Escolar Documentos

Profissional Documentos

Cultura Documentos

Travelling Trippers PDF

Enviado por

kalaiDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Travelling Trippers PDF

Enviado por

kalaiDireitos autorais:

Formatos disponíveis

Magnet House, 1st Floor,

Flat No. 601, 6th Floor,

Narottam Morarji Marg, Ballard Estate,

Paigah Plaza, Basheerbagh,

Ph : +91-11-223310788 / 23314540

Ph : +91-22-22616853 / 22641320

Ph : +91-40-23297630 / 23297631

Fax : +91-11-23722447

Fax : +91-22-22614085

Fax : +91-40-23297363

e-mail : nd@trf.co.in

e-mail : mum@trf.co.in

e-mail : hyd@trf.co.in

MUMBAI

Bulk Material Handling Equi pment

Block - D, 3rd Floor,

Assistant Divisional Manager

Cell: +91-9304813195

Ph: +91-657-3046259

Fax: +91 - 657-2345724

e-mail: r.k.shukla@trf.co.in

e-mail : biz.development@trf.co.in

Ph : +91-33-44033553

22 Camac Street, Kolkata - 700 016

HYDERABAD

Ph : +91-657 - 3046242

Cell : + 91 - 9334002278

Assistant General Manager

Bulk Material Handling Systems

Port &Yard Equi pment Division

TRF Limited

TECHNICAL SPECIFICATIONS

Himalaya House,

11th Floor 23, Kasturba Gandhi Marg

NEW DELHI

REGIONAL OFFICES

e-mail : dcjha@trf.co.in

Fax : +91-657-2345214

Business Development Department

MARKETING OFFICES

11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand

Phone : +91- 657-3046500/ 598

Fax no. : +91- 657-2345732, e-mail : co@trf.co.in

HEAD OFFICE & WORKS

= Comprises special design with concave and convex curve to minimise the un-supported length of belt

= Material handled coal, iron ore, limestone, etc. to fill the bunker or pile of mounted on ground

= Up to 2000 mm belt

= Driven electrically

= Manufactured as one-way chute, two-way chute & three-way chute

Likhra / Jsr. (0657) 2291356

SIDE VIEW OF A TRAVELLING TRIPPER

FRONT VIEW OF A TRAVELLING TRIPPER

Travelling Trippers

A

A

Travelling Trippers

Enterprise

TRF LIMITED

Enterprise

TRF LIMITED

Travelling Trippers

TRF LIMITED

individual actuators whichever is required by the customer.

material at the desired location on the conveyor with the help

single actuator either by using special link mechanism or by

The tripper is provided in the conveying system to stack the

The entire bunker opening is sealed by covering with a belt.

on each side. These trippers have a rigid welded steel frame

Bunker Belt Sealing

with wheels, which move on rails, placed parallel to conveyor

COAL

COAL

COAL

COAL

COAL

LIGNITE

chute discharge is cleared automatically to drop the material

used where continuous and uniform distribution of material

By virtue of such a belt profile, the bunker opening below the

Motorised trippers move on independent electric motors. It is

Enterprise

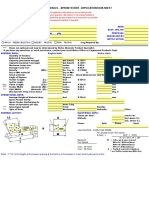

Material Handling, Capacity & other features of some Travelling Trippers:

MATERIAL

of chute/chutes fitted to the tripper. The tripper is provided

The covering belt is deflected in a particular profile with the

to resist shock and minimise distortion.

COAL

help of a set of idlers and it is mounted on the tripper chute.

Motorised Tripper

into bunker.

along the conveyor is required or where the tripper is moved

LIME

COAL

COAL

CLEAN COAL

CLEAN COAL

back and forth frequently. It can be automatically reversed at

CLEAN COAL

each end of its travel with the help of limit switches carried on

the tripper and actuated by stops placed where desired along

the runway. Push buttons are provided for manual control to

regulate the tripper. The tripper can be moved either when the

conveyor belt is moving or stationary. Each tripper is provided

with a hand operated powerful, quick action rail clamp for

holding it in a fixed position. The tripper is provided with a

platform for the operator.

COAL

COAL

Features

CRUSHED

COAL

l To minimize the over hang of belt, the tripper structure

has been designed with concave and convex curves.

L.S/DOLO

IRON ORE/

FLUX

l There are options of drive system. Drives with chain and

sprocket; direct drive with hollow shaft mounted

gearbox alongwith motor and brake.

COKE

SINTER

COAL

CRUSHED

COAL

l Direct drive is also given with hollow shaft mounted

geared motor with an inbuilt brake.

COAL

Long Travel Drive Assembly

Travel drive is through direct wheel axle drive design. A

hollow shaft mounted gear box is placed directly on the wheel

axle. The input of gearbox is coupled with an electric motor.

The brake is mounted on the rear extend shaft of the motor or

between input shaft of gearbox and motor shaft. All drive

components are mounted on a common drivebase which is

connected with the trippers main body with a torque arm.

Alternately geared motor may also be provided with hollow shaft

with inbuilt brake and torque arm arrangement to overcome

space constraint. The power is supplied by a cable reeling drum

mounted on tripper body or festooning cable arrangement, if the

travel length is small.

COAL

l The machine can be controlled either by local operation

from the machine or by remote operation from control

station with selector switch or both.

CRUSHED

COKE

COKE

IRON ORE

l The machine has been provided with all safety controls

and limit switches, such as over travel limit switch,

chute-jamming switch, etc.

350 TPH

(-) 100 mm

250 TPH

(-) 15 mm

1600 TPH

(-)250 mm

400 TPH

(-)20 mm

1800 TPH

(-)20 mm

1200 TPH

(-)30 mm

400 TPH

(-)50 mm

200 TPH

(-)25 TO 80 mm

500 TPH

(-)40/(-)30 mm

200 TPH

(-) 40 mm

800 TPH

(-) 20 mm

1350 TPH

(-) 25 mm

210 TPH

(-) 20 mm

125 TPH

(-) 20 mm

125 TPH

(-) 20 mm

50 TPH

(-) 20 mm

750 TPH

(-) 75 mm

1500 TPH

(-) 250 mm

300 TPH

(-) 20 mm

660 TPH

(-) 6 mm

750 TPH

20 mm

750 TPH

20 mm

750 TPH

20 mm

150 TPH

6 mm

1600 TPH

20 mm

150 TPH

6 mm

CAPACITY

RATED TPH

LUMP SIZE

mm

CAPACITY

DESIGN

165 TPH

1760 TPH

165 TPH

825 TPH

825 TPH

825 TPH

730 TPH

330 TPH

1800 TPH

825 TPH

60 TPH

150 TPH

150 TPH

230 TPH

1485 TPH

960 TPH

240 TPH

600 TPH

240 TPH

480 TPH

1440 TPH

1900 TPH

500 TPH

1900 TPH

275 TPH

385 TPH

3000 TPH

TYPE OF

CHUTE

BELT

WIDTH

2 WAY CHUTE

3.7 KW

1400

3.7 KW

3 WAY CHUTE

2200 TPH

2000 TPH

(-) 20 mm

1 WAY CHUTE

2760 TPH

2300 TPH

(-) 100 mm

2 WAY CHUTE

2760 TPH

2300 TPH

(-) 100 mm

3 WAY CHUTE

2420 TPH

2200 TPH

(-) 20 mm

3 WAY CHUTE

1760 TPH

1600 TPH

(-) 20 mm

2 WAY CHUTE

1200 TPH

1000 TPH

(-)5 TO (+) 5 mm

2 WAY CHUTE

1200 TPH

1000 TPH

(-)5 TO (+) 5 mm

2 WAY CHUTE

2880 TPH

2400 TPH

(-) 8 mm

1000 TPH

(-) 50 mm

1650 TPH

(-) 50 mm

1600 TPH

(-) 20 mm

1500 TPH

(-) 20 mm

300 TPH

(-) 6 mm

180 TPH

150 TPH

(-) 3 mm

480 TPH

MIDDDLINGS

COAL

COAL

COAL

COAL

COAL

COAL

COAL

COAL

COAL

COAL

COAL

360 TPH

1500 TPH

1760 TPH

1815 TPH

1200 TPH

3.7 KW

3.7 KW

5.5 KW

3.7 KW

2.2 KW

1 WAY CHUTE

3850 TPH

3500 TPH

(-) 10 mm

IRON ORE

5.5 KW

2.2 KW

2.2 KW

2.2 KW

2.2 KW

3.7 KW

2 WAY CHUTE

3850 TPH

3500 TPH

(-) 10 mm

COAL

(-) 13 mm

3.7 KW

3.7 KW

3.7 KW

2 WAY CHUTE

3850 TPH

3500 TPH

(-) 10 mm

IRON ORE

600 TPH

(-) 13 mm

3.7 KW

800

1200

1000

1000

1000

600

1400

1000

2 WAY CHUTE

650

650

650

1400

1200

800

1000

3.7 KW

1000

3.7 KW

1000

3.7 KW

1400

3.7 KW

1400

5.5 KW

1000

1.5/0.75 KW

1600

7.5 KW

1000

2 WAY CHUTE

3850 TPH

3500 TPH

(-) 10 mm

COAL

3300 TPH

(-) 20 mm

3.7 KW

3.7 KW

1500

2 WAY CHUTE

1980 TPH

1800 TPH

(-) 25 mm

COAL

COAL

COAL

TRAVEL DRIVE

POWER KW

650

3 WAY CHUTE

3 WAY CHUTE

2 WAY CHUTE

3 WAY CHUTE

3 WAY CHUTE

2 WAY CHUTE

1 WAY CHUTE

2 WAY CHUTE

500

1 WAY CHUTE

1 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

3 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

3 WAY CHUTE

3 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

1 WAY CHUTE

1200

2 WAY CHUTE

2 WAY CHUTE

3 WAY CHUTE

1320 TPH

1200 TPH

CHAR

l The machine can be provided with cradle assembly,

mounted on the machine to protect the conveyor belt

from damage due to the impact of discharged material.

400 TPH

3 WAY CHUTE

2420 TPH

2200 TPH

(-) 20 mm

(+)5mm TO (-)50 mm

COAL

Flapper Gate Drive Assembly

2500 TPH

1000

2 WAY CHUTE

435 TPH

360 TPH

COAL

The gate drive is through electro mechanical linear actuator

fitted with link mechanism. The actuator is supported on a

trunnion-mounted bracket. In a three-way chute two flap

gates are required. Both can be operated by a

(-) 6 mm

1200

2 WAY CHUTE

720 TPH

COAL

SINTER

(-) 150 mm

2000

3 WAY CHUTE

3630 TPH

COAL

FRONT VIEW OF A ONE-WAY CHUTE TRAVELLING TRIPPER

2 WAY CHUTE

2 x 3.7 KW

1000

1 WAY CHUTE

3.7 KW

650

3 WAY CHUTE

3.7 KW

1200

3 WAY CHUTE

3.7 KW

1400

3 WAY CHUTE

2 x 2.2 KW

1400

1 WAY CHUTE

2 x 2.2 KW

1600

2 WAY CHUTE

2 x 3.7 KW

1200

2 x 2.2 KW

1600

2 x 5.5 KW

1200

2 x 2.2 KW

1200

2 x 2.2 KW

1400

2 x 3.7 KW

1600

2 x 5.5 KW

1600

1 x 7.5 KW

1600

1 x 7.5 KW

1600

2 x 5.5 KW

1600

2 x 5.5 KW

1600

2 x 5.5 KW

2000

2 x 5.5 KW

2000

2 x 5.5 KW

1600

2 x 5.5 KW

1400

2 x 2.2 KW

1600

2 x 5.5 KW

2 x 3.7 KW

2 x 3.7 KW

2 x 7.5 KW

e-mail : mum@trf.co.in

e-mail : nd@trf.co.in

Fax : +91-40-23297363

Fax : +91-22-22614085

Fax : +91-11-23722447

Ph : +91-40-23297630 / 23297631

Ph : +91-22-22616853 / 22641320

Ph : +91-11-223310788 / 23314540

Narottam Morarji Marg, Ballard Estate,

11th Floor 23, Kasturba Gandhi Marg

Magnet House, 1st Floor,

Himalaya House,

MUMBAI

NEW DELHI

TECHNICAL SPECIFICATIONS

e-mail : hyd@trf.co.in

Paigah Plaza, Basheerbagh,

Flat No. 601, 6th Floor,

HYDERABAD

REGIONAL OFFICES

e-mail : dcjha@trf.co.in

Fax : +91-657-2345214

Assistant Divisional Manager

Cell: +91-9304813195

Ph: +91-657-3046259

Fax: +91 - 657-2345724

e-mail: r.k.shukla@trf.co.in

e-mail : biz.development@trf.co.in

Ph : +91-33-44033553

22 Camac Street, Kolkata - 700 016

Block - D, 3rd Floor,

Business Development Department

Ph : +91-657 - 3046242

Cell : + 91 - 9334002278

Assistant General Manager

Bulk Material Handling Systems

Port &Yard Equi pment Division

Bulk Material Handling Equi pment

MARKETING OFFICES

11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand

Phone : +91- 657-3046500/ 598

Fax no. : +91- 657-2345732, e-mail : co@trf.co.in

TRF Limited

HEAD OFFICE & WORKS

= Comprises special design with concave and convex curve to minimise the un-supported length of belt

= Material handled coal, iron ore, limestone, etc. to fill the bunker or pile of mounted on ground

= Up to 2000 mm belt

= Driven electrically

= Manufactured as one-way chute, two-way chute & three-way chute

Likhra / Jsr. (0657) 2291356

SIDE VIEW OF A TRAVELLING TRIPPER

FRONT VIEW OF A TRAVELLING TRIPPER

Travelling Trippers

A

A

Travelling Trippers

Enterprise

TRF LIMITED

Enterprise

TRF LIMITED

Travelling Trippers

TRF LIMITED

The tripper is provided in the conveying system to stack the

single actuator either by using special link mechanism or by

material at the desired location on the conveyor with the help

individual actuators whichever is required by the customer.

with wheels, which move on rails, placed parallel to conveyor

Material Handling, Capacity & other features of some Travelling Trippers:

MATERIAL

of chute/chutes fitted to the tripper. The tripper is provided

Bunker Belt Sealing

Enterprise

LUMP SIZE

mm

CAPACITY

RATED TPH

CAPACITY

DESIGN

TYPE OF

CHUTE

BELT

WIDTH

TRAVEL DRIVE

POWER KW

COAL

6 mm

150 TPH

165 TPH

2 WAY CHUTE

650

3.7 KW

COAL

20 mm

1600 TPH

1760 TPH

3 WAY CHUTE

1400

3.7 KW

on each side. These trippers have a rigid welded steel frame

The entire bunker opening is sealed by covering with a belt.

COAL

6 mm

150 TPH

165 TPH

3 WAY CHUTE

800

3.7 KW

to resist shock and minimise distortion.

The covering belt is deflected in a particular profile with the

COAL

20 mm

750 TPH

825 TPH

2 WAY CHUTE

1200

3.7 KW

COAL

20 mm

750 TPH

825 TPH

3 WAY CHUTE

1000

3.7 KW

COAL

20 mm

750 TPH

825 TPH

3 WAY CHUTE

1000

5.5 KW

LIGNITE

(-) 6 mm

660 TPH

730 TPH

2 WAY CHUTE

1000

3.7 KW

LIME

(-) 20 mm

300 TPH

330 TPH

1 WAY CHUTE

600

2.2 KW

COAL

(-) 250 mm

1500 TPH

1800 TPH

2 WAY CHUTE

1400

5.5 KW

COAL

(-) 75 mm

750 TPH

825 TPH

2 WAY CHUTE

1000

2.2 KW

CLEAN COAL

(-) 20 mm

50 TPH

60 TPH

1 WAY CHUTE

500

2.2 KW

CLEAN COAL

(-) 20 mm

125 TPH

150 TPH

1 WAY CHUTE

650

2.2 KW

back and forth frequently. It can be automatically reversed at

CLEAN COAL

(-) 20 mm

125 TPH

150 TPH

2 WAY CHUTE

650

2.2 KW

each end of its travel with the help of limit switches carried on

COAL

(-) 20 mm

210 TPH

230 TPH

2 WAY CHUTE

650

3.7 KW

COAL

(-) 25 mm

1350 TPH

1485 TPH

3 WAY CHUTE

1400

3.7 KW

CRUSHED

COAL

(-) 20 mm

800 TPH

960 TPH

2 WAY CHUTE

1200

3.7 KW

help of a set of idlers and it is mounted on the tripper chute.

Motorised Tripper

Motorised trippers move on independent electric motors. It is

By virtue of such a belt profile, the bunker opening below the

used where continuous and uniform distribution of material

chute discharge is cleared automatically to drop the material

along the conveyor is required or where the tripper is moved

the tripper and actuated by stops placed where desired along

the runway. Push buttons are provided for manual control to

regulate the tripper. The tripper can be moved either when the

conveyor belt is moving or stationary. Each tripper is provided

with a hand operated powerful, quick action rail clamp for

holding it in a fixed position. The tripper is provided with a

platform for the operator.

into bunker.

Features

l To minimize the over hang of belt, the tripper structure

has been designed with concave and convex curves.

l There are options of drive system. Drives with chain and

sprocket; direct drive with hollow shaft mounted

gearbox alongwith motor and brake.

l Direct drive is also given with hollow shaft mounted

geared motor with an inbuilt brake.

Long Travel Drive Assembly

Travel drive is through direct wheel axle drive design. A

hollow shaft mounted gear box is placed directly on the wheel

axle. The input of gearbox is coupled with an electric motor.

The brake is mounted on the rear extend shaft of the motor or

between input shaft of gearbox and motor shaft. All drive

components are mounted on a common drivebase which is

connected with the trippers main body with a torque arm.

Alternately geared motor may also be provided with hollow shaft

with inbuilt brake and torque arm arrangement to overcome

space constraint. The power is supplied by a cable reeling drum

mounted on tripper body or festooning cable arrangement, if the

travel length is small.

l The machine can be controlled either by local operation

from the machine or by remote operation from control

station with selector switch or both.

l The machine has been provided with all safety controls

and limit switches, such as over travel limit switch,

chute-jamming switch, etc.

l The machine can be provided with cradle assembly,

mounted on the machine to protect the conveyor belt

from damage due to the impact of discharged material.

Flapper Gate Drive Assembly

The gate drive is through electro mechanical linear actuator

fitted with link mechanism. The actuator is supported on a

trunnion-mounted bracket. In a three-way chute two flap

gates are required. Both can be operated by a

FRONT VIEW OF A ONE-WAY CHUTE TRAVELLING TRIPPER

L.S/DOLO

(-) 40 mm

200 TPH

240 TPH

2 WAY CHUTE

800

3.7 KW

IRON ORE/

FLUX

(-)40/(-)30 mm

500 TPH

600 TPH

2 WAY CHUTE

1000

3.7 KW

COKE

(-)25 TO 80 mm

200 TPH

240 TPH

3 WAY CHUTE

1000

3.7 KW

SINTER

(-)50 mm

400 TPH

480 TPH

3 WAY CHUTE

1000

3.7 KW

COAL

(-)30 mm

1200 TPH

1440 TPH

2 WAY CHUTE

1400

3.7 KW

CRUSHED

COAL

(-)20 mm

1800 TPH

1900 TPH

2 WAY CHUTE

1400

5.5 KW

COAL

(-)20 mm

400 TPH

500 TPH

2 WAY CHUTE

1000

1.5/0.75 KW

COAL

(-)250 mm

1600 TPH

1900 TPH

2 WAY CHUTE

1600

7.5 KW

CRUSHED

COKE

(-) 15 mm

250 TPH

275 TPH

1 WAY CHUTE

1000

3.7 KW

COKE

(-) 100 mm

350 TPH

385 TPH

2 WAY CHUTE

1200

3.7 KW

IRON ORE

(-) 150 mm

2500 TPH

3000 TPH

2 WAY CHUTE

1500

2 x 3.7 KW

MIDDDLINGS

(-) 6 mm

400 TPH

480 TPH

2 WAY CHUTE

1000

3.7 KW

COAL

(-) 3 mm

150 TPH

180 TPH

1 WAY CHUTE

650

3.7 KW

CHAR

(-) 6 mm

300 TPH

360 TPH

3 WAY CHUTE

1200

3.7 KW

COAL

(-) 20 mm

1500 TPH

1500 TPH

3 WAY CHUTE

1400

2 x 2.2 KW

COAL

(-) 20 mm

1600 TPH

1760 TPH

3 WAY CHUTE

1400

2 x 2.2 KW

COAL

(-) 50 mm

1650 TPH

1815 TPH

1 WAY CHUTE

1600

2 x 3.7 KW

COAL

(-) 50 mm

1000 TPH

1200 TPH

2 WAY CHUTE

1200

2 x 2.2 KW

COAL

(-) 8 mm

2400 TPH

2880 TPH

2 WAY CHUTE

1600

2 x 5.5 KW

COAL

(-)5 TO (+) 5 mm

1000 TPH

1200 TPH

2 WAY CHUTE

1200

2 x 2.2 KW

COAL

(-)5 TO (+) 5 mm

1000 TPH

1200 TPH

2 WAY CHUTE

1200

2 x 2.2 KW

COAL

(-) 20 mm

1600 TPH

1760 TPH

3 WAY CHUTE

1400

2 x 3.7 KW

COAL

(-) 20 mm

2200 TPH

2420 TPH

3 WAY CHUTE

1600

2 x 5.5 KW

COAL

(-) 100 mm

2300 TPH

2760 TPH

2 WAY CHUTE

1600

1 x 7.5 KW

COAL

(-) 100 mm

2300 TPH

2760 TPH

1 WAY CHUTE

1600

1 x 7.5 KW

COAL

(-) 20 mm

2000 TPH

2200 TPH

3 WAY CHUTE

1600

2 x 5.5 KW

IRON ORE

(-) 10 mm

3500 TPH

3850 TPH

1 WAY CHUTE

1600

2 x 5.5 KW

IRON ORE

(-) 10 mm

3500 TPH

3850 TPH

2 WAY CHUTE

1600

2 x 5.5 KW

COAL

(-) 10 mm

3500 TPH

3850 TPH

2 WAY CHUTE

2000

2 x 5.5 KW

COAL

(-) 10 mm

3500 TPH

3850 TPH

2 WAY CHUTE

2000

2 x 5.5 KW

COAL

(-) 25 mm

1800 TPH

1980 TPH

2 WAY CHUTE

1600

2 x 5.5 KW

SINTER

(+)5mm TO (-)50 mm

1200 TPH

1320 TPH

3 WAY CHUTE

1400

2 x 2.2 KW

COAL

(-) 20 mm

2200 TPH

2420 TPH

3 WAY CHUTE

1600

2 x 5.5 KW

COAL

(-) 13 mm

360 TPH

435 TPH

2 WAY CHUTE

1000

2 x 3.7 KW

COAL

(-) 13 mm

600 TPH

720 TPH

2 WAY CHUTE

1200

2 x 3.7 KW

COAL

(-) 20 mm

3300 TPH

3630 TPH

3 WAY CHUTE

2000

2 x 7.5 KW

e-mail : mum@trf.co.in

e-mail : nd@trf.co.in

Fax : +91-40-23297363

Fax : +91-22-22614085

Fax : +91-11-23722447

Ph : +91-40-23297630 / 23297631

Ph : +91-22-22616853 / 22641320

Ph : +91-11-223310788 / 23314540

Narottam Morarji Marg, Ballard Estate,

11th Floor 23, Kasturba Gandhi Marg

Magnet House, 1st Floor,

Himalaya House,

MUMBAI

NEW DELHI

TECHNICAL SPECIFICATIONS

e-mail : hyd@trf.co.in

Paigah Plaza, Basheerbagh,

Flat No. 601, 6th Floor,

HYDERABAD

REGIONAL OFFICES

e-mail : dcjha@trf.co.in

Fax : +91-657-2345214

Assistant Divisional Manager

Cell: +91-9304813195

Ph: +91-657-3046259

Fax: +91 - 657-2345724

e-mail: r.k.shukla@trf.co.in

e-mail : biz.development@trf.co.in

Ph : +91-33-44033553

22 Camac Street, Kolkata - 700 016

Block - D, 3rd Floor,

Business Development Department

Ph : +91-657 - 3046242

Cell : + 91 - 9334002278

Assistant General Manager

Bulk Material Handling Systems

Port &Yard Equi pment Division

Bulk Material Handling Equi pment

MARKETING OFFICES

11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand

Phone : +91- 657-3046500/ 598

Fax no. : +91- 657-2345732, e-mail : co@trf.co.in

TRF Limited

HEAD OFFICE & WORKS

= Comprises special design with concave and convex curve to minimise the un-supported length of belt

= Material handled coal, iron ore, limestone, etc. to fill the bunker or pile of mounted on ground

= Up to 2000 mm belt

= Driven electrically

= Manufactured as one-way chute, two-way chute & three-way chute

Likhra / Jsr. (0657) 2291356

SIDE VIEW OF A TRAVELLING TRIPPER

FRONT VIEW OF A TRAVELLING TRIPPER

Travelling Trippers

A

A

Travelling Trippers

Enterprise

TRF LIMITED

Enterprise

TRF LIMITED

Travelling Trippers

TRF LIMITED

The tripper is provided in the conveying system to stack the

single actuator either by using special link mechanism or by

material at the desired location on the conveyor with the help

individual actuators whichever is required by the customer.

with wheels, which move on rails, placed parallel to conveyor

Material Handling, Capacity & other features of some Travelling Trippers:

MATERIAL

of chute/chutes fitted to the tripper. The tripper is provided

Bunker Belt Sealing

Enterprise

LUMP SIZE

mm

CAPACITY

RATED TPH

CAPACITY

DESIGN

TYPE OF

CHUTE

BELT

WIDTH

TRAVEL DRIVE

POWER KW

COAL

6 mm

150 TPH

165 TPH

2 WAY CHUTE

650

3.7 KW

COAL

20 mm

1600 TPH

1760 TPH

3 WAY CHUTE

1400

3.7 KW

on each side. These trippers have a rigid welded steel frame

The entire bunker opening is sealed by covering with a belt.

COAL

6 mm

150 TPH

165 TPH

3 WAY CHUTE

800

3.7 KW

to resist shock and minimise distortion.

The covering belt is deflected in a particular profile with the

COAL

20 mm

750 TPH

825 TPH

2 WAY CHUTE

1200

3.7 KW

COAL

20 mm

750 TPH

825 TPH

3 WAY CHUTE

1000

3.7 KW

COAL

20 mm

750 TPH

825 TPH

3 WAY CHUTE

1000

5.5 KW

LIGNITE

(-) 6 mm

660 TPH

730 TPH

2 WAY CHUTE

1000

3.7 KW

LIME

(-) 20 mm

300 TPH

330 TPH

1 WAY CHUTE

600

2.2 KW

COAL

(-) 250 mm

1500 TPH

1800 TPH

2 WAY CHUTE

1400

5.5 KW

COAL

(-) 75 mm

750 TPH

825 TPH

2 WAY CHUTE

1000

2.2 KW

CLEAN COAL

(-) 20 mm

50 TPH

60 TPH

1 WAY CHUTE

500

2.2 KW

CLEAN COAL

(-) 20 mm

125 TPH

150 TPH

1 WAY CHUTE

650

2.2 KW

back and forth frequently. It can be automatically reversed at

CLEAN COAL

(-) 20 mm

125 TPH

150 TPH

2 WAY CHUTE

650

2.2 KW

each end of its travel with the help of limit switches carried on

COAL

(-) 20 mm

210 TPH

230 TPH

2 WAY CHUTE

650

3.7 KW

COAL

(-) 25 mm

1350 TPH

1485 TPH

3 WAY CHUTE

1400

3.7 KW

CRUSHED

COAL

(-) 20 mm

800 TPH

960 TPH

2 WAY CHUTE

1200

3.7 KW

help of a set of idlers and it is mounted on the tripper chute.

Motorised Tripper

Motorised trippers move on independent electric motors. It is

By virtue of such a belt profile, the bunker opening below the

used where continuous and uniform distribution of material

chute discharge is cleared automatically to drop the material

along the conveyor is required or where the tripper is moved

the tripper and actuated by stops placed where desired along

the runway. Push buttons are provided for manual control to

regulate the tripper. The tripper can be moved either when the

conveyor belt is moving or stationary. Each tripper is provided

with a hand operated powerful, quick action rail clamp for

holding it in a fixed position. The tripper is provided with a

platform for the operator.

into bunker.

Features

l To minimize the over hang of belt, the tripper structure

has been designed with concave and convex curves.

l There are options of drive system. Drives with chain and

sprocket; direct drive with hollow shaft mounted

gearbox alongwith motor and brake.

l Direct drive is also given with hollow shaft mounted

geared motor with an inbuilt brake.

Long Travel Drive Assembly

Travel drive is through direct wheel axle drive design. A

hollow shaft mounted gear box is placed directly on the wheel

axle. The input of gearbox is coupled with an electric motor.

The brake is mounted on the rear extend shaft of the motor or

between input shaft of gearbox and motor shaft. All drive

components are mounted on a common drivebase which is

connected with the trippers main body with a torque arm.

Alternately geared motor may also be provided with hollow shaft

with inbuilt brake and torque arm arrangement to overcome

space constraint. The power is supplied by a cable reeling drum

mounted on tripper body or festooning cable arrangement, if the

travel length is small.

l The machine can be controlled either by local operation

from the machine or by remote operation from control

station with selector switch or both.

l The machine has been provided with all safety controls

and limit switches, such as over travel limit switch,

chute-jamming switch, etc.

l The machine can be provided with cradle assembly,

mounted on the machine to protect the conveyor belt

from damage due to the impact of discharged material.

Flapper Gate Drive Assembly

The gate drive is through electro mechanical linear actuator

fitted with link mechanism. The actuator is supported on a

trunnion-mounted bracket. In a three-way chute two flap

gates are required. Both can be operated by a

FRONT VIEW OF A ONE-WAY CHUTE TRAVELLING TRIPPER

L.S/DOLO

(-) 40 mm

200 TPH

240 TPH

2 WAY CHUTE

800

3.7 KW

IRON ORE/

FLUX

(-)40/(-)30 mm

500 TPH

600 TPH

2 WAY CHUTE

1000

3.7 KW

COKE

(-)25 TO 80 mm

200 TPH

240 TPH

3 WAY CHUTE

1000

3.7 KW

SINTER

(-)50 mm

400 TPH

480 TPH

3 WAY CHUTE

1000

3.7 KW

COAL

(-)30 mm

1200 TPH

1440 TPH

2 WAY CHUTE

1400

3.7 KW

CRUSHED

COAL

(-)20 mm

1800 TPH

1900 TPH

2 WAY CHUTE

1400

5.5 KW

COAL

(-)20 mm

400 TPH

500 TPH

2 WAY CHUTE

1000

1.5/0.75 KW

COAL

(-)250 mm

1600 TPH

1900 TPH

2 WAY CHUTE

1600

7.5 KW

CRUSHED

COKE

(-) 15 mm

250 TPH

275 TPH

1 WAY CHUTE

1000

3.7 KW

COKE

(-) 100 mm

350 TPH

385 TPH

2 WAY CHUTE

1200

3.7 KW

IRON ORE

(-) 150 mm

2500 TPH

3000 TPH

2 WAY CHUTE

1500

2 x 3.7 KW

MIDDDLINGS

(-) 6 mm

400 TPH

480 TPH

2 WAY CHUTE

1000

3.7 KW

COAL

(-) 3 mm

150 TPH

180 TPH

1 WAY CHUTE

650

3.7 KW

CHAR

(-) 6 mm

300 TPH

360 TPH

3 WAY CHUTE

1200

3.7 KW

COAL

(-) 20 mm

1500 TPH

1500 TPH

3 WAY CHUTE

1400

2 x 2.2 KW

COAL

(-) 20 mm

1600 TPH

1760 TPH

3 WAY CHUTE

1400

2 x 2.2 KW

COAL

(-) 50 mm

1650 TPH

1815 TPH

1 WAY CHUTE

1600

2 x 3.7 KW

COAL

(-) 50 mm

1000 TPH

1200 TPH

2 WAY CHUTE

1200

2 x 2.2 KW

COAL

(-) 8 mm

2400 TPH

2880 TPH

2 WAY CHUTE

1600

2 x 5.5 KW

COAL

(-)5 TO (+) 5 mm

1000 TPH

1200 TPH

2 WAY CHUTE

1200

2 x 2.2 KW

COAL

(-)5 TO (+) 5 mm

1000 TPH

1200 TPH

2 WAY CHUTE

1200

2 x 2.2 KW

COAL

(-) 20 mm

1600 TPH

1760 TPH

3 WAY CHUTE

1400

2 x 3.7 KW

COAL

(-) 20 mm

2200 TPH

2420 TPH

3 WAY CHUTE

1600

2 x 5.5 KW

COAL

(-) 100 mm

2300 TPH

2760 TPH

2 WAY CHUTE

1600

1 x 7.5 KW

COAL

(-) 100 mm

2300 TPH

2760 TPH

1 WAY CHUTE

1600

1 x 7.5 KW

COAL

(-) 20 mm

2000 TPH

2200 TPH

3 WAY CHUTE

1600

2 x 5.5 KW

IRON ORE

(-) 10 mm

3500 TPH

3850 TPH

1 WAY CHUTE

1600

2 x 5.5 KW

IRON ORE

(-) 10 mm

3500 TPH

3850 TPH

2 WAY CHUTE

1600

2 x 5.5 KW

COAL

(-) 10 mm

3500 TPH

3850 TPH

2 WAY CHUTE

2000

2 x 5.5 KW

COAL

(-) 10 mm

3500 TPH

3850 TPH

2 WAY CHUTE

2000

2 x 5.5 KW

COAL

(-) 25 mm

1800 TPH

1980 TPH

2 WAY CHUTE

1600

2 x 5.5 KW

SINTER

(+)5mm TO (-)50 mm

1200 TPH

1320 TPH

3 WAY CHUTE

1400

2 x 2.2 KW

COAL

(-) 20 mm

2200 TPH

2420 TPH

3 WAY CHUTE

1600

2 x 5.5 KW

COAL

(-) 13 mm

360 TPH

435 TPH

2 WAY CHUTE

1000

2 x 3.7 KW

COAL

(-) 13 mm

600 TPH

720 TPH

2 WAY CHUTE

1200

2 x 3.7 KW

COAL

(-) 20 mm

3300 TPH

3630 TPH

3 WAY CHUTE

2000

2 x 7.5 KW

Magnet House, 1st Floor,

Flat No. 601, 6th Floor,

Narottam Morarji Marg, Ballard Estate,

Paigah Plaza, Basheerbagh,

Ph : +91-11-223310788 / 23314540

Ph : +91-22-22616853 / 22641320

Ph : +91-40-23297630 / 23297631

Fax : +91-11-23722447

Fax : +91-22-22614085

Fax : +91-40-23297363

e-mail : nd@trf.co.in

e-mail : mum@trf.co.in

e-mail : hyd@trf.co.in

MUMBAI

Bulk Material Handling Equi pment

Block - D, 3rd Floor,

Assistant Divisional Manager

Cell: +91-9304813195

Ph: +91-657-3046259

Fax: +91 - 657-2345724

e-mail: r.k.shukla@trf.co.in

e-mail : biz.development@trf.co.in

Ph : +91-33-44033553

22 Camac Street, Kolkata - 700 016

HYDERABAD

Ph : +91-657 - 3046242

Cell : + 91 - 9334002278

Assistant General Manager

Bulk Material Handling Systems

Port &Yard Equi pment Division

TRF Limited

TECHNICAL SPECIFICATIONS

Himalaya House,

11th Floor 23, Kasturba Gandhi Marg

NEW DELHI

REGIONAL OFFICES

e-mail : dcjha@trf.co.in

Fax : +91-657-2345214

Business Development Department

MARKETING OFFICES

11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand

Phone : +91- 657-3046500/ 598

Fax no. : +91- 657-2345732, e-mail : co@trf.co.in

HEAD OFFICE & WORKS

= Comprises special design with concave and convex curve to minimise the un-supported length of belt

= Material handled coal, iron ore, limestone, etc. to fill the bunker or pile of mounted on ground

= Up to 2000 mm belt

= Driven electrically

= Manufactured as one-way chute, two-way chute & three-way chute

Likhra / Jsr. (0657) 2291356

SIDE VIEW OF A TRAVELLING TRIPPER

FRONT VIEW OF A TRAVELLING TRIPPER

Travelling Trippers

A

A

Travelling Trippers

Enterprise

TRF LIMITED

Enterprise

TRF LIMITED

Travelling Trippers

TRF LIMITED

individual actuators whichever is required by the customer.

material at the desired location on the conveyor with the help

single actuator either by using special link mechanism or by

The tripper is provided in the conveying system to stack the

The entire bunker opening is sealed by covering with a belt.

on each side. These trippers have a rigid welded steel frame

Bunker Belt Sealing

with wheels, which move on rails, placed parallel to conveyor

COAL

COAL

COAL

COAL

COAL

LIGNITE

chute discharge is cleared automatically to drop the material

used where continuous and uniform distribution of material

By virtue of such a belt profile, the bunker opening below the

Motorised trippers move on independent electric motors. It is

Enterprise

Material Handling, Capacity & other features of some Travelling Trippers:

MATERIAL

of chute/chutes fitted to the tripper. The tripper is provided

The covering belt is deflected in a particular profile with the

to resist shock and minimise distortion.

COAL

help of a set of idlers and it is mounted on the tripper chute.

Motorised Tripper

into bunker.

along the conveyor is required or where the tripper is moved

LIME

COAL

COAL

CLEAN COAL

CLEAN COAL

back and forth frequently. It can be automatically reversed at

CLEAN COAL

each end of its travel with the help of limit switches carried on

the tripper and actuated by stops placed where desired along

the runway. Push buttons are provided for manual control to

regulate the tripper. The tripper can be moved either when the

conveyor belt is moving or stationary. Each tripper is provided

with a hand operated powerful, quick action rail clamp for

holding it in a fixed position. The tripper is provided with a

platform for the operator.

COAL

COAL

Features

CRUSHED

COAL

l To minimize the over hang of belt, the tripper structure

has been designed with concave and convex curves.

L.S/DOLO

IRON ORE/

FLUX

l There are options of drive system. Drives with chain and

sprocket; direct drive with hollow shaft mounted

gearbox alongwith motor and brake.

COKE

SINTER

COAL

CRUSHED

COAL

l Direct drive is also given with hollow shaft mounted

geared motor with an inbuilt brake.

COAL

Long Travel Drive Assembly

Travel drive is through direct wheel axle drive design. A

hollow shaft mounted gear box is placed directly on the wheel

axle. The input of gearbox is coupled with an electric motor.

The brake is mounted on the rear extend shaft of the motor or

between input shaft of gearbox and motor shaft. All drive

components are mounted on a common drivebase which is

connected with the trippers main body with a torque arm.

Alternately geared motor may also be provided with hollow shaft

with inbuilt brake and torque arm arrangement to overcome

space constraint. The power is supplied by a cable reeling drum

mounted on tripper body or festooning cable arrangement, if the

travel length is small.

COAL

l The machine can be controlled either by local operation

from the machine or by remote operation from control

station with selector switch or both.

CRUSHED

COKE

COKE

IRON ORE

l The machine has been provided with all safety controls

and limit switches, such as over travel limit switch,

chute-jamming switch, etc.

350 TPH

(-) 100 mm

250 TPH

(-) 15 mm

1600 TPH

(-)250 mm

400 TPH

(-)20 mm

1800 TPH

(-)20 mm

1200 TPH

(-)30 mm

400 TPH

(-)50 mm

200 TPH

(-)25 TO 80 mm

500 TPH

(-)40/(-)30 mm

200 TPH

(-) 40 mm

800 TPH

(-) 20 mm

1350 TPH

(-) 25 mm

210 TPH

(-) 20 mm

125 TPH

(-) 20 mm

125 TPH

(-) 20 mm

50 TPH

(-) 20 mm

750 TPH

(-) 75 mm

1500 TPH

(-) 250 mm

300 TPH

(-) 20 mm

660 TPH

(-) 6 mm

750 TPH

20 mm

750 TPH

20 mm

750 TPH

20 mm

150 TPH

6 mm

1600 TPH

20 mm

150 TPH

6 mm

CAPACITY

RATED TPH

LUMP SIZE

mm

CAPACITY

DESIGN

165 TPH

1760 TPH

165 TPH

825 TPH

825 TPH

825 TPH

730 TPH

330 TPH

1800 TPH

825 TPH

60 TPH

150 TPH

150 TPH

230 TPH

1485 TPH

960 TPH

240 TPH

600 TPH

240 TPH

480 TPH

1440 TPH

1900 TPH

500 TPH

1900 TPH

275 TPH

385 TPH

3000 TPH

TYPE OF

CHUTE

BELT

WIDTH

2 WAY CHUTE

3.7 KW

1400

3.7 KW

3 WAY CHUTE

2200 TPH

2000 TPH

(-) 20 mm

1 WAY CHUTE

2760 TPH

2300 TPH

(-) 100 mm

2 WAY CHUTE

2760 TPH

2300 TPH

(-) 100 mm

3 WAY CHUTE

2420 TPH

2200 TPH

(-) 20 mm

3 WAY CHUTE

1760 TPH

1600 TPH

(-) 20 mm

2 WAY CHUTE

1200 TPH

1000 TPH

(-)5 TO (+) 5 mm

2 WAY CHUTE

1200 TPH

1000 TPH

(-)5 TO (+) 5 mm

2 WAY CHUTE

2880 TPH

2400 TPH

(-) 8 mm

1000 TPH

(-) 50 mm

1650 TPH

(-) 50 mm

1600 TPH

(-) 20 mm

1500 TPH

(-) 20 mm

300 TPH

(-) 6 mm

180 TPH

150 TPH

(-) 3 mm

480 TPH

MIDDDLINGS

COAL

COAL

COAL

COAL

COAL

COAL

COAL

COAL

COAL

COAL

COAL

360 TPH

1500 TPH

1760 TPH

1815 TPH

1200 TPH

3.7 KW

3.7 KW

5.5 KW

3.7 KW

2.2 KW

1 WAY CHUTE

3850 TPH

3500 TPH

(-) 10 mm

IRON ORE

5.5 KW

2.2 KW

2.2 KW

2.2 KW

2.2 KW

3.7 KW

2 WAY CHUTE

3850 TPH

3500 TPH

(-) 10 mm

COAL

(-) 13 mm

3.7 KW

3.7 KW

3.7 KW

2 WAY CHUTE

3850 TPH

3500 TPH

(-) 10 mm

IRON ORE

600 TPH

(-) 13 mm

3.7 KW

800

1200

1000

1000

1000

600

1400

1000

2 WAY CHUTE

650

650

650

1400

1200

800

1000

3.7 KW

1000

3.7 KW

1000

3.7 KW

1400

3.7 KW

1400

5.5 KW

1000

1.5/0.75 KW

1600

7.5 KW

1000

2 WAY CHUTE

3850 TPH

3500 TPH

(-) 10 mm

COAL

3300 TPH

(-) 20 mm

3.7 KW

3.7 KW

1500

2 WAY CHUTE

1980 TPH

1800 TPH

(-) 25 mm

COAL

COAL

COAL

TRAVEL DRIVE

POWER KW

650

3 WAY CHUTE

3 WAY CHUTE

2 WAY CHUTE

3 WAY CHUTE

3 WAY CHUTE

2 WAY CHUTE

1 WAY CHUTE

2 WAY CHUTE

500

1 WAY CHUTE

1 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

3 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

3 WAY CHUTE

3 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

2 WAY CHUTE

1 WAY CHUTE

1200

2 WAY CHUTE

2 WAY CHUTE

3 WAY CHUTE

1320 TPH

1200 TPH

CHAR

l The machine can be provided with cradle assembly,

mounted on the machine to protect the conveyor belt

from damage due to the impact of discharged material.

400 TPH

3 WAY CHUTE

2420 TPH

2200 TPH

(-) 20 mm

(+)5mm TO (-)50 mm

COAL

Flapper Gate Drive Assembly

2500 TPH

1000

2 WAY CHUTE

435 TPH

360 TPH

COAL

The gate drive is through electro mechanical linear actuator

fitted with link mechanism. The actuator is supported on a

trunnion-mounted bracket. In a three-way chute two flap

gates are required. Both can be operated by a

(-) 6 mm

1200

2 WAY CHUTE

720 TPH

COAL

SINTER

(-) 150 mm

2000

3 WAY CHUTE

3630 TPH

COAL

FRONT VIEW OF A ONE-WAY CHUTE TRAVELLING TRIPPER

2 WAY CHUTE

2 x 3.7 KW

1000

1 WAY CHUTE

3.7 KW

650

3 WAY CHUTE

3.7 KW

1200

3 WAY CHUTE

3.7 KW

1400

3 WAY CHUTE

2 x 2.2 KW

1400

1 WAY CHUTE

2 x 2.2 KW

1600

2 WAY CHUTE

2 x 3.7 KW

1200

2 x 2.2 KW

1600

2 x 5.5 KW

1200

2 x 2.2 KW

1200

2 x 2.2 KW

1400

2 x 3.7 KW

1600

2 x 5.5 KW

1600

1 x 7.5 KW

1600

1 x 7.5 KW

1600

2 x 5.5 KW

1600

2 x 5.5 KW

1600

2 x 5.5 KW

2000

2 x 5.5 KW

2000

2 x 5.5 KW

1600

2 x 5.5 KW

1400

2 x 2.2 KW

1600

2 x 5.5 KW

2 x 3.7 KW

2 x 3.7 KW

2 x 7.5 KW

Você também pode gostar

- Kobelco CKE600 Operator ManualDocumento19 páginasKobelco CKE600 Operator Manualgraig27100% (2)

- Analisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIDocumento10 páginasAnalisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIWaris La Joi WakatobiAinda não há avaliações

- Pulley Idler Shaft F9265C65B8F87Documento3 páginasPulley Idler Shaft F9265C65B8F87souvonik100% (1)

- Screw Take UpsDocumento7 páginasScrew Take Upsjonodo89Ainda não há avaliações

- Belt ConveyorDocumento12 páginasBelt Conveyorjuan carlos alvarez gomez100% (1)

- Failure Analysis and Prospects of Modification in Industrial Belt Conveyor SystemDocumento3 páginasFailure Analysis and Prospects of Modification in Industrial Belt Conveyor SystemGogyAinda não há avaliações

- Fenner-Dunlop Conveyor Problems & SolutionsDocumento18 páginasFenner-Dunlop Conveyor Problems & Solutionsmickey262010Ainda não há avaliações

- SIDE ARM CHARGER Design-R0 PDFDocumento8 páginasSIDE ARM CHARGER Design-R0 PDFSripara KrishnaAinda não há avaliações

- The Design of Conveyor PulleysDocumento8 páginasThe Design of Conveyor PulleysWaris La Joi WakatobiAinda não há avaliações

- Metso Minerals - Apron Feeder - Application Data SheetDocumento2 páginasMetso Minerals - Apron Feeder - Application Data SheetAnonymous 8t0V9SAinda não há avaliações

- Shell Thickness PDFDocumento6 páginasShell Thickness PDFLucia ZambranoAinda não há avaliações

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshAinda não há avaliações

- Conveyor Pulley Failure Analysis PDFDocumento3 páginasConveyor Pulley Failure Analysis PDFriysallAinda não há avaliações

- Belt Conveyor CalculationDocumento8 páginasBelt Conveyor CalculationFarrahxviiiAinda não há avaliações

- Belt Conveyor Vertical CurvesDocumento1 páginaBelt Conveyor Vertical CurvesmlacordAinda não há avaliações

- Bearing Centre and Face Width in Conveyor PulleyDocumento8 páginasBearing Centre and Face Width in Conveyor PulleyPrashant MishraAinda não há avaliações

- Finite Element Analysis and Improved Design of Large Scale Belt Conveyor DrumsDocumento13 páginasFinite Element Analysis and Improved Design of Large Scale Belt Conveyor Drumsjhon ortizAinda não há avaliações

- Loeffler Engineering Group Conveyor Design and Estimating Software Updated 4-13-07Documento5 páginasLoeffler Engineering Group Conveyor Design and Estimating Software Updated 4-13-07Luis Matamala MoAinda não há avaliações

- PD2021-Plant Design Workflow Using Autodesk Plant Design Suite UltimateDocumento12 páginasPD2021-Plant Design Workflow Using Autodesk Plant Design Suite UltimatekalaiAinda não há avaliações

- SME 2017 Design and Analysis of Conveyor Pulleys - A HustrulidDocumento34 páginasSME 2017 Design and Analysis of Conveyor Pulleys - A Hustrulidtadela_553439598Ainda não há avaliações

- Conveyor Belt Engineering TablesDocumento5 páginasConveyor Belt Engineering Tablestaohung1120Ainda não há avaliações

- ConyevorsDocumento9 páginasConyevorsRohan MalkarAinda não há avaliações

- IdlerDesignGuide PROKDocumento25 páginasIdlerDesignGuide PROKEge UgurluAinda não há avaliações

- Take Up Brochure - Web PDFDocumento16 páginasTake Up Brochure - Web PDFM Sulaiman0% (1)

- Hosch Opearting Manual1 PDFDocumento13 páginasHosch Opearting Manual1 PDFZahoor AhmedAinda não há avaliações

- Japan Pipe Belt Conveyor Sy...Documento7 páginasJapan Pipe Belt Conveyor Sy...salkan_rahmanovic810Ainda não há avaliações

- Bulk Material Handling: Practical Guidance for Mechanical EngineersNo EverandBulk Material Handling: Practical Guidance for Mechanical EngineersNota: 5 de 5 estrelas5/5 (1)

- CHP SpecifictionDocumento36 páginasCHP SpecifictionVaibhav Jain100% (1)

- Belt Conveyor PulleysDocumento24 páginasBelt Conveyor PulleysPok Jak Salleh100% (2)

- Bulk Material Handling Belt-Conveyor-CatalogDocumento21 páginasBulk Material Handling Belt-Conveyor-CatalogjayAinda não há avaliações

- Jenikes' TheoryDocumento209 páginasJenikes' TheoryMohammad Bataineh100% (1)

- Design Aspects of A Motorised Travelling TripperDocumento5 páginasDesign Aspects of A Motorised Travelling Trippercar5lyle100% (1)

- Vibrating FeederDocumento7 páginasVibrating FeederRk Upadhyay100% (1)

- Conveyor Idler StandardsDocumento10 páginasConveyor Idler StandardsObiwan1483100% (1)

- MMG Australia Limited, 2 5 Dam Tailing Storage Facility, Rosebery - Dpemp - Appendix A - Design Report - Part 1Documento78 páginasMMG Australia Limited, 2 5 Dam Tailing Storage Facility, Rosebery - Dpemp - Appendix A - Design Report - Part 1kalaiAinda não há avaliações

- 9.long Overland ConveyorsDocumento14 páginas9.long Overland ConveyorsMauricio MpintoAinda não há avaliações

- BELT CONVEYOR - Discharge TrajectoryDocumento3 páginasBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteAinda não há avaliações

- Steel Cord Conveyor Belt 1 PDFDocumento16 páginasSteel Cord Conveyor Belt 1 PDFSudarshan deshpandeAinda não há avaliações

- Aditya Tech Diary PDFDocumento155 páginasAditya Tech Diary PDFSiddhant Satpathy100% (1)

- Extract From The Book Belt FeederDocumento93 páginasExtract From The Book Belt FeederPushp Dutt100% (1)

- PNR vs. IACDocumento2 páginasPNR vs. IACNeil bryan Moninio100% (1)

- Static Shaft Pulleys With Internal BearingsDocumento14 páginasStatic Shaft Pulleys With Internal Bearingsjonodo89100% (1)

- Terex T340 1XLDocumento8 páginasTerex T340 1XLKatarina Milosavljevic100% (1)

- Belt Conveyor Pulley Design - Why The FailuresDocumento16 páginasBelt Conveyor Pulley Design - Why The FailuresenrimauryAinda não há avaliações

- BOStrab - en Version 2008Documento74 páginasBOStrab - en Version 2008Panagiotis XanthosAinda não há avaliações

- Traveling Tripper Operation ProcedureDocumento10 páginasTraveling Tripper Operation Procedureratan das75% (4)

- Bucket Elevator ChainDocumento4 páginasBucket Elevator Chainluisreng100% (1)

- Manual Helix Delta t6Documento309 páginasManual Helix Delta t6Ricardo Garay Reinoso100% (2)

- TS of Travelling TripperDocumento10 páginasTS of Travelling TripperShashank HegdeAinda não há avaliações

- General Material: CommentsDocumento10 páginasGeneral Material: CommentsRafael FerreiraAinda não há avaliações

- OSepaseparator 1Documento6 páginasOSepaseparator 1Slobodan StrainovićAinda não há avaliações

- Flexowell - 2013 - EnglischDocumento5 páginasFlexowell - 2013 - Englischeduardo_chaban100% (1)

- Bins & Feeders in Cement IndustryDocumento29 páginasBins & Feeders in Cement IndustryNaelAinda não há avaliações

- Is 8531 1986Documento6 páginasIs 8531 1986Srini KumarAinda não há avaliações

- Apron Feeder SpecDocumento2 páginasApron Feeder Spec20106285Ainda não há avaliações

- Elevator Belt and Splice Installation GuideDocumento17 páginasElevator Belt and Splice Installation Guide4B Braime ComponentsAinda não há avaliações

- Iso 3684 1990Documento8 páginasIso 3684 1990joaquin fuentealba moralesAinda não há avaliações

- Covered (Stick) Electrodes (SMAW)Documento5 páginasCovered (Stick) Electrodes (SMAW)Hanny Dewi SaragihAinda não há avaliações

- USITT 2006 Winch Session ComDocumento104 páginasUSITT 2006 Winch Session Comrajee7Ainda não há avaliações

- Truwater - TCM SeriesDocumento12 páginasTruwater - TCM SeriesnkhhhAinda não há avaliações

- 0 34 Chain Conveyor RL and RMDocumento1 página0 34 Chain Conveyor RL and RMFlamingorosadoAinda não há avaliações

- Woodworking ToolsDocumento21 páginasWoodworking Toolsbenderman1Ainda não há avaliações

- Cable TerminationDocumento2 páginasCable TerminationElectrical RadicalAinda não há avaliações

- Column Drilling MachineDocumento8 páginasColumn Drilling MachineShubhadeep MajumdarAinda não há avaliações

- O-A2 Parts IndexDocumento36 páginasO-A2 Parts IndexNathan BukoskiAinda não há avaliações

- nf00032067 2 PDFDocumento76 páginasnf00032067 2 PDFkalaiAinda não há avaliações

- nf00032067 2 PDFDocumento76 páginasnf00032067 2 PDFkalaiAinda não há avaliações

- Ijett V10P331 PDFDocumento6 páginasIjett V10P331 PDFkalaiAinda não há avaliações

- SideDraft Product Bulletin PDFDocumento1 páginaSideDraft Product Bulletin PDFkalaiAinda não há avaliações

- English ReflectionDocumento2 páginasEnglish ReflectionRainier TarpinAinda não há avaliações

- Design + Construction Magazine (October To December 2018)Documento88 páginasDesign + Construction Magazine (October To December 2018)Khuta JhayAinda não há avaliações

- Charterhouse Antiques Auction March 23 2012Documento28 páginasCharterhouse Antiques Auction March 23 2012bromellAinda não há avaliações

- Forth Ports Imperial Grain Silo Demoltion. Main ReportDocumento99 páginasForth Ports Imperial Grain Silo Demoltion. Main ReportGreenerLeithAinda não há avaliações

- Transport or Transportation (US) Is The Movement of Humans, Animals andDocumento1 páginaTransport or Transportation (US) Is The Movement of Humans, Animals andFSugarAinda não há avaliações

- Flyover: Solutions Po ProblemsDocumento2 páginasFlyover: Solutions Po Problemspragati kashyapAinda não há avaliações

- Company ProfileDocumento27 páginasCompany ProfileWathik AbmAinda não há avaliações

- Central Railway Central Railway: Alcon Builder & Engineers Alcon Builder & EngineersDocumento1 páginaCentral Railway Central Railway: Alcon Builder & Engineers Alcon Builder & EngineersKoteswara Rao MAinda não há avaliações

- Estimation QuestionDocumento66 páginasEstimation Questionnikesh25Ainda não há avaliações

- BEMLDocumento93 páginasBEMLPrashanth PB100% (4)

- Kontroll4-Jb10 jb11Documento2 páginasKontroll4-Jb10 jb11suhailfarhaanAinda não há avaliações

- APTA Peer Review of Fare PolicyDocumento33 páginasAPTA Peer Review of Fare PolicyMetro Los AngelesAinda não há avaliações

- Geography Project WorkDocumento10 páginasGeography Project WorkingridAinda não há avaliações

- Anything For U AnjaliDocumento30 páginasAnything For U Anjalinalayathan123Ainda não há avaliações

- Neptun LaborcsoportDocumento15 páginasNeptun LaborcsoportsyyAinda não há avaliações

- Meriden Transit Oriented Development Master Plan: April 2012Documento23 páginasMeriden Transit Oriented Development Master Plan: April 2012Lucian AnastasiuAinda não há avaliações

- VSB6 Vehicle RegulationDocumento35 páginasVSB6 Vehicle Regulationct0720054858Ainda não há avaliações

- CE8702-Railways Airports Docks and Harbour EngineeringDocumento12 páginasCE8702-Railways Airports Docks and Harbour EngineeringAK BaldaboiAinda não há avaliações

- Brooklyn Marriot Floor PlanDocumento7 páginasBrooklyn Marriot Floor PlanKJ Gast100% (2)

- MV Switchgear PDFDocumento13 páginasMV Switchgear PDFsouheil boussaidAinda não há avaliações

- 18 Items HistoryOfPortlandOregon HistoryPortlandOregon - Scott - 794pgs PDFDocumento792 páginas18 Items HistoryOfPortlandOregon HistoryPortlandOregon - Scott - 794pgs PDFNickLocherAinda não há avaliações

- Paris GuideDocumento3 páginasParis GuideCarmelo RiveraAinda não há avaliações

- Pendant StationDocumento2 páginasPendant StationVenu GopalAinda não há avaliações

- Design of Aberdeen Channel Bridge - Hong KongDocumento8 páginasDesign of Aberdeen Channel Bridge - Hong KongUlasi IfeanyiAinda não há avaliações

- 67-68 Cougar Rear TorqueArmDocumento18 páginas67-68 Cougar Rear TorqueArmChristian VillaAinda não há avaliações

- MLine Manual0303Documento32 páginasMLine Manual0303Eagles1988Ainda não há avaliações

- Double Elimination BracketDocumento52 páginasDouble Elimination BracketAmanda RhodesAinda não há avaliações

- Kashmeregateisbt 140914100001 Phpapp01Documento8 páginasKashmeregateisbt 140914100001 Phpapp01Iqra QaziAinda não há avaliações