Escolar Documentos

Profissional Documentos

Cultura Documentos

Datasheet STERLING 6630pdf

Enviado por

Luis Antonio RivasDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Datasheet STERLING 6630pdf

Enviado por

Luis Antonio RivasDireitos autorais:

Formatos disponíveis

PRODUCT DATA SHEET

STERLING 6630 carbon black

GENERAL DESCRIPTION

STERLING 6630 carbon black was developed for superior performance in

extruded and molded rubber product applications where eliminating surface

defects and minimizing scrap rates are critical.

The surface area and structure of STERLING 6630 carbon black conforms to

ASTM N550 target values. STERLING 6630 carbon black is cleaner than standard

ASTM semi-reinforcing carbon blacks, which results in fewer defects on extruded

rubber surfaces. The improved cleanliness of STERLING 6630 carbon black can

also contribute to a longer screen life (fewer screen changes) and less wear on

extruder barrel, screw and die from abrasion compared to conventional ASTM

carbon black products.

STERLING 6630 carbon black is designed to provide longer scorch time resulting

in improved processing safety. In continuous vulcanization operations, the

increased scorch time with STERLING 6630 carbon black can provide more

consistent and larger cell size for sponge products.

PERFORMANCE FEATURES

Higher cleanliness than standard ASTM semi-reinforcing carbon blacks,

which can result in:

oo fewer product surface defects and lower scrap rates,

oo longer extruder screen life or less frequent screen changes,

oo longer die life,

oo less barrel and screw wear,

Good reinforcing in EPDM for consistent high-temperature,

continuous-cure applications

Better tensile strength than ASTM N650 carbon black

TYPICAL APPLICATIONS

Industrial Rubber Product Applications

oo Seals

oo Weather stripping

oo Hoses

oo Belts

oo Extruded profiles

oo Mounts and bushings

STERLING 6630 carbon black

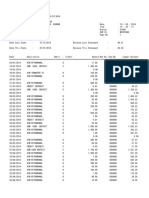

TECHNICAL DATA

1) STERLING 6630 carbon black exhibits rubber reinforcement and processing properties similar to those of ASTM N550

carbon black, but imparts fewer visible imperfections on the surfaces of extruded rubber parts.

Test formulation: 100 EPDM, 75 Paraffinic Oil, 20 phr Whiting, Sulphur cure vulcanization system

STERLING 6630

Loading (phr)

70

Dispersion on 265 cm2 extruded EPDM tape surface:

ASTM N550

70

Extruded Tape defect counts

PROCESSING PROPERTIES

41

Tape defect counts

ML (1+4) at 100C, (M.U.)

43

PHYSICAL PROPERTIES

Hardness

Shore A

52

52

10.7

10.7

100% Modulus, MPa

1.8

2.0

300% Modulus, MPa

6.0

6.1

440

450

Tensile Properties

Tensile Strength, MPa

Elongation at Break, %

ASTM N550

300

Mooney Viscosity

STERLING 6630

250

200

150

100

50

0

150-200 m

200-250 m

> 250 m

Tape defect size classes, ( m)

2) Screen Pack Pressure Rise in an EPDM test compound (100 phr carbon black)

In an extrusion through a 325 mesh (45 micron) screen pack at 100C and a rate

of 50 gram/minute, STERLING 6630 carbon black shows a lower rate of pressure

rise than two competitive ASTM N550 carbon black products.

PRESSURE (PSI)

6,000

5,000

4,000

SCREEN Break

3,000

2,000

ASTM N550 Competitor 1

ASTM N550 Competitor 2

1,000

STERLING 6630

NORTH AMERICA

SOUTH AMERICA

EMEA*

Cabot Corporation

1095 Windward Ridge

Parkway

Suite 200

Alpharetta, GA 30005

USA

TEL +800 472 4889

Cabot Brasil Industria e

Comrcio Ltda.

Rua do Paraiso 148-5th floor

Sao Paulo SP, Brazil

Paraiso CEP.: 04103-000

TEL +55 11 2144 6400

CUSTOMER SERVICE

0800 195959

Cabot EMEA Business Service Centre

SIA Cabot Latvia

101 Mukusalas Street

Riga, LV-1004

Latvia

TEL +371 67050700

*Europe, Middle East and Africa

60

120 180 240 300 360 420 480 540 600

TIME (sec)

CHINA

Cabot China Ltd.

558 Shuangbai Road

Minghang District

Shanghai 201108

China

TEL +86 21 5175 8800

ASIA PACIFIC NORTH

Cabot Japan K.K.

Sumitomo Shiba-Daimon Bldg. 3F

2-5-5 Shiba Daimon,

Minato-ku

Tokyo 105-0012

Japan

TEL +81 3 3431 1770

ASIA PACIFIC SOUTH

PT. Cabot Indonesia

Talavera Office Park

Jl. Letjen TB Simatupang

Kav 22-26, Cilandak

Jakarta 12430

Indonesia

TEL +62 21 27584100

This information is provided as a convenience and for informational purposes only. No guarantee or warranty as to this information, or any

product to which it relates, is given or implied. This information may contain inaccuracies, errors or omissions and CABOT DISCLAIMS ALL

WARRANTIES EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE AS TO (i) SUCH INFORMATION, (ii)

ANY PRODUCT OR (iii) INTELLECTUAL PROPERTY INFRINGEMENT. In no event is Cabot responsible for, and Cabot does not accept and hereby

disclaims liability for, any damages whatsoever in connection with the use of or reliance on this information or any product to which it relates.

cabotcorp.com

S6630_pds 09/2014

Você também pode gostar

- Small Block Chevrolet: Stock and High-Performance RebuildsNo EverandSmall Block Chevrolet: Stock and High-Performance RebuildsNota: 4 de 5 estrelas4/5 (6)

- Essential Rubber Formulary: Formulas for PractitionersNo EverandEssential Rubber Formulary: Formulas for PractitionersNota: 3 de 5 estrelas3/5 (1)

- Afton Lube Specification HandbookDocumento425 páginasAfton Lube Specification HandbookvsssarmaAinda não há avaliações

- Mecanic AsDocumento6 páginasMecanic AsAnderson SantosAinda não há avaliações

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsNo EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsNota: 4.5 de 5 estrelas4.5/5 (17)

- Weld Like a Pro: Beginning to Advanced TechniquesNo EverandWeld Like a Pro: Beginning to Advanced TechniquesNota: 4.5 de 5 estrelas4.5/5 (6)

- SH210 5 SERVCE CD PDF Pages 1 33Documento33 páginasSH210 5 SERVCE CD PDF Pages 1 33Em sulistio87% (23)

- Heat TreatmentsDocumento14 páginasHeat Treatmentsravishankar100% (1)

- Datasheet Black Pearls 2000pdfDocumento2 páginasDatasheet Black Pearls 2000pdfGUNZAinda não há avaliações

- TYCO Keystone F14.Lined - Butterfly.valve enDocumento4 páginasTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuAinda não há avaliações

- Rubber LiningDocumento16 páginasRubber Liningbbmoksh100% (1)

- Huck BOM: The Highest Strength Blind Fasteners in The WorldDocumento5 páginasHuck BOM: The Highest Strength Blind Fasteners in The WorldEldori1988Ainda não há avaliações

- Catalogue CSM PDFDocumento4 páginasCatalogue CSM PDFFran IgledominguezAinda não há avaliações

- Bollard GuideDocumento8 páginasBollard GuideCtr YlAinda não há avaliações

- Shortex CutterDocumento2 páginasShortex CutterMuhammad SafdarAinda não há avaliações

- Qualitek 381F No Clean Flux: Technical Specifications Technical Data SheetDocumento4 páginasQualitek 381F No Clean Flux: Technical Specifications Technical Data SheetteknoartistAinda não há avaliações

- Robotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icDocumento8 páginasRobotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icAsrul Arashi IrdianaAinda não há avaliações

- Datasheet MONARCH 570pdf PDFDocumento2 páginasDatasheet MONARCH 570pdf PDFSUDARSHAN dAWAinda não há avaliações

- Imi Cci 860hpcDocumento4 páginasImi Cci 860hpcWilliam SukyonoAinda não há avaliações

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Documento3 páginasMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsAinda não há avaliações

- SINO - KA300 - Scale ManualDocumento21 páginasSINO - KA300 - Scale ManualAnonymous jW9BkgbQmE100% (1)

- CATALOGO U-Bolt Cote BrochureDocumento4 páginasCATALOGO U-Bolt Cote BrochureEdwin Junior Castillo Luzon100% (1)

- John Crane 502Documento6 páginasJohn Crane 502Eh OngAinda não há avaliações

- Adco Ball ValveDocumento20 páginasAdco Ball ValverajeshygawdeAinda não há avaliações

- Company Profile Piling PipeDocumento52 páginasCompany Profile Piling PipeMargaretta WijayantiAinda não há avaliações

- Datasheet STERLING NSPDF PDFDocumento2 páginasDatasheet STERLING NSPDF PDFhery siregarAinda não há avaliações

- Om 340Documento3 páginasOm 340RAinda não há avaliações

- OM SAI ProfileDocumento10 páginasOM SAI ProfileBittuAinda não há avaliações

- SUNPAL Architectural System-BrochureDocumento20 páginasSUNPAL Architectural System-BrochureGirish Dhawan0% (1)

- Desmopan BayerDocumento22 páginasDesmopan BayerGabriel SalomonAinda não há avaliações

- Monarch® 160 Specialty Carbon Black: Product HighlightsDocumento2 páginasMonarch® 160 Specialty Carbon Black: Product HighlightsInasio ArcilaAinda não há avaliações

- O-Rings & SealsDocumento10 páginasO-Rings & SealsPartsGopher.comAinda não há avaliações

- GLK7673-20100826174134-2010 Aroflint FlyerDocumento2 páginasGLK7673-20100826174134-2010 Aroflint FlyerUsama AwadAinda não há avaliações

- Monolithic Insulating JointsDocumento5 páginasMonolithic Insulating JointsTran Thanh TungAinda não há avaliações

- Alpha Om-338 Teknisk DatabladDocumento3 páginasAlpha Om-338 Teknisk Databladnormans00Ainda não há avaliações

- Castrol RLX Super 40Documento2 páginasCastrol RLX Super 40HurAinda não há avaliações

- Ap Getoel EpDocumento1 páginaAp Getoel EpSami KahtaniAinda não há avaliações

- Alpha Aqualine 6000 WRC TB SM479-8 English 20171228Documento3 páginasAlpha Aqualine 6000 WRC TB SM479-8 English 20171228Barbara AlejoAinda não há avaliações

- Block and Bleed Valve-SystemsDocumento4 páginasBlock and Bleed Valve-Systemsvmr456Ainda não há avaliações

- Tech BS 4449 2005Documento10 páginasTech BS 4449 2005Syed RizwanAinda não há avaliações

- 2300JKVDocumento44 páginas2300JKVmedi38Ainda não há avaliações

- Tooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool CompanyDocumento4 páginasTooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool Companyjavier_mor69Ainda não há avaliações

- LOCK-O-RING Flanges and PlugsDocumento6 páginasLOCK-O-RING Flanges and Plugsrafael_camacho_15Ainda não há avaliações

- Datasheet MONARCH 430Documento2 páginasDatasheet MONARCH 430Nicoleta HomescuAinda não há avaliações

- Diaphragm Wall Equipment PartsDocumento16 páginasDiaphragm Wall Equipment PartsBinSayeedAinda não há avaliações

- O-Rings & SealsDocumento10 páginasO-Rings & SealstribleprinceAinda não há avaliações

- SigmaCover 280Documento5 páginasSigmaCover 280ajuhaseenAinda não há avaliações

- Value Bond VB NominalDocumento4 páginasValue Bond VB NominaljessikaAinda não há avaliações

- Sensor de FlujoDocumento2 páginasSensor de FlujoDany Chl100% (1)

- Alcomer 115: Technical InformationDocumento3 páginasAlcomer 115: Technical InformationPrototypeAinda não há avaliações

- Chi CharraDocumento6 páginasChi CharraMax PawerAinda não há avaliações

- Twi Training & Certification (S.E. Asia) SDN - BHDDocumento1 páginaTwi Training & Certification (S.E. Asia) SDN - BHDjasminneeAinda não há avaliações

- Api Plan 11Documento6 páginasApi Plan 11johnsaballaAinda não há avaliações

- NUPLEX Plastics NU 006 Resins Automotive Plastics 14-15Documento6 páginasNUPLEX Plastics NU 006 Resins Automotive Plastics 14-15Emilio HipolaAinda não há avaliações

- API Flange Bolting Torque ChartDocumento8 páginasAPI Flange Bolting Torque ChartCristian Alfredo OyarzunAinda não há avaliações

- Data Sheets For GRP Pipe PN10Documento7 páginasData Sheets For GRP Pipe PN10nilanga123Ainda não há avaliações

- Vallourec IPC-207Documento4 páginasVallourec IPC-207zapspazAinda não há avaliações

- Modern Glass CharacterizationNo EverandModern Glass CharacterizationMario AffatigatoAinda não há avaliações

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyNo EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyNota: 5 de 5 estrelas5/5 (1)

- IP Based Fingerprint Access Control & Time Attendance: FeatureDocumento2 páginasIP Based Fingerprint Access Control & Time Attendance: FeaturenammarisAinda não há avaliações

- Notice For AsssingmentDocumento21 páginasNotice For AsssingmentViraj HibareAinda não há avaliações

- QuizDocumento11 páginasQuizDanica RamosAinda não há avaliações

- tdr100 - DeviceDocumento4 páginastdr100 - DeviceSrđan PavićAinda não há avaliações

- Milestone 9 For WebsiteDocumento17 páginasMilestone 9 For Websiteapi-238992918Ainda não há avaliações

- COGELSA Food Industry Catalogue LDDocumento9 páginasCOGELSA Food Industry Catalogue LDandriyanto.wisnuAinda não há avaliações

- La Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanDocumento4 páginasLa Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanKarlle ObviarAinda não há avaliações

- Nissan E-NV200 Combi UKDocumento31 páginasNissan E-NV200 Combi UKMioMaulenovoAinda não há avaliações

- Steam Source Book PDFDocumento108 páginasSteam Source Book PDFJose Levican A100% (1)

- An Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)Documento18 páginasAn Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)gurumurthy38Ainda não há avaliações

- Bank Statement SampleDocumento6 páginasBank Statement SampleRovern Keith Oro CuencaAinda não há avaliações

- Fundamental RightsDocumento55 páginasFundamental RightsDivanshuSharmaAinda não há avaliações

- 1980WB58Documento167 páginas1980WB58AKSAinda não há avaliações

- SPC Abc Security Agrmnt PDFDocumento6 páginasSPC Abc Security Agrmnt PDFChristian Comunity100% (3)

- Reference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsDocumento43 páginasReference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsNisha JosephAinda não há avaliações

- CEA 4.0 2022 - Current Draft AgendaDocumento10 páginasCEA 4.0 2022 - Current Draft AgendaThi TranAinda não há avaliações

- LICDocumento82 páginasLICTinu Burmi Anand100% (2)

- Descriptive Statistics - SPSS Annotated OutputDocumento13 páginasDescriptive Statistics - SPSS Annotated OutputLAM NGUYEN VO PHIAinda não há avaliações

- Safety Data Sheet: Fumaric AcidDocumento9 páginasSafety Data Sheet: Fumaric AcidStephen StantonAinda não há avaliações

- Introduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions ManualDocumento12 páginasIntroduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions Manualethelbertsangffz100% (34)

- Admissibility of Whatsapp Messages in Court For Family MattersDocumento3 páginasAdmissibility of Whatsapp Messages in Court For Family Mattersnajihah adeliAinda não há avaliações

- Hierarchy of The Inchoate Crimes: Conspiracy Substantive CrimeDocumento18 páginasHierarchy of The Inchoate Crimes: Conspiracy Substantive CrimeEmely AlmonteAinda não há avaliações

- Epenisa 2Documento9 páginasEpenisa 2api-316852165100% (1)

- Braga - 2016 - On Standing's A Precariat Charter - Confronting The Precaritisation of Labour in Brazil and PortugalDocumento12 páginasBraga - 2016 - On Standing's A Precariat Charter - Confronting The Precaritisation of Labour in Brazil and PortugalLiam MurciaAinda não há avaliações

- Vice President Enrollment Management in Oklahoma City OK Resume David CurranDocumento2 páginasVice President Enrollment Management in Oklahoma City OK Resume David CurranDavidCurranAinda não há avaliações

- Kayako Support Suite User Manual PDFDocumento517 páginasKayako Support Suite User Manual PDFallQoo SEO BaiduAinda não há avaliações

- Income Tax Calculator 2023Documento50 páginasIncome Tax Calculator 2023TARUN PRASADAinda não há avaliações

- BSBOPS601 Develop Implement Business Plans - SDocumento91 páginasBSBOPS601 Develop Implement Business Plans - SSudha BarahiAinda não há avaliações