Escolar Documentos

Profissional Documentos

Cultura Documentos

PLA NatureWorks

Enviado por

tblosDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PLA NatureWorks

Enviado por

tblosDireitos autorais:

Formatos disponíveis

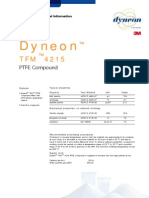

NatureWorks PLA Polymer 3051D

Injection Molding Process Guide

PLA (polylactide) polymer 3051D, a

NatureWorks product, is designed

for injection molding applications

where the requirements are clarity

with heat deflection temperatures

lower than 130F (55C). See Table

1 for properties.

Applications

The variety of products made with

PLA 3051D grow every day. Applications include cutlery, cups, plates

and saucers, and

outdoor novelties. And this is

just the beginning.

Processing Temperature Profile

Melt Temperature

390F

Feed Throat

70F

20C

Feed Temperature

330F

165C

Compression Section

380F

195C

Metering Section

400F

205C

Nozzle

400F

205C

Mold

75F

25C

Screw Speed

100-175 rpm

Back Pressure

50-100 psi

Mold Shrinkage

.004 in/in. +/-.001

Note: These are starting points and may need to be optimized.

Table 1 Typical Material & Application Properties

Amorphous vs. Crystalline

Pellets*

ASTM

Method

Specific Gravity

1.24

D792

Melt Index, g/10 min (190C/2.16K)

10-30

D1238

Relative Viscosity

3.0-3.5

PLA Resin

Physical Properties

Crystalline Melt Temperature ( C)

145-155

D3418

Glass Transition Temperature ( C)

55-65

D3417

Clarity

Transparent

Mechanical Properties

Tensile Yield Strength, psi (MPa)

7,000 (48)

Tensile Elongation, %

2.5

D638

Notched Izod Impact, ft-lb/in (J/m)

0.3 (0.16)

D256

* NatureWorks 3051D is delivered as a

D638

Flexural Strength (MPa)

12,000 (83)

D790

Flexural Modulus (MPa)

555,000 (3828)

D790

(1)

Crystalline and amorphous pellets

look significantly different. SemiCrystalline pellets are opaque and

amorphous pellets are transparent

(See figure below.) Please refer to

drying chart on the following page for

instructions on drying amorphous

PLA pellets.

(1)

(General Purpose)

Processing Information

3051D resin can be processed on

conventional injection molding

equipment. The material is stable

in the molten state, provided that the

drying procedures are followed. Mold

flow is highly dependent on melt

temperature. It is recommended to

balance screw speed, back pressure,

and process temperature to control

melt temperature. Injection speed

should be medium to fast.

200C

Typical properties; not to be construed as specifications.

1.

Process Details

Startup and Shutdown

PLA polymer 3051D is not compatible

with a wide variety of polyolefin

resins, and special purging

sequences should be followed:

1.

Clean extruder and bring

temperatures to steady

state with low-viscosity,

general-purpose polystyrene or polypropylene.

2.

Vacuum out hopper system

to avoid contamination.

3.

Introduce PLA polymer into

the extruder at the operating conditions used in Step

crystalline pellet.

4.

Once PLA polymer has

purged, reduce barrel temperatures to desired set

points.

5.

At shutdown, purge machine with high-viscosity

polystyrene or polypropylene.

NatureWorks PLA Polymer 3051D

Oce Temperature Profile

Drying

In-line drying is recommended for

PLA resins. A moisture content of

less than 0.010% (100 ppm) is

recommended to prevent viscosity

degradation. Polymer is supplied in

foil-lined boxes or bags dried to

<250 ppm.The resin should not be

exposed to atmospheric conditions

after drying. Keep the package

sealed until ready to use and

promptly dry and reseal any unused

material. The drying curves for both

amorphous and crystalline resins

are shown to the right.

Note: Amorphous polymer must

be dried below 120F (50C).

Compostability

Composting is a method of waste

disposal that allows organic materials to be recycled into a product

that can be used as a valuable soil

amendment. PLA is made primarily

of polylactic acid, a repeating chain

of lactic acid, which undergoes a

2-step degradation process. First,

the moisture and heat in the compost pile attack the PLA polymer

chains and split them apart, creating smaller polymers, and finally,

lactic acid. Microorganisms in

compost and soil consume the

smaller polymer fragments and

lactic acid as nutrients. Since lactic

acid is widely found in nature, a

large number of organisms metabolize lactic acid. At a minimum,

fungi and bacteria are involved in

PLA degradation. The end result of

the process is carbon dioxide, water and also humus, a soil nutrient.

This degradation process is temperature and humidity dependent.

Regulatory guidelines and standards for composting revolve

around four basic criteria: Material

Characteristics, Biodegradation,

Disintegration, and Ecotoxicity.

Description of the requirements of

these testing can be found in the

appropriate geographical area:

DIN V 54900-1 (Germany), EN

13432 (EU), ASTM D 6400 (USA),

GreenPla (Japan). This grade of

NatureworksTM PLA meets the requirements of these four standards

with limitation of maximum layer

thickness of 1650 m and for coating layers up to 37 m thick

food types and B-H use conditions.

We urge all of our customers to

perform GMP (Good Manufacturing Procedures) when constructing

a package so that it is suitable for

the end use. Again, for any application, should you need further

clarification, please do not hesitate

to contact NatureWorks LLC.

FDA Status

European Status

This grade of NatureWorks PLA

complies with EU Plastics Directive

2002/72/EC, which applies to all

EU member states. The Plastics

Directive is a consolidated version

of the Monomers Directive (Commission Directive 90/128/EEC) and

its first 7 amendments. This

grade of NatureWorks PLA is also

in compliance with "Bedarfgegenstnde Gesetz", which is the

German implementation of the EU

Plastics Directive 2002/72/EC.

Substances used in the manufacturing of this product which are not

yet regulated by EU Plastics Directive 2002/72/EC, as amended, are

in compliance with appropriate EU

national regulations. NatureWorks

LLC would like to draw your attention to the fact that the EUDirective 2002/72/EC, which applies to all

U.S. Status-

This is to advise you that on January 3, 2002 FCN 000178 submitted

by NatureWorks LLC to FDA became effective. This effective

notification is part of list currently

maintained on FDAs website at

http://www.cfsan.fda.gov/~dms/opa

-fcn.html. This grade of NatureWorks PLA may therefore be

used in food packaging materials

and, as such, is a permitted component of such materials pursuant

to section 201(s) of the Federal,

Drug, and Cosmetic Act, and Parts

182, 184, and 186 of the Food Additive Regulations. All additives

and adjuncts contained in the referenced NatureWorksTM PLA

formulation meet the applicable

sections of the Federal Food,

Drug, and Cosmetic Act. The finished polymer is approved for all

EU-Member States, includes a

limit of 10 mg/dm2 of the overall

migration from finished plastic articles into food. In accordance with

EU-Directive 2002/72/EC the migration should be measured on

finished articles placed into contact

with the foodstuff or appropriate

food simulants for a period and at

a temperature which are chosen

by reference to the contact conditions in actual use, according to

the rules laid down in EUDirectives 93/8/EEC (amending

82/711/EEC) and 85/572/EEC

Please note that it is the responsibility of both the manufacturers of

finished food contact articles as

well as the industrial food packers

to make sure that these articles in

their actual use are in compliance

with the imposed specific and

overall migration requirements.

Again, for any application, should

you need further clarification,

please

do not hesitate to contact NatureWorks LLC

Safety and Handling Considerations

Material Safety Data (MSD) sheets for PLA polymers are

available from NatureWorks LLC. MSD sheets are

provided to help customers satisfy their own handling,

safety, and disposal needs, and those that may be

required by locally applicable health and safety

regulations, such as OSHA (U.S.A.), MAK (Germany), or

WHMIS (Canada). MSD sheets are updated regularly;

therefore, please request and review the most current

MSD sheets before handling or using any product.

The following comments apply only to PLA polymers;

additives and processing aids used in fabrication and

other materials used in finishing steps have their own

safe-use profile and must be investigated separately.

Hazards and Handling Precautions

PLA polymers have a very low degree of toxicity and,

under normal conditions of use, should pose no unusual

problems from incidental ingestion, or eye and skin

contact. However, caution is advised when handling,

storing, using, or disposing of these resins, and good

housekeeping and controlling of dusts are necessary for

safe handling of product. Workers should be protected

from the possibility of contact with molten resin during

fabrication. Handling and fabrication of resins can result

in the generation of vapors and dusts that may cause

irritation to eyes and the upper respiratory tract. In dusty

atmospheres, use an approved dust respirator. Pellets or

beads may present a slipping hazard. Good general

ventilation of the polymer processing area is

recommended. At temperatures exceeding the polymer

melt temperature (typically 170C), polymer can release

fumes, which may contain fragments of the polymer,

creating a potential to irritate eyes and mucous

membranes. Good general ventilation should be sufficient

for most conditions. Local exhaust ventilation is recommended for melt operations. Use safety glasses if there

is a potential for exposure to particles which could cause

mechanical injury to the eye. If vapor exposure causes

eye discomfort, use a full-face respirator. No other

precautions other than clean, body-covering clothing

should be needed for handling PLA polymers. Use gloves

with insulation for thermal protection when exposure to the

melt is localized.

Combustibility

PLA polymers will burn. Clear to white smoke is produced

when product burns. Toxic fumes are released under

conditions of incomplete combustion. Do not permit dust

to accumulate. Dust layers can be ignited by spontaneous

combustion or other ignition sources. When suspended

in air, dust can pose an explosion hazard. Firefighters

should wear positive-pressure, self-contained breathing

apparatuses and full protective equipment. Water or water

fog is the preferred extinguishing medium. Foam, alcoholresistant foam, carbon dioxide or dry chemicals may also

be used. Soak thoroughly with water to cool and prevent

re-ignition.

Disposal

DO NOT DUMP INTO ANY SEWERS, ON THE

GROUND, OR INTO ANY BODY OF WATER. For unused

or uncontaminated material, the preferred options include

recycling into the process or sending to an industrial

composting facility, if available; otherwise, send to an

incinerator or other thermal destruction device. For

used or contaminated material, the disposal options

remain the same, although additional evaluation is

required. (For example, in the U.S.A., see 40 CFR, Part

261, Identification and Listing of Hazardous Waste.) All

disposal methods must be in compliance with Federal,

State/Provincial, and local laws and regulations.

NOTICE: No freedom from any patent owned by NatureWorks LLC or others is to be inferred. Because use

conditions and applicable laws may differ from one location to another and may change with time, Customer is

responsible for determining whether products and the

information in this document are appropriate for Customers use and for ensuring that Customers

workplace and disposal practices are in compliance with

applicable laws and other governmental enactments.

NatureWorks LLC assumes no obligation or liability for the

information in

this document. NO WARRANTIES ARE GIVEN; ALL

IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR USE ARE EXPRESSLY

EXCLUDED.

Environmental Concerns

Generally speaking, lost pellets are not a problem in

the environment except under unusual circumstances

when they enter the marine environment. They are

benign in terms of their physical environmental impact,

but if ingested by waterfowl or aquatic life, they may

mechanically cause adverse effects. Spills should be

minimized, and they should be cleaned up when they

happen. Plastics should not be discarded into the ocean

or any other body of water.

Product Stewardship

NatureWorks LLC has a fundamental duty to all those

that make and use our products, and for the environment

in which we live. This duty is the basis for our Product

Stewardship philosophy, by which we assess the health

and environmental information on our products and their

intended use, then take appropriate steps to protect the

environment and the health of our employees and the

public.

Customer Notice

NatureWorks LLC encourages its customers and potential

users of its products to review their applications for such

products from the standpoint of human health and

environmental quality. To help ensure our products are

not used in ways for which they were not intended or

tested, our personnel will assist customers in dealing with

ecological and product safety considerations. Your sales

representative can arrange the proper contacts.

NatureWorks LLC literature, including Material Safety Data

sheets, should be consulted prior to the use of the

companys products. These are available from your Nature

representative.

NOTICE REGARDING PROHIBITED USE

RESTRICTIONS: NatureWorks LLC doeses not recommend any of its products, including samples, for use as:

Components of, or packaging for, tobacco products;

Components of products where the end product is intended for human or animal consumption; In any

application that is intended for any internal contact with

human body fluids or body tissues; As a critical component in any medical device that supports or sustains

human life; In any product that is designed specifically for

ingestion or internal use by pregnant women; and in any

application designed specifically to promote or interfere

with human reproduction.

For additional information in the U.S. and

Canada,

call toll-free 1-877-423-7659

In Europe, call 31-(0)35-699-1344

In Japan, call 81-33-285-0824

15305 Minnetonka Blvd.,

Minnetonka, MN 55345

NatureWorks and the NatureWorks logo are

trademarks of NatureWorks LLC

Copyright 2005 NatureWorks LLC

Você também pode gostar

- Bottles, Preforms and Closures: A Design Guide for PET PackagingNo EverandBottles, Preforms and Closures: A Design Guide for PET PackagingNota: 4.5 de 5 estrelas4.5/5 (3)

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNo EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlAinda não há avaliações

- Ingeo 2003DDocumento3 páginasIngeo 2003Djsk789Ainda não há avaliações

- Dow 3504Documento2 páginasDow 3504khantoAinda não há avaliações

- JOTUN Jotamastic 80Documento5 páginasJOTUN Jotamastic 80Hafiz KamalAinda não há avaliações

- HF4760 BL3Documento2 páginasHF4760 BL3Niraj HattangdiAinda não há avaliações

- DOW Propylene OxideDocumento2 páginasDOW Propylene OxideA MahmoodAinda não há avaliações

- PEEK-OPTIMA Processing Guide SecuredDocumento0 páginaPEEK-OPTIMA Processing Guide SecuredAngel LagrañaAinda não há avaliações

- Anabond 7931 Aaf TdsDocumento2 páginasAnabond 7931 Aaf TdsNanjappa K NuchumaniandaAinda não há avaliações

- Desmopan TPU ProcessingDocumento48 páginasDesmopan TPU ProcessingA Mahmood100% (1)

- Baltoflake - English (Uk) - Issued.25.03.2010Documento4 páginasBaltoflake - English (Uk) - Issued.25.03.2010Mohamed FaragAinda não há avaliações

- Penguard Primer PDFDocumento4 páginasPenguard Primer PDFheri_prasetyadi7715Ainda não há avaliações

- Brochure Coating Raw Materials For Building Protection 14-06-2011 EDocumento32 páginasBrochure Coating Raw Materials For Building Protection 14-06-2011 EΣταύρος ΒουγιουκλίδηςAinda não há avaliações

- Baltoflake S2000 Technical Data SheetDocumento4 páginasBaltoflake S2000 Technical Data Sheetrezza182Ainda não há avaliações

- Hardtop Flexi Technical Data SheetDocumento3 páginasHardtop Flexi Technical Data SheetMohamed FaragAinda não há avaliações

- SDS Sarafil Polyester Film 2023Documento4 páginasSDS Sarafil Polyester Film 2023Chiaranan KerdsamutAinda não há avaliações

- Fixapret F-ECO TIDocumento5 páginasFixapret F-ECO TISajida HafeezAinda não há avaliações

- TDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Documento4 páginasTDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Robert ClarkAinda não há avaliações

- Primastic UniversalDocumento5 páginasPrimastic UniversalaleventAinda não há avaliações

- TDS - Penguard Express ZP - English (Uk) - Issued.26.11.2010Documento4 páginasTDS - Penguard Express ZP - English (Uk) - Issued.26.11.2010Anindya Aulia PratiwiAinda não há avaliações

- Two-Pack Epoxy Primer Technical DataDocumento4 páginasTwo-Pack Epoxy Primer Technical Datawey5316Ainda não há avaliações

- Biograde BL-FDocumento3 páginasBiograde BL-FXuân Giang NguyễnAinda não há avaliações

- Penguard FC - English (Uk) - Issued.06.12.2007Documento4 páginasPenguard FC - English (Uk) - Issued.06.12.2007Mohamed FaragAinda não há avaliações

- Elastollan Processing Recommendations PDFDocumento28 páginasElastollan Processing Recommendations PDFNicolae MariusAinda não há avaliações

- Lupolen 2420 D: Features ApplicationsDocumento2 páginasLupolen 2420 D: Features ApplicationsGabs GabrielaAinda não há avaliações

- Futura As - English (Uk) - Issued.06.12.2007Documento3 páginasFutura As - English (Uk) - Issued.06.12.2007Mohamed FaragAinda não há avaliações

- Penguard Express ZPDocumento5 páginasPenguard Express ZPMustafa Al-YasseriAinda não há avaliações

- ACP-2017-01-04.lampiran Tds Alkydprimer PDFDocumento5 páginasACP-2017-01-04.lampiran Tds Alkydprimer PDFBayumi Tirta JayaAinda não há avaliações

- Marthon Jotun Marine PaintDocumento5 páginasMarthon Jotun Marine PaintNishanthAinda não há avaliações

- Penguard Topcoat (Azad)Documento4 páginasPenguard Topcoat (Azad)Anonymous f1NlMPnAinda não há avaliações

- Fixapret F ECODocumento4 páginasFixapret F ECOSajida Hafeez0% (1)

- TDS - Alkyd Topcoat - English (Uk) - Issued.28.02.2011 JotunDocumento3 páginasTDS - Alkyd Topcoat - English (Uk) - Issued.28.02.2011 JotunmanbkkAinda não há avaliações

- Technical Data Sheet for Hardtop XP Polyurethane CoatingDocumento5 páginasTechnical Data Sheet for Hardtop XP Polyurethane Coatingadeoye_okunoyeAinda não há avaliações

- Intertherm 838Documento4 páginasIntertherm 838Ashta VakrAinda não há avaliações

- TDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200Documento4 páginasTDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200wey5316Ainda não há avaliações

- TDS 20500 Durosan Medium Tex Euk GBDocumento3 páginasTDS 20500 Durosan Medium Tex Euk GBMido AbdoAinda não há avaliações

- Technical Information: Gecko Primer For Metalized FilmsDocumento3 páginasTechnical Information: Gecko Primer For Metalized FilmsAtmaja SuryadiAinda não há avaliações

- TDS 2280 Penguard+FC Euk GB PDFDocumento5 páginasTDS 2280 Penguard+FC Euk GB PDFRyukiAinda não há avaliações

- Clamp Seals and DIN 11864 O Rings GB enDocumento16 páginasClamp Seals and DIN 11864 O Rings GB enIvancho GrAinda não há avaliações

- Ester Gum EastmanDocumento2 páginasEster Gum EastmanshishirchemAinda não há avaliações

- Biograde WS-50Documento4 páginasBiograde WS-50Xuân Giang NguyễnAinda não há avaliações

- FT Forbo 233 EUROSOLDocumento3 páginasFT Forbo 233 EUROSOLAndreiAinda não há avaliações

- Jotun Hardtop XP - Technical Data SheetDocumento5 páginasJotun Hardtop XP - Technical Data Sheetamarican100% (1)

- Polypropylene Tatren Im 6 56: Technical Data SheetDocumento4 páginasPolypropylene Tatren Im 6 56: Technical Data Sheetser222Ainda não há avaliações

- TFM 4215Documento2 páginasTFM 4215Mohit SharmaAinda não há avaliações

- Alkydprimer - English (Uk) - Issued.06.12.2007Documento3 páginasAlkydprimer - English (Uk) - Issued.06.12.2007Mohamed FaragAinda não há avaliações

- (Painting) Jotamastic 87Documento5 páginas(Painting) Jotamastic 87Mohd FadliAinda não há avaliações

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Documento2 páginasPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaAinda não há avaliações

- Penguard Tie CoatDocumento4 páginasPenguard Tie CoatajuhaseenAinda não há avaliações

- Zinc Silicate Coating TDSDocumento5 páginasZinc Silicate Coating TDSadeoye_okunoyeAinda não há avaliações

- Phenoline 187 Primer PDSDocumento2 páginasPhenoline 187 Primer PDSVajid MadathilAinda não há avaliações

- Processing Guides Partially Oriented Yarn PDFDocumento7 páginasProcessing Guides Partially Oriented Yarn PDFviren199008Ainda não há avaliações

- CRYOGENIC MORTAR C-1 - PRODUCT DATA SHEET Ed. 2Documento4 páginasCRYOGENIC MORTAR C-1 - PRODUCT DATA SHEET Ed. 2ANIBAL LOPEZAinda não há avaliações

- Amercoat 3279 DatasheetDocumento0 páginaAmercoat 3279 Datasheetmekag94Ainda não há avaliações

- Zytel-All in One Extrusion ProcessesDocumento10 páginasZytel-All in One Extrusion ProcessesYiğit IlgazAinda não há avaliações

- Ahlstrom Naturemold Brochure enDocumento3 páginasAhlstrom Naturemold Brochure enRadu Victor TapuAinda não há avaliações

- Erapol EHP70DDocumento2 páginasErapol EHP70DqwepoolAinda não há avaliações

- Jotashield Alkali Resistant Primer Technical Data SheetDocumento3 páginasJotashield Alkali Resistant Primer Technical Data Sheetomda4wadyAinda não há avaliações

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryAinda não há avaliações

- Influence of heat treatment on microstructure, properties and machinability of mold steelDocumento43 páginasInfluence of heat treatment on microstructure, properties and machinability of mold steeltblosAinda não há avaliações

- Influence of heat treatment on microstructure, properties and machinability of mold steelDocumento43 páginasInfluence of heat treatment on microstructure, properties and machinability of mold steeltblosAinda não há avaliações

- A Design For Energy Minimization' Approach To Reduce Energy Consumption During The Manufacturing PhaseDocumento13 páginasA Design For Energy Minimization' Approach To Reduce Energy Consumption During The Manufacturing PhasetblosAinda não há avaliações

- Sustainable Manufacturing Strategies: A Literature Review On Additive Manufacturing ApproachDocumento11 páginasSustainable Manufacturing Strategies: A Literature Review On Additive Manufacturing ApproachtblosAinda não há avaliações

- Simulation-Based Machining Condition Optimization For Machine Toolenergy Consumption ReductionDocumento9 páginasSimulation-Based Machining Condition Optimization For Machine Toolenergy Consumption ReductiontblosAinda não há avaliações

- Edison Multi IntroDocumento9 páginasEdison Multi IntrotblosAinda não há avaliações

- ADAfruit Infill PatternDocumento4 páginasADAfruit Infill PatterntblosAinda não há avaliações

- 08.3dison Stealth Series (En)Documento2 páginas08.3dison Stealth Series (En)tblosAinda não há avaliações

- PRO Quick Guide - ENDocumento2 páginasPRO Quick Guide - ENtblosAinda não há avaliações

- Mechanical Properties of Ultem FDM PartsDocumento5 páginasMechanical Properties of Ultem FDM PartstblosAinda não há avaliações

- Biodegradable Packaging For Food ProductsDocumento20 páginasBiodegradable Packaging For Food ProductsHarsh GoyalAinda não há avaliações

- Research Assistant - Associate in Polymer and Composite Engineering at Imperial College LondonDocumento3 páginasResearch Assistant - Associate in Polymer and Composite Engineering at Imperial College LondonOzden IsbilirAinda não há avaliações

- Food preservation and packaging essentialsDocumento53 páginasFood preservation and packaging essentialsfujiwaramiyukiAinda não há avaliações

- O. 64 Farid Agouillal: EmailDocumento12 páginasO. 64 Farid Agouillal: EmailbebbbAinda não há avaliações

- Biodegradble Plastic BagDocumento29 páginasBiodegradble Plastic BagRajesh KumarAinda não há avaliações

- Polymer Chemistry For Packaging ApplicationsDocumento25 páginasPolymer Chemistry For Packaging ApplicationsdivyaAinda não há avaliações

- Enau Polyla (FDM Filament) : Problem StatementDocumento1 páginaEnau Polyla (FDM Filament) : Problem Statementhakim nasirAinda não há avaliações

- Lactic Acid Production From Cane MolassesDocumento4 páginasLactic Acid Production From Cane MolassesSenkatuuka LukeAinda não há avaliações

- Abstract (Green Chemistry)Documento3 páginasAbstract (Green Chemistry)ArunkumarAinda não há avaliações

- Formfutura Filamenti PDFDocumento40 páginasFormfutura Filamenti PDFStratton OakmontAinda não há avaliações

- ICNF2023 PosterSessionDocumento2 páginasICNF2023 PosterSessionVijay BahetiAinda não há avaliações

- Synthesis of Poly (Lactic Acid) A ReviewDocumento26 páginasSynthesis of Poly (Lactic Acid) A ReviewTOUFIKAinda não há avaliações

- Journal of Analytical and Applied PyrolysisDocumento6 páginasJournal of Analytical and Applied PyrolysisAmara LuciaAinda não há avaliações

- Index: 1. Abstract 5 6 3. Design 8Documento46 páginasIndex: 1. Abstract 5 6 3. Design 8prajeeshAinda não há avaliações

- Building Your Own 3D PrinterDocumento42 páginasBuilding Your Own 3D PrintergrafpapAinda não há avaliações

- Effect of Processing Conditions On The Mechanical Properties of Polylactic Acid/clay CompositesDocumento4 páginasEffect of Processing Conditions On The Mechanical Properties of Polylactic Acid/clay CompositesPim NavaAinda não há avaliações

- Production of Lactic Acid From Renewable Resources Using Electrodialysis For Product RecoveryDocumento329 páginasProduction of Lactic Acid From Renewable Resources Using Electrodialysis For Product RecoveryLily SyafinazAinda não há avaliações

- Industrial Biotech J ProjectDocumento39 páginasIndustrial Biotech J Projectchelsea charlesAinda não há avaliações

- 18 3D Printer Filament Types and Uses Comparison Guide (Dec. 2019)Documento50 páginas18 3D Printer Filament Types and Uses Comparison Guide (Dec. 2019)dwarfalopeAinda não há avaliações

- BiopolymersDocumento57 páginasBiopolymersdow2008Ainda não há avaliações

- Purification of Dilactide through Melt CrystallizationDocumento4 páginasPurification of Dilactide through Melt CrystallizationRaj SolankiAinda não há avaliações

- Bioplastics and Global SustainabilityDocumento3 páginasBioplastics and Global SustainabilityopabalekeAinda não há avaliações

- Nylon and Biodegradable Packaging Technologies for FoodDocumento15 páginasNylon and Biodegradable Packaging Technologies for FoodSONIA NABIAinda não há avaliações

- Pemanfaatan Limbah AgroindustriDocumento37 páginasPemanfaatan Limbah AgroindustribellaAinda não há avaliações

- Additives For Thermoplastics: Additive Selection Chart TP-AG 1Documento4 páginasAdditives For Thermoplastics: Additive Selection Chart TP-AG 1DidikHariantoAinda não há avaliações

- Materials Today Communications: Judith Vergara-Figueroa, Serguei Alejandro-Martin, Fabiola Cerda-Leal, William GacitúaDocumento12 páginasMaterials Today Communications: Judith Vergara-Figueroa, Serguei Alejandro-Martin, Fabiola Cerda-Leal, William GacitúaWalter Ricardo BritoAinda não há avaliações

- Polymer Applications in Drug Delivery SystemsDocumento32 páginasPolymer Applications in Drug Delivery SystemsMaoth AhmedAinda não há avaliações

- MAKALAH POLIMER-dikonversiDocumento14 páginasMAKALAH POLIMER-dikonversiShellyYuliantiAinda não há avaliações

- Figure 1. Structure of PLGADocumento5 páginasFigure 1. Structure of PLGAJessie ChuAinda não há avaliações

- (Plastics Engineering) Albertsson - Degradable Polymers, Recycling, and Plastics Waste Management (1995, CRC Press)Documento336 páginas(Plastics Engineering) Albertsson - Degradable Polymers, Recycling, and Plastics Waste Management (1995, CRC Press)rusalinaAinda não há avaliações