Escolar Documentos

Profissional Documentos

Cultura Documentos

Process Simulation V 2016

Enviado por

Tuấn Kiệt NguyễnTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Process Simulation V 2016

Enviado por

Tuấn Kiệt NguyễnDireitos autorais:

Formatos disponíveis

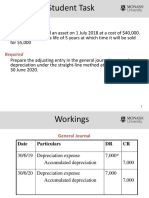

Unit 3-5-1

Process Simulation V

Reactor Design and

Performance

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-1

Unit 3-5-2

Reactor Performance

Production of Desired Product

Conversion

Yield

Selectivity

Reactor

Performance

Chemical Reactor

Volume

Residence Time

Catalyst

Reactor model

Reactor Configuration

Reaction Kinetics

Concentration

Temperature

Pressure

Reaction Mechanism

Catalyst

Thermodynamic Limitations

Copyright, The University Of Adelaide, Australia.

Heat Transfer

Exothermic

Endothermic

Heat Exchange Configuration

3030/7054 Reactor

3-5-2

Unit 3-5-3

Chemical Reactions

Chemical Reactions

Single reactions A+B C

Parallel reactions A+B C BD

Series reactions A+B CE

Series and parallel reactions A+B CE BD

Reaction

Conversion

Yield

Selectivity

Reaction kinetics and thermodynamics

Thermodynamics sets limits on possible conversion in a

reacting system

Chemical reactors

CSTR, PFR, Fluidized Reactor, Moving Bed Reactor, etc.

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-3

Reactor Simulation and Design

Unit 3-5-4

What is the product composition for given feed

composition & process conditions?

What is the heat of reaction at process temperature and

pressure?

How much catalyst is needed to achieve the desired

conversion

What is the rate of catalyst make-up or regeneration?

What other feed or process conditions must be

controlled?

What is the reactor size to achieve the desired

conversion?

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-4

Level I Input for Reactors

Unit 3-5-5

b

c

d

A+ B C+ D

a

a

a

r = k pA1.5 pB0.5

k=A e(-Ea/RT)

Unit of r; k; A

Forward order

Base component

Reaction phase

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-5

Unit 3-5-6

Reactions in Hysys

Conversion

Reaction equations

No need of any thermodynamic knowledge

Conversion rate (C=Co+C1*T+C2*T2) (C must be less than 100)

Can not be grouped with other types of reactions in the reaction set

Can be grouped with other conversion reactions and ranked to

operate simultaneously or sequentially

Lowest ranking occurs first

Can not be used with PFR or CSTR.

can not provide sizing information

Input thermal mode of operation

Only basic M&E balances are performed

Can be useful for the first-time simulation of a process

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-6

Unit 3-5-7

Conversion

b

c

d

A+ B C + D

a

a

a

N A = N A0 (1 X A )

b

N B = N B 0 N A0 X A

a

c

N C = N C 0 + N A0 X A

a

d

N D = N D 0 + N A0 X A

a

a, b, c, d the respective

stoichiometric coefficient of the

reacants (A& B) and products (C&

D)

A==the base reactant

B=the base reactant not in the

limiting quantity

N*--the final moles of components

A to D

N*0-the initial moles of

components A to D

XA the conversion of the base

component A

In HYSYS, C must be between 0-100

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-7

Unit 3-5-8

Reactions in Hysys

Equilibrium

aA + bB cC + dD

Reaction equations

[C ]c [ D]d

Specify Keq by

K=

a

b

[

A

]

[

B

]

A constant: Ln(Keq) or Keq;

Gibbs free energy;

ln Keq = G(reaction) / RT

o

Valid at T=25-426.85 C

Ideal Gas Gibbs Free Energy Coefficients

Gibbs reaction takes non ideal into consideration

A function of T;

A,B,C,D,E,F,G,H :constants ln( Keq ) = a + b

T unit: Kelvin

B

Keq vs T table.

a = A + + CLn (T ) + DT

T

Only used with equilibrium or

general reactors

b = ET 2 + FT 3 + GT 4 + HT 5

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-8

Unit 3-5-9

Reactions in Hysys

Gibbs

No reaction set

Minimizing the total Gibbs free energy of the effluent mixture

To provide the theoretical conversion limits

Kinetic Reactor (PFR or CSTR)

Reaction set

Reactor type

Kinetics rate constant

Kinetic

Heterogeneous Catalytic Reaction

Simple rate reaction

Sizing reactor available !

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-9

Unit 3-5-10

Kinetic Reaction

aA + bB cC + dD

rA = kf (Basis) k ' f (Basis)

k = forward reaction rate

constant

k' = reverse reaction rate

constant

A, E, , Arrhenius Parameters

for the forward reaction.

A', E', Arrhenius Parameters

for the reverse reaction.

dN A

FA0 FA + VrA dV =

dt

$ E '

k = A exp &

)T

% RT (

Example : CO + Cl2 COCl2

$ E' '

k ' = A'exp &

)T '

rCO = k[CO][Cl2 ]

% RT (

1

k

rHysys = r c

for catalyst-based PFR

K eq =

k'

3/2

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-10

Heterogeneous Catalytic Reaction

Unit 3-5-11

aA + bB cP

(kinetic term)(potential term)

r =

(adsorption term)

k + K A K B C AC B

r=

(Langmuir - Hinshelwood model)

2

(1 + K AC A + K B C B + K P C P )

k + K B C AC B

r=

(Eley - Rideal Model)

(1 + K B C B + K P C P )

kC A

r=

(Mars - van Krevelen Model)

n

*

1 + (a / b)(k / k )CAC B

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-11

HCR

Unit 3-5-12

k* = the adsorption rate constant for component *

k+ = the forward reaction rate constant

k = reaction rate constant for oxidation of hydrocarbon

k* = reaction rate constant for surface re-oxidation

In Hysys, generalised form:

reac tan ts

kf

r=

Ci i k r

i =1

Pr oducts

Cj

j =1

g

1 + K k C g

k =1 g =1

Copyright, The University Of Adelaide, Australia.

kf,kr = rate constant of the

forward and reverse kinetic

rate expressions

K= the adsorption rate

constant

M-number of adsorbed

reactants and products plus

inert species

3030/7054 Reactor

3-5-12

Unit 3-5-13

Simple Rate Reaction

aA + bB cC + dD

rA = kf ( Basis) k ' f ( Basis / K eq )

dN A

FA0 FA + VrA dV =

dt

E

k = A exp

T

RT

ln( K eq ) = A'+ B ' / T + c' Ln (T ) + D ' T

T must be in Kelvin Unit !

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-13

Unit 3-5-14

Example 3-5-1

Considering the following reaction starting with

natural gas feed. Reactions are

CH 4 + H 2O 3H 2 + CO (1)

CO + H 2O H 2 + CO 2

(2)

Reaction (1) is the reforming reaction and reaction (2)

is water gas shift reaction, an equilibrium reaction.

Reaction (1) can be modelled by LangmuirHinshelwood equation

E

a1

DBED * k m * e RT * P * ym

r1 =

1 + K h * P * yh

Reaction (2) uses the Estandard kinetic form

r2 = DBED * A * e

Copyright, The University Of Adelaide, Australia.

a2

RT

* ( yc * yw yd * yh / K eq 2 )

3030/7054 Reactor

3-5-14

Unit 3-5-15

Example cont.

Variable

Abbreviation

Value

Units

Bed Density

DBED

1200

kg/m3

Pre-exponential Rate Constant

km

5.517e6

mol/kg/s/atm

Activation Energy of Reaction 1

Ea1

1.849e8

J/mol

Gas Constant

8.314

J/mol/K

Pressure

30.0

atm

Absorption Parameter

Kh

4.053

atm-1

Mole fraction of CH4

ym

Varies

Unitless

Mole fraction of CO

yc

Varies

Unitless

Mole fraction of H2

yh

Varies

Unitless

Mole fraction of H2O

yh

Varies

Unitless

Pre-exponential Rate Constant

4.95e8

mol/kg/s

Activation Energy of Reaction 2

Ea2

1.163e5

J/mol

Equilibrium Constant1

Keq2

e-4.946 + 4897/T

Unitless (T in K)

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-15

Unit 3-5-16

Example-Cont.

1 Correctly set up all parameters for

kinetic equations

2 Compare the performance of the

kinetic reactors with Gibbs and

Equilibrium Reactors.

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-16

Unit 3-5-17

Example Cont.

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-17

Reactor Set-up

Unit 3-5-18

Reaction (1) has a format of Langmuir-Hinshelwood

equationchoosing the heterogeneous catalytic reaction

Comparing Hysys general format and r1 given from the

reaction information

reac tan ts

kf

r=

Ci k r

i =1

Pr oducts

j =1

g

1 + K k C g

k =1 g =1

Ea1

RT

DBED * k m * e

* P * ym

r1 =

1 + K h * P * yh

k f = DBED * k m * e

Ea1

RT

= A*e

Ea 1

RT

In the numerator: No reversion reaction; in the forward

reaction, only methane, based on partial pressure

In the denominator, only hydrogen, n=1

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-18

Unit 3-5-19

Setup cont.

The reaction basis is partial pressure with a unit of atm,

and the reaction in the vapour phase.

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-19

Unit 3-5-20

Setup cont.

Only methane has a forward order of 1.0; others are set

as 0.0

A=DBED*km =1200 kg/m3* 5.517e6 mol/kg/s/atm

=6.6204E9 mol/(m3 s atm) = 6.6204E6 kmol/(m3 s atm)

E=1.849E8 J/mol =1.849E8 KJ/kmol

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-20

Unit 3-5-21

Setup cont.

A=Kh = 4.053 atm-1, only hydrogen is chosen for this

case in the denominator.

n=1

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-21

Setup cont.

Unit 3-5-22

Reaction (2) is a kinetic reaction with an equilibrium

constant, so this reaction is modelled by simple rate

reaction

rA = kf ( Basis) k ' f ( Basis / K eq )

E

k = A exp

T

RT

ln( K eq ) = A'+ B' / T + c' Ln (T ) + D' T

K eq 2 = -4.946 + 4897/T

r2 = DBED * A * e

Ea 2

RT

* ( yc * yw yd * yh / K eq 2 )

Reaction basis is molar fraction; A=DBED*A; E=Ea2;

A=-4.946; B=4897; =0;

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-22

Unit 3-5-23

Setup cont.

A=1200 kg/m3* 4.95e8 mol/kg/s =5.94E11 mol/m3s

= 5.94E8 kmol/m3s

E=Ea2= 1.163e5 J/mol = 1.163E5 kJ/kmol =2.8E5 kcal/

kmol

A=-4.946; B=4897;

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-23

Unit 3-5-24

Results from Kinetics

Kinetic reaction set includes the above two reactions,

attached to Antoine package

Set the reactor size as 10 m in length and 2.21 in

diameter; void fraction as 1.0

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-24

Unit 3-5-25

Reactor Comparison

Using the same feed, choosing Gibbs reaction without

any reaction set

Using the same feed, choosing equilibrium reactor with

the Keq vs T with a table

The results are compared

Reforming reaction has a low reaction rate in the kinetic

model.

Methane molar flow increasing from both Gibbs and

Equilibrium comparing with kinetic reactions

Both Gibbs and Equilibrium have quite similar results.

Changing equilibrium constant to calculate from Gibbs free

energy, the results are even closer

Only choosing the water gas shift reaction of the reaction set in

the Equilibrium reactor, very similar results as kinetic reactor

can be obtained

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-25

Unit 3-5-26

Comparison Cont.

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-26

Level II with Heat Transfer

Unit 3-5-27

Reactor equations

Energy balance on reaction side

Energy balance on heat transfer

medium side

Heat transfer performance equation

(Q=UATm)

Pressure drop in packed bed (Ergun

Equation)

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-27

Heat Transfer in Reactors

Unit 3-5-28

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-28

Unit 3-5-29

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-29

Unit 3-5-30

Reactor Sizing Steps

Using Gibbs reactor to determine the theoretical

conversion limit

Residence time and volumetric flow rate are used to

size reactors

Using Adjust Function to determine the reactor

volume

Check the conversion at the calculated dimensions

less than the conversion limit.

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-30

Unit 3-5-31

Heuristics for Reactors

Dimensions of catalyst particles are 0.1 mm in

fluidized beds, 1 mm in slurry beds, and 2-5 mm in

fixed beds.

The optimum proportions of stirred tank reactors are

with liquid level equal to the tank diameter

Tubular flow reactors are suited to high production

rates at short residence times (sec or min) and when

substantial heat transfer is needed

PFR contains 20 segments in Hysys. Each segment

represents ideal CSTR.

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-31

Unit 3-5-32

Numerical Methods

Newton's Method.

usually converges quickly

Default method

Rate Iterated.

A partial Newton's method, and assumes that the offdiagonal elements of the Jacobian matrix are equal to zero.

The Method works well when there is very little interaction

between reactions.

Rate Integrated.

This method integrates the reaction equations until all time

derivatives are zero.

stable, but slow.

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-32

Unit 3-5-33

Tips and Hints

After creating the reaction, need to create a reaction

set and attach the reaction set to a fluid package.

Always check the unit for the reaction kinetic data A

and E

Always choose the reaction phase

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-33

Unit 3-5-34

Example 3-5-2

You are working as a process engineer to design an acetone

production unit. One of key parameter is the number of tubes. You are

asked to calculate the process using Hysys. Basic information:

Acetone is produced by endothermal reaction

(CH3)2CHOH (isopropyl alcohol)(CH3)2CO (acetone) + H2

No significant side reactions. The reaction takes place in the gas phase

on a solid catalyst with a kinetics rIPA = k cIPA kmol/m3 reactor s

Where k = 3.156x105 exp(-8720/T) where T is in K.

The current process uses a PFR with a heat transfer medium, HTM, on

the shell side, at 1x105 kgmol/hr and the heat capacity is 75 KJ/Kmol/C

Because there is a concern about operation of the downstream

separation section, the IPA reaction conversion is held constant at 90%

to ensure a constant feed composition to the separation section even

though the flow rate of this stream may change.

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-34

Unit 3-5-35

Flowrate (kmol/h)

234

stream

2.16

feed

feed

acetone

0.16

IPA

38.64

water

19.04

Equipment

Specifications

Reactor

MOC: carbon steel

Tube

Number-??

Diameter 2 in

Length 20 ft

Wall Heat transfer

coefficient

60 W/(m2 oC)

hydrogen

oC

bar

350

350

1.91

Copyright, The University Of Adelaide, Australia.

htm in

htm out

reactor

effluent

3030/7054 Reactor

3-5-35

Reactor Setup

Unit 3-5-36

234

2.16

Flowrate (kmol/h)

stream

feed

hydrogen

acetone

0.16

IPA

38.64

water

19.04

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-36

Unit 3-5-37

Heat Transfer

dP:

Ergun

Eqn

Duty

param

eters:

Formu

la

Copyright, The University Of Adelaide, Australia.

Input

Hysys

Default

3030/7054 Reactor

3-5-37

Unit 3-5-38

Reactor Rating

Diameter

Height

Leave number of tubes empty

Wall thickness 5.00E-03 m as default

Void fraction 0.9

Adjust function to adjust the conversion

rate as a function of reactor volume.

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-38

ResultsMaterial Stream

Unit 3-5-39

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-39

Unit 3-5-40

Results - Reactor

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-40

Unit 3-5-41

Option 1 No Formula

Use Direct Q Value Option, and set the outlet temperature of

Stream 2 as 350 C. The results are below. The utility fluid is

from Hysys Default.

Use Formula, the exit temperature is 344.8 C, and number of

tubes is 307 !

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-41

Unit 3-5-42

Summary

Hysys reactor setups for kinetics,

conversion, equilibrium and Gibbs

reactors

Reactors with heat-transfer

Reactor sizing

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-42

Unit 3-5-43

References

Copyright, The University Of Adelaide, Australia.

3030/7054 Reactor

3-5-43

Você também pode gostar

- OPM5002 Innovation in The Project Context Semester 1, 2020: Unit GuideDocumento15 páginasOPM5002 Innovation in The Project Context Semester 1, 2020: Unit GuideTuấn Kiệt NguyễnAinda não há avaliações

- Zoom SlidesDocumento10 páginasZoom SlidesTuấn Kiệt NguyễnAinda não há avaliações

- OPM5002 Marking Rubric: Assessment 1 - Individual Investigative EssayDocumento1 páginaOPM5002 Marking Rubric: Assessment 1 - Individual Investigative EssayTuấn Kiệt NguyễnAinda não há avaliações

- Future Ready - Research On Incorporating Career Education in The Australian CurriculumDocumento39 páginasFuture Ready - Research On Incorporating Career Education in The Australian CurriculumTuấn Kiệt NguyễnAinda não há avaliações

- What Is Accounting?: Learning ObjectivesDocumento10 páginasWhat Is Accounting?: Learning ObjectivesTuấn Kiệt NguyễnAinda não há avaliações

- Core Skills For Work Developmental FrameworkDocumento14 páginasCore Skills For Work Developmental FrameworkTuấn Kiệt NguyễnAinda não há avaliações

- What Kind of Networking Strategy Advice Should Career Counsellors Offer University Graduates Searching For A JobDocumento22 páginasWhat Kind of Networking Strategy Advice Should Career Counsellors Offer University Graduates Searching For A JobTuấn Kiệt NguyễnAinda não há avaliações

- Eleanor Smith: Official Monash Assignment Cover SheetDocumento7 páginasEleanor Smith: Official Monash Assignment Cover SheetTuấn Kiệt NguyễnAinda não há avaliações

- Brochure Gelatoexpert 10 2019 PDFDocumento20 páginasBrochure Gelatoexpert 10 2019 PDFTuấn Kiệt Nguyễn0% (2)

- Supply and Demand For Higher-Level SkillsDocumento40 páginasSupply and Demand For Higher-Level SkillsTuấn Kiệt NguyễnAinda não há avaliações

- Columbia and Challenger: Organizational Failure at NASA: Article in PressDocumento9 páginasColumbia and Challenger: Organizational Failure at NASA: Article in PressTuấn Kiệt NguyễnAinda não há avaliações

- The Evolving Face of Ethics in Technical and Professional Communication: Challenger To ColumbiaDocumento14 páginasThe Evolving Face of Ethics in Technical and Professional Communication: Challenger To ColumbiaTuấn Kiệt NguyễnAinda não há avaliações

- Process Simulation IV 2016 PDFDocumento33 páginasProcess Simulation IV 2016 PDFTuấn Kiệt NguyễnAinda não há avaliações

- Steam Turbines and GeneratorsDocumento18 páginasSteam Turbines and GeneratorsTuấn Kiệt Nguyễn100% (1)

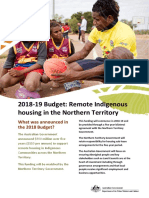

- 2018-19 Budget: Remote Indigenous Housing in The Northern TerritoryDocumento2 páginas2018-19 Budget: Remote Indigenous Housing in The Northern TerritoryTuấn Kiệt NguyễnAinda não há avaliações

- Successes and Failures in Australian Indigenous Housing: Melinda Chan, Jessie Fowler, Frank Vedelago, Steph WestbrookDocumento51 páginasSuccesses and Failures in Australian Indigenous Housing: Melinda Chan, Jessie Fowler, Frank Vedelago, Steph WestbrookTuấn Kiệt NguyễnAinda não há avaliações

- sol-HA1 2Documento1 páginasol-HA1 2Tuấn Kiệt NguyễnAinda não há avaliações

- Sample ExamDocumento6 páginasSample ExamTuấn Kiệt NguyễnAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Sparkle EffectDocumento22 páginasThe Sparkle EffectVida Betances-ReyesAinda não há avaliações

- Portable Manual - DIG-360Documento44 páginasPortable Manual - DIG-360waelmansour25Ainda não há avaliações

- BHS Inggris 2021Documento6 páginasBHS Inggris 2021Muhammad FirmanAinda não há avaliações

- VIP45Documento92 páginasVIP45Román IsraelAinda não há avaliações

- CH Six Global Transportation Planning and ExecutionDocumento41 páginasCH Six Global Transportation Planning and ExecutionDsh ShAinda não há avaliações

- 6RA80 Quick Commissioning Without TachoDocumento7 páginas6RA80 Quick Commissioning Without TachoBaldev SinghAinda não há avaliações

- Pezzol Catalog 21 - INTERNATIONALDocumento74 páginasPezzol Catalog 21 - INTERNATIONALAhmed CapoAinda não há avaliações

- Squares and Square Roots Chapter Class ViiiDocumento24 páginasSquares and Square Roots Chapter Class ViiiManas Hooda100% (1)

- Wind Load CompututationsDocumento31 páginasWind Load Compututationskim suarezAinda não há avaliações

- Safety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationDocumento10 páginasSafety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationEscobar ValderramaAinda não há avaliações

- Mold Maintenance StepDocumento0 páginaMold Maintenance StepMonica JoynerAinda não há avaliações

- The Seventh House in AstrologyDocumento6 páginasThe Seventh House in Astrologytratak100% (1)

- Module III Rural MarketingDocumento30 páginasModule III Rural MarketingNikita YadavAinda não há avaliações

- The Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateDocumento22 páginasThe Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateOkawa TakeshiAinda não há avaliações

- Origami Undergrad ThesisDocumento63 páginasOrigami Undergrad ThesisEduardo MullerAinda não há avaliações

- Book 1Documento1 páginaBook 1PES SAFETYAinda não há avaliações

- Traffic Cases in GSMDocumento18 páginasTraffic Cases in GSMkamal100% (1)

- Latest Research Papers On Manet SecurityDocumento7 páginasLatest Research Papers On Manet Securitygz9g97haAinda não há avaliações

- DysphagiaDocumento4 páginasDysphagiaMicaAinda não há avaliações

- 120 BE5678 CenterDocumento2 páginas120 BE5678 CenterDipika GuptaAinda não há avaliações

- Catalogue Mp200Documento33 páginasCatalogue Mp200Adrian TudorAinda não há avaliações

- ECE 374 - Part - 1c - S2017Documento37 páginasECE 374 - Part - 1c - S2017Zakaria ElwalilyAinda não há avaliações

- Anish Pandey ResumeDocumento4 páginasAnish Pandey ResumeAnubhav ChaturvediAinda não há avaliações

- SC4860-48120 (-MPV) User Manual EN 202107Documento23 páginasSC4860-48120 (-MPV) User Manual EN 202107Nattachai BoonchooAinda não há avaliações

- Power - Distribution Transformers @2020V2Documento34 páginasPower - Distribution Transformers @2020V2Musfiqul AzadAinda não há avaliações

- Techniques and Applications of Automatic Tube Current Modulation For CTDocumento9 páginasTechniques and Applications of Automatic Tube Current Modulation For CTdestian ryanAinda não há avaliações

- E11133 MB Pin Definition v2 Print Vendor Only PDFDocumento18 páginasE11133 MB Pin Definition v2 Print Vendor Only PDFLuciano MalancaAinda não há avaliações

- Block-1 BLIS-03 Unit-2 PDFDocumento15 páginasBlock-1 BLIS-03 Unit-2 PDFravinderreddynAinda não há avaliações

- 1C09-08 Design For Seismic and Climate ChangesDocumento31 páginas1C09-08 Design For Seismic and Climate ChangesSanketWadgaonkarAinda não há avaliações