and 317. Decoders 315 and 317 may be

from the volume of flow in the opposite direction,

of type 74HC138. Address lines A0-A2 are the select

means for computing a ?rst corrected volume of flow

inputs for decoders 315 and 317, and thus the read or

by correcting the net uncorrected volume of flow for

write function selected. The read/write output of the 45

?ows due to the expansion of the hydraulic system,

microprocessor is inverted by Schmitt trigger 319 and

means for computing a second corrected volume of

fed to an enable input of decoder 317, and inverted

flow by correcting the ?rst corrected volume of ?ow

again by Schmitt trigger 321 and fed to an enable input

for flows due to the relaxation of the hydraulic sys

of decoder 315, thus the read/ write selection is made by

enabling either decoder 315 or decoder 317. The micr 50

term,

means for computing a final corrected volume of flow

processor clock is fed into the G1 enable input of decod

correcting the second corrected volume of ?ow for

ers 315 and 317 so that the read/write functions are

flows due to lost motion elimination of mechanical

synchronized. Buffer and line driver 323 is used on the

output of decoder 315 to provide the write signals.

clearances in the system and device, and

The majority of the circuitry shown in FIG. 3 could 55 means for converting the ?nal corrected volume of ?ow

to a signal for the position of the device.

be replaced by equivalent software. That is, the First

*

Phase and Second Phase could be inputted to a micro

65

Você também pode gostar

- Sensorless step recognition for stepping motorsDocumento8 páginasSensorless step recognition for stepping motorsMamoun Slamah AlzyoudAinda não há avaliações

- United States Patent: Lindoerfer Et A) - (10) Patent N0.: (45) Date of PatentDocumento9 páginasUnited States Patent: Lindoerfer Et A) - (10) Patent N0.: (45) Date of PatentdollarrbillAinda não há avaliações

- Rotor Rim-Ventilated Generator with Turning Vanes for Rotor Inlet Coolant Gas FlowDocumento4 páginasRotor Rim-Ventilated Generator with Turning Vanes for Rotor Inlet Coolant Gas FlowHamedJamshidiAinda não há avaliações

- United States Patent: Forward-Reverse and BrakeDocumento6 páginasUnited States Patent: Forward-Reverse and Brakejai2009Ainda não há avaliações

- Torque ControlDocumento6 páginasTorque Controlochenapothik2012Ainda não há avaliações

- Vol III Rev 0Documento871 páginasVol III Rev 0Anonymous nwByj9LAinda não há avaliações

- U.S. Patent 2,719,942, Entitled "Motor Control System", To Kallenbach, Oct. 4, 1955.Documento6 páginasU.S. Patent 2,719,942, Entitled "Motor Control System", To Kallenbach, Oct. 4, 1955.Anonymous a7S1qyXAinda não há avaliações

- US 20130092673A1 - Wire Feed Motor Speed Control System and MethodDocumento13 páginasUS 20130092673A1 - Wire Feed Motor Speed Control System and MethodIan McNairAinda não há avaliações

- TestReport ThermalDocumento12 páginasTestReport ThermalDepri YantriAinda não há avaliações

- Instrumentation Monitoring Turbine ComponentsDocumento119 páginasInstrumentation Monitoring Turbine ComponentsRamachandran Marappan100% (1)

- United States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Documento8 páginasUnited States Patent (19) (111 4,230,151: Jonsson (45) Oct. 28, 1980Stanislas AchardAinda não há avaliações

- Experimental Study of Swirling Flow in a Francis Turbine Draft TubeDocumento12 páginasExperimental Study of Swirling Flow in a Francis Turbine Draft TubeHugh MolletAinda não há avaliações

- US patent for forward-reverse clutch control apparatusDocumento6 páginasUS patent for forward-reverse clutch control apparatusjai2009Ainda não há avaliações

- Load Sensing CompareDocumento13 páginasLoad Sensing Comparepiteng1945100% (1)

- Shaft Mounting Device Measures and Controls Thrust LoadsDocumento7 páginasShaft Mounting Device Measures and Controls Thrust LoadsNicandroGonzalesAinda não há avaliações

- Bul 36115 Servo Valve OperationDocumento12 páginasBul 36115 Servo Valve Operationrikkitech100% (1)

- Application of Electro PneumaticsDocumento2 páginasApplication of Electro PneumaticsMaribel C. MagbanuaAinda não há avaliações

- Scienfdgfdce Seawater SgfdgdfcientistDocumento8 páginasScienfdgfdce Seawater SgfdgdfcientistAhmed MagdyAinda não há avaliações

- JP2020180696A Proportional Solenoid VV in Hyd CKT PDFDocumento12 páginasJP2020180696A Proportional Solenoid VV in Hyd CKT PDFRajesh CAinda não há avaliações

- US2108014 (Tachometer)Documento6 páginasUS2108014 (Tachometer)Aaron Choco De GuzmanAinda não há avaliações

- Brevete Internationale HidraulicaDocumento41 páginasBrevete Internationale HidraulicaValentino Miroiu0% (1)

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1Documento14 páginasUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1zbhdzpAinda não há avaliações

- Horiba ABX Micros 60 - Technical ManualDocumento205 páginasHoriba ABX Micros 60 - Technical ManualFrancisco Hernandez100% (1)

- Chapter 12Documento12 páginasChapter 12bhaskarAinda não há avaliações

- Meccanismo T.R.Documento6 páginasMeccanismo T.R.Marco Raneo PezzanoAinda não há avaliações

- JKR Specification For 11 KV High VoltageDocumento16 páginasJKR Specification For 11 KV High VoltageCherry AngAinda não há avaliações

- Public Review Draft 2083Documento4 páginasPublic Review Draft 2083Motasim_mAinda não há avaliações

- 6ALBR5233JQODocumento23 páginas6ALBR5233JQOpinticaniulian9042Ainda não há avaliações

- EmersonDocumento21 páginasEmersoncrustytheclown99Ainda não há avaliações

- Wahba Etal 2015 GTPDocumento9 páginasWahba Etal 2015 GTPEhab Attia SelimAinda não há avaliações

- Emerson-Valve Sizing Calculations (Traditional Method)Documento21 páginasEmerson-Valve Sizing Calculations (Traditional Method)iqtorresAinda não há avaliações

- Reduce CMV in VFDs with Dead-Time CancellationDocumento17 páginasReduce CMV in VFDs with Dead-Time CancellationLava KumarAinda não há avaliações

- Md1 0 V 111-09-00008 A Extraction System RequirementsDocumento29 páginasMd1 0 V 111-09-00008 A Extraction System RequirementsNguyễn ĐứcAinda não há avaliações

- 33kv GIS SpecificationDocumento37 páginas33kv GIS SpecificationSudharsan SD67% (3)

- Electrical ActuatorDocumento7 páginasElectrical Actuatorمحمد علي كريم شكرAinda não há avaliações

- International Journal of Pressure Vessels and Piping: ArticleinfoDocumento10 páginasInternational Journal of Pressure Vessels and Piping: ArticleinfoMahdiAinda não há avaliações

- Hydraulic engine mount with variable movement absorptionDocumento17 páginasHydraulic engine mount with variable movement absorptionmarcglebAinda não há avaliações

- KRT Planing Information-DataDocumento110 páginasKRT Planing Information-DataNicolas Alvarez GomezAinda não há avaliações

- United States Patent 119) : K / - :I - L I// SystemDocumento6 páginasUnited States Patent 119) : K / - :I - L I// Systemrte678Ainda não há avaliações

- Presentacion Curso Ot 1888 Cotemar - Fa-3750Documento54 páginasPresentacion Curso Ot 1888 Cotemar - Fa-3750Allen BradleyAinda não há avaliações

- 13.8kV Bus Duct Sizing For Arar Dated 23.03.2005Documento9 páginas13.8kV Bus Duct Sizing For Arar Dated 23.03.2005srigirisetty208Ainda não há avaliações

- Pdvsa: Engineering Design ManualDocumento9 páginasPdvsa: Engineering Design ManualPedro Elias Castro ArenasAinda não há avaliações

- To Microcomputer: Unlted States Patent (19) (11) Patent Number: 4,712,050Documento11 páginasTo Microcomputer: Unlted States Patent (19) (11) Patent Number: 4,712,050Donz RahmandaniAinda não há avaliações

- 6ALBR5233JQODocumento23 páginas6ALBR5233JQOTom CatAinda não há avaliações

- Valve ActuatorsDocumento10 páginasValve Actuatorsluagu100% (1)

- V. Krungleviciute, Lei: KEYWORDS: Safety - Water - FlowDocumento11 páginasV. Krungleviciute, Lei: KEYWORDS: Safety - Water - FlowRoman KrautschneiderAinda não há avaliações

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1No EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Nota: 3.5 de 5 estrelas3.5/5 (3)

- Common Rail Fuel Injection Technology in Diesel EnginesNo EverandCommon Rail Fuel Injection Technology in Diesel EnginesAinda não há avaliações

- Control of DC Motor Using Different Control StrategiesNo EverandControl of DC Motor Using Different Control StrategiesAinda não há avaliações

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideNo EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideNota: 4 de 5 estrelas4/5 (8)

- Rechargeable Batteries Applications HandbookNo EverandRechargeable Batteries Applications HandbookNota: 2 de 5 estrelas2/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNota: 4.5 de 5 estrelas4.5/5 (10)

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlAinda não há avaliações

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkAinda não há avaliações

- Variable Speed AC Drives with Inverter Output FiltersNo EverandVariable Speed AC Drives with Inverter Output FiltersAinda não há avaliações

- Istec Bookazine Vibration WebDocumento77 páginasIstec Bookazine Vibration WebJarot PrakosoAinda não há avaliações

- CFD - Run of Rivers PDFDocumento10 páginasCFD - Run of Rivers PDFpradip panthaAinda não há avaliações

- Design of Spillway Tainter GatesDocumento113 páginasDesign of Spillway Tainter GatesshahinexAinda não há avaliações

- KEFID 100-150 TPH Crushing PlantDocumento1 páginaKEFID 100-150 TPH Crushing Plantpradip panthaAinda não há avaliações

- Water 11 00715 v2 PDFDocumento19 páginasWater 11 00715 v2 PDFpradip panthaAinda não há avaliações

- Engineering Controls Reduce Hydro Powerplant NoiseDocumento33 páginasEngineering Controls Reduce Hydro Powerplant Noisepradip panthaAinda não há avaliações

- Hydraulic Structures in Power Plants - DHI Solution2 PDFDocumento2 páginasHydraulic Structures in Power Plants - DHI Solution2 PDFpradip panthaAinda não há avaliações

- Micro Hydropower Design AidsDocumento27 páginasMicro Hydropower Design Aidsmagembe2100% (1)

- Guide to Hydropower DevelopmentDocumento138 páginasGuide to Hydropower Developmentbedilu77Ainda não há avaliações

- Catalogue ALL COMBINED PDFDocumento28 páginasCatalogue ALL COMBINED PDFpradip panthaAinda não há avaliações

- KEFID 50 TPH Crushing and Screening PlantDocumento1 páginaKEFID 50 TPH Crushing and Screening Plantpradip panthaAinda não há avaliações

- KEFID QUOTATION OF 50tph Crushing PlantDocumento9 páginasKEFID QUOTATION OF 50tph Crushing Plantpradip panthaAinda não há avaliações

- Sustainability 12 01676 PDFDocumento40 páginasSustainability 12 01676 PDFpradip panthaAinda não há avaliações

- Sustainable Energy Handbook Module 4.1: HydroelectricityDocumento12 páginasSustainable Energy Handbook Module 4.1: Hydroelectricitypradip panthaAinda não há avaliações

- Contract Breach and Payment For Environmental Services: A Case From The Kulekhani III Hydroelectric Project in NepalDocumento7 páginasContract Breach and Payment For Environmental Services: A Case From The Kulekhani III Hydroelectric Project in Nepalpradip panthaAinda não há avaliações

- Design of pressure tunnels for Turkish hydro plantDocumento7 páginasDesign of pressure tunnels for Turkish hydro plantpradip panthaAinda não há avaliações

- ASME B31.3 Questions and Answers-SignedDocumento5 páginasASME B31.3 Questions and Answers-Signedpradip panthaAinda não há avaliações

- Computational Fluid Dynamics (CFD) Modeling of Run-of-River IntakesDocumento10 páginasComputational Fluid Dynamics (CFD) Modeling of Run-of-River Intakespradip panthaAinda não há avaliações

- Hydro Users GuideDocumento102 páginasHydro Users GuideRodrigoAinda não há avaliações

- 3 Hydrostatic Force Tutorial SolutionDocumento25 páginas3 Hydrostatic Force Tutorial SolutionGerold Molina91% (11)

- SP38Documento293 páginasSP38Rajesh Mosuganti80% (5)

- Electrical Infrastructure - Plants and Switchyards: Design Standards No. 4Documento48 páginasElectrical Infrastructure - Plants and Switchyards: Design Standards No. 4pradip panthaAinda não há avaliações

- 0 PDFDocumento4 páginas0 PDFpradip panthaAinda não há avaliações

- Spherical Roller Bearings: DimensionsDocumento4 páginasSpherical Roller Bearings: Dimensionskamal arabAinda não há avaliações

- Sketch For Intermediate Pier EM Parts ArrangementDocumento1 páginaSketch For Intermediate Pier EM Parts Arrangementpradip panthaAinda não há avaliações

- Penstock EXP-1320ModelDocumento1 páginaPenstock EXP-1320Modelpradip panthaAinda não há avaliações

- BOQ-Bend Pipe Material Weight CalculationDocumento1 páginaBOQ-Bend Pipe Material Weight Calculationpradip panthaAinda não há avaliações

- Trash Rack Cleaning MachineDocumento9 páginasTrash Rack Cleaning Machinepradip panthaAinda não há avaliações

- Vertical Fixed Wheel Gate-02Documento1 páginaVertical Fixed Wheel Gate-02pradip panthaAinda não há avaliações

- Quotation Purpose Boq HM PDFDocumento1 páginaQuotation Purpose Boq HM PDFpradip panthaAinda não há avaliações

- PIC6F506Documento114 páginasPIC6F506Rick TowAinda não há avaliações

- Oscillators and Wave Shaping Circuits ExplainedDocumento20 páginasOscillators and Wave Shaping Circuits Explainedgebretsadkan abrhaAinda não há avaliações

- First Order Active Filters (LPF, HPF) : (A) Low Pass FilterDocumento12 páginasFirst Order Active Filters (LPF, HPF) : (A) Low Pass FilterVRAinda não há avaliações

- Unit 4Documento149 páginasUnit 4Sree HariAinda não há avaliações

- Chapter 7 Digital Integrated CircuitsDocumento36 páginasChapter 7 Digital Integrated Circuitsjun deeAinda não há avaliações

- tdc-gp22 Datasheet en v1Documento93 páginastdc-gp22 Datasheet en v1Martin Rodriguez MelgarejoAinda não há avaliações

- MC14060B 14-Bit Binary Counter and Oscillator: Marking DiagramsDocumento8 páginasMC14060B 14-Bit Binary Counter and Oscillator: Marking DiagramsdenisAinda não há avaliações

- ELM327DSDocumento94 páginasELM327DSElkin Limas Rojas100% (1)

- Schmitt TriggerDocumento3 páginasSchmitt Triggerafzal ansariAinda não há avaliações

- Complete LICA Lab ManualDocumento54 páginasComplete LICA Lab Manualnuthan9150% (2)

- Three-Phase PWM Rectifier Based On Integrated Power Module and Fixed-Point Digital Signal Processor For Rapid Prototyping IssuesDocumento13 páginasThree-Phase PWM Rectifier Based On Integrated Power Module and Fixed-Point Digital Signal Processor For Rapid Prototyping IssuesDenise JenningsAinda não há avaliações

- 7400 IC SeriesDocumento16 páginas7400 IC SeriesRaj ZalariaAinda não há avaliações

- 74HC164Documento10 páginas74HC164mejmakAinda não há avaliações

- Chapter 4 TimerDocumento33 páginasChapter 4 TimerLian Ai ChenAinda não há avaliações

- 5382A Operating and Service HPDocumento43 páginas5382A Operating and Service HPJosé GuedesAinda não há avaliações

- Calculation of Upper and Lower Tripping Point PF Schmitt TrigerDocumento6 páginasCalculation of Upper and Lower Tripping Point PF Schmitt TrigerAjay Kumar SinghAinda não há avaliações

- HTC Korea TAEJIN Tech CD4093BD - C510571Documento9 páginasHTC Korea TAEJIN Tech CD4093BD - C510571SABBIR HOSSAINAinda não há avaliações

- ADELAB15Documento74 páginasADELAB15Mohammed FarhanAinda não há avaliações

- Pulse & Digital Circuits Lab Manual 3Documento61 páginasPulse & Digital Circuits Lab Manual 3Suda KrishnarjunaraoAinda não há avaliações

- Calculation Spreadsheet for Radio Frequency and Analogue ElectronicsDocumento48 páginasCalculation Spreadsheet for Radio Frequency and Analogue ElectronicsDimitrios MilionisAinda não há avaliações

- Elm327 PDFDocumento51 páginasElm327 PDFmiroljubAinda não há avaliações

- 3 To 8 Line Decoder DemultiplexerDocumento11 páginas3 To 8 Line Decoder DemultiplexerDistribuidorIBoolPedregalDeSantoDomingoAinda não há avaliações

- PIC16 F88 Data SheetDocumento228 páginasPIC16 F88 Data SheetNivek AstiAinda não há avaliações

- LIC Unit 3Documento14 páginasLIC Unit 3Gaurav SinghAinda não há avaliações

- Wideband analog switch for high-end color monitorsDocumento14 páginasWideband analog switch for high-end color monitorsqfacuAinda não há avaliações

- Electronic - Schematic Circuits For The HobbyistDocumento159 páginasElectronic - Schematic Circuits For The HobbyistDaniel ComeglioAinda não há avaliações

- Wave SapingDocumento43 páginasWave SapinglsrinivasnteceAinda não há avaliações

- Communications PDFDocumento461 páginasCommunications PDFJovie OsabelAinda não há avaliações

- 68hc705j1 Microcontrolador MotorolaDocumento163 páginas68hc705j1 Microcontrolador MotorolaNefi Martinez TorresAinda não há avaliações

- Transformador de PulsoDocumento22 páginasTransformador de PulsoFreddy de los SantosAinda não há avaliações