Escolar Documentos

Profissional Documentos

Cultura Documentos

Hover Flight Helicopter

Enviado por

ernestozagDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hover Flight Helicopter

Enviado por

ernestozagDireitos autorais:

Formatos disponíveis

Actas de las XXXVI Jornadas de Automtica, 2 - 4 de septiembre de 2015.

Bilbao

ISBN 978-84-15914-12-9 2015 Comit Espaol de Automtica de la IFAC (CEA-IFAC)

473

Hover Flight Helicopter Modelling and Vibrations Analysis

Salvador Castillo-Rivera

The School of Engineering and Mathematical Sciences. The City University London. United Kingdom,

email: Salvador.Castillo-Rivera.1@city.ac.uk

M. Tomas-Rodriguez

The School of Engineering and Mathematical Sciences. The City University London. United Kingdom,

email: Maria.Tomas-Rodriguez.1@city.ac.uk

Abstract

In this work, different modelling aspects of helicopter

aerodynamics are discussed. The helicopter model is

on Sikorsky configuration, main rotor in

perpendicular combination with a tail rotor. The

rotors are articulated and their blades are rigid. The

main rotor implementation takes into account flap,

lag and feather degrees of freedom for each of the

equispaced blades as well as their dynamic

couplings. The model was built by using VehicleSim,

software specialized in modelling mechanical

systems composed by rigid bodies. Appearing

vibrations due to the rotating behaviour of the rotors

are studied in here. This work presents an

aerodynamic model that allows to simulate hover

flight. The aerodynamic model has been built up

using blade element theory. The aerodynamic load

creates vibrations on the helicopter and these are

analyzed on the fuselage by using short time Fourier

transform processing to study the vibrations

spectrum. The results of the simulations are

presented and compared to existing mechanical

vibrations generated by a dynamic model developed

by the authors as well as existing theory in the

specialist literature.

Keywords: Vibrations,

aerodynamics.

helicopter,

dynamics,

1 INTRODUCTION

Helicopter vibration is common a problem which

involves complex interactions between the inertial,

structural loads and aerodynamic loads. The major

source of vibrations in helicopters is the main rotor,

whereas in fixed-wing aircraft, the vibrations are

mostly originated by the engines or are caused by

atmospheric turbulences. In aircraft's design,

vibrations have remained one of the major problems

affecting helicopter development for years. In fact,

the maximum speed and manoeuvring capabilities for

most of the modern helicopters are limited by

excessive vibration. Vibrations frequencies are either

equal to the rotors frequencies or multiple of them.

The rotors frequencies are a function of the angular

speeds at which they rotate [5].

Vibrations affect ride comfort, adds to the fatigue of

pilots, crew, and passengers and increases

maintenance time and cost. High vibration levels

experienced by a helicopter could in many cases pose

a limitation to the vehicles forward speed and

manoeuvring capabilities. In addition to this,

vibrations affect the helicopter handling qualities,

contribute to the fatigue of structural components,

reduce the reliability of on board electronic

equipment, and influence the precision of equipment

such as cameras, measure devices, etc. [7], [11].

The reduction of helicopter vibrations has

traditionally been a difficult task to achieve.

Vibrations should be analysed and study in order to

identify their main frequencies. This information can

be used to design vibration control methods for

helicopters [8].

The structure of the article is as follows: in sections 2

and 3, the aspects of the dynamic helicopter model

are considered. Section 4 describes VehicleSim

environment, used to implement the model of the

helicopter. In section 5, a hover aerodynamic model

is provided. Vibrations analysis on the fuselage, as a

consequence of the aerodynamic and dynamic loads

are given in Section 6. Section 7 contains the

conclusions of the article.

2 DYNAMIC MODEL

The helicopter under study is on Sikorsky

configuration i.e., main rotor in perpendicular

combination with a tail rotor. Both systems are

mounted on the fuselage. The helicopter model

consists of fuselage, main rotor and tail rotor, both

articulated. The main rotor consists of four equally

spaced blades joined to a central hub and the tail

rotor consists of two equally spaced blades joined to

a secondary hub. The blades are rigid in both rotors.

Actas de las XXXVI Jornadas de Automtica, 2 - 4 de septiembre de 2015. Bilbao

ISBN 978-84-15914-12-9 2015 Comit Espaol de Automtica de la IFAC (CEA-IFAC)

The helicopter has six degrees of freedom: three

translations along the (X, Y, Z) axes and three

rotations around the same axes. The model presented

in this paper is based in previous works developed by

the authors (see [2], [3], [4], [10], [14]).

2.1 FUSELAGE

The fuselage is the rotorcraft's main body section that

holds crew and passengers, amongst other. Its

degrees of freedom are the lateral and longitudinal

translation in the horizontal plane X-Y axis, vertical

translation (Z axis) and rotation about these same

axes corresponding to yaw, pitch and roll.

2.2 MAIN ROTOR

The role of the main rotor is to support the aircraft's

weight, as it generates the lift force. It allows to keep

the helicopter suspended in the air and provides the

control that allows to follow a prescribed trajectory

in the various spatial directions by changing altitude

and executing turns. It transfers prevailingly

aerodynamic forces and moments from the rotating

blades to the non-rotating frame (fuselage). The

blades are kept in uniform rotational motion

(rotational speed ), by a shaft torque from the

engine. A common design solution adopted in the

development of the helicopter is to use hinges at the

blades roots that allow free motion of the blade

normal to and in the plane of the disc. The most

common of these hinges is the flap hinge which

allows the blade to flap, this is, to move in a plane

containing the blade and the shaft, of the disc plane,

about either the actual flap hinge or in some other

cases, the flap hinge is substituted by a region of

structural flexibility at the root of the blade. The flap

hinge is more frequently designed to be a short

distance from the centre line. This is termed an

"offset" (eR), and it offers the designer a number of

important advantages.

A blade which is free to flap, experiences large

Coriolis moments in the plane of rotation and a

further hinge (called lag) is provided to relieve these

moments. This degree of freedom produces blade

motion on the same plane as the disc. In presence of

aerodynamic loads this degree of freedom generates

the blades drag force.

A blade can also feather around an axis parallel to the

blade span. Blade feather motions are necessary to

control the aerodynamic lift developed and, in

forward motion of the helicopter, to allow the

advancing blade to have a lower angle of incidence

than the retreating blade and thereby to balance the

lift across the craft. In order to be able to climb up,

the feather angle needs to be increased. On the other

hand, in order to descend, the blade's feather angle is

474

decreased. Because all blades are acting

simultaneously in this case, or collectively, this is

known as collective feather and allows the rotorcraft

to rise/fall vertically. Additionally to this control, for

achieving forward, backward and sideways flight, a

different additional change of feather is required. The

feather on each individual blade is increased at the

same selected point on its circular pathway. This is

known as cyclic feather or cyclic control. Blade

feather control is achieved through linkage of the

blade to a swashplate.

2.3 TAIL ROTOR

The tail rotor is mounted in perpendicular to the main

rotor. It counteracts the torque and the yaw motion

that the main rotor disc naturally produces. In

accordance to Newton's third law of action and

reaction, the fuselage tends to rotate on the opposite

direction to the main rotor's blades as a reaction of

the torque that appears (see Figure 1).

Figure 1: Tail rotor counteracting the torque induced

by the main rotor rotation.

This torque must be counteracted and/or controlled

before any type of flight is possible. Two anti-torque

pedals allow the pilot to compensate for torque

variance by providing a means of changing pitch

(angle of attack) of the tail rotor blades. This

provides heading and directional control in hover and

at low airspeeds. Driven by the main rotor at a

constant ratio, the tail rotor produces thrust in a

horizontal plane opposite to torque reaction

developed by the main rotor. Since the main rotor

torque varies during flight when power changes are

made, it is necessary to vary the thrust of the tail

rotor. A significant part of the engine power is

required to drive the tail rotor, especially during

operations when maximum power is used. Any

change in engine power output produces a change in

the torque effect.

Actas de las XXXVI Jornadas de Automtica, 2 - 4 de septiembre de 2015. Bilbao

ISBN 978-84-15914-12-9 2015 Comit Espaol de Automtica de la IFAC (CEA-IFAC)

3 VEHICLESIM AS MODELLING

TOOL

VehicleSim is a multibody modelling software. It has

been used over a wide range of mechanical dynamic

studies, mainly in connection to vehicle dynamics

[13] and it has provided the basis for commercial

simulation codes such as TruckSim, CarSim and

BikeSim [6]. The syntactic rules of VehicleSim are

straightforward. The output from VehicleSim can

take one of several forms: (a) a rich text format file

containing the symbolic equations of motion of the

system described; (b) a C language simulation

program with appropriate data files containing

parameter values and simulation run control

parameters or (c) linear state space equations in a

MATLAB Mfile format that contains symbolic

statespace A, B, C, D matrices that can be used for

linear analysis. Once the model has been built, it

becomes independent of VehicleSim and can be

executed at any time.

4 PROGRAM STRUCTURE

VehicleSim Lisp is used to develop the multibody

system code that represents a helicopter system. The

multibody system is subdivided into its constituent

bodies for the purpose of writing the VehicleSim

code. The bodies are arranged as a parent-child

relationship. The first body is the inertial frame and it

has the fuselage as its only child. The fuselage is

located at the origin of the inertial coordinates system

and it is the parent of both the main and tail rotors.

The main rotor rotates around its vertical axis, Z axis.

The main rotor is the parent of the flap hinge that

rotates around the corresponding X axis, the lag

hinge is the child of the flap hinge. The lag hinge

rotates around the Z axis. The feather hinge is the

child of the lag hinge. The feather hinge rotates

around the Y axis. Finally, the blade is added to the

program structure as the child of the feather hinge.

The tail rotor is built up following this same parentchild structure.

475

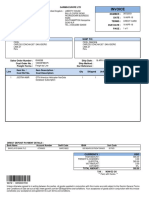

Table 1: Parameters values.

Parameters

Helicopter Mass

Blade one mass

Blade two mass

Blade three mass

Blade four mass

Spring flap hinge

Spring lag hinge

Damping lag hinge

Main Rotor Speed

Symbol

mh

mbl1

mbl2

mbl3

mbl4

kfj

klj

dlj

Value

2064 (kg)

31.06 (kg)

31.26 (kg)

29.96 (kg)

31.16 (kg)

46772 (Nm/rad)

314938(Nm/rad)

349.58(Nms/rad)

44.4 (rad/s)

5 AERODYNAMIC MODEL IN

HOVER

5.1 AIR DENSITY

For every flight condition, the air density changes

with the height (h), for the lower atmosphere where

helicopters fly below 6000 m, the standard value of

air density can be approximated as:

where h is expressed in meters and o is 1.225 kg/m3

(air density at sea level) [9].

5.2 INDUCED HOVER SPEED

In hovering flight, the induced velocity can be

obtained as vi = vio, vio is the hover induced velocity,

which can be considered constant in hover, the

traction force, T, becomes equal to the disc loading

(weight of the helicopter), see Figure 2 [9]:

4.1 DYNAMIC MODEL DESCRIPTION

The parameters used for the dynamic simulation

carried out in this work are shown in table 1 ([14]).

For the purpose of dynamical modelling only, the

action of external forces not considered, for example:

gravity. The system can be considered in the vacuum.

An unbalance of masses is considered on the main

and the tail rotors blades in order to simulate a source

of vibrations in the helicopter with an amplitude to be

detected in the spectrum. On the other hand, in order

to simulate the engine effects on each rotor, the main

and tail rotors angular speeds are modelled using PID

controllers.

Figure 2: Main forces acting on a helicopter in hover

flight.

Actas de las XXXVI Jornadas de Automtica, 2 - 4 de septiembre de 2015. Bilbao

ISBN 978-84-15914-12-9 2015 Comit Espaol de Automtica de la IFAC (CEA-IFAC)

476

5.3 BLADE ELEMENT ANALYSIS IN HOVER

FLIGHT

Blade element theory forms the basis of most modern

analyses in helicopter rotor aerodynamics as it

estimates the radial and azimuthal distributions of

blade aerodynamic forces (and moments). In addition

to this, the rotor performance can be obtained by

integrating the sectional airloads at each blade's

elements over the length of the blade and averaging

the result over a rotor revolution [9].

Figure 3 is a plan view of the rotor disc, viewed from

above. The blade radius is R and the tip speed is

given by R. An elementary blade section is

considered at radius y, of chord length c and

spanwise width dy.

Figure 4: Velocity components UT and Up.

If the feather angle at the blade element is , then the

aerodynamic or effective angle of attack is:

The resultant incremental lift, dL, and drag dD per

unit span on a blade element are:

where is the air density, Cl and Cd are the lift and

drag coefficients, c is the local blade chord. The lift

dL and drag dD act perpendicular and parallel

respectively to the resultant flow velocity.

Figure 3: Main rotor disc viewed from above.

5.4 THRUST COEFFICIENT

The velocity components on the blade's section are

shown in Figure 4. The flow seen by the section has

velocity components y in the disc plane and (vi +

Vc) (vi is the induced velocity and Vc is the upward

velocity) perpendicular to it [12].

The resultant local flow velocity at any blade element

at a radial distance y from the rotational axis has an

out of plane component Up = (vi +Vc) normal to the

rotor plane as a result of climb and induced inflow

and an in plane component UT = y parallel to the

rotor due to blade rotation, relative to the disc plane.

The resultant velocity at the blade element is

therefore the composition of both [9]:

The blades feather angle , is imposed by the pilot's

collective control input. The angle between the flow

direction and the plane of rotation, known as the

inflow angle , is therefore [12]:

The thrust coefficient approximation for hover flight

can be written as:

is the feather angle, a is the lift slope, = vih/R,

vih is the induced hover velocity, R is the rotor radius

and is the solidity factor which for a constant blade

chord is given by:

N is the number of main rotor blades and c is the

blade chord [12].

6 VIBRATIONS ANALYSIS

The analysis of the vibration modes on a helicopter is

a difficult task due to the complexity of the structure,

Actas de las XXXVI Jornadas de Automtica, 2 - 4 de septiembre de 2015. Bilbao

ISBN 978-84-15914-12-9 2015 Comit Espaol de Automtica de la IFAC (CEA-IFAC)

477

but reasonable accuracy is achievable with modern

techniques.

This work is carried out by estimating the vibrations

appearing in hover flight when the aerodynamical

model has been implemented as well as a comparison

to dynamic vibrations generated under the excitation

conditions described previously. In order to develop

the proposed analysis, it is necessary to follow the

next steps: a) detection of vibration signals on the

fuselage as a consequence of the hover aerodynamic

load and with unbalance of masses, separately b)

analysis of the spectrogram for identification of the

detected vibrations.

6.1 VIBRATIONS IN HOVER FLIGHT

Figure 5: Vibrations on the fuselage's X axis for

hover flight.

In here, the vibrations appearing on the fuselage's

axes X (roll) and Y (pitch) during hover flight are

studied. Only two axes are analysed as these are

enough to validate the expected behaviour. It is

known that vibrations are generally low in hover

flight [7]. The aerodynamic model satisfies the

following structural characteristics: the flap and lag

degrees of freedom do not have springs fitted

although the lag maintains a damper. In addition to

this, it does not exist an unbalance of masses on the

main and tail rotors.

There is a consequence of the use of a rotating frame

of reference that affects vibration frequencies created

in the rotor and transmitted to the fuselage. The

frequencies generated in the rotor may contain the

rotational frequency of the rotor and the external

perturbation frequency [15].

In order to analyze the vibrations appearing on the

fuselage, the Short Time Fourier Transform (STFT)

is used.

A hover flight simulation is done; the simulations are

carried out for 50 seconds, although the results

plotted in figures 5, 7, 9 and 11 show the first 5

seconds only, for clarity of the view. The height is h

= 250 m and the main rotor's collective feather angle

is 0.175 rad and tail rotor's collective feather angle is

also 0.175 rad. Figure 5, shows the fuselage's

oscillations (vibrations) on the X axis during hover

flight for 5 seconds. Figure 6, shows the

corresponding spectrogram obtained for this

simulation. Various predominant frequencies which

come from the main rotor loads (approximately 7.6

Hz) can be seen, this is the flap frequency. There is a

second predominant frequency (approximately 15.2

Hz) this is twice the flap frequency and a third

predominant frequency is found at around 37.1 Hz,

this frequency coincides with the tail rotor blades

flap frequency.

Figure 6: Fuselage's X axis spectrogram in hover

flight conditions.

Similar analysis is carried out for the oscillations

appearing on the fuselage's Y axis (see Figure 7).

The three predominant frequencies of these

vibrations appear in the spectrogram in Figure 8.

These are approximately 7.6 Hz which are caused by

the main rotor blades flap, the second frequency is

approximately 15.2 Hz, this value is twice the main

rotor flap frequency and the third frequency is around

37.1 Hz, it is associated to the tail rotor flap motion.

Figure 7: Vibrations on the fuselage's Y axis for

hover flight.

Actas de las XXXVI Jornadas de Automtica, 2 - 4 de septiembre de 2015. Bilbao

ISBN 978-84-15914-12-9 2015 Comit Espaol de Automtica de la IFAC (CEA-IFAC)

478

presented in this case), the oscillation on the

fuselage's X axis shows two predominant frequencies

which are originated at the main rotor (7 Hz

approximately) and at the tail rotor, in this case, the

value is around of 37 Hz.

Figure 8: Fuselage's Y axis spectrogram in hover

flight.

6.2 DYNAMIC VIBRATIONS

In this section, the vibrations when both flap and lag

modes are coupled will be studied when the main and

tail rotor have a constant angular speed. In this case,

the vibrations are introduced in the model by

unbalance of masses in both rotors; the mass of the

blades on the main rotor are mbl1 = 31.06 kg, mbl2 =

31.26 kg, mbl3 = 29.96 kg and mbl4 = 31.16 kg and

on the tail rotor they are; mbltl1 = 6.212 kg and

mbltl2 = 6.222 kg. The collective and cyclic feather

angles are zero in the main rotor.

Figure 10: Fuselage vibrations spectrogram on the X

axis for mbl1 = 31.06 kg, mbl2 = 31.26 kg, mbl3 =

29.96 kg and mbl4 = 31.16 kg and on the tail rotor

they are; mbltl1 = 6.212 kg and mbltl2 = 6.222 kg.

Similar analysis can be carried out for the

spectrogram of frequencies in fuselages Y axis (see

figures 11 and 12). Two predominant frequencies

appear, these vibrations are originated at the main

and tail rotors', similarly to the X axis.

The tail rotor flap dynamics are modelled as a

Fourier series: tl=ao - a1 cos(t) -b1 sin(t) where ao

= 0.01 rad, a1 = 0.01 rad and b1 = 0.01 rad are the

corresponding coefficients, and the collective angle is

0.01 rad. The main rotor angular speed is constant at

44.4 rad/s. Figure 9, shows the fuselage's oscillations

(vibrations) around the X axis under the previous

conditions.

Figure 11: Y axis fuselage vibrations for mbl1 =

31.06 kg, mbl2 = 31.26 kg, mbl3 = 29.96 kg and mbl4

= 31.16 kg and on the tail rotor they are; mbltl1 =

6.212 kg and mbltl2 = 6.222 kg.

Figure 9: X axis fuselage vibrations for mbl1 = 31.06

kg, mbl2 = 31.26 kg, mbl3 = 29.96 kg and mbl4 =

31.16 kg and on the tail rotor they are; mbltl1 = 6.212

kg and mbltl2 = 6.222 kg.

From the spectrogram of frequencies shown in Figure

10 (the window length is reduced in order to check

the noise and other additional frequencies are not

A comparison can be carried out for the vibrations

presented in these sections. Clearly, the aerodynamic

load is a source of vibrations on the helicopter's

fuselage. The obtained spectrograms for hover flight

agree with theoretical predictions: a) there is an

important source of helicopter vibrations, the

aerodynamics forces [7], b) the aerodynamic loads on

a helicopter rotor blade vary considerably as it moves

around the rotor disc. These loads arise from the

aerodynamic forces on the rotor blades, together with

Actas de las XXXVI Jornadas de Automtica, 2 - 4 de septiembre de 2015. Bilbao

ISBN 978-84-15914-12-9 2015 Comit Espaol de Automtica de la IFAC (CEA-IFAC)

the inertial forces produced by the flap and lag

motions of the blade [1].

479

early stage and the authors expect to develop further

analogies with experimental results in future work.

In summary, a full helicopter model has been

modelled using VehicleSim. Spectrograms analysis

on the fuselages roll and pitch axes captured the

appearing vibrations as a consequence of the

aerodynamic load in hover flight, these results have

been compared to dynamic vibrations obtained with

identical helicopter model under the action of

unbalance of masses on the rotors. As a result of this,

the vibrations in hover have been shown to satisfy the

predicted behaviour.

References

Figure 12: Fuselage vibrations Spectrogram on the Y

axis for mbl1 = 31.06 kg, mbl2 = 31.26 kg, mbl3 =

29.96 kg and mbl4 = 31.16 kg and on the tail rotor

they are; mbltl1 = 6.212 kg and mbltl2 = 6.222 kg.

7 CONCLUSIONS

The helicopter model under study is on Sikorsky

configuration, the model reproduces the dynamic

behaviour of a helicopter, which is capable to

transmit perturbations from the main rotor to the

fuselage in form of vibrations. The model has been

implemented in VehicleSim, a program allows to

define the systems as composition of several bodies

and ligatures by using a parental relationship

parent/child structure.

This work has presented a helicopter aerodynamic

model in which the blade element theory has been

used for implementation hover flight. This is

important in order to study and analyze the vibrations

appearing in the fuselage as a consequence of

aerodynamic load under these flying conditions.

Various tests under the action of these conditions

were carried out in order to study pure vibrations

appearing on the fuselage roll and pitch axes.

In hover flight and under unbalance of masses on

both rotors, fuselage vibrations spectrograms were

obtained and analyzed by using a short time Fourier

transform process, various cases were considered,

when the aerodynamic load for hover flight was

included in the dynamic helicopter model, the

obtained results match those predicted by theoretical

approaches. In addition to this, these vibrations were

compared to dynamic vibrations generated with the

same helicopter model in absence of the aerodynamic

load. As a consequence, the spectrograms were also

studied and these showed a reasonable discrepancy

according to the expected behaviour introduced by

the aerodynamic model. These results are still on an

[1] Bramwell, A. R. S., Done, G., Balmford, D.

(2001)

Bramwell's

Helicopter

Dynamics.

Butterworth-Heinemann.

[2] Castillo-Rivera, S. (2014) Advanced Modelling

of

Helicopter

Nonlinear

Dynamics

and

Aerodynamics. PhD Thesis. School of Engineering

and Mathematical Sciences. City University London.

[3] Castillo-Rivera, S., Tomas-Rodriguez, M.,

Marichal-Plasencia, G., N. (2014) Helicopter Main

Rotor Vibration Analysis with Varying Rotating

Speed. XXXV Jornadas de Automatica. pp. 34-41.

ISBN-13: 978-84-697-5089-6.

[4] Castillo-Rivera, S., Tomas-Rodriguez, M.,

Marichal, G.,N., Lpez, A. (2013) Estudio de la

interaccin del fuselaje y el movimiento de aleteo de

las palas del rotor principal en un helicptero.

XXXIV Jornadas de Automatica. pp. 514-521. ISBN

978-84-616-5063-7.

[5] Ferrer, R., Krysinski, T., Aubourg, P., Bellizi, S.

(2001). New Methods for Rotor Tracking and

Balance Tuning and Defect Detection Applied to

Eurocopter Products American Helicopter Society

57th Annual Forum, Washington, DC, May 9-11.

[6] http://www.carsim.com/products/supporting/

vehiclesim/index.php.

[7] Johnson, W. (1980)

Helicopter Theory.

Princeton, NJ: Princeton Univ. Press.

[8] Keysan, O., Ertan, H. Higher Order Rotor Slot

Harmonics for Rotor Speed & Position Estimation.

12th International Conference on Optimization of

Electrical and Electronic Equipment, OPTIM. 978-14244-7040-4.

[9] Leishman, J. G. (2007) Principles of Helicopter

Aerodynamics. Cambridge University Press.

Actas de las XXXVI Jornadas de Automtica, 2 - 4 de septiembre de 2015. Bilbao

ISBN 978-84-15914-12-9 2015 Comit Espaol de Automtica de la IFAC (CEA-IFAC)

[10] Marichal, G.,N., Tomas-Rodriguez, M., Lopez,

A., Castillo-Rivera, S.,

Campoy, P. (2012)

Vibration Reduction for Vision System on Board

UAV using a neuro-fuzzy Controller. Journal of

Vibration

and

Control.

DOI

10.1177/1077546313479632.

[11] Nguyen K. (1994) High Harmonic Control

Analysis for Vibration Reduction of Helicopter Rotor

Systems. NASA Technical Memorandum 103855.

[12] Seddon, J. (1990) Basic Helicopter

Aerodynamics. Blackwell Scientific Publications

(BSP) Professional Books.

[13] Sharp, R, S., Evangelou, S., Limebeer, D, J, N.

(2005) Multibody aspects of motorcycle modeling

with special reference to Autosim, Advances in

Computational Multibody Systems, J. G. Ambrosio

(Ed.), Springer-Verlag, Dordrecht, The Netherlands,

45-68.

[14] Tomas-Rodriguez M., Sharp R. (2007)

Automated Modeling of Rotorcraft Dynamics with

Special Reference to Autosim. Automation Science

and Engineering. CASE 2007. IEEE International

Conference, pp: 974-979.

[15] Watkinson. J. (2004) The art of the helicopter.

Elsevier Butterworth-Heinemann.

480

Você também pode gostar

- Garmin Invoice for Helicopter Navigation Data SubscriptionDocumento1 páginaGarmin Invoice for Helicopter Navigation Data SubscriptionernestozagAinda não há avaliações

- Mil STD 810gDocumento804 páginasMil STD 810gEddieT100% (1)

- Garmin Invoice for Helicopter Navigation Data SubscriptionDocumento1 páginaGarmin Invoice for Helicopter Navigation Data SubscriptionernestozagAinda não há avaliações

- Garmin Invoice for Helicopter Navigation Data SubscriptionDocumento1 páginaGarmin Invoice for Helicopter Navigation Data SubscriptionernestozagAinda não há avaliações

- Measurement and Analysis of VibrationsDocumento6 páginasMeasurement and Analysis of VibrationsernestozagAinda não há avaliações

- Interface GTN 750Documento3 páginasInterface GTN 750ernestozagAinda não há avaliações

- Pressure-Gain Combustion For Gas Turbines: Dan Paxson NASA John H. Glenn Research Center Cleveland, OHDocumento35 páginasPressure-Gain Combustion For Gas Turbines: Dan Paxson NASA John H. Glenn Research Center Cleveland, OHernestozagAinda não há avaliações

- Garmin Invoice for Helicopter Navigation Data SubscriptionDocumento1 páginaGarmin Invoice for Helicopter Navigation Data SubscriptionernestozagAinda não há avaliações

- LOLER Inspection Checklist - 7 Free TemplatesDocumento7 páginasLOLER Inspection Checklist - 7 Free TemplatesernestozagAinda não há avaliações

- 1965013440Documento188 páginas1965013440ernestozagAinda não há avaliações

- Interface GTN 750Documento3 páginasInterface GTN 750ernestozagAinda não há avaliações

- Mason - Applied Computational Aerodynamics PDFDocumento450 páginasMason - Applied Computational Aerodynamics PDFDiana DumitrascuAinda não há avaliações

- Pump Life Cycle CostDocumento19 páginasPump Life Cycle CostSAMEER100% (3)

- Helicopter WeighingDocumento2 páginasHelicopter WeighingernestozagAinda não há avaliações

- Diagnosis TestDocumento2 páginasDiagnosis TesternestozagAinda não há avaliações

- Grease 28 Tech DataDocumento2 páginasGrease 28 Tech DataernestozagAinda não há avaliações

- AeronauticsDocumento72 páginasAeronauticsAna-Maria Neculăescu100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Comic Strip Lesson PlanDocumento3 páginasComic Strip Lesson Planapi-242583948Ainda não há avaliações

- Pi Ai LokåcåryaDocumento88 páginasPi Ai Lokåcåryaraj100% (1)

- CWR Resources 2011Documento56 páginasCWR Resources 2011Adam Dickens0% (1)

- TPR Method for Language LearningDocumento13 páginasTPR Method for Language LearningjnhmoAinda não há avaliações

- Written TestDocumento4 páginasWritten TestBiswajit BeheraAinda não há avaliações

- Origins of South African LawDocumento43 páginasOrigins of South African LawValentineSithole80% (5)

- LP - SAS Congruence Postulates Julius EDocumento9 páginasLP - SAS Congruence Postulates Julius EJoel BulawanAinda não há avaliações

- The Program For Better VisionDocumento223 páginasThe Program For Better VisionBlasa100% (6)

- Growing Up Hindu and Muslim: How Early Does It Happen?: Latika GuptaDocumento7 páginasGrowing Up Hindu and Muslim: How Early Does It Happen?: Latika Guptagupta_latikaAinda não há avaliações

- ASSIGNMENT - Rousseau's ConfessionsDocumento2 páginasASSIGNMENT - Rousseau's Confessionsridvikaarora16Ainda não há avaliações

- TMP - 12322 Mantras Sacred Words of Power by John Blofeld 052547451x 1786418995 PDFDocumento5 páginasTMP - 12322 Mantras Sacred Words of Power by John Blofeld 052547451x 1786418995 PDFJoseph50% (2)

- Experimental Design Graphic OrganizerDocumento2 páginasExperimental Design Graphic OrganizerApplesauce90Ainda não há avaliações

- People and Participation FinalDocumento61 páginasPeople and Participation Finalgilbertociro100% (2)

- Choices Key To DestinyDocumento38 páginasChoices Key To DestinyemmanueloduorAinda não há avaliações

- Shinde R.Documento8 páginasShinde R.rutuja shindeAinda não há avaliações

- Sermon Notes: "Restore Us To Yourself, O Lord" (Lamentations 5)Documento3 páginasSermon Notes: "Restore Us To Yourself, O Lord" (Lamentations 5)NewCityChurchCalgaryAinda não há avaliações

- Questões Língua InglesaDocumento3 páginasQuestões Língua InglesaBruna BoarettoAinda não há avaliações

- Annotated BibliographyDocumento14 páginasAnnotated BibliographyDrew TilleyAinda não há avaliações

- Chapter 3 Twenty-First-Century Thinking About Leadership and ManagementDocumento25 páginasChapter 3 Twenty-First-Century Thinking About Leadership and ManagementFrancessé Layle TezonAinda não há avaliações

- Conversion Between Displacement, Velocity and Acceleration - CBMAppsDocumento3 páginasConversion Between Displacement, Velocity and Acceleration - CBMAppsniraj_hwbAinda não há avaliações

- FASB's Conceptual Framework and Social RealityDocumento19 páginasFASB's Conceptual Framework and Social RealityRitesh Kumar DubeyAinda não há avaliações

- Analysis of Chapters 1-3 in A Separate PeaceDocumento31 páginasAnalysis of Chapters 1-3 in A Separate PeaceMarlo ChismAinda não há avaliações

- WESTERMAN, Jonah. Between Action and Image - Performance As Inframedium' (2015)Documento4 páginasWESTERMAN, Jonah. Between Action and Image - Performance As Inframedium' (2015)BIAGIOPECORELLIAinda não há avaliações

- Teacher Classroom Observation ChecklistDocumento4 páginasTeacher Classroom Observation ChecklistAphze Bautista VlogAinda não há avaliações

- Song of Songs of SolomonDocumento103 páginasSong of Songs of SolomonAndré Rademacher100% (3)

- Figurative Language EssayDocumento14 páginasFigurative Language EssayRosalía ImlAinda não há avaliações

- Information Technology Project Management: by Jack T. MarchewkaDocumento34 páginasInformation Technology Project Management: by Jack T. MarchewkaYasmitha LAinda não há avaliações

- Translations of Persian LiteratureDocumento18 páginasTranslations of Persian LiteratureAfshin IraniAinda não há avaliações

- The Biblical Basis of Missions Course-Introduction and Chapter 1Documento8 páginasThe Biblical Basis of Missions Course-Introduction and Chapter 1m28181920Ainda não há avaliações

- EVE Online Chronicles PDFDocumento1.644 páginasEVE Online Chronicles PDFRazvan Emanuel GheorgheAinda não há avaliações