Escolar Documentos

Profissional Documentos

Cultura Documentos

Work Procedure For CFA Piles

Enviado por

krmchariTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Work Procedure For CFA Piles

Enviado por

krmchariDireitos autorais:

Formatos disponíveis

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Issue

Page(s)

14

All

Revision Description

Document review.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

1 of 10

Prepared

By:

Reviewed

By:

Authorised

By:

NB

ID

NB

This document is for circulation within the Company only, and it or extracts from it must not be passed or copied to other

BBGE personnel, other companies or persons without the permission of the HSEQ Department.

copyright Balfour Beatty 2008

Registered Holder*

Key

N Burrows - Process Manager

The Insp column refers to inspections which are one of the following:

REVIEW POINT - a stage where documents are reviewed, i.e. checking that all materials certificates are in order.

HOLD POINT - a specific stage in the construction process beyond which the works will not proceed without an

inspection or check being made and recorded by BBGE personnel.

WITNESS POINT - this is defined as a Hold Point for BBGE personnel but where the Clients (or other)

representative has requested to witness the inspection. Should the Clients or other representative not be present, the

work may proceed.

NOTIFICATION POINT - a specific stage where the Clients (or other) representative is given notice that an activity

will take place.

Item No.

Procedure

General

1.1

This document should be read in conjunction with the Standard Works Procedures

Insp.

Responsible

Person

SWP-002 (for Blowing out)

SWP-004 (Pumping Out The Lines With Water)

SWP-003 (Instrument Calibration)

And when applicable

SWP-007 (Secant Walling)

SWP-016 (Rebar Fabrication)

SWP-017 (Manual Monitoring of CFA Pile Construction)

SWP-014 (CFA Trial Bores)

SWP-018 (Welding Rebar)

SWP-071 (Concrete Pumping)

Reference needs to be made to the COSYSTEM to ensure the current version of

procedures are used.

1.2

The Principal Contractor shall provide suitable access for tracked and wheeled

vehicles and plant onto the site and to and from the works. Routing of vehicles shall

be such that the crossing of concrete hoses is only at designated points, as described

Principal

Contractor

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Item No.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

2 of 10

Procedure

Insp.

Responsible

Person

in SWP-071.

1.3

Prior to mobilising any plant or equipment to site, BBGE will issue the Principal

Contractor with details of the size and weight of all plant. The Principal Contractor

will use this information to design and construct a suitable piling platform. Before

any work may commence both the Working Platform Certificate QR-196 and the

Permit to Work QR-192 shall be signed and issued by the Principal Contractor.

1.4

The major items of plant and equipment to be used:

Principal

Contractor

Contracts

Engineer/

Foreman

Hydraulic Self-Erecting Piling Rigs.

Service Cranes generally 40T/80T Crawler Cranes.

Mobile Cranes, as required.

Concrete Agitators and Concrete Pumps.

Drilling equipment HD or XHD CFA Augers.

SIRIS Instrumentation.

1.5

It is the responsibility of the Operations Manager to ensure the appropriate rig is

selected and a QR-204 CFA Plant and Consumable List must be completed at the

beginning and end of the contract.

Ops. Manager

1.6

Each rig is issued with a 10 store container comprising as a minimum, the standard

CFA equipment including but not limited to; all concrete sampling equipment

including cube tank powered by a built in generator, lifting equipment including chain

brothers, kidney chains for lifting hoses and auger lifting head. All consumables as

required.

Foreman

1.7

It is the responsibility of the contract engineer, prior to mobilising, has ensured that

an appropriate supply of water is readily available and can be utilised from a 2m3

agitator header tank or similar to carry out the procedure SWP-004 ( Pumping out the

Concrete Lines With Water).

Contracts

Engineer

1.8

It is the responsibility of the Labour Supervisor to select necessary labour resource to

meet the contract requirements. This shall include the nomination of a competent rig

operator for the designated rig, a trained Banksman/Slinger/Frontman and Concrete

Pumpman.

Labour

Supervisor

1.9

The Foreman must check all personnel are in receipt of the required relevant

certification prior to commencing work.

Foreman

1.10

Before starting on site it is the responsibility of the Contracts Engineer to compile the

Foremans file. This shall be issued to the Foreman before commencing piling.

Contracts

Engineer

1.11

Before starting on site it is the responsibility of the Contracts Engineer to check the

calibration of the rig instrumentation transducers which are currently utilised to

record pressure and volume and issue calibration certificates accordingly.

Contracts

Engineer

1.12

The Foreman may be nominated by the Contracts Engineer to carry out the calibration

in accordance with SWP-003.

Foreman

1.13

Callipers are stored in each rig container. The diameter of the lead auger must be

checked weekly and recorded on form QR-126. In aggressive ground such as rock or

dense gravel, the augers should be checked daily and recorded on the daily diary. A

Banksman /

Foreman

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Item No.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

3 of 10

Procedure

Insp.

Responsible

Person

tolerance of minus 5% of the diameter of the auger is permissible however the auger

must cut a hole of at least the nominal diameter.

1.14

Prior to commencing piling operations the Contracts Engineer or Foreman will brief

the whole operations team on the anticipated ground strata and site specific

conditions and/or hazards. This briefing will include but will not be limited to:

1.15

Contracts

Engineer /

Foreman

Rig Operator /

Anticipated strata details e.g. clay/gravel, hard/soft, wet/dry

Trials bores

Concrete wastage and tram line settings

Frequency of calibrations

Minimum spacing of consecutive piles and sequence of piling

Expected penetration rates and maximum over rotation values

Refusal criteria where applicable

Basis of design

Position verticality tolerances, 1 in 75, 1 in 150 etc

Significant issues raised during the site start-up meeting

Items listed on the risk assessment part of the HSEQ Plan

Comments made by the Design Engineer including level controls (Steel PPL)

Layout of Pump, Agitator and Concrete Pipeline

Lift Plan detailing approved location of operating cranes in relation to piling

platform areas

Specific agreed contract specification i.e. slump tests / cube quantities etc

Ground Contamination i.e. Concrete wash out areas if required

If an error occurs with the instrumentation (where any part of the instrumentation fails

to work) either before or during piling, the foreman must be told immediately. The

Foreman must in turn report this immediately to the Contracts Engineer and seek

instructions.

Foreman

1.16

If pile construction has already commenced when an instrumentation malfunction of

the depth or flow measurement occurs, then the procedure detailed in SWP-017 must

be followed, to finish the pile.

1.17

THE DECISION AS TO WHETHER TO PROCEED WITH PILING WILL BE

MADE BY THE OPERATIONS MANAGER

Ops Manager

1.18

A pile schedule is to clearly identify the following:-

Contract

Engineer

1.19

Pile number

Pile diameter

Pile length

Cage type

Platform level

Pile cut off level

If the Pile Schedule has been drawn up by BBGE, it must be in the standard approved

format QR-016, with the column headings printed on each page. A numbered pile

layout plan MUST be made available to the site Foreman which is one of the standard

documents placed within the Foremans File along with the desired sequence of

Foreman

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Item No.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

4 of 10

Procedure

Insp.

Responsible

Person

working.

1.20

In addition, the pile design and schedule will be submitted to the Client and approval

requested prior to commencing.

PROTECTION & SAFETY

2.1

In addition to the briefing described in Item 1.10, the workforce will receive a full

Safety Induction highlighting the site specific risks identified for the project.

2.2

The briefing will be recorded on form QR-180 and the items discussed and actions

agreed identified.

Foreman

2.3

All movement of the piling rig and service cranes will be under the direction of a

competent Banksman / Frontman and co-ordinated by the piling foreman.

Foreman /

Banksman /

2.4

Frontmen can only control the movements of the piling rig and cannot sling any loads

unless they are a qualified Banksman /Slinger.

Frontman

2.5

Pile reinforcement cages should be designed to finish at ground level, therefore

reducing trip and fall hazards. Where this is not possible plastic Cemcaps shall be

placed on the top of protruding reinforcement to protect against impalement injuries.

Contract

Engineer /

Banksman

2.6

No other work is to be carried out by other contractors in the vicinity of piling

operations.

Principal

Contractor

2.7

Concrete Pumping must be carried out strictly in accordance with Standard Works

Procedure SWP-071 (Concrete Pumping).

Foreman /

Pumpman

2.8

Cleaning out the concrete lines must be strictly in accordance with Standard Works

Procedure SWP-004 (Pumping clear the concrete lines with water).

Foreman

Foreman

Note: The use of compressed air is only to be adopted as the last resort to clear the

concrete within the concrete lines as described within SWP-002 (Blowing Out Concrete

Lines).

2.9

When lifting augers vertically an auger lifting head or Kidney chain must be used,

when lifting horizontally, suitable 2 leg chain brothers should be used.

Foreman /

Banksman /

2.10

When lifting augers vertically from within a bore then an auger lifting head MUST be

used to ensure a direct lift. WIRE ROPE AND NYLON SLINGS MUST NOT BE

USED AROUND THE CIRCUMFERENCE OF THE AUGER.

Frontman

3.1

At all times the rig shall be operated in accordance with the manufacturers details,

contained within the machine file. This shall include rigging up procedures and safe

rig operation and tracking. The machine file is to be kept in the rig cab.

Rig Operator

3.2

During the installation of the first piles the instrumentation is to be checked.

Reference should be made to the proforma sheet QR-126 and the operating

procedure for the specific instrumentation. A record sheet of the check and

calibration is to be maintained within the machine file. Reference should be

made to SWP-003 Standard Works Procedure for CFA Instrumentation

Calibration prior to commencing.

During or before the first pile is constructed a strata bore log shall be

Rig Operator /

Foreman /

Engineer

Foreman

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Item No.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

5 of 10

Procedure

Insp.

Responsible

Person

completed QR-003. Any deviations discovered should be reported to the

Contract Engineer before completing any further piles.

Foreman

3.3

During the contract start-up meeting the initial level of oversupply will be decided

based on the ground investigation information available at the time. The Foreman will

check that the rig instrumentation is set to this target over break.

3.4

During the course of the contract, the driver in conjunction with the Foreman will

review the actual over break percentage being achieved and with the agreement of the

Contracts Engineer adjust the target if required. The over break (tramline settings)

must be reviewed weekly and a record made on QR-059(Concrete reconciliation log)

Foreman

3.5

The rig operator will set the pre-charge volume at the beginning of the job and at each

auger change. With the SIRIS system the concrete line diameter (4 or 5) and auger

string length are to be input to allow automatic calculation of the pre-charge. Auger

string length must not be over estimated.

Foreman /

Rig Operator /

3.6

In an attempt to reduce pre-charge volume and the likely hood of blockages the auger

string length must be kept to a minimum through out the duration of a contract, i.e. if

a section of auger is not required for a while then simply remove it. This can only be

accomplished by managing the pile sequence making this process effective and

efficient.

3.7

Important Note: A reduction in pre-charge volumes could cause SEVERE

consequences to the performance of the pile base and in turn could cause costly

financial loss to the company if not evaluated and managed accordingly. Therefore

any reduction can only be undertaken if agreed with the Contract Engineer.

Contract

Engineer

3.8

The Contract Engineer shall require agreement from the CFA Process Manager or the

Operation Manager in his absence.

Process Manager/

Foreman

Operation

Manager

3.9

The position of each pile shall be marked by a steel pin driven vertically into firm

ground and referenced with the pile number.

Setting-out

Engineer

3.10

The rig shall be positioned over the pile position with the auger gates securely closed.

The banksman and rig operator shall check that the mast is vertical in both directions.

The auger now can be lowered so the tip can be accurately positioned over the pile

centre pin.

Banksman / Rig

Operator

3.11

The mast foot now can be lowered firmly onto the ground. A second check to verify

that the mast is vertical and the auger is accurately positioned over the pile centre pin

is necessary at this stage.

Banksman / Rig

Operator

The centre of the auger shall be referenced with two offset pins. With the mast foot in

place and the mast vertical the auger is to be lowered to ground level and the

instrumentation depth gauge set to zero.

4

BORING

4.1

Prior to commencing boring the auger gates will be closed. In order to reduce kick

off due to minor near surface obstructions, the gates will remain closed until

sufficient auger rotation speed and penetration have been achieved. The gates should

remain closed as long as possible when the augers are rotating however it shall be the

responsibility of the piling rig banksman to prevent ANYONE from approaching the

Rig Operator /

Banksman

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Item No.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

6 of 10

Procedure

Insp.

Responsible

Person

augers while they are rotating. If, for whatever reason, it is necessary for anyone to

approach the augers, then the banksman must signal to the rig operator to stop

rotating the augers before the approach is made.

4.2

Once the auger has penetrated the first 2-3m of ground the position of the auger will

be checked against the two offset pins and the deviations will be recorded by the

driver on QR-0-17.

Banksman/ Rig

Operator

4.3

Every 5m of boring the mast verticality should be checked using either a mast bubble

or automatic target level. In addition the verticality of the auger shall be visually

checked. If the mast is more than 13mm per 1m (1 in 75) out of vertical then the rig

operator shall halt boring and seek advice from the Foreman.

Rig Operator /

Banksman

4.4

Secant Walls / Tight Tolerances: Additional measures may need to be implemented to

check the verticality of the augers (Vertical laser / theodolite) Engineer/Works

Managers to advise.

Engineer/ Works

Managers

4.5

The auger shall not be raised during the boring process unless instructed by the

Foreman. This includes lifting from the toe to allow clearance for the bung / flap to

blow.

Foreman / Rig

Operator

If instructed to raise the auger during boring the appropriate procedure detailed below

must be used.

If the augers are fully removed from the bore the pile details need to be reentered into Siris. Siris will suffix the pile number with an R the final

bored length must always be a minimum of 500mm beyond the point at

which the augers was removed (when possible).

If the augers are raised but not fully removed after reaching full design

length, then the bored length must be increased by 500mm (when possible).

If the augers are raised from the toe of the bore to facilitate the removal of

spoil from the auger, to allow the reduction of excessive rotational torque

caused by the utilisation of the Kelly Pole Extension, prior to the concreting

process then the bored length must be increased by 500mm. To avoid an

increased bored length raise the augers when more than 500mm from the toe

so that the final bored length remains the same as intended.

4.6

Should unanticipated ground conditions be encountered, including reduced

penetration rates, over rotation and overflighting, this must be immediately referred to

the Contract Engineer and no further piles constructed until instructed to do so by the

Contracts Engineer.

4.7

If an obstruction is encountered, then this depth shall be recorded. If the bore is

within loose ground conditions and next to a building then the auger must be left in

place and advice sought from the Contracts Engineer or Designer.

Foreman

Rig Operator/

Foreman/

Engineer

CONCRETING

5.1

The use of a Concrete Pump, Agitator and Pipeline will be strictly in accordance with

SWP-071 (Concrete Pumping).

Pumpman

5.2

The Pumpman shall check the concrete Delivery Docket before accepting discharge

of the concrete. He will then visually inspect and confirm the satisfactory condition

Pumpman

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Item No.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

7 of 10

Procedure

Insp.

Responsible

Person

of the concrete in each concrete wagon prior to pumping. The requirements set out

within the agreed works specification must be followed. I.e. slump tests, flow test etc.

5.3

The Pumpman shall make concrete cubes as specified in the HSEQ Plan.

Pumpman

5.4

Before commencing the boring and concreting phase of a pile, it may be necessary to

have all of the concrete to complete the pile on site. Consideration must be taken of

the ground strata, ground water and cage length.

Rig Operator

5.5

The Pump Operator should zero the stroke counter on the pump and record the

number of pump strokes for each pile, on form QR-0-18 or inform the Rig Operator

of the pump strokes immediately after each pile is constructed.

5.6

The auger shall not be raised until the full pre-charge volume has been placed. Once

pre-charge has been achieved the withdrawal of the auger may gradually commence.

A positive pressure may be displayed whilst re-charging the augers. However this

may be air pressure, so the Rig Operator should look for a sudden pressure reduction

indicating the bung or flap has released. The concrete is now flowing from the auger

tip; at this point reference should be made to the depth of the auger in relation to the

maximum bored depth. If the augers have been raised in excess of 100mm then reboring will be necessary.

Foreman

Pumpman

Rig Operator

If it is necessary to lift the augers before initiating the flow of concrete, the auger

must be returned to the maximum bored depth to ensure a competent base to the pile.

The maximum distance augers can be lifted is 100mm.

5.7

The auger shall not be raised until the full pre-charge volume has been placed. Once

pre-charge has been achieved the withdrawal of the auger may gradually commence.

A positive pressure may be displayed whilst pre-charging the augers. However this

may be air pressure, so the Rig Operator should look for a sudden pressure reduction

indicating the bung or flap has released. The concrete is now flowing from the auger

tip; at this point reference should be made to the depth of the auger in relation to the

maximum bored depth. If the augers have been raised in excess of 100mm then reboring will be necessary.

Rig Operator

If it is necessary to lift the augers before initiating the flow of concrete, the auger

must be returned to the maximum bored depth to ensure a competent base to the pile.

The maximum distance augers can be lifted is 100mm.

5.8

If at any time the oversupply rate drops below 0% (theoretical volume) for more than;

Rig Operator

1mtr of pile length for piles up to 600 diameter

0.5mtr of pile length for 750 diameter piles

0.25mtr of pile length for piles above 750 diameter

Then extraction of the auger shall be halted and re-boring undertaken to correct this

error. Re-boring shall be a minimum depth of 0.5 metres beyond undersupply level

first encountered. It is not necessary to stop the concrete pump for this process. The

instrumentation will show that re-boring has occurred. If under-supply reoccurs over

the same section of the pile concreting shall be halted and advice sought from the

Foreman.

5.9

In general auger withdrawal shall be matched to achieve a steady oversupply. In

dense or stiff ground, pressure may be used alone to guide the extraction rate. The

operator will have to switch off the auto winches and manually control the withdrawal

Foreman

H

Rig Operator

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Item No.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

8 of 10

Procedure

Insp.

Responsible

Person

Rig Operator

of the augers. If during this process the instrumentation indicates an oversupply of

less than 10% the contracts Engineer must be advised and the CFA Process Manager

informed.

5.10

In general auger withdrawal shall be matched to achieve a steady oversupply. In

dense or stiff ground, pressure may be used alone to guide the extraction rate. The

operator will have to switch off the auto winches and manually control the withdrawal

of the augers. If during this process the instrumentation indicates an oversupply of

less than 10% the contracts Engineer must be advised and the CFA Process Manager

informed.

5.11

When the auger tip is within 0.3m of the commencing surface pumping shall be halted

and the auger withdrawn. If excessive amounts of concrete exist at the top of the pile

following extraction the levels of oversupply are to be reviewed by the Contracts

Engineer and Foreman and modified if necessary. Any alterations are to be recorded

on QR-059 (Concrete reconciliation log).

Contracts

Engineer /

Foreman

5.12

TEST PILES

Foreman

When the auger tip is within 1.0m of the commencing surface, pumping shall be

halted. The centre of the auger shall be referenced with two offset pins so that on

completion of the pile an exact position for the centre of the test pile cap can be

located. Concreting can then resume.

5.13

Following completion of the pile the QR-0-17 record shall be completed with the

exact volume of concrete pumped as recorded by the instrumentation.

Rig Operator

AUGER CLEANING

6.1

The rig shall be fitted with an Automatic Auger Cleaner.

Plant Dept

6.2

In the event that it is not possible to use the Automatic Auger Cleaner then the bucket

of the attending excavator may be used to clean the augers. It is acceptable to weld a

bar (or similar) to the side of the bucket to make this method more effective.

Foreman

6.3

In some cases where conditions dictate the Auger may be cleaned manually. The

Auger must not be rotated when it is being cleaned manually. For piles 750mm

diameter and above 2 no. Operatives shall be employed. Pile spoil must not go above

head height.

Foreman

6.4

At regular intervals during withdrawal, spoil built up at the foot of the auger shall be

withdrawn clear by the attending excavator to allow auger cleaning to continue. This

process will also allow the Rig Operator and Banksman to visually assess the

displaced material from the bore.

Rig Operator /

Banksman

DELAYS DURING CONSTRUCTION

7.1

If a delay, in excess of 10mins is experienced during concreting, re-boring should be

undertaken to ensure that the integrity of the pile is maintained. In this case the pile

should be re-bored for a minimum of 1m and at least three pump stokes counted

before extraction continues.

AUGER EXTENSIONS

8.1

If the pile requires the use of an auger extension the concreting of the pile is to be

paused, while the extension operation is carried out. Once the operation has been

completed concrete pumping shall re-commence prior to re-starting the withdrawal of

Rig Operator

Rig Operator

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Item No.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

9 of 10

Procedure

Insp.

Responsible

Person

the auger. This process will be automatically recorded on the instrumentation log. If

the augers need restraining this must be carried out strictly in accordance with SWP019 (Safe Method of Restraining CFA Augers within the Pile Bore).

9

REINFORCEMENT

9.1

Each pile reinforcement cage shall be fabricated in accordance with the approved

design and pile schedule. Reinforcement cages may either be fabricated on site or

pre-fabricated off site and delivered in accordance with the pile construction

sequence.

Foreman

9.2

Delivery of Pre-Fabricated Reinforcement Cages Upon delivery, the reinforcement

cage details are to be checked against the pile design. Any cages that do not conform

to the design are to be labelled DO NOT USE and stored on site until instructed

further by the Contracts Engineer.

Foreman

9.3

If there is more than one type of reinforcement cage required, then each

reinforcement cage must be correctly identified and labelled with its respective pile

number or cage type or colour coded with spray paint. Cage types shall be

rationalised where possible.

Engineer /

Foreman

9.4

Site Fabricated Reinforcement Cages Upon completion of the fabrication of each

reinforcement cage, the cage shall be checked against the design and labelled

accordingly with its pile number and or cage type.

Foreman

9.5

All reinforcement, whether it is loose bar or fabricated reinforcement cages, is to be

stored on timber or suitable hardcore to ensure that no contamination occurs. In the

case of reinforcement cages, they are not to be stacked more than two cages high.

Contract

Engineer /

Foreman

9.6

One spacer is to be fitted per Principal bar. i.e. For six bars, six spacers are required.

Spacers are to be at a maximum spacing of every 4m along the cage. For other than

simple cages, refer to SWP-016 (Reinforcement Fabrication).

As each reinforcement cage is lifted (refer to SWP-O16) and lowered into the

completed pile, it must be checked to ensure that the required number of spacers

has been fitted and de-bonding foam where required has been fitted correctly. It is

likely that no spacers have previously been fitted over the length of the cage that was

resting on the timber / hardcore. As the cage is lowered into the concrete, spacers

MUST be added to this section of the reinforcement cage. The reinforcement details

are recorded on form QR-017.

Contract

Engineer /

Foreman

Note: For lifting single bars reference shall be made to PROJECT LIFT PLAN STNQR-3130b.

Banksman

9.7

Any spoil shall be shovelled from the pile head and position of the pile determined.

The pile cage shall be lowered vertically into the fluid concrete. Longer or

lightweight cages may be surged in or pushed/tapped in using the excavator bucket.

The cage will be centralised within the pile. If the bars protrude above ground level

and are a trip/fall hazard, they shall be capped with Cemcaps.

Frontman

10

AFTER CONSTRUCTION

10.1

The pile construction sequence must be devised in order to minimise the risk of

damage to freshly cast piles from our own plant and equipment. The Principal

Principal

Contractor

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Item No.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

10 of 10

Procedure

Insp.

Responsible

Person

Contractor shall ensure that traffic is kept off the piling area, to prevent damage to

newly cast piles.

11

RECORDS

11.1

The following records will be completed in full at the appropriate time and submitted

for approval where necessary:

Foreman

QR-003 Strata bore log

QR-006 Confirmation of verbal Instruction/Request for Further Information/Site

Letter

QR-012 Pile Log

QR-017 CFA Pile Construction Log

QR-018 Pump stroke counter log sheet

QR-059 Concrete reconciliation log

QR-126 Calibration Record

QR-204 Plant yard Field Indent

11.2

The CFA Pile Construction Log QR-017 must record where any non-compliance has

occurred and where the Foreman has been informed.

Rig Operator /

Foreman

If the Foreman is satisfied that the non-compliance is not detrimental to the pile

performance, a note should be added to the QR-017 record e.g. re-bored, concrete

seen at surface before auger removed, etc.

If any anomaly is not easily explained, and the instrumentation data does not add

up, the instrumentation record should be referred to the Contract Engineer and the

Designer. Any action taken is to be recorded.

11.3

The following checks should be carried out:

Foreman

At the end of each shift the delivered concrete volumes are to be checked.

The delivered concrete volume details should be compared with the recorded

concrete volumes on SIRIS.

The number of pump strokes recorded by the Pumpman on form QR-018 should

be compared to that recorded by SIRIS.

Note: QR-018 does not need to be completed if the pump operator is able to inform

the Rig Operator of the pump strokes immediately after each pile is constructed and a

record made by the Rig Operator on QR-017.

These checks should be recorded on QR-017 and QR-059(Concrete

reconciliation log).

11.4

The methods outlined within this Operating Procedure are intended to serve as a

guide for the installation of CFA piles. The do not attempt to replace sound practice

or experience.

11.5

The SIRIS database shall be accessed immediately after the first piles have been

constructed and then weekly by the Contracts Engineer and the individual pile logs

shall be reviewed and checked.

11.6

The rig instrumentation (SIRIS) must be calibrated weekly or

Contracts

Engineer

R

Integrated Management System

Method Statement/Work Procedure for CFA Piling

Item No.

Reference No.

STN-SWP-3001

Issue

14

Issue Date

23/06/08

Page

11 of 10

Procedure

A

B

C

D

E

F

As soon as a new contract commences.

Whenever a different pump is used.

On a weekly basis for ongoing contracts.

Whenever the length of the concrete hose is changed.

Whenever the daily concrete usage indicated by SIRIS does not agree with

the actual volume delivered on site.

Whenever you have a different concrete mix, which includes Male / Female.

Reference needs to be made to SWP-003 CFA Calibration.

Insp.

Responsible

Person

Você também pode gostar

- Method Statement For Piling Work (Edited)Documento18 páginasMethod Statement For Piling Work (Edited)Faeez Zain100% (6)

- Excavation Safety Policy: City of LincolnDocumento11 páginasExcavation Safety Policy: City of LincolnMianAinda não há avaliações

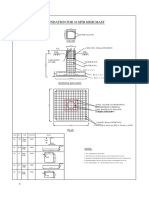

- High Mast Foundation Layout - DiagramDocumento8 páginasHigh Mast Foundation Layout - DiagramTanveer Ahmad89% (9)

- Method Statement Dewatering (Final) Rev1Documento11 páginasMethod Statement Dewatering (Final) Rev1Bala50% (2)

- Wms - Concrete Repairing Works (Pedestals)Documento4 páginasWms - Concrete Repairing Works (Pedestals)krmchari100% (1)

- The Views Tangent Pile-Method StatementDocumento5 páginasThe Views Tangent Pile-Method Statementaliengineer953Ainda não há avaliações

- Socket H PileDocumento9 páginasSocket H PilejoeliAinda não há avaliações

- Material RequiredDocumento2 páginasMaterial RequiredNikhil88% (8)

- M.S & R.S For Soil Investigation WorksDocumento14 páginasM.S & R.S For Soil Investigation WorksAL BASTAKI CONTRACTING L.L.C.100% (1)

- Method of Statement For Concrete T WallsDocumento6 páginasMethod of Statement For Concrete T Wallsmohammad.a.d94100% (1)

- Method Statement For Shoring WorkDocumento24 páginasMethod Statement For Shoring WorkAzhar Ali78% (9)

- (నిత్య పూజా విధానం)Documento10 páginas(నిత్య పూజా విధానం)VV RAMANA MURTHYAinda não há avaliações

- Method Statement: ApprovalDocumento21 páginasMethod Statement: ApprovalzhanghuiAinda não há avaliações

- Method Statement Bored PileDocumento9 páginasMethod Statement Bored PileShuvro ChakravortyAinda não há avaliações

- MS - Dewatering PDFDocumento46 páginasMS - Dewatering PDFMahata PriyabrataAinda não há avaliações

- Method of Slotted DrainDocumento5 páginasMethod of Slotted Drainzultrsb689100% (1)

- Is - 14687-1999 Falsework For Concrete StructuresDocumento27 páginasIs - 14687-1999 Falsework For Concrete StructuresJarrod HarrellAinda não há avaliações

- 3.method Statement of Structure Work-Eng PDFDocumento85 páginas3.method Statement of Structure Work-Eng PDFSiampol Feepakphor100% (1)

- Asphalt Paving Airfield PosterDocumento1 páginaAsphalt Paving Airfield Posterdavidhmoloney100% (1)

- MS - 7 Method Statement For Dewatering Rev.3Documento15 páginasMS - 7 Method Statement For Dewatering Rev.3Syed Umair HashmiAinda não há avaliações

- MS 1004 R0 DewateringDocumento6 páginasMS 1004 R0 Dewateringnaran75Ainda não há avaliações

- TATA Structura BrochureDocumento20 páginasTATA Structura Brochurecjm100% (2)

- Bored PilingDocumento3 páginasBored PilingAdonis AlabiAinda não há avaliações

- Ms For Plate Load Test Rev1Documento6 páginasMs For Plate Load Test Rev1FOZCANAinda não há avaliações

- Submission of Construction Methodology of Piling Works - Reg.Documento5 páginasSubmission of Construction Methodology of Piling Works - Reg.SHYAMA PRASAD SAMANTA100% (1)

- Method Statement Steel Structure 1 4 Meg PDFDocumento26 páginasMethod Statement Steel Structure 1 4 Meg PDFemeka2012Ainda não há avaliações

- Precast Pile Analysis & Design.400Documento4 páginasPrecast Pile Analysis & Design.400civixxAinda não há avaliações

- Injection SystemDocumento20 páginasInjection Systemsdabdulazees2016Ainda não há avaliações

- Method Statement For Bored Piling of Peru II BridgeDocumento3 páginasMethod Statement For Bored Piling of Peru II BridgeRafael Abedes0% (1)

- Method Statement Sheet PilingDocumento9 páginasMethod Statement Sheet PilingAMA MUTTAHIZI AHADAN AUHAN100% (1)

- MS For Survey Works (Draft) R5Documento47 páginasMS For Survey Works (Draft) R5Tegar Pilar RamadhanAinda não há avaliações

- MS - Jet Grouting SecuenceDocumento8 páginasMS - Jet Grouting SecuenceDinesh PriyankaraAinda não há avaliações

- MOS For Demolition & Pile Extraction PDFDocumento7 páginasMOS For Demolition & Pile Extraction PDFMin KhantAinda não há avaliações

- Pilingworkmethodstatement CM Ms BW 002 141120013224 Conversion Gate01Documento21 páginasPilingworkmethodstatement CM Ms BW 002 141120013224 Conversion Gate01civil_ramAinda não há avaliações

- Execution Plan PDFDocumento60 páginasExecution Plan PDFASAD MALIKAinda não há avaliações

- Method Statement of Excavation and StrutDocumento26 páginasMethod Statement of Excavation and StrutBadhur ZamanAinda não há avaliações

- Work Procedure For Plumbing and Sanitary Wor1Documento5 páginasWork Procedure For Plumbing and Sanitary Wor1krmchariAinda não há avaliações

- 1-Method Statement For Cfa PilesDocumento5 páginas1-Method Statement For Cfa Pilesahmed hashemAinda não há avaliações

- Part417 Continuous Flight Auger PilesDocumento5 páginasPart417 Continuous Flight Auger PilesNaga RjkAinda não há avaliações

- Blue Star Qatar W.L.LDocumento29 páginasBlue Star Qatar W.L.LAnonymous iI88LtAinda não há avaliações

- 6 Methods For Curing of ConcreteDocumento3 páginas6 Methods For Curing of ConcreteNeetesh KumarAinda não há avaliações

- Method Statement For Excavation: Skandhanshi Infra Projects PVT LTDDocumento6 páginasMethod Statement For Excavation: Skandhanshi Infra Projects PVT LTDVinod MasaniAinda não há avaliações

- 4 Phases Involved in Bored Cast inDocumento3 páginas4 Phases Involved in Bored Cast inRajesh KhadkaAinda não há avaliações

- Sealex Zota M150 Modified PU 600MLDocumento2 páginasSealex Zota M150 Modified PU 600MLJohn Joseph Idano0% (1)

- Rebar Cage SuspensionDocumento4 páginasRebar Cage SuspensionAnonymous S7Cq7ZDgPAinda não há avaliações

- Bored Cast-In Situ PilesDocumento7 páginasBored Cast-In Situ PilesPathankot MandiAinda não há avaliações

- Method Statement of Crossing Box CulvertDocumento2 páginasMethod Statement of Crossing Box CulvertNur EmalinAinda não há avaliações

- Bored Pile - Method StatementDocumento13 páginasBored Pile - Method Statementbtcong93100% (2)

- Theme Based Safety Discussion (TBT) - Mechanical Material HandlingDocumento4 páginasTheme Based Safety Discussion (TBT) - Mechanical Material HandlingSANDEEP YAVAAinda não há avaliações

- Paint CalculatorDocumento2 páginasPaint CalculatorHafiz Usama ShahzadAinda não há avaliações

- ABB-VTR..4 Approval LetterDocumento4 páginasABB-VTR..4 Approval LetterGerson NevesAinda não há avaliações

- Method Statement For Surveying WorkDocumento3 páginasMethod Statement For Surveying WorkShenbagaraja PandianAinda não há avaliações

- 04 PDFDocumento146 páginas04 PDFEli RochaAinda não há avaliações

- 2020 10 26 AGUS PRANOLO MR Ticket Receipt JKT DOH MAD ALC 26OCT2020Documento2 páginas2020 10 26 AGUS PRANOLO MR Ticket Receipt JKT DOH MAD ALC 26OCT2020mil crewingAinda não há avaliações

- Method Statement For Construction of Access Bridge by MVVDocumento12 páginasMethod Statement For Construction of Access Bridge by MVVPhong Trần100% (1)

- Edited Excavation, Shoring, Dewatering & Construction MsDocumento6 páginasEdited Excavation, Shoring, Dewatering & Construction MsArun Chandra Babu100% (1)

- Building Fire SafetyDocumento78 páginasBuilding Fire SafetykrmchariAinda não há avaliações

- Method Statement For Pile DrivingDocumento2 páginasMethod Statement For Pile DrivingLim Han Jian100% (5)

- Proposal For Maintenance of Iyana Ipaja Bridge (New Lagos - Abeokuta Dual Carriageway) in Lagos StateDocumento9 páginasProposal For Maintenance of Iyana Ipaja Bridge (New Lagos - Abeokuta Dual Carriageway) in Lagos Stateadetokunbo fapuroAinda não há avaliações

- Precast Box CulvertDocumento4 páginasPrecast Box CulvertHermann PankowAinda não há avaliações

- 066 Method Statement For Construction of Bull Point Access PDFDocumento11 páginas066 Method Statement For Construction of Bull Point Access PDFMrr KuxAinda não há avaliações

- L9 - Construction Methodology - 1Documento20 páginasL9 - Construction Methodology - 1J. Kumar Infraprojects LtdAinda não há avaliações

- Piles ConstructionDocumento17 páginasPiles ConstructionSaurabh PrasadiAinda não há avaliações

- Method Statement For Exposed ColumnsDocumento12 páginasMethod Statement For Exposed ColumnsdeviesrigatiAinda não há avaliações

- Method Statement For Grout ColumnDocumento1 páginaMethod Statement For Grout ColumnAlsonChin100% (1)

- 2.0 Method StatementDocumento2 páginas2.0 Method StatementArden NeriAinda não há avaliações

- Method Statement of Overwatervilla and WalkwayDocumento10 páginasMethod Statement of Overwatervilla and WalkwayMuhammad Uwais100% (1)

- Rectification of Existing Slab ITPDocumento2 páginasRectification of Existing Slab ITPrayAinda não há avaliações

- Outline Activities, Needed: Sequence Method, ResourcesDocumento10 páginasOutline Activities, Needed: Sequence Method, ResourcesNasrul HakimAinda não há avaliações

- Core Drilling ProcedureDocumento7 páginasCore Drilling ProcedureEngineeri TadiyosAinda não há avaliações

- Annex A PHC Jet A1 Rev2Documento30 páginasAnnex A PHC Jet A1 Rev2Chisom IkengwuAinda não há avaliações

- Method Statement Construction & Casting of Concrete Manholes P-2Documento17 páginasMethod Statement Construction & Casting of Concrete Manholes P-2a.nunezAinda não há avaliações

- Rotating Equipment Installation ProcedureDocumento2 páginasRotating Equipment Installation ProcedureathithancapeAinda não há avaliações

- Svs Projects India PVT LTD: 1 Beam B6 (600X600) 1E-1FDocumento36 páginasSvs Projects India PVT LTD: 1 Beam B6 (600X600) 1E-1FkrmchariAinda não há avaliações

- Aquamet Multi Jet MeterDocumento1 páginaAquamet Multi Jet MeterkrmchariAinda não há avaliações

- V.K Electro Power: M/S. NSL Infratech HyderabadDocumento1 páginaV.K Electro Power: M/S. NSL Infratech HyderabadkrmchariAinda não há avaliações

- Tower Crane Dismantling Method StatementDocumento6 páginasTower Crane Dismantling Method StatementkrmchariAinda não há avaliações

- User Name: Contacts@nslgroup - in Password: Nslgroup@123 Email Address: Contacts@nslgroup - in Synchronized Mode: Outlook Server (Merge)Documento1 páginaUser Name: Contacts@nslgroup - in Password: Nslgroup@123 Email Address: Contacts@nslgroup - in Synchronized Mode: Outlook Server (Merge)krmchariAinda não há avaliações

- Bore Water Analysis ReportDocumento2 páginasBore Water Analysis ReportkrmchariAinda não há avaliações

- For Traffic ConsultantDocumento1 páginaFor Traffic ConsultantkrmchariAinda não há avaliações

- Area Statement R4Documento1 páginaArea Statement R4krmchariAinda não há avaliações

- KK ProfileDocumento12 páginasKK ProfilekrmchariAinda não há avaliações

- Road Starting Point ObstructionDocumento5 páginasRoad Starting Point ObstructionkrmchariAinda não há avaliações

- R3-Slaes and Marketing Office Arch Drawing-Model PDFDocumento1 páginaR3-Slaes and Marketing Office Arch Drawing-Model PDFkrmchariAinda não há avaliações

- Expansion Joint - Technical SpecificationDocumento1 páginaExpansion Joint - Technical SpecificationkrmchariAinda não há avaliações

- NSL - Arena Residential: Quality Observations 28 Jan 2019Documento9 páginasNSL - Arena Residential: Quality Observations 28 Jan 2019krmchariAinda não há avaliações

- Ardex Cl11: Commercial Levelling & Smoothing CompoundDocumento4 páginasArdex Cl11: Commercial Levelling & Smoothing CompoundkrmchariAinda não há avaliações

- Print A3 RaftDocumento1 páginaPrint A3 RaftkrmchariAinda não há avaliações

- Pbu DTP Detailed Cost Plan Template 1st EditionDocumento29 páginasPbu DTP Detailed Cost Plan Template 1st EditionkrmchariAinda não há avaliações

- NJ BLDG Chapter19Documento12 páginasNJ BLDG Chapter19krmchariAinda não há avaliações

- Trial Mix Status - 1Documento2 páginasTrial Mix Status - 1krmchariAinda não há avaliações

- CL 11 MsdsDocumento4 páginasCL 11 MsdskrmchariAinda não há avaliações

- ARIPL-Shuttering Utilization ReportDocumento1 páginaARIPL-Shuttering Utilization ReportkrmchariAinda não há avaliações

- BSL Scaffolding Account StatementDocumento2 páginasBSL Scaffolding Account StatementkrmchariAinda não há avaliações

- Price ListDocumento1 páginaPrice ListkrmchariAinda não há avaliações

- Andhra Pradesh Automobile and Auto Components Policy 2015-20Documento19 páginasAndhra Pradesh Automobile and Auto Components Policy 2015-20Harshith TammuAinda não há avaliações

- PDFServlet 2 PDFDocumento1 páginaPDFServlet 2 PDFDeepak Gupta100% (1)

- pn23 102Documento4 páginaspn23 102barriodelimanilaAinda não há avaliações

- Volvo FMX 460BSIV 19.5 2017Documento3 páginasVolvo FMX 460BSIV 19.5 2017A RamasubramanianAinda não há avaliações

- Power Amplifier PDFDocumento2 páginasPower Amplifier PDFIordan Dan FfnAinda não há avaliações

- NHW 4e Upp-Int WB Answer KeyDocumento12 páginasNHW 4e Upp-Int WB Answer KeySophia KastrovskayaAinda não há avaliações

- Llantas RimsDocumento19 páginasLlantas RimsantagusAinda não há avaliações

- Personal ConveyanceDocumento2 páginasPersonal ConveyanceMorris TruckingAinda não há avaliações

- Parent-Taught Driver Education in Texas: Traffic Safety FactsDocumento2 páginasParent-Taught Driver Education in Texas: Traffic Safety FactskeyawallaceAinda não há avaliações

- Maersk QuestionsDocumento2 páginasMaersk Questionsbuferok1Ainda não há avaliações

- Question Bank C To BDocumento211 páginasQuestion Bank C To Bsushiljp1984Ainda não há avaliações

- Mv. Sbi Achilles - Draft BLDocumento1 páginaMv. Sbi Achilles - Draft BLIrwan SianturiAinda não há avaliações

- Supply Chain Management - Future Trends. Prihor AdinaDocumento11 páginasSupply Chain Management - Future Trends. Prihor AdinaAdinaOanaPrihor100% (2)

- Human Resources Slide 1: Uber and Volvo Joint VentureDocumento14 páginasHuman Resources Slide 1: Uber and Volvo Joint Venturedaksh tutejaAinda não há avaliações

- Danone - Scorecard Catman Trade MarketingDocumento49 páginasDanone - Scorecard Catman Trade MarketingOrso2010Ainda não há avaliações

- Kubota Rc60 21b Mower Deck Wheel 850304062Documento7 páginasKubota Rc60 21b Mower Deck Wheel 850304062Roy MyersAinda não há avaliações

- Assignment #1 422 PDFDocumento5 páginasAssignment #1 422 PDFhelo_gobuAinda não há avaliações

- Stray Current Calculation and Monitoring in DC Mass-Transit SystemsDocumento8 páginasStray Current Calculation and Monitoring in DC Mass-Transit SystemsPrasenjit DeyAinda não há avaliações

- Railway Electrification (Pink Book 2019-2020)Documento9 páginasRailway Electrification (Pink Book 2019-2020)Muhammad Meraj AlamAinda não há avaliações

- Pom 16 - MRPDocumento65 páginasPom 16 - MRPNikhil AggarwalAinda não há avaliações

- Indian Railway DivisionDocumento3 páginasIndian Railway Divisionsujit kumar poddarAinda não há avaliações

- 21 Useful Charts For Service TaxDocumento35 páginas21 Useful Charts For Service TaxSonali SarkarAinda não há avaliações

- DS-P1 (Dispatch Sales)Documento1 páginaDS-P1 (Dispatch Sales)Muhammad ZohaibAinda não há avaliações

- Air Regs Mock Test 1Documento2 páginasAir Regs Mock Test 1arvindAinda não há avaliações

- Text 1 The Wright BrothersDocumento3 páginasText 1 The Wright BrothersputrisuardaniAinda não há avaliações