Escolar Documentos

Profissional Documentos

Cultura Documentos

Sample Exam

Enviado por

Tuấn Kiệt NguyễnDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sample Exam

Enviado por

Tuấn Kiệt NguyễnDireitos autorais:

Formatos disponíveis

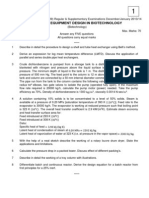

SEMESTER 2, 2014

Examination for the Degree of B.E. (Chem)

105523

SIMULATION & CONCEPT DESIGN

CHEM ENG 3030

SIMULATION & CONCEPT DESIGN

CHEM ENG 7054

105998

Official Reading Time:

Writing Time:

Total Duration:

Parts

A

B

10 mins

150 mins

160 mins

Questions

Answer all questions

Answer all questions

Time

60 mins

90 mins

Marks

as shown

as shown

INSTRUCTIONS TO CANDIDATES:

1. PART A is CLOSED BOOK books, lecture notes and other materials are not to be used or

consulted. PART A BOOKLETS will be COLLECTED at END of the FIRST HOUR or must

be HANDED IN BEFORE PART B is COMMENCED.

2. PART B is COMPUTOR-based OPEN BOOK. It may be commenced at any time after Part A

Booklets are handed in.

3. Maximum Mark = 120. Marks for each question are shown. Attempt ALL questions.

Write your name and student number on all loose diagrams.

PERMITTED MATERIALS:

1. English language dictionary is permitted.

2. Calculator without alphanumeric memory or remote communications capability is permitted.

Part A Closed Book

Answer all questions

Question 1

[30 Marks]

<The following information is for examination purpose only, and this may not

represent the real industrial operation>

Ethylene oxide with a molecular weight of 44.05 is the simplest cyclic ether. Ethylene

oxide is very reactive because its highly strained ring can be opened easily, and is thus

one of the most versatile chemical intermediates. However, because of its reactivity,

danger of explosion, and toxicity, it is quite often manufactured and consumed inside the

manufacturing facility.

Currently ethylene oxide is produced mainly by the oxygen-based process. The reactions

are as follows.

C2 H 4 + 0.5O2 C2 H 4O

C2 H 4 + 3O2 2CO2 + 2H 2O

C2 H 4O + 2.5O2 2CO2 + 2H 2O

(1)

(2)

(3)

The kinetic expressions are, respectively,

r1 =

1.96 exp(2400 / RT )pethylene

1+ 0.00098exp(11, 200 / RT )pethy lene

r2 =

0.0936 exp(6400 / RT )pethylene

1+ 0.00098exp(11, 200 / RT )pethy lene

r3 =

2

0.4276 exp(6200 / RT )p ethylene

_ oxide

2

1+ 0.000033exp(21, 200 / RT )p ethy lene _ oxide

The units for the reaction rates are moles/m3.s. The pressure unit is bar. The activation

energy numerator is in cal/mol. The catalyst used for the reaction is silver on an inert

support. The support consists of 7.5mm diameter spheres that have a bulk density of

1250 kg/m3 and a void fraction of 0.4.

For the silver-catalyzed oxidation process, dry air at 25 oC and 1 bar and ethylene (vapor

phase) at 25 oC and 50 bar is used. The reaction is exothermic and temperature has to be

carefully controlled. Conversion in the reactor is often kept low to enhance selectivity for

the desired product. The initial estimate of temperature and pressure for the reaction is

240 oC and 26 bar and the conversion in this reactor is less than 40% based on the

ethylene reactant. A secondary reactor at the same reaction condition is required to

improve the conversion. Please note that temperature of the catalyst tubes are restricted

by the maximum design pressure, which usually does not allow temperatures higher than

300 oC.

After the reaction, ethylene oxide is scrubbed by water at 30 oC and 30 bar. Liquid

ethylene oxide and water are completely miscible in all proportions. The ethylene oxide

aqueous solution is distilled at a distillation column at 45 oC and 10 bar. The final product

purity 99.5wt% is required after distillation column.

Based on the information above, use the Means-End Analysis method to develop your

process flow diagram to produce 100,000 tones of ethylene oxide. The boiling points of

ethylene and ethylene oxide at different pressures are attached for your reference.

Table 1 Boiling Points of Ethylene and Ethylene Oxide at different pressures

Pressure

(Bar)

1

10

26

30

Boiling points of ethylene

(oC)

-104.3

-51.81

-19.02

-13.2

Boiling points of ethylene oxide

(oC)

10.8

86.2

132.4

140.4

Question 2

[20 Marks]

The figure below is a simple process flowsheet. Find a suitable set of tear streams, and

appropriate computation order for sequential modular solution of material and energy

balances in the flowsheet.

Product A

Feed

6

Product B

Question 3

[10 Marks]

Consider the multiproduct batch plant described in the following table.

Table 1 Equipment processing times for processes A, B and C

Process

A

B

C

Mixer

2.0 h

3.0 h

1.0 h

Reactor

5.0 h

4.0 h

3.0 h

Separator

4.0 h

3.5 h

4.5 h

(1) For a multiproduct campaign using the sequence CBACBACBA., work out the

cycle time for three batches. Assuming the clean time and transfer time are

negligible, and zero-wait transfer policy is applied.

(2) Determine the number of batches for the sequence of CBACBACBAthat can be

produced in one year (assume 300 days).

Part B Computer-based Open Book

Answer all questions

Question 4

[20 Marks]

In Question 1, for the oxidation process, the reaction kinetics are given for the three

reactions.

C2 H 4 + 0.5O2 C2 H 4O

C2 H 4 + 3O2 2CO2 + 2H 2O

C2 H 4O + 2.5O2 2CO2 + 2H 2O

(1)

(2)

(3)

The kinetic expressions are, respectively,

r1 =

1.96 exp(2400 / RT )pethylene

1+ 0.00098exp(11, 200 / RT )pethy lene

r2 =

0.0936 exp(6400 / RT )pethylene

1+ 0.00098exp(11, 200 / RT )pethy lene

r3 =

2

0.4276 exp(6200 / RT )p ethylene

_ oxide

2

1+ 0.000033exp(21, 200 / RT )p ethy lene _ oxide

The units for the reaction rates are moles/m3.s. The pressure unit is bar. The activation

energy numerator is in cal/mol. The catalyst used for the reaction is silver on an inert

support. The support consists of 7.5mm diameter spheres that have a bulk density of

1250 kg/m3 and a void fraction of 0.4.

Using Hysys to simulate the above reactions in a reactor. The feed materials are 1000

kmol/h for C2H4 and 1000 kmol/h for O2 at 240 oC and 26 bar.

(1) Providing the reactor volume of 80 m3 with a length of 1.0 m and 1000 tubes, if the

temperature is to be controlled at 240 oC, find out the overall conversion of

ethylene and selectivity for producing ethylene oxide.

(2) Establish a case study to find out the reaction conversion rate of reaction (1) by

adjusting the product stream temperature from 100 to 300 oC with a step size of 10

o

C. Plot your result.

(3) Upload your file into the designated file folder in MyUni.

Question 5

[30 Marks]

A distillation tower with sieve trays is to separate benzene from monochlorobenzene. The

feed is 1000 kmol/hr containing equal molar ratio of benzene and monochlorobenzene at

20 psia. The specifications are the top product containing 0.5 mol % impurity and the

bottom product containing 0.5 mol% impurity.

(1) Determine the appropriate operating pressure at the top of the tower (the critical

temperature for monochlorobenzene can be found in the pure compound

properties)

(2) Use the short-cut method to determine the number of stages using the external

flux ratio of 1.5.

(3) To achieve the specifications for the top and bottom products, work out the tower

diameter using the Hysys sizing utility. Please comment whether the sieve tray is

suitable to achieve the desired specifications. If not, what is the best format for the

distillation column.

(4) Upload your file into the designated file folder in MyUni.

Question 6

[10 Marks]

You will use SuperPro Designer to complete the following task.

A in solvent chloroform will change into B at a temperature of 50 oC in a stirred reactor

with a reaction constant of 0.0015 s-1. To complete the reaction, two reactors are used.

100 kg of chloroform and 50 kg of A are charged into the first reactor, stirring for 15 min

and then heated to 50 oC. After the reaction in the first reactor for 20 min, all contents are

transferred into the second reactor. The same reaction occurs in the second reactor with

the same reaction constant at 50 oC for 20 min. After the reaction, the contents are sent to

a batch distiller. In batch distillation, the relative volativity of A and chloroform is 1.2 and 5

when the reference component B is ued. The distillation lasts 3 hr and the reflux ratio is

1.5 and molar percentage distilled is set as 50%. To complete the mass balance for the

above process and work out the operation Gantt chart for 3 batches. Upload your file into

the designated file folder in MyUni.

Você também pode gostar

- CSTR Lab ReportDocumento16 páginasCSTR Lab Reportleenzalal100% (5)

- Distillation Aspen HysysDocumento66 páginasDistillation Aspen HysysCzarina MasicatAinda não há avaliações

- Design of An Plant For Manufacturing of AcetaldehydeDocumento4 páginasDesign of An Plant For Manufacturing of AcetaldehydeClaudio Martinez BernalAinda não há avaliações

- Allyl CDocumento15 páginasAllyl CTengku Mohd Imran0% (1)

- Chemical Reactor DesignDocumento15 páginasChemical Reactor DesignluisruizfuneAinda não há avaliações

- Metrics That Matter - Uncovering KPIs That Justify Operational ImprovementsDocumento43 páginasMetrics That Matter - Uncovering KPIs That Justify Operational ImprovementsOscar NilaAinda não há avaliações

- 3126B Serial DCS02760 Arr 2077523 Repair ManualDocumento1.196 páginas3126B Serial DCS02760 Arr 2077523 Repair Manualviemey1952100% (4)

- Sipcot RanipetDocumento18 páginasSipcot RanipetTamil Selvam79% (42)

- 619PT304Documento4 páginas619PT304arpit gargAinda não há avaliações

- Homework 2 - 2020 - 01 - Sent (v4)Documento4 páginasHomework 2 - 2020 - 01 - Sent (v4)DeividAinda não há avaliações

- IV B. TECH (Chemical Engineering) I SemesterDocumento14 páginasIV B. TECH (Chemical Engineering) I SemesterPiyush AmbulgekarAinda não há avaliações

- CL405 2021 End Term ExaminationDocumento4 páginasCL405 2021 End Term ExaminationArpit GuptaAinda não há avaliações

- 2010 ChE 471 HW 8 FinalDocumento4 páginas2010 ChE 471 HW 8 FinalSiti HannaAinda não há avaliações

- Assignment 2: (Subject: Ch.E. 401 Chemical Reactor Design) Related To CLO1Documento4 páginasAssignment 2: (Subject: Ch.E. 401 Chemical Reactor Design) Related To CLO1imtiazAinda não há avaliações

- Mid Semester Examination Faculty of EngineeringDocumento3 páginasMid Semester Examination Faculty of EngineeringSunmoon Al-HaddabiAinda não há avaliações

- I 2 Ii 2 Iii 2 2Documento2 páginasI 2 Ii 2 Iii 2 2Bizoy RahmanAinda não há avaliações

- 3102 HT & Thermo 2014 PrimaryDocumento8 páginas3102 HT & Thermo 2014 PrimaryAkmal BhattiAinda não há avaliações

- Indian Institute of Technology Madras Department of Chemical EngineeringDocumento2 páginasIndian Institute of Technology Madras Department of Chemical Engineeringkarthickclean8827Ainda não há avaliações

- Multiphase Tutorial 7Documento7 páginasMultiphase Tutorial 7Anders Rojas Coa.Ainda não há avaliações

- Question Paper Code:: Reg. No.Documento4 páginasQuestion Paper Code:: Reg. No.Guru PrakashAinda não há avaliações

- Appendix A: - .Sizing of Distillation ColumnsDocumento14 páginasAppendix A: - .Sizing of Distillation ColumnsBlack WidowAinda não há avaliações

- ExercisesDocumento13 páginasExercisesRajpriya GuptaAinda não há avaliações

- 9A23702 Process Equipment Design in BiotechnologyDocumento4 páginas9A23702 Process Equipment Design in BiotechnologysivabharathamurthyAinda não há avaliações

- 2010 ChE 471 HW 8 FinalDocumento4 páginas2010 ChE 471 HW 8 FinalpinhonceteAinda não há avaliações

- Tray Distillation Column With RefluxDocumento26 páginasTray Distillation Column With RefluxMelvin MoorAinda não há avaliações

- 2 - Prob Batch 11-12 14-22 EnglishDocumento3 páginas2 - Prob Batch 11-12 14-22 EnglishAbiola AjiginniAinda não há avaliações

- Code: 9A03302 B.Tech II Year I Semester (R09) Regular & Supplementary Examinations December/January 2013/14Documento4 páginasCode: 9A03302 B.Tech II Year I Semester (R09) Regular & Supplementary Examinations December/January 2013/14sivabharathamurthyAinda não há avaliações

- Simulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017Documento5 páginasSimulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017ajali1957Ainda não há avaliações

- The Design of A Chemical Plant For The Production of Methanol From Synthesis GasDocumento4 páginasThe Design of A Chemical Plant For The Production of Methanol From Synthesis GasHenry NwidoAinda não há avaliações

- Chemical Process Equipment DesignDocumento9 páginasChemical Process Equipment Designraghu_iictAinda não há avaliações

- Reactor Exercises - 2013 PDFDocumento19 páginasReactor Exercises - 2013 PDFtehbear0% (1)

- CHE2162 - Semester1 - 2011 PDFDocumento11 páginasCHE2162 - Semester1 - 2011 PDFvenkieeAinda não há avaliações

- Lab 5: Adiabatic Production of Acetic Anhydride ObjectivesDocumento1 páginaLab 5: Adiabatic Production of Acetic Anhydride ObjectivesNajwa NaqibahAinda não há avaliações

- Problem Set 1Documento6 páginasProblem Set 1Emilee Noven RamirezAinda não há avaliações

- Homework1 1Documento2 páginasHomework1 1Oguz KurtulanAinda não há avaliações

- CENG40001 Mastery 1Documento44 páginasCENG40001 Mastery 1Kelvin Zhou (KelvinsChicken)Ainda não há avaliações

- 47th IChO-Theoretical Problems With Solutions and Grading Schemes Final 26 07Documento41 páginas47th IChO-Theoretical Problems With Solutions and Grading Schemes Final 26 07George UmbrarescuAinda não há avaliações

- IChO 2015 Problems and SolutionsDocumento71 páginasIChO 2015 Problems and SolutionsScience Olympiad Blog100% (2)

- Cre-II EndtermDocumento2 páginasCre-II Endtermbt21cme061Ainda não há avaliações

- Thermodynamics Assignment 2 2014Documento5 páginasThermodynamics Assignment 2 2014ravikr950% (1)

- Module Title: Plant & Process Design Module Code:: +417.5 KJ/KG)Documento4 páginasModule Title: Plant & Process Design Module Code:: +417.5 KJ/KG)doniaAinda não há avaliações

- Me309 2015 11 PDFDocumento4 páginasMe309 2015 11 PDFgift mudimuAinda não há avaliações

- Final ReportDocumento17 páginasFinal ReportFahad KhokharAinda não há avaliações

- CH 08Documento44 páginasCH 08kentalAinda não há avaliações

- Tutorial-3 CRE1 CLL122 PDFDocumento4 páginasTutorial-3 CRE1 CLL122 PDFSunandita BorahAinda não há avaliações

- Che F244 1183 C 2015 2Documento4 páginasChe F244 1183 C 2015 2shubhamAinda não há avaliações

- Art6 WesterterpDocumento8 páginasArt6 WesterterpCristhian GómezAinda não há avaliações

- CRE I Assignment 5Documento2 páginasCRE I Assignment 5Sumit KatkarAinda não há avaliações

- Me8595 Iq R17Documento2 páginasMe8595 Iq R17Narayanan SubramanianAinda não há avaliações

- Unidad2 IR1Documento1 páginaUnidad2 IR1Melissa Daniela Romero TrujilloAinda não há avaliações

- Reactor ModelDocumento12 páginasReactor ModelTanuja ThanuAinda não há avaliações

- For Hysys UsersDocumento5 páginasFor Hysys UsersZohaib RanaAinda não há avaliações

- Group 3 - Acetone Production Via The Dehydrogenation of IPADocumento7 páginasGroup 3 - Acetone Production Via The Dehydrogenation of IPAQuỳnh Như PhạmAinda não há avaliações

- Chemical Engineering Job QuestionsDocumento9 páginasChemical Engineering Job QuestionsMunia AkterAinda não há avaliações

- Tute 3Documento4 páginasTute 3ArunAinda não há avaliações

- Reactor Exercises 2013Documento19 páginasReactor Exercises 2013RafiHunJian100% (2)

- 1174rr320801 Mass Transfer Operations IIDocumento8 páginas1174rr320801 Mass Transfer Operations IIsobichemAinda não há avaliações

- Engr2276 Apr03Documento10 páginasEngr2276 Apr03Mohamed AlqaisiAinda não há avaliações

- Design (Ch.1 Problems)Documento5 páginasDesign (Ch.1 Problems)John UnkAinda não há avaliações

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasAinda não há avaliações

- OPM5002 Innovation in The Project Context Semester 1, 2020: Unit GuideDocumento15 páginasOPM5002 Innovation in The Project Context Semester 1, 2020: Unit GuideTuấn Kiệt NguyễnAinda não há avaliações

- OPM5002 Marking Rubric: Assessment 1 - Individual Investigative EssayDocumento1 páginaOPM5002 Marking Rubric: Assessment 1 - Individual Investigative EssayTuấn Kiệt NguyễnAinda não há avaliações

- Zoom SlidesDocumento10 páginasZoom SlidesTuấn Kiệt NguyễnAinda não há avaliações

- Future Ready - Research On Incorporating Career Education in The Australian CurriculumDocumento39 páginasFuture Ready - Research On Incorporating Career Education in The Australian CurriculumTuấn Kiệt NguyễnAinda não há avaliações

- What Is Accounting?: Learning ObjectivesDocumento10 páginasWhat Is Accounting?: Learning ObjectivesTuấn Kiệt NguyễnAinda não há avaliações

- Core Skills For Work Developmental FrameworkDocumento14 páginasCore Skills For Work Developmental FrameworkTuấn Kiệt NguyễnAinda não há avaliações

- What Kind of Networking Strategy Advice Should Career Counsellors Offer University Graduates Searching For A JobDocumento22 páginasWhat Kind of Networking Strategy Advice Should Career Counsellors Offer University Graduates Searching For A JobTuấn Kiệt NguyễnAinda não há avaliações

- Eleanor Smith: Official Monash Assignment Cover SheetDocumento7 páginasEleanor Smith: Official Monash Assignment Cover SheetTuấn Kiệt NguyễnAinda não há avaliações

- Brochure Gelatoexpert 10 2019 PDFDocumento20 páginasBrochure Gelatoexpert 10 2019 PDFTuấn Kiệt Nguyễn0% (2)

- Supply and Demand For Higher-Level SkillsDocumento40 páginasSupply and Demand For Higher-Level SkillsTuấn Kiệt NguyễnAinda não há avaliações

- Columbia and Challenger: Organizational Failure at NASA: Article in PressDocumento9 páginasColumbia and Challenger: Organizational Failure at NASA: Article in PressTuấn Kiệt NguyễnAinda não há avaliações

- The Evolving Face of Ethics in Technical and Professional Communication: Challenger To ColumbiaDocumento14 páginasThe Evolving Face of Ethics in Technical and Professional Communication: Challenger To ColumbiaTuấn Kiệt NguyễnAinda não há avaliações

- Process Simulation IV 2016 PDFDocumento33 páginasProcess Simulation IV 2016 PDFTuấn Kiệt NguyễnAinda não há avaliações

- sol-HA1 2Documento1 páginasol-HA1 2Tuấn Kiệt NguyễnAinda não há avaliações

- 2018-19 Budget: Remote Indigenous Housing in The Northern TerritoryDocumento2 páginas2018-19 Budget: Remote Indigenous Housing in The Northern TerritoryTuấn Kiệt NguyễnAinda não há avaliações

- Successes and Failures in Australian Indigenous Housing: Melinda Chan, Jessie Fowler, Frank Vedelago, Steph WestbrookDocumento51 páginasSuccesses and Failures in Australian Indigenous Housing: Melinda Chan, Jessie Fowler, Frank Vedelago, Steph WestbrookTuấn Kiệt NguyễnAinda não há avaliações

- Steam Turbines and GeneratorsDocumento18 páginasSteam Turbines and GeneratorsTuấn Kiệt Nguyễn100% (1)

- Viscosity ReportDocumento12 páginasViscosity ReportBF3nobelAinda não há avaliações

- API RP 2A 21st 2000 Vs 2007-FatigueDocumento16 páginasAPI RP 2A 21st 2000 Vs 2007-Fatiguesm8575Ainda não há avaliações

- 4-Eclairage 6pDocumento69 páginas4-Eclairage 6pghhAinda não há avaliações

- Activated Sludge Wastewater Treatment Processes and Control of Foam FormationDocumento10 páginasActivated Sludge Wastewater Treatment Processes and Control of Foam FormationGeorge MarkasAinda não há avaliações

- B1ADocumento7 páginasB1ASumantrra Chattopadhyay0% (1)

- Brick BondsDocumento42 páginasBrick BondsNaveen PahalAinda não há avaliações

- Wedi Technical Data Sheet Building Board GB 2016 v1 RZ SCREENDocumento3 páginasWedi Technical Data Sheet Building Board GB 2016 v1 RZ SCREENRui ConceiçãoAinda não há avaliações

- Role and Scope of OpmDocumento11 páginasRole and Scope of OpmMohammed ShahrukhAinda não há avaliações

- INN-QC-FR-15 Painting RecordDocumento1 páginaINN-QC-FR-15 Painting RecordchandraAinda não há avaliações

- Hot & Cold WorkingDocumento18 páginasHot & Cold WorkingMadushan MadushaAinda não há avaliações

- TECH - Wyntk - Truss Facts For Eng and ArcDocumento24 páginasTECH - Wyntk - Truss Facts For Eng and Arcshaikh85Ainda não há avaliações

- Approval Ballast eDocumento7 páginasApproval Ballast eAbd ZouhierAinda não há avaliações

- Hypertac Cid Series Connectors PDFDocumento3 páginasHypertac Cid Series Connectors PDFdilnair99Ainda não há avaliações

- As 1074-1989 Steel Tubes and Tubulars For Ordinary ServiceDocumento7 páginasAs 1074-1989 Steel Tubes and Tubulars For Ordinary ServiceSAI Global - APAC50% (2)

- Mechanic Machine Tool Maintenance-Nsqf PDFDocumento63 páginasMechanic Machine Tool Maintenance-Nsqf PDFUjjwal Chauhan100% (3)

- Ti Alkadur p82 136 enDocumento2 páginasTi Alkadur p82 136 enKelvinAinda não há avaliações

- 11 Equip+water+toiletDocumento14 páginas11 Equip+water+toiletTharrmaselan manimaranAinda não há avaliações

- Just in TimeDocumento4 páginasJust in TimeRohit KumarAinda não há avaliações

- E9018 M Specifications PDFDocumento2 páginasE9018 M Specifications PDFMohamed MostafaAinda não há avaliações

- David Brown in International MiningDocumento9 páginasDavid Brown in International MiningKroya HunAinda não há avaliações

- Heat InputDocumento2 páginasHeat InputjovanradovanoviAinda não há avaliações

- Particle Size AnalysisDocumento36 páginasParticle Size AnalysisAayush Jha SauravAinda não há avaliações

- Teco Programmable Logic RelayDocumento1 páginaTeco Programmable Logic RelayEduardo_77Ainda não há avaliações

- G1909HSDocumento2 páginasG1909HSeisenbarger5607Ainda não há avaliações

- Xaloy Barrel BR Russian Rev1Documento4 páginasXaloy Barrel BR Russian Rev1matic91Ainda não há avaliações

- Manual de La Ingleteadora BOSCH GCM12SDDocumento164 páginasManual de La Ingleteadora BOSCH GCM12SDChristopher DavisAinda não há avaliações

- HSL650 7Documento6 páginasHSL650 7sweetsabinaAinda não há avaliações