Escolar Documentos

Profissional Documentos

Cultura Documentos

5S Project Checklist PDF

Enviado por

Huynh HienTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

5S Project Checklist PDF

Enviado por

Huynh HienDireitos autorais:

Formatos disponíveis

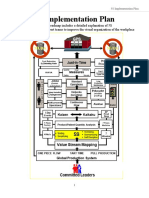

PROJECT CHECKLIST

Organize your 5S teams, assign responsibilities and set completion deadlines.

Select your 5S team; list names .

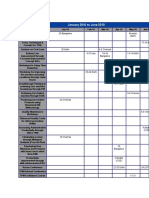

Sort

1. Set boundaries for the area

2. Identify a Red Tag Area within close proximity to the work area

3. Take BEFORE pictures of the area

4. Develop sorting and disposition rules

5. Sort, tag and remove unneeded items

6. Take AFTER pictures of the area

Waste can be hiding as:

Excess tools & equipment (totes, bins, shelves)

Outdated information (documents, manuals, samples)

Owner

Due Date

Complete

Unnecessary furniture (carts, desks, chairs, cabinets)

Obsolete or excess material/inventory

Set in Order

Owner

1. Team members that work in the area set locations for the value-added items

2. Place needed items in locations that eliminate unnecessary motion

3. Think ergonomics and safety

4. Create a border and address for each item that casts a shadow

5. Measure and document the improvements made

6. Take AFTER pictures of the area

Look for improvements and demonstrate the power of workplace organization:

Missing information

Time spent searching

Eliminating obsolete information

Walking or bending

Due Date

Complete

Shine

Owner

1. Team identies opportunities to improve cleanliness

2. Cleaning supplies/tools are gathered

3. Sources of contamination are identied and eliminated

4. Area is cleaned

5. Develop daily/weekly/monthly checklists to maintain cleanliness

6. Create standard work instructions for all cleaning processes

7. Create a smart place for cleaning items that include borders and ID labels

8. Take AFTER pictures

Cleanliness must become a part of our standard work and should include:

Transportation equipment

Work surfaces

Racks, desks, chairs, walls and lights

Equipment, tools, xtures

Due Date

Complete

Standardize

Owner

Due Date

1. Develop a standard 5S tool kit/cart

2. Create standard work instructions and train team on all workplace processes

3. Develop 5S audit procedures (who, what, where, when, and how?)

4. Implements management feedback system to evaluate adherence to standards

5. Establish a visual display to communicate 5S progress and current levels

Tool Kits should include products for maintaining borders, ID labels, work instructions and cleanliness.

Abnormal conditions should be visible at a glance.

A formalized feedback system with ownership and accountability will encourage continuous management participation.

Complete

Sustain

Owner

Due Date

Complete

1. Create a 5S area map and assign owners for accountability

2. Create a storyboard to illustrate the workplace organization journey

3. Benchmark ideas from other departments, divisions and industries

4. Schedule quarterly team meetings to review current state and identify progress

5. Display all 5S communications, audits and feedback locally in each area

Management support/communication is crucial to the sustainment of an organized workplace; use many means to communicate:

Newsletters

Dedicated 5S facilitators

Employee feedback and suggestion programs

Benchmarking

1167-V0612

www.visualworkplaceinc.com

616-583-9400

Você também pode gostar

- 5S Technique DataDocumento9 páginas5S Technique DataMuhammad Luqman FarooquiAinda não há avaliações

- Project Checklist: Organize Your 5S Teams, Assign Responsibilities and Set Completion DeadlinesDocumento1 páginaProject Checklist: Organize Your 5S Teams, Assign Responsibilities and Set Completion DeadlinesLeana Polston-MurdochAinda não há avaliações

- 6S in HealthcareDocumento13 páginas6S in HealthcareChannel MedicalAinda não há avaliações

- 5S Implementation Manual Part 2Documento63 páginas5S Implementation Manual Part 2jgprasadAinda não há avaliações

- 6s Evaluation FormDocumento3 páginas6s Evaluation FormDhananjay PatilAinda não há avaliações

- 7QC Tools - Training WorkshopDocumento10 páginas7QC Tools - Training Workshopb-consultant960Ainda não há avaliações

- Five S Implementation: SORT (Clearing Up Space) OrganizationDocumento8 páginasFive S Implementation: SORT (Clearing Up Space) OrganizationDONAinda não há avaliações

- Presentation On House Keeping TechniquesDocumento82 páginasPresentation On House Keeping TechniquesJanak DoshiAinda não há avaliações

- Kaizen Event Project Charter: Project Name Agency/Division/ Location Scope Meeting Date Target Event DateDocumento3 páginasKaizen Event Project Charter: Project Name Agency/Division/ Location Scope Meeting Date Target Event DateDebashishDolonAinda não há avaliações

- CANDO Pillar Audit Check SheetDocumento2 páginasCANDO Pillar Audit Check SheetharpreetmuditAinda não há avaliações

- 5S Thoughts - AllDocumento12 páginas5S Thoughts - Allssk3712Ainda não há avaliações

- Syllabus Primavera P6Documento6 páginasSyllabus Primavera P6Sandeep JoshiAinda não há avaliações

- 5S Red Tag ProcessDocumento8 páginas5S Red Tag ProcessSwj OkeAinda não há avaliações

- 6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1Documento5 páginas6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1stylish eagleAinda não há avaliações

- 7 QC ToolsDocumento21 páginas7 QC Toolsrakeshkumar20Ainda não há avaliações

- TQM Question and Answers 1. What Is PDCA?Documento10 páginasTQM Question and Answers 1. What Is PDCA?palaniappan_pandianAinda não há avaliações

- 6S (5S+1) Audit Check Sheet AdaptiveDocumento4 páginas6S (5S+1) Audit Check Sheet AdaptiveJose OrtegaAinda não há avaliações

- International Business Centre (Ibc) : One Day Training Programme OnDocumento35 páginasInternational Business Centre (Ibc) : One Day Training Programme Onanpuselvi125Ainda não há avaliações

- 5 S Information and Training OutlineDocumento5 páginas5 S Information and Training Outlinekprasad_mlAinda não há avaliações

- MOM FormatDocumento2 páginasMOM FormatahamedmubeenAinda não há avaliações

- 11 PM Weekly Maint Schedule & Criminal - CriticalDocumento14 páginas11 PM Weekly Maint Schedule & Criminal - CriticalReneeAinda não há avaliações

- 5S A Way of LifeDocumento33 páginas5S A Way of LifeSandulescu GeorgeAinda não há avaliações

- The 5S Number GameDocumento7 páginasThe 5S Number GameSaurabh SaoAinda não há avaliações

- Kaizen Blitz Charter: Date: Area: Team NameDocumento10 páginasKaizen Blitz Charter: Date: Area: Team Nameanjo0225Ainda não há avaliações

- Lesson 1 - From Waste To Wealth - Session 2 WorksheetDocumento1 páginaLesson 1 - From Waste To Wealth - Session 2 WorksheetNicole Angela NavarroAinda não há avaliações

- 2018 MBB Bok MapDocumento12 páginas2018 MBB Bok MapMohammed YasserAinda não há avaliações

- Basic 7 Tools of Quality: Presentation By: Carla Scardino The Pennsylvania State UniversityDocumento37 páginasBasic 7 Tools of Quality: Presentation By: Carla Scardino The Pennsylvania State Universityjitenderbhati07Ainda não há avaliações

- 7qc Tools ExplanationDocumento64 páginas7qc Tools ExplanationRajAinda não há avaliações

- 16 Types of Loss in GembaDocumento5 páginas16 Types of Loss in GembashivendrakumarAinda não há avaliações

- 06 5s Implementation Plan and Training Guide v20130618Documento13 páginas06 5s Implementation Plan and Training Guide v20130618thouraya hsan100% (1)

- 5S Audit ProcessDocumento5 páginas5S Audit ProcessChatnoir NoirAinda não há avaliações

- 6S Levels of Achievement Matrix Self AssessmentDocumento3 páginas6S Levels of Achievement Matrix Self AssessmentAnbalagan Ravichandran100% (1)

- Visual Management Audit ChecklistDocumento1 páginaVisual Management Audit ChecklistOswald mAinda não há avaliações

- 5S Is A Defined Visual Simple Method For Maintaining The Workplace in The Optimum Condition and Eliminate WasteDocumento1 página5S Is A Defined Visual Simple Method For Maintaining The Workplace in The Optimum Condition and Eliminate WastejplaraziAinda não há avaliações

- TPM Event CalenderDocumento3 páginasTPM Event Calenderamarpal07Ainda não há avaliações

- Focused Improvement: Prepared By: Lamis Essam El-Sayed Taghreed El-Sayed NayelDocumento26 páginasFocused Improvement: Prepared By: Lamis Essam El-Sayed Taghreed El-Sayed NayelLamis EssamAinda não há avaliações

- Delux Bearings Pvt. LTD.: Why Why Analysis For In-House RejectionDocumento4 páginasDelux Bearings Pvt. LTD.: Why Why Analysis For In-House RejectionmaulikgadaraAinda não há avaliações

- 5S Audit ChecklistDocumento1 página5S Audit ChecklistMd nuraza AkterAinda não há avaliações

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Documento1 páginaAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SAinda não há avaliações

- TPS Checklist UpdatedDocumento28 páginasTPS Checklist UpdatedMani Rathinam RajamaniAinda não há avaliações

- 5S Audit FormDocumento1 página5S Audit FormViorel IosubAinda não há avaliações

- 5s Training Slides 138Documento60 páginas5s Training Slides 138Farrukh AhmedAinda não há avaliações

- Office 5S ChecklistDocumento15 páginasOffice 5S ChecklistRohit NegiAinda não há avaliações

- WAAREE Energies PVT Ltd-LatestDocumento40 páginasWAAREE Energies PVT Ltd-LatestJp Gupta100% (2)

- Mahindra Black Belt Project Template - NewDocumento66 páginasMahindra Black Belt Project Template - NewSharma MaheshAinda não há avaliações

- 5sevaluation Radar ChartDocumento2 páginas5sevaluation Radar ChartMichelle Morgan LongstrethAinda não há avaliações

- Question BankDocumento16 páginasQuestion BankAman SinghAinda não há avaliações

- 5S Evaluation Criteria - Updated MI-10Documento6 páginas5S Evaluation Criteria - Updated MI-10Shashi Kant GuptaAinda não há avaliações

- The Lean Stack - Part 1Documento15 páginasThe Lean Stack - Part 1iNFuT™ - Institute for Future TechnologyAinda não há avaliações

- 7 Equip Loss Def. by JIPMSDocumento5 páginas7 Equip Loss Def. by JIPMSRanjit BhandariAinda não há avaliações

- Industrial Solutions, Inc: Lean Assessment ScorecardDocumento5 páginasIndustrial Solutions, Inc: Lean Assessment Scorecardrgrao85Ainda não há avaliações

- LWMC Final HR ManualDocumento172 páginasLWMC Final HR ManualUsama QayyumAinda não há avaliações

- Six Sigma and Lean OperationsDocumento66 páginasSix Sigma and Lean Operationsjitendrasutar1975Ainda não há avaliações

- Chromatography Solution: 5S AuditDocumento3 páginasChromatography Solution: 5S Auditabhijit612Ainda não há avaliações

- 5S Basic Training: Whatis5Sandwhydowewanttodoit?Documento15 páginas5S Basic Training: Whatis5Sandwhydowewanttodoit?Mahdi ZeynAinda não há avaliações

- Practical Approach To Practice 5SDocumento4 páginasPractical Approach To Practice 5SNikola DjorovicAinda não há avaliações

- Agile Essentials You Always Wanted To Know: Self Learning ManagementNo EverandAgile Essentials You Always Wanted To Know: Self Learning ManagementAinda não há avaliações

- Quality Management System Process A Complete Guide - 2020 EditionNo EverandQuality Management System Process A Complete Guide - 2020 EditionAinda não há avaliações

- QCTinChi PDFDocumento15 páginasQCTinChi PDFHuynh HienAinda não há avaliações

- Guia para Facilitador 5 SDocumento16 páginasGuia para Facilitador 5 SEve LynAinda não há avaliações

- Design of Distillation Column Control SystemsDocumento540 páginasDesign of Distillation Column Control SystemsVysagh Boban67% (3)

- Fuel PropertiesDocumento20 páginasFuel Propertiesanhhung80Ainda não há avaliações

- Getting Started LabviewDocumento91 páginasGetting Started LabviewCarlos A. RuizAinda não há avaliações

- (Ebook) - Labview - Pid Control Toolset - User Manual - 11'2001 PDFDocumento180 páginas(Ebook) - Labview - Pid Control Toolset - User Manual - 11'2001 PDFmekanicobucaroAinda não há avaliações

- 01 XRD Intro PDFDocumento9 páginas01 XRD Intro PDFWill Aguilar MamaniAinda não há avaliações

- c10 Gobbo PDocumento4 páginasc10 Gobbo PHuynh HienAinda não há avaliações

- X-Ray Diffraction and Crystal StructureDocumento15 páginasX-Ray Diffraction and Crystal StructureImran KhanAinda não há avaliações

- The World Energy Outlook After The Financial CrisisDocumento18 páginasThe World Energy Outlook After The Financial CrisisHuynh HienAinda não há avaliações

- Gas Conditioning Processing - Vol 4 - Gas and Liquid Sweetening PDFDocumento379 páginasGas Conditioning Processing - Vol 4 - Gas and Liquid Sweetening PDFThanh HuyAinda não há avaliações

- Gas Conditioning & Processing Vol 3 PDFDocumento438 páginasGas Conditioning & Processing Vol 3 PDFAlvaro Parihuancollo EncinasAinda não há avaliações

- SAE J404 V 002Documento6 páginasSAE J404 V 002DylkanWingsAinda não há avaliações

- FN1168 Multiple PLMN and Inter-PLMN Handover SupportDocumento25 páginasFN1168 Multiple PLMN and Inter-PLMN Handover SupportRazvan Corban50% (2)

- A1798504 - Chem Eng 4036 Assignment 1 ValidationDocumento12 páginasA1798504 - Chem Eng 4036 Assignment 1 ValidationHoang Uyen Vy NguyenAinda não há avaliações

- 966h 972h Sn-bj6 WXZ Bs6 NpeDocumento75 páginas966h 972h Sn-bj6 WXZ Bs6 NpeevanAinda não há avaliações

- Kim EsbensenDocumento25 páginasKim EsbensenJaime Mercado BenavidesAinda não há avaliações

- Wireshark LabDocumento5 páginasWireshark LabAmrit Kumar PatiAinda não há avaliações

- XCP 2.3 Development GuideDocumento124 páginasXCP 2.3 Development GuideRohan PrashanthAinda não há avaliações

- 1756 pp015 - en P PDFDocumento2 páginas1756 pp015 - en P PDFreinaldomdAinda não há avaliações

- Ekinex® Price List (APRIL 2019)Documento7 páginasEkinex® Price List (APRIL 2019)Federico Ungureanu100% (1)

- HP StorageWorks EML E-Series Tape Library - ModelsDocumento34 páginasHP StorageWorks EML E-Series Tape Library - ModelsMehdi KheirandishAinda não há avaliações

- Lms Admin GuideDocumento57 páginasLms Admin GuideDawit David ZeruAinda não há avaliações

- A Comparison of Liquid-Filled and Dry-Type Transformers For Industrial ApplicationsDocumento5 páginasA Comparison of Liquid-Filled and Dry-Type Transformers For Industrial Applicationsmilad rouhiniaAinda não há avaliações

- Catalogo Kaeser PDFDocumento7 páginasCatalogo Kaeser PDForlando_ubaldoAinda não há avaliações

- GEA31966 Hazrd Areas App Guide - R6Documento16 páginasGEA31966 Hazrd Areas App Guide - R6tjahyo02Ainda não há avaliações

- AS350 - Full Capacity - Spec - Rev2.2Documento5 páginasAS350 - Full Capacity - Spec - Rev2.2Fin HasAinda não há avaliações

- Swot DoleDocumento5 páginasSwot DoleAndie BibaresAinda não há avaliações

- BatteryCrossRef PDFDocumento138 páginasBatteryCrossRef PDFAM76Ainda não há avaliações

- NC Perfect Part Brochure 2011 WebDocumento12 páginasNC Perfect Part Brochure 2011 WebMetrology Software Products Ltd (MSP)Ainda não há avaliações

- HiPath 3000 v6.0 SMDocumento1.202 páginasHiPath 3000 v6.0 SMAngel Fernando RosasAinda não há avaliações

- Base Station Antennas1Documento66 páginasBase Station Antennas1redha_rebaiAinda não há avaliações

- OMN-FAC-170 Specification For MV & LV Electrical CableDocumento13 páginasOMN-FAC-170 Specification For MV & LV Electrical Cablesumit kumarAinda não há avaliações

- Na Dell 24 Monitor P2417H Product Spec Sheet US EnglishDocumento2 páginasNa Dell 24 Monitor P2417H Product Spec Sheet US Englishمحمد كريشةAinda não há avaliações

- XML API Developer GuideDocumento159 páginasXML API Developer GuidegirishpoojariAinda não há avaliações

- Unimotor Manual v2bDocumento119 páginasUnimotor Manual v2bFranCanavAinda não há avaliações

- Indian Standard - Fire Safety of Buildings (General) - Details of Construction-Code of PracticeDocumento32 páginasIndian Standard - Fire Safety of Buildings (General) - Details of Construction-Code of PracticeJyoti SinghAinda não há avaliações

- Branz Advisory Trower PartitionsDocumento6 páginasBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- Web Results: Specification (Technical Standard) - WikipediaDocumento4 páginasWeb Results: Specification (Technical Standard) - WikipediaAJ SaAinda não há avaliações

- M800 M80 E80 PLC Development ManualDocumento736 páginasM800 M80 E80 PLC Development ManualTensaigaAinda não há avaliações

- QP 06 Calibration of IMTEDocumento3 páginasQP 06 Calibration of IMTEShanmuga PrakashAinda não há avaliações

- PLC Connection PDFDocumento761 páginasPLC Connection PDFKhalid RafiqueAinda não há avaliações