Escolar Documentos

Profissional Documentos

Cultura Documentos

Supercritical Water Oxidation - Paper 介绍 PDF

Enviado por

czhang001Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Supercritical Water Oxidation - Paper 介绍 PDF

Enviado por

czhang001Direitos autorais:

Formatos disponíveis

Journal of Environmental Sciences 19(2007) 513522

Supercritical water oxidation for the destruction of toxic organic

wastewaters: A review

VERIANSYAH Bambang, KIM Jae-Duck

Supercritical Fluid Research Laboratory, Korea Institute of Science and Technology (KIST)Department of Green Process and System Engineering,

University of Science and Technology (UST), 39-1 Hawolgok-dong, Seoungbuk-gu, Seoul 136-791, Korea. E-mail: jdkim@kist.re.kr

Received 16 June 2006; revised 28 September 2006; accepted 11 October 2006

Abstract

The destruction of toxic organic wastewaters from munitions demilitarization and complex industrial chemical clearly becomes an

overwhelming problem if left to conventional treatment processes. Two options, incineration and supercritical water oxidation (SCWO),

exist for the complete destruction of toxic organic wastewaters. Incinerator has associated problems such as very high cost and public

resentment; on the other hand, SCWO has proved to be a very promising method for the treatment of many different wastewaters

with extremely efficient organic waste destruction 99.99% with none of the emissions associated with incineration. In this review, the

concepts of SCWO, result and present perspectives of application, and industrial status of SCWO are critically examined and discussed.

Key words: supercritical water oxidation; toxic wastewater treatment; SCWO industrial status

Introduction

The world is facing a waste crisis from organic and toxic

wastes today. Every year the amount of those wastes generated by industrial and domestic sources increase rapidly.

The treatment of organic and toxic waste is becoming more

difficult and costly because of more stringent treatment

standards and discharge limitations. Public health concerns

are the driving force for the continued legislation aimed at

providing a cleaner and safer environment. Furthermore,

EPA (Environmental Protection Agency) goals suggest

destruction levels up to 99.9999% of some compounds and

use of totally enclosed treatment facilities. The increased

environmental constrains and unfavorable public opinion

have challenged the continuing application of conventional

waste management techniques (Li et al., 1991).

Conventional technologies currently used to treat all

types of organic and toxic wastes include adsorption,

biological oxidation, chemical oxidation, land-based, and

incineration. Each of these treatment methods has shortcomings and therefore may not be the best option for

treating organic and toxic wastes. Supercritical water oxidation (SCWO) has been proposed as a technology capable

of destroying a very wide range of organic hazardous

waste. It has been drawing much attention due to effectively destroy a large variety of high-risk wastes resulting

from munitions demilitarization and complex industrial

chemical.

The primary advantage of the SCWO process over such

Project supported by the Korea Institute of Science and Technology

(KIST). *Corresponding author. E-mail: jdkim@kist.re.kr.

land-based alternatives as land filling, deep-well injection,

and lagooning is the destruction method. Land-based disposal does not address the ultimate destruction of toxic

components of the waste and can result in the possible

contamination of surrounding soil and groundwater. Deepwell injection systems are subject to plugging or fouling

if organic concentration of 1% or higher are allowed.

Landfills and lagoons can contribute to contamination

of the air by volatile organics. The increasing of public

concern and regulatory action will restrict or prohibit landbased disposal of many organic wastes in the future.

Destruction methods based on oxidation of organic content for aqueous wastes include activated carbon treatment,

biological treatment, incineration, wet air oxidation, and

supercritical oxidation. For very dilute aqueous waste

whose organic contents are less than 1%, activated carbon

treatment or biological treatment is often an effective destruction method. In activated carbon treatment, organics

are first adsorbed onto carbon and then oxidized during

regeneration of carbon. Partially oxidized materials are

perfectly destroyed by after-burner treatment. Main cost

is proportional to the organic content. So this method is

not economically useful for waste containing more than

1% organic. Biological treatment systems often become

poisoned and cannot be sustained for many wastes with

organic concentrations of 1% or more.

Incineration, on the other hand, is restricted for economic reasons to waste streams relatively high organic

concentrations. To attain high destruction efficiency for

hazardous and toxic wastes, incineration must be operated

at very high temperature as 9001100C and often with

excess air of 100%200%. With aqueous wastes, the

514

VERIANSYAH Bambang et al.

energy required to bring the water component of the waste

to this temperature is substantial. For the aqueous wastes

with organic content more than 25%, the heat required

for high temperature can be generated from wastes. With

decreasing organic content, the supplemental fuel required

to satisfy the energy balance becomes a major cost. Thus,

controlled incineration of aqueous waste with less than

20% organics is the only consideration in extenuating

circumstances (Thomason and Modell, 1984). Incineration

is also being regulated to restrict stack gas emissions

to the atmosphere. Extensive equipment must now be

used downstream of the reaction system to remove NO x ,

acid gasses, and particulates from the stack gases before

discharge. The cost of this equipment often exceeds that of

the incinerator itself.

In the range of concentration of 1% to 20% organic, wet

air oxidation or SCWO is far less costly than incineration

or active carbon treatment. Wet air oxidation (WAO) has

been offered as a method to treat wastewater, industrial

wastes, and sludge. From a public perception standpoint,

WAO is more favorable than incineration, land application,

deep well injection, and ocean dumping because the waste

products can be completely converted to inert materials

and the process can be conducted as a closed system which

does not produce any hazardous byproducts. Capital costs

are often higher than incineration; however, operating costs

are lower. It is possible to recover energy and inorganic

in WAO. Wet air oxidation, commonly associated with

sludge conditioning and some organic destruction, is a lowtemperature process (Boock, 1996).

The Zimpro-Passavants WAO process is typically operated in a temperature range of 150C to 350C and pressure

range of 220 MPa. The operating pressure is maintained

well above the saturation pressure corresponding to the

operating temperature so that the reaction is carried out

in the liquid phase. Residence times may range from 15

120 min, and the chemical oxygen demand (COD) removal

may typically be approximately 75%90%. Volatile acids

constitute a substantial portion of remaining COD. The

formation of volatile acids, particularly acetic acid, is

a limitation for WAO. Furthermore, the effluent from

incomplete (partial) wet oxidation of some wastewaters

Vol. 19

may be intensely colored and toxic (Li et al., 1991).

The above examples illustrate the utility of WAO as an

alternative to incineration for the treatment of dilute aqueous wastes. However, a number of compounds, including

m-xylene and acetic acid are refractory towards oxidation at these conditions. Additionally, WAO often cannot

achieve the 99.9% destruction efficiencies that many newer

regulations require. This motivated a look at oxidation

under more severe conditions, such as higher temperatures

and pressures, which bring the reaction mixture above its

critical point. Thus, the supercritical oxidation process was

born. Supercritical water oxidation, on the other hand, is

known to attain nearly complete destruction of various

organics such as PCBs, and dioxins in very short time

(Boock, 1996).

1 Supercritical water oxidation

Supercritical water oxidation defined as oxidation process which occurs in water above its critical point

(T c =374C and Pc =22.1 MPa). It uses supercritical water

as a reaction medium and exploits the unique solvating properties to provide enhanced solubility of organic

reactants and permanent gases (like oxygen and carbon

dioxide), a single-phase environment free of inter-phase

mass transfer limitations, faster reaction kinetics, and

an increased selectivity to complete oxidation products

(Tester et al., 1993; Savage et al., 1995; Schimeider and

Abeln, 1999).

SCWO provides a potential alternative for processing hazardous military wastes without the concomitant

production of noxious byproducts as might be experienced with combustion-based technologies (Downey et

al., 1995). The process usually operates in a temperature

range of 450600C and pressure range of 2428 MPa.

It consists of the general steps shown in the block flow

diagram in Fig.1. The aqueous waste stream containing the

organic is pressurized and preheated to reactor conditions.

The oxidant stream, which can be an aqueous solution

of hydrogen peroxide, pure oxygen, or air, is pressurized

and mixed with the organic stream. The one-phase mixture

of water, organic and oxidant enters the reaction zone,

Fig. 1 Block flow diagram of typical SCWO process.

No. 5

Supercritical water oxidation for the destruction of toxic organic wastewaters: A review

where both organic compounds and oxygen are completely

soluble, and the temperature is high enough that free

radical oxidation reactions proceed rapidly. The organic

oxidizes rapidly and completely (destruction efficiency

>99.99% with residence times less than one minute) to

CO2 and H2 O (Tester et al., 1993; Savage et al., 1995;

Schmieder and Abeln, 1999; Modell, 1989).

If any nitrogen is present, either introduced with the

waste or if air is used as the source of O2 , the resulting

product is N2 or N2 O (Killilea and Swallow, 1992). NO x

and SO x gases, typical undesired by-products of combustion processes, are not formed because the temperature

is too low for these oxidation pathways to be favored.

Any N2 O found can be catalytically converted to N2 .

Heteroatoms (e.g., chlorine, phosphorous, sulfur) react to

form their corresponding mineral acids. With the addition

of a suitable base, acids are neutralized and form their

corresponding salts which precipitate out of the reacting

mixture allowing for their removal. It has already been

proved that SCWO is an environment friendly waste

treatment technology that produces disposable clean liquid

(pure water), clean solid (metal oxides) and clean gases

(CO2 and N2 ) (Bianchetta et al., 1999; Brunner, 1994;

Fang et al., 2000, 2005; Goto et al., 1999; Kritzer and

Dinjus, 2001; Kronholm et al., 2003; Lee et al., 2004; Rice

and Steeper, 1998; Sullivan and Tester, 2004; Veriansyah et

al., 2005a, 2005b, 2005c).

2 Toxic organic wastes treated with supercritical water oxidation

The SCWO process as a hazardous waste treatment

technology has been proven to be a viable and effective

technique by both academia and industrial researchers.

These researchers showed that SCWO indiscriminately

and rapidly destroys a broad spectrum of organic wastes.

SCWO has been shown effective in the treatment of toxic

chlorinated chemicals such as polychlorinated biphenyls

(PCBs) (Anitescu and Tavlarides, 2000, 2002, 2005; Anitescu et al., 2004, 2005; Fang et al., 2004, 2005; Hatakeda

et al., 1997a, 1997b, 1999; Kubatova et al., 2003; OBrien

et al., 2005; Rahuman et al., 2000; Sako et al., 1999;

Staszak et al., 1987; Weber et al., 2002) and the pesticide

DDT (Modell, 1990), bacteria and dioxins (Thomason et

al., 1990), chlorophenol and chlorobenzene (Lin et al.,

1998, 1999; Lin and Wang, 1999a, 1999b, 2000a, 2000b,

2001; Muthukumaran and Gupta, 2000; Namasivayam and

Kavitha, 2003; Svishchev and Plugatyr, 2006) process

waste waters (Li et al., 1993; Sawicki and Casas, 1993;

Park et al., 2003; Portela et al., 2001a; Veriansyah et al.,

2005b), and pharmaceutical and biopharmaceutical waste

(Aki and Abraham, 1999; Johnston et al., 1988; Qi et

al., 2002). Compounds which are problematic to recycle

or dispose due to the formation of hazardous by-products

and residues such as the polymer polyvinylchloride

(PVC), the flame retardant tetrabromobisphenol A, and the

chlorocarbon -hexachlorocyclohexane and hexachlorocyclohexane, are completely oxidized without hazardous

by-product formation (Hirth et al., 1998). SCWO has

515

also been shown effective in the treatment of a highly

contaminated activated sludge (Patterson et al., 2001;

Griffith and Raymond, 2002; Stendahl and Jafverstrom,

2003), municipal sludges (Shanableh and Gloyna, 1991;

Tongdharmachart and Gloyna, 1991; Goto et al., 1997;

Mizuno et al., 2000), sludges from the pulp and paper

industry (Modell, 1990; Modell et al., 1992, 1995), deinking sludge from the recycle paper industry (Gidner and

Stenmark, 2002), and a combination of sludge from a primary clarifier mixed with effluent from a bleach plant and a

decant of pond sludge (Cooper et al., 1997). Additionally,

wastes which are typically treated by a bioremediation

process, such as urea (Timberlake et al., 1982), human

wastes (Hong et al., 1987, 1988), and waste from manned

space missions (Takahashi et al., 1988) are all destroyed

by SCWO.

SCWO process has been identified as a promising

alternative technology to incineration for the destruction

of the chemical weapons stockpile (NRC, 1993). In the

US, approximately 25000 t of chemical weapons are

slated for destruction by 2006. Originally in 1982, these

weapons were to be incinerated at each of the eight storage

sites in the continental USA (Umatilla Depot Activity,

Oregon; Tooele Army Depot, Utah; Pueblo Depot Activity,

Colorado; Pine Bluff Arsenal, Arkansas; Newport Army

Ammunition Plant, Indiana; Lexington Blue Grass Depot

Activity, Kentucky; Anniston Army Depot, Alabama; and

Aberdeen Proving Ground, Maryland) and on Johnston Island in the Pacific (Harigel, 2000; Hogendoorn, 1997). Due

to operational problems at the Johnston Island incinerator,

the increasingly poor public perception of incineration and

the unanticipated local public opposition to building new

incinerators at the remaining storage locations, the Army

was forced to consider alternative methods for destroying

these weapons in the early 1990s (U.S. Congress, 1992).

In that report, SCWO was selected as one of four possible

alternative technologies.

SCWO has been shown effective for destroying the

stockpiled chemical warfare agents (Bianchetta et al.,

1999; Downey et al., 1995; Lachance et al., 1999; Snow

et al., 1996; Sullivan and Tester, 2004; Veriansyah et al.,

2005a, 2005c, 2006), propellants and energetics (Buelow,

1990, 1992; Harradine et al., 1993), and military smokes

and dyes (Robinson, 1992; Rice et al., 1994). Because of

the ability of SCWO to destroy broad classes of organic

wastes and its ability to destroy chemical warfare agents,

the three branches of USA military are building SCWO

units for their purposes. The USA Navy is developing compact SCWO units for the on-board treatment of hazardous

wastes (Kirts, 1995; Cohen et al., 1998). The USA Army

commissioned Foster Wheeler Development Corporation

in conjunction with Sandia National Laboratories and

Gencorp Aerojet to build a SCWO facility at the Pine

Bluff Arsenal in Arkansas for destroying smokes, dyes,

and pyrotechnics (Haroldsen et al., 1996a, 1996b). The

Army is also undergoing testing the SCWO facility built by

General Atomics in Toole, Utah for treating VX and GB.

The USA Air Force awarded a contract to General Atomics

to design a plant for destroying solid rocket propellant

516

VERIANSYAH Bambang et al.

(Hurley, 1996).

3 Supercritical water oxidation reactor system

3.1 Batch system

Various batch reactors suitable for conducting SCWO

of organic waste are described in the literature (Calvo and

Vallejo, 2002; Goto et al., 1999; Mizuno et al., 2000;

Portela et al., 2001b; Jin et al., 2001; Lachance et al., 1999;

Thornton and Savage, 1992). This reactor usually has two

temperature zones, the upper part, to keep the reactor above

critical temperature, and the lower part, to dissolve the salt

precipitant at subcritical temperature (Kupferer, 2002).

Vol. 19

3.2.2 Floating type reactor (SUWOX)

SUWOX was designed to prevent corrosion problem,

which was solved by dividing the construction into two

vessels, the pressure-resistant vessel and the inner vessel

(Casal and Schmidt, 1998). Fig.3 shows the design of the

reactor. The SCWO reaction occurs in the inner nonporous

vessel. Between those two vessels, there is a gap for small

stream of water.

3.2 Continuous-flow system

Organic waste treated by SCWO mostly conduct in

continuous-flow system. This is due to its flexibility for

expansion to plant or industrial scale. The type of reactor is

developed from basic tubular type to the current transpiring

wall reactor (Crooker et al., 2000; Fauvel et al.,2003, 2005;

Lee et al.,2005; Marrone et al., 2004, 2005; Wellig et al.,

2005).

3.2.1 Transpiring wall reactor (TWR)

The concept behind the TWR design includes a dual

shell consisting of an outer pressure-resistant vessel and

an inner porous vessel (Daman, 1996; Kritzer and Dinjus,

2001). Through the porous wall, supercritical water will

get through to form a thin, protecting water film. Through

this complex perspiration system, the porous liner is said

to protect the reactor against corrosion and salt deposition.

Fig.2 shows a simple schematic diagram of TWR. Some

group have developed a hydrothermal flame as internal

heat source in TWR (Wellig et al., 2005) and another group

have studied its application on halogenated hydrocarbons

(2,4-dichlorophenol) with 98.7% conversion at residence

time of 32 s., temperature of 713 K and pressure of 25

MPa (Lee et al., 2005). Current study and review related to

this type of reactor is described in literature (Fauvel et al.,

2003, 2005; Marrone et al., 2004, 2005).

Fig. 3 SUWOX reactor (Baur et al., 2005).

Extensive study for this type of reactor was conducted

in Germany (Baur et al., 2005). They explore four types

of SUWOX-base reactor for biocides treatment in SCWO.

The destruction of organic with conversion 99.9% could be

achieved, even at low oxygen supply and the shortest residence time (1.37 min). Salt content in the effluent remained

dissolve, with concentration >200 g/L (NaCl). Another

group, successfully decomposed 2,4-dichlorophenol with

99.9% conversion at residence time of 34 s, temperature

of 693 K and pressure of 25 MPa (Lee et al., 2005). This

result was higher, compare to when they employed TWR

at the similar conditions.

4 Industrial status

Fig. 2 Transpiring wall reactor (Daman, 1996).

Several reviews have summarized the current general

state of SCWO technology, as well as pilot work recently performed or in progress in support of a number

of applications (Kritzer and Dinjus, 2001; NRC, 1998;

Schmieder and Abeln, 1999; Shaw and Dahmen, 2000;

Tester and Cline, 1999; Yoo et al., 2004). The promotion

of SCWO for treating industrial wastes has also met

with limited success. The main drawbacks are the high

operating pressure, possible of the reactor plugging due

to salt formation, corrosive behavior under certain T-P-

No. 5

Supercritical water oxidation for the destruction of toxic organic wastewaters: A review

xi conditions, and pre-commercial higher processing costs.

With active research underway to understand and resolve

the problems of plugging from salts and corrosion, the

development of novel reactor designs to alleviate these

problems and the disappearance of landfills, SCWO may

yet become a viable waste treatment option for industrial

wastes and find a nice market (Hodes et al., 2004; Kritzer

et al., 1999; Kritzer and Dinjus, 2001; Kritzer, 2004).

An even more serious problem facing SCWO having

nothing to do with the process itself is the unwillingness of

industries to invest in novel, and potentially superior, waste

treatment technologies. This barrier will likely prove more

difficult than the technical problem facing SCWO. Regulatory pressure does not suffer from these constraints, and

changes in industrial effluent discharge regulations may

be needed. The success of SCWO in treating the military

waste will be important for its industrial acceptance.

Table 1 contains a list of full-scale facilities and licensees of the SCWO processes developed by several

companies, along with recent feed material that have been

processed. MODAR, Inc., the first company to attempt to

exploit the technology commercially, performed extensive

studies of destruction efficiencies for organic compound

in the 1980s and early 1990s in an attempt to validate

the SCWO process and develop large-scale reactor system

for treating industrial wastes. MODAR, Inc., was acquired

by General Atomics (GA) in 1996, but GA is currently

only using the technology for treating military wastes.

A full-scale SCWO facility based on MODAR process

(i.e., reverse flow, tank reactor) was constructed by Organo

Co. by Japan in 1998 (Oe et al., 1998). In addition to

having a licence to the MODAR process, organo is a licensee of the MODEC process (designed a SCWO reactor

system capable of avoiding the salt plugging problems

and eliminating corrosion issues for many wastes). Two

other Japanese companies, Hitachi Plant Engineering and

Construction Co. and NGK Insulator Ltd., and a Canadian

firm, NORAM Engineering and Constructors, Ltd., are

517

also MODEC licensee. Hitachi and NGK are interested in

developing the MODEC process further for sewage sludge

treatment (Japan Chemical Week, 1998).

Both GA and Foster Wheeler have been very active in

recent years with several projects being conducted for three

branches of the U.S. Armed Forces. GA has demonstrated

successful treatment of chemical agent (HD, GB and VX)

hydrolysate and energetics hydrolysate/secondary wastes

for the U.S. Armys Assembled Chemical Weapons Assessment (ACWA) program (U.S. DOD ACWA, 1999),

SCWO is part of GAs Total Solution proposed to ACWA

for demilitarization of the complete munition (projectiles,

mortars, rockets) and associated storage and processing materials. The energetics hydrolysate/secondary waste

feeds consisted of slurry of hydrolyzed energetics (tetrytol, Composition B, and/or M28 propellant) along with

shredded wood, plastics, and activated carbon. GA recently

completed further pilot testing for ACWA in support of a

full-scale design for demilitarization of chemical weapons

stored in Pueblo, CO, and Lexington, KY (U.S. DOD

ACWA, 2002). GA also designed and tested a compact

SCWO system for the U.S. Navy in 1999 for destruction

of shipboard wastes (Elliott et al., 2000). GA conducted

hydrolysis and SCWO testing of rocket motor propellant

for the USA Air Force in 1995 using a 1 gpm (3.8 L/min)

pilot-scale system (Defense, 1995). The Japanese companies Komatsu, Ltd., and Kurita Water Industries, Ltd., have

a licensing agreement with GA in commercializing SCWO

technology in Asia (Schmieder and Abeln, 1999).

Foster Wheeler constructed a full-scale SCWO system

based on their transpiring wall reactor design for the U.S.

Armys Pine Bluff Arsenal in Arkansas in 1998 (Crooker

et al., 2000). The system was designed to treat obsolete

smoke and dye munitions at a rate of 80 lb/h (36 kg/h)

of munitions. It is being operated by Sandia National

Laboratories and has been undergoing extensive systemization with surrogate feed materials since construction

completion. Foster Wheeler has also conducted pilot-scale

Table 1 Commercially designed SCWO facilities currently in existence

Company

Licenses

Large-scale plants

Application

MODAR

Organo

Semiconductor manufacture wastes

MODEC

Organo, Hitachi,

NGK

Komatsu, Kurita

Waste Industries

Nittetsu Semiconductor,

Japan (constructed by Organo)

None

General Atomics

Foster-Wheeler

U.S. Army Newport Chemical

Depot, Newport, IN

EcoWaste

Technologies (EWT)

Chematur

Chematur

U.S. Army Pine Bluff Arsenal,

Pine Bluff, AR (operate by

Sandia National Laboratory)

Huntsman Chemical, Austin, TX

Shinko Pantec

Johnson Matthey, Brimsdown, UK

SRI International

Mitsubishi Heavy

Industries

Hydro-Processing

Hanwha Chemical

Japan (constructed by Shinko Pantec)

Japan

Harlingen Wastewater Treatment

Plant No.2, Harlingen, TX

Namhae Chemical Corp, Korea

Pharmaceutical wastes, pulp, and paper mill wastes,

sewage sludge

Bulk VX nerve agent hydrolysate; other feed processed

in smaller-scale system; chemical agent, explosives, and

dunnage (U.S. Army), shipboard wastes (U.S. Navy),

rocket, propellant (U.S. Army Force)

Smokes and dyes; other feeds processed in smallerscale systems: chemical agent and explosives

(U.S. Army), shipboard wastes (U.S. Navy)

Oxygenated and nitrogen-containing hydrocarbon

(e.g., alcohols, glycols, amines)

Spent catalyst (recover platinum group metals and

destroy organic contaminants)

Municipal sludge

PCBs, chlorinated wastes

Mixed municipal and industrial wastewater sludge

Wastewater from DNT/MNT Plant and Melamine Plant

518

VERIANSYAH Bambang et al.

testing of a transpiring wall SCWO system for the USA

Navy and Army ACWA program similar to that described

for GA. Testing for the Navy was performed in 1999

with halogenated solvents and photographic solution feeds

at 80209 lbs/h (3695 kg/h) (Crooker et al.,2000). The

same system was used for ACWA testing in 2000, in

which mixtures of agent (HD, GB, VX) and energetic

(tetrytol, Composition B, M28 propellant) hydrolysates

were processed with minimal corrosion and salt buildup

in the reactor (U.S. DOD ACWA, 2001). Foster Wheeler is

part of a team whos proposed Total Solution to ACWA for

munition demilitarization includes co-processing of agent

and energetic hydrolysates via SCWO as demonstrated.

The hydrolysate feed recipes were chosen to represent

compositions expected from processing actual munitions.

Foster Wheeler recently completed further pilot testing

for ACWA in 2002 in support of a full-scale design for

demilitarization of chemical weapons stored in Lexington,

KY.

EcoWaste Technologies (EWT) designed and built the

first operating commercial SCWO plant in the USA. The

plant was constructed for the Huntsman Co. (formerly

Texaco Chemical Co.) in Austin, TX, for destruction

of non-halogenated organic wastes produced on-site at

their Austin Research Laboratories. The tubular reactor

system began operation in 1994. The waste feed consisted

primarily of a blend of alcohols, glycols, and amines with

an overall organic loading of 10 wt%, and was fed at a rate

of 2425 lb/h (1100 kg/h) (McBrayer et al., 1996).

Chematur Engineering (1999) acquired a licensing

agreement for the EWT SCWO process in Europe in 1995,

and acquired the exclusive world-wide rights for EWT

SCWO in 1999. SCWO is marketed by Chematur under

the trade name Aqua Critoxr . Chematur built a 550 lb/h

(250 kg/h) pilot-scale SCWO system in 1998 that has since

been tested with several mostly nitrogen-containing wastes

(amine production wastes, non-halogenated spent cutting

fluid, de-inking sludge, and sewage sludge) (Stenmark,

2001; Gidner and Stenmark, 2002). Chematur has also

constructed its first full-scale SCWO facility for Johnson

Matthey in the UK (Chematur, 2001). Chematur has licensed the EWT SCWO process to the Shinko Pantec

Co. of Japan. Under this license agreement, Shinko Pantec

has constructed an 2425 lb/h(1100 kg/h) SCWO plant for

treating municipal sludge, which was commissioned in

2000.

SRI International granted its first licensing agreement of

the AHO process (i.e., carbonate-filled reactor for catalytic

oxidation and salt product adsorption) to Mitsubishi Heavy

Industries (MHI) in 1999 (Waste Treatment Technology

News, 1999). MHI has been working with SRI on commercializing the AHO process since 1995, and plans to

use it to destroy polychlorinated biphenyl (PCB) wastes

at commercial facilities. Since 1998, MHI has conducted

tests with PCBs in a pilot-scale system in Japan, demonstrating greater than 99.9999% destruction at 380C and

270 atm. MHI also owns a patent on the AHO process

as applied to PCB decomposition (Tateishi et al., 2000).

MHI is currently designing the first full-scale commercial

Vol. 19

AHO system in Japan for PCB destruction, with plans to

build several more plants for both government and private

clients.

HydroProcessing, LLC, has focused on the application

of SCWO for treating municipal wastewater sludge. Their

patented process (Griffith et al., 1999), referred to as the

HydroSolidsr process, is intended to replace traditional sludge digestion and dewatering units in a standard

wastewater treatment plant. They have operated a 0.4 gpm

(1.5 L/min) tubular reactor pilot system with this feed since

1996, and have built a full-scale system for the Harlingen

Wastewater Treatment Plant in Harlingen, TX. The system

is intended to process both municipal wastewater sludge

and industrial wastewater sludge from an adjacent factory

(Wofford and Griffith, 2001). HydroProcessing states that

operating costs are about 180 USD/t (dry) on (not including any projected benefits from energy or CO2 recovery),

compared to a cost of 275 USD/t for sludge disposal by

landfill or land application (Parkinson, 2001). Because of

the inherently greater amount of solids contained in the

sludge feed (as compared to liquid wastes), the process

incorporates a hydrocyclone after the reactor for solids

removal, and a separate patented downstream system for

handling pressure letdown of the solids-containing effluent

stream.

There are other companies trying to commercialize

SCWO technology, as well. For example, Hanwha Chemical has constructed 2000 kg/h SCWO plant for treating

DNT/MNT Plant wastewater and 35000 kg/h SCWO

plant for treating Melamine Plant wastewater, which

were commissioned in 2000 (Hanwha Chemical, 2000).

ProChemTech International, Inc. designed and built a

small tubular SCWO system of 0.1 gpm (0.4 L/min) capacity in 1993 for treating organic-laden wastewater from a

semi-conductor manufacturer (ProChemTech, 2004). Noram Engineering and Constructors, Ltd., has recently been

issued a patent (Boyd et al., 2001) on a process for

utilizing SCWO for oxidation of redwater (a waste from

the manufacture of nitroaromatic explosive compounds).

Daimler Chrysler of Germany has also been interested in

the application of SCWO for the treatment of electronic

scrap (e.g., circuit boards) and, in collaboration with the

Fraunhofer Institute ITC, has built a mobile plant (20

L/h) containing a tubular reactor for treating this waste

(Schmieder and Abeln, 1999).

5 Conclusions

SCWO provides a potential alternative for processing

hazardous and toxic organic wastes without the concomitant production of noxious byproduct, as might be

experienced with combustion based technologies. The

primary challenges that are inhibiting the rapid commercialization of SCWO are the high operating pressure,

possible plugging of the reactor due to salt formation,

corrosive behavior, and pre-commercial higher processing

costs. With active research underway to understand and

resolve the problems of plugging from salts and corrosion,

the development of novel reactor designs to alleviate these

No. 5

Supercritical water oxidation for the destruction of toxic organic wastewaters: A review

problems and the disappearance of landfills, SCWO may

yet become a viable waste treatment option for industrial

wastes and find a nice market. Given the resolution of reliability and other engineering issues, SCWO technology has

the potential to stake a claim in toxic waste management

industry and to return a sufficient profit.

Acknowledgements

This work has been supported by the Korea Institute of

Science and Technology (KIST) program for supercritical

fluid research. The authors would like to thank to the Korea

Institute of Science and Technology, Korea.

References

Aki S N V K, Abraham M A, 1999. Catalytic supercritical

water oxidation of pyridine: kinetic and mass transfer[J].

Chemical Engineering Science, 54: 35333542.

Anitescu G, Tavlarides L L, 2000. Oxidation of aroclor 1248 in

supercritical water: a global kinetic study[J]. Industrial &

Engineering Chemistry Research, 39: 583591.

Anitescu G, Tavlarides L L, 2002. Methanol as a cosolvent and rate-enhancer for the oxidation kinetics of

3,30 ,4,40 -tetrachlorobiphenyl decomposition in supercritical

water[J]. Industrial & Engineering Chemistry Research, 41:

921.

Anitescu G, Tavlarides L L, Munteanu V, 2004. Decomposition

of monochlorobiphenyl isomers in supercritical water in the

presence of methanol[J]. American Institute of Chemical

Engineers Journal, 50: 15361544.

Anitescu G, Tavlarides L L, 2005. Oxidation of biphenyl in supercritical water: reaction kinetics, key pathways, and main

products[J]. Industrial & Engineering Chemistry Research,

44: 12261232.

Anitescu G, Munteanu V, Tavlarides L L, 2005. Co-oxidation

effects of methanol and benzene on the decomposition

of 4-chlorobiphenyl in supercritical water[J]. Journal of

Supercritical Fluids, 33: 139147.

Baur S, Schmidt H, Kramer A et al., 2005. The destruction of

industrial aqueous waste containing biocides in supercritical waterdevelopment of the SUWOX process for the

technical application [J]. Journal of Supercritical Fluids, 33:

149157.

Bianchetta S, Li L, Gloyna E F, 1999. Supercritical water oxidation of methylphosphonic acid[J]. Industrial & Engineering

Chemistry Research, 38: 29022910.

Boock L T, 1996. A quantitative analysis of reactions in

supercritical water: experimental kinetics and mechanistic modeling[D]. Ph.D. Dissertation. The University of

Delaware.

Boyd D A, Gairns S A, Guenkel A A, 2001. Integrated effluent

treatment process for nitroaromatic manufacture[P]. USA

Patent 6 288 289.

Brunner G D, 1994. Extraction and destruction of waste with

supercritical water[M]. In: Supercritical fluids (Kiran E.,

Sengers J. M. H. L., ed.). The Netherlands: Kluwer Academic Publisher. 697705.

Buelow S J, 1990. Destruction of propellant components in supercritical water[Z]. LA-UR-90-1338, Los Alamos National

Laboratory.

Buelow S J, 1992. Chemical reactions of nitrogen containing

compounds in supercritical water[C]. In: Proceedings of

Workshop on Federal Programs Involving Supercritical

519

Water Oxidation, Gaithersburg, MD. 7.

Calvo L, Vallejo D, 2002. Formation of organic acids during

the hydrolysis and oxidation of several wastes in sub- and

supercritical water[J]. Industrial & Engineering Chemistry

Research, 41: 65036509.

Casal V, Schmidt H, 1998. SUWOXa facility for the destruction

of chlorinated hydrocarbons[J]. Journal of Supercritical

Fluids, 13: 269276.

Chematur A B, 1999. Company web page[EB]. http://www.

chematur.se, news release dated February 18, 1999.

Chematur A B, 2001. Company web page[EB]. http://www.

chematur.se, news release dated November 26, 2001.

Cohen L S, Jensen D, Lee G et al., 1998. Hydrothermal oxidation

of navy excess hazardous materials[J]. Waste Management,

18: 539546.

Cooper S P, Folster H G, Gairns S A et al., 1997. Treatment of

lagoon sludge, primary clarifier sludge, and bleach plant

effluent by supercritical water oxidation[J]. Pulp & PaperCanada, 98(10): 3741.

Crooker P J, Ahluwalia K S, Fan Z, 2000. Operating results

from supercritical water oxidation plants[J]. Industrial &

Engineering Chemistry Research, 39: 48654870.

Daman E L, 1996. Process and apparatus for supercritical water

oxidation[P]. USA Patent 5 571 423.

Defense Daily, 1995. General Atomics successfully destroys

rocket motor propellant (Use of hydrothermal oxidation for

disposal of solid rocket motor propellant and hazardous

materials)[N]. Defense Daily, 188(27): 210.

Downey K W, Snow R H, Hazlebeck D A et al., 1995. Corrosion

and chemical agent destruction: research on supercritical water oxidation of hazardous military wastes[M]. In:

Innovation in supercritical fluids science and technology

(Hutchenson K. W., Foster N. R., ed.). Washington DC:

American Chemical Society. ACS Symposium Series #608,

Chapter 21.

Elliott J P, Hazlebeck D A, Ordway D W et al., 2000. Update

on hydrothermal oxidation developments on DARPA/ONR

and air force projects at General Atomic[C]. In: Proceedings of the International Conference on Incineration and

Thermal Treatment Technologies, Portland, OR. 25.

Fang Z, Xu S K, Kozinski J A, 2000. Behavior of metals during

combustion of industrial organic wastes in supercritical

water[J]. Industrial & Engineering Chemistry Research, 39:

45364542.

Fang Z, Xu S K, Butler I S et al., 2004. Destruction of

decachlorobiphenl using supercritical water oxidation[J].

Energy & Fuels, 18: 12571265.

Fang Z, Xu S K, Smith Jr R L et al., 2005. Destruction of

deca-chlorobiphenyl in supercritical water under oxidizing

conditions with and without Na2 CO3 [J]. Journal of Supercritical Fluids, 33: 247258.

Fauvel E, Joussot-Dubien C, Pomier E et al., 2003. Modeling of

a porous reactor for supercritical water oxidation by a residence time distribution study[J]. Industrial & Engineering

Chemistry Research, 42: 21222130.

Fauvel E, Joussot-Dubien C, Tanneur V et al., 2005. A porous reactor for supercritical water oxidation: experimental results

on salty compounds and corrosive solvents oxidation[J].

Industrial & Engineering Chemistry Research, 44: 8968

8971.

Gidner A, Stenmark L, 2002. Oxidation of de-inking sludge

in supercritical water[R]. In: Workshop of managing

pulp and paper process residues, Barcelona, Spain (Report is also available on the chematur company website:

520

VERIANSYAH Bambang et al.

http://www.chematur.se ).

Goto M, Nada T, Kawajiri S et al., 1997. Decomposition of municipal sludge by supercritical water oxidation[J]. Journal

of Chemical Engineering of Japan, 30(5): 813818.

Goto M, Nada T, Kodama A et al., 1999. Kinetic analysis

for destruction of municipal sewage sludge and alcohol

distillery wastewater by supercritical water oxidation[J].

Industrial & Engineering Chemistry Research, 38: 1863

1865.

Griffith J W, Wofford W T, Griffith J R, 1999. Apparatus for

oxidizing undigested wastewater sludges[P]. USA Patent 5

888 389.

Griffith J W, Raymond D H, 2002. The first commercial supercritical water oxidation sludge processing plant[J]. Waste

Management, 22: 453459.

Hanwha Chemical[EB], 2000. http://hcc.hanwha.co.kr/English/

Product/newbusiness clean05. html, company webpage.

Harigel G G, 2000. The concept of weapons of mass destruction:

Chemical and biological weapons, use in warfare, impact

on society and environment[C]. In: Proceeding of Seventh

ISODARCO-Beijing Seminar on Arms Control, Xian, China.

Haroldsen B L, Ariizumi D Y, Mills B E et al., 1996a. Transpiring

wall supercritical water oxidation reactor salt deposition

studies[R]. Sandia National Laboratories, Livermore, CA

SAND96-8213 UC-702.

Haroldsen B L, Ariizumi D Y, Mills B E et al., 1996b. Transpiring wall supercritical water oxidation test reactor design

report[R]. Sandia National Laboratories, Livermore, CA,

SAND96-8213 UC-402.

Harradine D M, Buelow S J, DellOrco P C et al., 1993.

Oxidation chemistry of energetic materials in supercritical

water[J]. Hazardous Waste and Hazardous Materials, 10(2):

233246.

Hatakeda K, Ikushima Y, Ito S et al., 1997a. Supercritical water

oxidation of a PCB of 3-chlorobiphenyl using hydrogen

peroxide[J]. Chemistry Letters, 3: 245246.

Hatakeda K, Ikushima Y, Ito S et al., 1997b. Supercritical water

oxidation (SCWO) of polychlorinated biphenyls (PCBs)

using hydrogen peroxide[C]. In: Proceeding of 4th International Symposium on Supercritical Fluids, Sendai, Japan.

Hatakeda K, Ikushima Y, Sato O et al., 1999. Supercritical

water oxidation of polychlorinated biphenyls using hydrogen peroxide[J]. Chemical Engineering Science, 54(15/16):

30793084.

Hirth T, Heck L, Jahnke S et al., 1998. Supercritical water

oxidationwaste destruction and synthesis[C]. In: Koatsuryoku no Kagaku to Gijutsu 7 (Proceedings of International Conference-AIRAPT-16 and HPCJ-38-on High

Pressure Science and Technology, 1997). 1375.

Hodes M, Marrone P A, Hong G T et al., 2004. Salt precipitation

and scale control in supercritical water oxidation: Part

A. Fundamental and research[J]. Journal of Supercritical

Fluids, 29: 265288.

Hogendoorn E J, 1997. A chemical weapons atlas[J]. Bulletin of

the Atomic Scientists, 53(5): 3539.

Hong G T, Fowler P K, Killilea W R et al., 1987. Supercritical

water oxidation: treatment of human waste and system

configuration tradeoff study[C]. In: Proceeding of 17th Intersociety Conference on Environmental Systems, Seattle,

WA.

Hong G T, Killilea W R, Thomason T B, 1988. Supercritical

water oxidation: space application[C]. In: Proceedings of

ASCE Space, Albuquerque, NM.

Vol. 19

Hurley J A, 1996. Development of hydrothermal oxidation reactor technology for the destruction of hazard class 1.1.

propellant[C]. Presented at the Third International Conference on Advanced Oxidation Technologies for Water and

Air Remediation, Cincinnati, OH.

Japan Chemical Week, 1998. Supercritical water oxidation process inducted from U.S[Z]. Hitachi Plant Engineering and

Construction and NGK Insulators licenses supercritical

water oxidation technology from Modec Corp. 7.

Jin F M, Kishita A, Moriya T et al., 2001. Kinetics of oxidation

of food wastes with H2 O2 in supercritical water[J]. Journal

of Supercritical Fluids, 19: 251262.

Johnston J B, Hannah R E, Cunningham V L et al., 1988. Destruction of pharmaceutical and biopharmaceutical waste by

MODAR supercritical water oxidation process[J]. Biotechnology, 6: 14231427.

Killilea W R, Swallow K C, 1992. The fate of nitrogen in

supercritical-water oxidation[J]. Journal of Supercritical

Fluids, 5: 7278.

Kirts R E, 1995. Destruction of Navy hazardous wastes by

supercritical water oxidation[C]. In: Proceedings of Annual

MeetingAir Waste Management Association. 9.

Kritzer P, Boukis N, Dinjus E, 1999. Factors controlling corrosion

in high-temperature aqueous solutions: a contribution to

the dissociation and solubility data influencing corrosion

processes[J]. Journal of Supercritical Fluids, 15: 205227.

Kritzer P, Dinjus E, 2001. An assessment of supercritical water

oxidation (SCWO) existing problems, possible solutions

and new reactor concepts[J]. Chemical Engineering Journal, 83: 207214.

Kritzer P, 2004. Corrosion in high-temperature and supercritical

water and aqueous solutions: a review[J]. Journal of Supercritical Fluids, 29: 129.

Kronholm J, Kuosmanen T, Hortonen K et al., 2003. Destruction

of PAHs from soil by using pressurized hot water extraction

coupled with supercritical water oxidation[J]. Waste Management, 23: 253260.

Kubatova A, Herman J, Steckler T S et al., 2003. Subcritical

(hot/liquid) water dechlorination of PCBs (Aroclor 1254)

with metal additives and in waste paint[J]. Environ Sci

Technol, 37: 57575762.

Kupferer D N, 2002. An evaluation of supercritical water oxidation technology[D]. Master Thesis. Massachussets Institute

of Technology.

Lachance R, Paschkewitz J, DiNaro J et al., 1999. Thiodiglycol

hydrolysis and oxidation in sub- and supercritical water[J].

Journal of Supercritical Fluids, 16: 133147.

Lee H C, In J H, Hwang K Y et al., 2004. Decomposition

of ethylenediaminetetraacetic acid by supercritical water

oxidation[J]. Industrial & Engineering Chemistry Research,

43: 32233227.

Lee H C, In J H, Lee S Y et al., 2005. An anti-corrosive reactor

for the decomposition of halogenated hydrocarbons with

supercritical water oxidation[J]. Journal of Supercritical

Fluids, 36: 5969.

Li L, Chen P, Gloyna E F, 1991. Generalized kinetic model for

wet oxidation of organic compounds[J]. American Institute

of Chemical Engineers Journal, 37(11): 16871697.

Li L, Gloyna E F, Sawicki J E, 1993. Treatability of DNT process wastewater by supercritical water oxidation[J]. Water

Environment Research, 62: 250257.

Lin K S, Wang H P, Li M C, 1998. Oxidation of 2,4dichlorophenol in supercritical water[J]. Chemosphere,

36(9): 20752083.

No. 5

Supercritical water oxidation for the destruction of toxic organic wastewaters: A review

Lin K S, Wang H P, 1999a. Rate enhancement by cations in

supercritical water oxidation of 2-chlorophenol[J]. Environmental Science and Technology, 33(18): 32783280.

Lin K S, Wang H P, 1999b. Shape selectivity of trace by-products

for supercritical water oxidation of 2-chlorophenol effected

by CuO/ZSM-48[J]. Applied Catalysis B: Environmental,

22: 261267.

Lin K S, Wang H P, Yang Y W, 1999. Supercritical water oxidation of 2-chlorophenol effected by Li+ and CuO/zeolites[J].

Chemosphere, 39(9): l3851396.

Lin K S, Wang H P, 2000a. Byproduct shape selectivity in

supercritical water oxidation of 2-chlorophenol effected by

CuO/ZSM-5[J]. Langmuir, 16: 26272631.

Lin K S, Wang H P, 2000b. Supercritical water oxidation of 2chlorophenol catalyzed by Cu2+ cations and copper oxide

clusters[J]. Environ Sci Technol, 34: 48494854.

Lin K S, Wang H P, 2001. Catalytic oxidation of 2-chlorophenol

in confined channels of ZSM-48[J]. Journal Physical Chemistry B, 105: 49564960.

Marrone P A, Hodes M, Smith K A et al., 2004. Salt precipitation

and scale control in supercritical water oxidationpart B:

commercial/full-scale applications[J]. Journal of Supercritical Fluids, 29: 289312.

Marrone P A, Cantwell S D, Dalton D W, 2005. SCWO system designs for waste treatment: application to chemical

weapons destruction[J]. Industrial & Engineering Chemistry Research, 44: 90309039.

McBrayer R N, Griffith J W, Gidner A, 1996. Operation of

the first commercial supercritical water oxidation industrial

waste facility[C]. In: Proceedings of International Conference on Oxidation Technologies for Water and Wastewater

Treatment.

Mizuno T, Goto M, Kodama A et al., 2000. Supercritical water

oxidation of municipal solid waste[J]. Industrial & Engineering Chemistry Research, 39: 28072810.

Modell M, 1989. Supercitical water oxidation[M]. In: Standard

handbook of hazardous waste treatment and disposal (Freeman H.M., ed.). New York: McGraw-Hill.

Modell M, 1990. Treatment of pulp mill sludges by supercritical

water oxidation[R]. Final Report, DOE Contract No. FG0590CE40914.

Modell M, Larson J, Sobczynski S F, 1992. Supercritical water

oxidation of pulp mill sludges[J]. Tappi Journal, 75: 195202.

Modell M, Mayr S, Kemna A, 1995. Supercritical water oxidation

of aqueous wastes[C]. In: Proceedings of 56th Annual

International Water Conference, Pittsburgh, PA. 478.

Muthukumaran P, Gupta R B, 2000. Sodium-carbonate-assisted

supercritical water oxidation of chlorinated waste[J]. Industrial & Engineering Chemistry Research, 39: 45554563.

Namasivayam C, Kavitha D, 2003. Adsorptive removal of 2chlorophenol by low-cost coir pith carbon[J]. Journal of

Hazardous Materials, 98: 257274.

NRC (National Research Council), 1993. Alternative technology

for the destruction of chemical agents and munitions[M].

Washington, D.C: National Academy Press.

NRC (National Research Council), 1998. Using supercritical

water oxidation to treat hydrolysate from VX neutralization[M]. Washington, D.C: National Academy Press.

OBrien C P, Thies M C, Bruce D A, 2005. Supercritical

water oxidation of the PCB congener 2-chlorobiphenyl in

methanol solutions: a kinetic analysis[J]. Environ Sci and

Technol, 39: 68396844.

Oe T, Suzuki A, Suzugaki H et al., 1998. Commercialization of

521

the first supercritical water oxidation facility for semiconductor manufacturing wastes[C]. In: Proceedings of 1998

Semiconductor Pure Water and Chemicals Conference. 399.

Park T J, Lim J S, Lee Y W et al., 2003. Catalytic supercritical

water oxidation of wastewater from terephthalic acid manufacturing process[J]. Journal of Supercritical Fluids, 26:

201213.

Parkinson G, 2001. Supercritical water oxidation takes on a citys

sludge output[Z]. News-Chementator: Chemical Engineering,

Patterson D A, Stenmark L, Hogan F, 2001. Pilot-scale supercritical water oxidation of sewage sludge[C]. Presented at the

6th European Biosolids and Organic Residuals Conference,

United Kingdom.

Portela J R, Lopez J, Nebot E et al., 2001a. Elimination of cutting

oil wastes by promoted hydrothermal oxidation[J]. Journal

of Hazardous Material, 88: 95106.

Portela J R, Nebot E, Ossa E M, 2001b. Kinetic comparison

between subcritical and supercritical water oxidation of

phenol[J]. Chemical Engineering Journal, 81: 287-299.

ProChemTech International Inc.[EB], 2004. Company web

page, http://www.prochemtech.com/Products/Equipment/

equipment.html.

Qi X H, Zhuang Y Y, Yuan Y C et al., 2002. Decomposition

of aniline in supercritical water[J]. Journal of Hazardous

Material, 90: 5162.

Rahuman M S M M, Pistone L, Trifir`o F et al., 2000. Destruction

technologies for polychlorinated biphenyls (PCBs)[C]. In:

Proceedings of Expert Group Meetings on POPs and Pesticides Contamination: Remediation Technologies and on

Clean Technologies for the Reduction and Elimination of

POPs, Trieste, Italy.

Rice S F, LaJeunesse C A, Hanush R G et al., 1994. Supercritical

water oxidation of colored smoke, dye, and pyrotechnic

composition[Z]. SAND94-8209, Sandia National Laboratory.

Rice S F, Steeper R R, 1998. Oxidation rates of common organic

compounds in supercritical water[J]. Journal of Hazardous

Material, 59: 261278.

Robinson C, 1992. Demilitarization R&D technology for conventional munitions via SCWO of colored smokes, dyes,

and pyrotechnics[C]. In: Proceedings of Workshop on

Federal Programs Involving Supercritical Water Oxidation,

Gaithersburg, MD.

Sako T, Sugeta T, Otake K et al., 1999. Dechlorination of PCBs

with supercritical water hydrolysis[J]. Journal of Chemical

Engineering of Japan, 32(6): 830832.

Savage P E, Gopalan S, Mizan T I et al., 1995. Reactions at

supercritical conditions: application and fundamentals[J].

American Institute of Chemical Engineers Journal, 41(7):

17231778.

Sawicki J E, Casas B, 1993. Wet oxidation systemsprocess

concept to design[J]. Environmental Progress, 12: 275283.

Schmieder H, Abeln J, 1999. Supercritical water oxidation: state

of art[J]. Chemical Engineering and Technology, 22(11):

903908.

Shanableh A, Gloyna E F, 1991. Supercritical water oxidation

wastewater and sludges[J]. Water Science Technology, 23:

389398.

Shaw R W, Dahmen N, 2000. Destruction of toxic organic

materials using supercritical water oxidation: current state

of the technology[M]. In: Supercritical fluids-fundamentals

and application (Kiran E., Debenedetti P. G., Peters C. J.,

ed.). The Netherlands: Kluwer Academic Publishers. 425

522

VERIANSYAH Bambang et al.

437.

Snow R H, Sabato W, Taylor K et al., 1996. Demilitarization

of chemical agents by hydrolysis and supercritical water

oxidation[C]. In: Proceedings of ERDEC Scientific Conference on Chemical and Biological Defense Research. 359.

Staszak C N, Malinowski K C, Killilea W R, 1987. The pilotscale demonstration of the MODAR oxidation process for

the destruction of hazardous waste materials[J]. Environmental Progress, 6(1): 3943.

Stendahl K, Jafverstrom S, 2003. Phosphate recovery from

sewage sludge in combination with supercritical water

oxidation[J]. Water Science Technology, 48(1): 185190.

Stenmark L, 2001. Aqua Critoxr , the Chematur Engineering

concept for SCWO[M]. In: Supercritical water oxidationarchievements and challenges in commercial applications

(Nazeri A., Shaw R. W., Marrone P. A., ed.). Arlington, VA:

Stategic Analysis, Inc.

Sullivan P A, Tester J W, 2004. Methylphosphonic acid oxidation

kinetics in supercritical water[J]. American Institute of

Chemical Engineers Journal, 50(3): 673683.

Svishchev I M, Plugatyr A, 2006. Supercritical water oxidation

of o-dichlorobenzene: degradation studies and simulation

insights[J]. Journal of Supercritical Fluids, 37: 94101.

Takahashi Y T, Wydeven T, Koo C, 1988. Subcritical and

supercritical water oxidation of CELSS model wastes[J].

Advances in Space Research, 9: 99110.

Tateishi M, Tsuchiyama Y, Yamauchi Y et al., 2000. PCB

decompositon process[P]. USA Patent 6 162 958.

Tester J W, Holgate H R, Armellini F J et al., 1993. Supercritical water oxidation technology: a review of Process

Development and Fundamental Research[M]. In: Emerging

technologies in hazardous waste management III (Tedder D.W., Pohland F.G., ed.). Washington, DC: American

Chemical Society. Chapter 3.

Tester J W, Cline J A, 1999. Hydrolysis and oxidation in sub- and

supercritical water: connection process engineering science

to molecular interactions[J]. Corrosion, 55(11): 10881100.

Thomason T B, Modell M, 1984. Supercritical water destruction

of aqueous wastes[J]. Hazardous Waste, 1(4): 453467.

Thomason T B, Hong G T, Swallow K C et al., 1990. The

MODAR supercritical water oxidation process[M]. In:

Innovative hazardous waste treatment technology series

(Freeman H.M., ed.). Lancaster, PA: Technomic Publishing.

Volume I: Thermal Processes.

Thornton T D, Savage P E, 1992. Phenol oxidation pathways in

supercritical water[J]. Industrial & Engineering Chemistry

Research, 31: 24512456.

Timberlake S H, Hong G T, Simson M et al., 1982. Supercritical

water oxidation for wastewater treatment: preliminary study

of urea destruction[C]. In: Proceedings of 12th Intersociety

Conference on Environmental Systems, San Diego, CA.

Tongdhamachart C, Gloyna E F, 1991. Supercritical water oxidation of anaerobically digested municipal sludge[R]. CRWR

Vol. 19

Technical Report 229, University of Texas at Austin, Austin,

TX.

U.S. Congress, 1992. O.T.A. Disposal of Chemical Weapons:

Alternative Technologies-Background Paper[Z]. OTA-BPO-95, U.S. Government Printing Office, Washington D.C.

U.S. Department of Defense (DOD), 1999. Assembled chemical

weapons assessment (ACWA) program[R]. Supplemental

report to Congress, Report is also available on the ACWA

website: http://www.pmacwa.army.mil/ip/archive.htm .

U.S. Department of Defense (DOD), 2001. Assembled chemical

weapons assessment (ACWA) program[R]. Supplemental

report to Congress, Report is also available on the ACWA

website: http://www.pmacwa.army.mil/ip/archive.htm .

U.S. Department of Defense (DOD), 2002. Assembled chemical

weapons assessment (ACWA) program[R]. Supplemental

report to Congress, Report is also available on the ACWA

website: http://www.pmacwa.army.mil/ip/index r.htm .

Veriansyah B, Kim J D, Lee J C et al., 2005a. OPA oxidation rates

in supercritical water[J]. Journal of Hazardous Material,

124: 119124.

Veriansyah B, Park T J, Lim J S et al., 2005b. Supercritical water

oxidation of wastewater from LCD manufacturing process:

kinetic and formation of chromium oxide nanoparticles[J].

Journal of Supercritical Fluids, 34: 5161.

Veriansyah B, Kim J D, Lee J C, 2005c. Supercritical water oxidation of thiodiglycol[J]. Industrial & Engineering

Chemistry Research, 44: 90149019.

Veriansyah B, Kim J D, Lee Y W, 2006. Decomposition kinetics

of dimethyl methylphospate (chemical agent simulant) by

supercritical water oxidation[J]. Journal of Environmental

Sciences, 18(1): 1316.

Yoo K P, Lim J S, Kim S Y et al., August 2004. Recent

commercial applications of SFE, SFD, SCWO, SCORR

and Nano-Materials in Korea[C]. In: Proceedings of 11th

International Symposium and Exhibit on Supercritical Fluid

Chromatography, Extraction and Processing, Pittsburgh,

Pennsylvania, U.S.

Waste Treatment Technology News, 1999. Supercritical treatment technology licensed, 14(5).

Weber R, Yoshida S, Miwa K, 2002. PCB destruction in subcritical and supercritical water s evaluation of PCDF formation

and initial steps of degradation mechanisms[J]. Environ Sci

Technol, 36: 18391844.

Wellig B, Lieball K, von Rohr P R, 2005. Operating characteristics of a transpiring-wall SCWO reactor with a

hydrothermal flame as internal heat source[J]. Journal of

Supercritical Fluids, 34: 3550.

Wofford W T, Griffith J W, 2001. Commercial application of

SCWO to the treatment of municipal sludge[M]. In: Supercritical water oxidation-archievements and challenges in

commercial applications (Nazeri A., Shaw R.W., Marrone

P. A., ed.). Arlington, VA.: Stategic Analysis, Inc.

Você também pode gostar

- Cyber-Shot ManualDocumento123 páginasCyber-Shot ManualSofiaAinda não há avaliações

- qw3134 PDFDocumento15 páginasqw3134 PDFVentas SA TabAinda não há avaliações

- Water Dielectric ConstantDocumento3 páginasWater Dielectric Constantczhang001Ainda não há avaliações

- Theory and Application of RF&Microwave AbsorbersDocumento19 páginasTheory and Application of RF&Microwave AbsorbersBhargav BikkaniAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Vapotherm Precision Flow Technical Service ManualDocumento29 páginasVapotherm Precision Flow Technical Service ManualJJ MM100% (1)

- Exc 7 Gas SM 09Documento3 páginasExc 7 Gas SM 09Tushar AgrawalAinda não há avaliações

- J Jconhyd 2019 103517Documento35 páginasJ Jconhyd 2019 103517rolan smkn1Ainda não há avaliações

- Interior Plantscaping PDFDocumento4 páginasInterior Plantscaping PDFRaniPaviAinda não há avaliações

- PAS95-2011-Specification Draft - Hypoxic Fire Prevention Systems For Occupied Spaces PDFDocumento40 páginasPAS95-2011-Specification Draft - Hypoxic Fire Prevention Systems For Occupied Spaces PDFJarrod CurrinAinda não há avaliações

- CourseNotes Section 2Documento24 páginasCourseNotes Section 2Ajinkya BhoskarAinda não há avaliações

- Winkler Method For Dissolved Oxygen AnalysisDocumento5 páginasWinkler Method For Dissolved Oxygen AnalysisAngeli FacunAinda não há avaliações

- 5129 w10 Ms 2Documento6 páginas5129 w10 Ms 2mstudy123456Ainda não há avaliações

- Pak Mcqs Every Day Science Mcqs in PDFDocumento171 páginasPak Mcqs Every Day Science Mcqs in PDFQazi Abdul BasitAinda não há avaliações

- Rotameter Overview PDFDocumento8 páginasRotameter Overview PDFSteve Goke AyeniAinda não há avaliações

- Introduction To Bio Inorganic ChemistryDocumento62 páginasIntroduction To Bio Inorganic ChemistryGupta BDAinda não há avaliações

- Chapter 42 - Corrosion of Pipeline SteelDocumento69 páginasChapter 42 - Corrosion of Pipeline SteelFaysal F. EliyanAinda não há avaliações

- FormallabreportenzymesDocumento15 páginasFormallabreportenzymesapi-267590857Ainda não há avaliações

- ManuScript10 ETIGamma24Documento69 páginasManuScript10 ETIGamma24wayne thompsonAinda não há avaliações

- Earth Science: Physical SettingDocumento24 páginasEarth Science: Physical SettingKris TineAinda não há avaliações

- Crossword Puzzles ScienceDocumento4 páginasCrossword Puzzles ScienceNorazah AhmadAinda não há avaliações

- Chemical ResistanceDocumento12 páginasChemical ResistancechenguemoralesAinda não há avaliações

- 4th Periodical Test English Science Hks 6Documento9 páginas4th Periodical Test English Science Hks 6Aldrin PaguiriganAinda não há avaliações

- Mark Scheme (Results) Summer 2016Documento25 páginasMark Scheme (Results) Summer 2016elezabethAinda não há avaliações

- Benzocaine (2 Steps)Documento11 páginasBenzocaine (2 Steps)checolonoski0% (1)

- Inert SystemsDocumento56 páginasInert Systemsnkvd134Ainda não há avaliações

- Astm D888-12Documento12 páginasAstm D888-12Claudia Mireya HigueraAinda não há avaliações

- Boiler Efficiency CalculationDocumento5 páginasBoiler Efficiency CalculationMutiara ValentinaAinda não há avaliações

- Mallinckrodt PTS2000 DatasheetDocumento2 páginasMallinckrodt PTS2000 Datasheetouyangxin1991Ainda não há avaliações

- Coursework: Name: Student Number: DateDocumento7 páginasCoursework: Name: Student Number: DateACHIENG REBECCAAinda não há avaliações

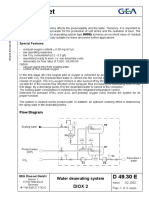

- Water Deaerating System DIOX 2 - GEA DiesselDocumento2 páginasWater Deaerating System DIOX 2 - GEA DiesselGeorgiosKirkimtzisAinda não há avaliações

- Coal OxidationDocumento11 páginasCoal Oxidationmukesh vikramAinda não há avaliações

- Philippa Et Al. (2008) - Science Works Student Book 2 Answers. Oxford University PressDocumento28 páginasPhilippa Et Al. (2008) - Science Works Student Book 2 Answers. Oxford University PressJoeAinda não há avaliações

- Purging While WeldingDocumento16 páginasPurging While Weldingchapulincolorado100% (1)

- Corpuscles To Chemical Atomic TheoryDocumento6 páginasCorpuscles To Chemical Atomic TheoryRommel Desuyo100% (2)