Escolar Documentos

Profissional Documentos

Cultura Documentos

Report

Enviado por

Zohaib AhmedDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Report

Enviado por

Zohaib AhmedDireitos autorais:

Formatos disponíveis

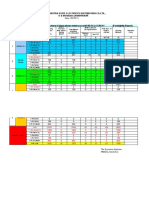

Output Summary

Page 1

Released to the following HTRI Member Company:

NED

Syed Zohaib Ahmed

Xist E Ver. 6.00 26/11/2016 20:28 SN: Vals100+

Desgin of Water heater

Design of HR system for Oil Heater

Design - Horizontal Multipass Flow TEMA AEL Shell With Single-Segmental Baffles

No Data Check Messages.

See Runtime Message Report for Warning Messages.

Process Conditions

Hot Shellside

Fluid name

Flow rate

(kg/s)

Inlet/Outlet Y (Wt. frac vap.)

Inlet/Outlet T

(Deg C)

Inlet P/Avg

(kPa)

dP/Allow.

(kPa)

Fouling

(m2-K/W)

1.000

315.00

50.001

13.897

SI Units

Cold Tubeside

FLUE GAS

0.3530

1.000

150.00

43.052

0.000

0.000880

0.000

35.00

700.010

0.406

WATER

0.3330

0.000

85.00

699.807

0.000

0.000352

Exchanger Performance

Shell h

Tube h

Hot regime

Cold regime

EMTD

(W/m2-K)

(W/m2-K)

(--)

(--)

(Deg C)

187.51

823.17

Sens. Gas

Sens. Liquid

156.7

Actual U

Required U

Duty

Area

Overdesign

Shell Geometry

TEMA type

Shell ID

Series

Parallel

Orientation

Baffle type

Baffle cut

Baffle orientation

Central spacing

Crosspasses

Tube Geometry

Tube type

Tube OD

Length

Pitch ratio

Layout

Tubecount

Tube Pass

(--)

(mm)

(m)

(--)

(deg)

(--)

(--)

Thermal Resistance, %

Shell

Tube

Fouling

Metal

65.43

17.87

15.99

0.71

122.70

95.17

0.0693

4.595

28.92

Baffle Geometry

AEL

205.004

1

1

0.00

(--)

(mm)

(--)

(--)

(deg)

(W/m2-K)

(W/m2-K)

(MegaWatts)

(m2)

(%)

(--)

(Pct Dia.)

(--)

(mm)

(--)

Single-Seg.

45.00

Perpend.

157.562

15

Nozzles

Plain

25.400

2.930

1.3333

30

20

Shell inlet

Shell outlet

Inlet height

Outlet height

Tube inlet

Tube outlet

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

150.000

150.000

10.507

10.507

26.645

26.645

2

Velocities, m/s

Shellside

Tubeside

Crossflow

Window

30.53

9.616e-2

27.37

25.21

Flow Fractions

A

B

C

E

F

0.022

0.727

0.168

0.083

0.000

Final Results

Page 2

Released to the following HTRI Member Company:

NED

Syed Zohaib Ahmed

Xist E Ver. 6.00 26/11/2016 20:28 SN: Vals100+

Desgin of Water heater

Design of HR system for Oil Heater

Design - Horizontal Multipass Flow TEMA AEL Shell With Single-Segmental Baffles

Process Data

Fluid name

Fluid condition

Total flow rate

Weight fraction vapor, In/Out

Temperature, In/Out

Temperature, Average/Skin

Wall temperature, Min/Max

Pressure, In/Average

Pressure drop, Total/Allowed

Velocity, Mid/Max allow

Mole fraction inert

Average film coef.

Heat transfer safety factor

Fouling resistance

Hot Shellside

FLUE GAS

(kg/s)

(--)

(Deg C)

(Deg C)

(Deg C)

(kPa)

(kPa)

(m/s)

(--)

(W/m2-K)

(--)

(m2-K/W)

SI Units

Cold Tubeside

WATER

Sens. Gas

0.3530

1.000

150.00

115.76

120.57

43.052

1.000

315.00

232.50

60.94

50.001

13.897

30.53

0.000

35.00

60.00

60.30

700.010

0.406

9.616e-2

Sens. Liquid

0.3330

0.000

85.00

89.27

118.73

699.807

0.0000

187.51

1.000

0.000880

823.17

1.000

0.000352

Overall Performance Data

Overall coef., Reqd/Clean/Actual

Heat duty, Calculated/Specified

Effective overall temperature difference

EMTD = (MTD) * (DELTA) * (F/G/H)

(W/m2-K)

(MegaWatts)

(Deg C)

(Deg C)

95.17 /

0.0693 /

156.7

157.82 *

146.05 /

0.0685

0.9929

122.70

* 1.0000

See Runtime Messages Report for

warnings.

Exchanger Fluid Volumes

Approximate shellside (L)

Approximate tubeside (L)

205

mm

2.93

m

75.7

41.0

Shell Construction Information

TEMA shell type

AEL

Shells Series

1 Parallel

Passes Shell

1 Tube

Shell orientation angle (deg)

0.00

Impingement present

No

Pairs seal strips

1

Shell expansion joint

Yes

Weight estimation Wet/Dry/Bundle

1

2

Shell ID

Total area

Eff. area

(mm)

(m2)

(m2/shell)

205.004

4.676

4.595

Passlane seal rods (mm) 0.000 No. 0

Rear head support plate

No

571.65 /

454.99 /

88.41 (kg/shell)

Baffle Information

Type

Perpend. Single-Seg.

Crosspasses/shellpass

15

Central spacing

(mm) 157.562

Inlet spacing

(mm) 415.412

Outlet spacing

(mm) 415.412

Baffle thickness

(mm)

3.175

Baffle cut (% dia) 45.00

No. (Pct Area) (mm) to C.L

1

44.46

10.250

2

0.00

0.000

Tube Information

Tube type

Overall length

Effective length

Total tubesheet

Area ratio

Tube metal

Plain

(m)

2.930

(m)

2.879

(mm)

50.800

(out/in)

1.1990

Carbon steel

Tubecount per shell

Pct tubes removed (none)

Outside diameter

(mm)

Wall thickness

(mm)

Pitch (mm)

33.8658 Ratio

Tube pattern (deg)

20

25.400

2.108

1.3333

30

Final Results

Page 3

Released to the following HTRI Member Company:

NED

Syed Zohaib Ahmed

Xist E Ver. 6.00 26/11/2016 20:28 SN: Vals100+

Desgin of Water heater

Design of HR system for Oil Heater

Design - Horizontal Multipass Flow TEMA AEL Shell With Single-Segmental Baffles

SI Units

Shellside Performance

Nom vel, X-flow/window

27.37 / 25.21

Flow fractions for heat transfer

0.779

A=0.0220 B=0.7273 C=0.1680 E=0.0827

F=0.0000

Shellside Heat Transfer Corrections

Total

0.788

Beta

0.746

Cross

25.63

MOMENTUM

Window

62.94

Gamma

1.056

End

0.942

Fin

1.000

Pressure Drops (Percent of Total)

Ends

4.01

0.00

Nozzle

Inlet

Outlet

Shell

4.36

3.06

Tube

48.68

31.76

Two-Phase Parameters

Method

Inlet

Center

Outlet

Mix F

H. T. Parameters

Shell

Tube

Overall wall correction

Midpoint

Prandtl no.

Midpoint

Reynolds no.

Bundle inlet

Reynolds no.

Bundle outlet

Reynolds no.

Fouling layer

(mm)

1.000

0.75

39021

15665

20522

1.015

3.04

4263

2843

5978

Thermal Resistance

Shell

Tube

65.43

17.87

Total fouling resistance

Differential resistance

Shell Nozzles

Inlet at channel end-No

Number at each position

Diameter

Velocity

Pressure drop

Height under nozzle

Nozzle R-V-SQ

Shell ent.

Fouling

15.99

Metal

0.71

Over Des

28.92

0.00130

0.00236

(mm)

(m/s)

(kPa)

(mm)

(kg/m-s2)

(kg/m-s2)

Inlet

1

150.000

17.67

0.607

10.507

353.07

945.24

Outlet

1

150.000

12.70

0.425

10.507

253.63

679.01

(mm)

(m/s)

(kPa)

(kg/m-s2)

Inlet

RADIAL

26.645

0.60

0.198

359.17

Outlet

RADIAL

26.645

0.62

0.129

368.20

Inlet

Outlet

Tube Nozzle

Diameter

Velocity

Pressure drop

Nozzle R-V-SQ

Annular Distributor

Length

Height

Slot area

Liquid

Outlet

0

Liquid

Outlet

(mm)

(mm)

(mm2)

Diametral Clearances (mm)

Baffle-to-shell

3.1750

Bundle-to-shell

21.0140

Tube-to-baffle

0.7938

Supplementary Results

Page 4

Released to the following HTRI Member Company:

NED

Syed Zohaib Ahmed

Xist E Ver. 6.00 26/11/2016 20:28 SN: Vals100+

Desgin of Water heater

Design of HR system for Oil Heater

Design - Horizontal Multipass Flow TEMA AEL Shell With Single-Segmental Baffles

Externally Enhanced Tube Geometry

Type

Fin density

Fin height

Fin thickness

Root diameter

Area/length

Plain

Internally Enhanced Tube Geometry

Type

Thickness

Pitch

(fin/meter)

(mm)

(mm)

(mm)

(m2/m)

None

(mm)

(L/D)

Mean Metal Temperatures

Mean shell temperature

219.46 (C)

Mean tube metal temperature in each tubepass, (C)

Tube Pass

1

2

Inside

88.88

106.01

Outside

90.06

107.07

Radial

89.51

106.57

SI Units

HEAT EXCHANGER SPECIFICATION SHEET

Page 5

SI Units

Job No.

Customer

Artisitic Millliners

Reference No.

Address

Proposal No.

Plant Location

AM-2 Unit, Main Korangi Industrial Rd.,Karachi

Date

26/11/2016

Rev

Service of Unit

Item No.

Size

205.004 x 2929.92 mm

Type AEL

Horz. Connected In

1 Parallel

1 Series

Surf/Unit (Gross/Eff) 4.68 / 4.59 m2

Shell/Unit

1

Surf/Shell (Gross/Eff) 4.68 / 4.59 m2

PERFORMANCE OF ONE UNIT

Fluid Allocation

Shell Side

Tube Side

Fluid Name

FLUE GAS

WATER

Fluid Quantity, Total

kg/hr

1270.81

1198.81

Vapor (In/Out)

1270.81

1270.81

Liquid

1198.81

1198.81

Steam

Water

Noncondensables

Temperature (In/Out)

C

315.00

150.00

35.00

85.00

Specific Gravity

0.9935

0.9691

Viscosity

mN-s/m2

0.0273

0.0209

0.7192

0.3335

Molecular Weight, Vapor

Molecular Weight, Noncondensables

Specific Heat

kJ/kg-C

1.1921

1.1481

4.2183

4.2670

Thermal Conductivity

W/m-C

0.0440

0.0320

0.6238

0.6733

Latent Heat

kJ/kg

Inlet Pressure

kPa

50.001

700.010

Velocity

m/s

30.53

9.616e-2

Pressure Drop, Allow/Calc kPa

13.897

0.406

Fouling Resistance (min) m2-K/W

0.000880

0.000352

Heat Exchanged W

MTD (Corrected)

156.7 C

69261.4

Transfer Rate, Service

95.17 W/m2-K

Clean

146.05 W/m2-K

122.70 W/m2-K

Actual

CONSTRUCTION OF ONE SHELL

Sketch (Bundle/Nozzle Orientation)

Shell Side

Tube Side

Design/Test Pressure

kPaG

1400.02 /

1400.02 /

Design Temperature

C

410.00

410.00

No Passes per Shell

1

2

Corrosion Allowance

mm

Connections

In

mm

1 @ 150.000

1 @ 26.645

Size &

Out

mm

1 @ 150.000

1 @ 26.645

Rating

Intermediate

@

@

Tube No.

Thk(Avg) 2.108 mm

Length 2.930 m

Pitch 33.866 mm

Layout 30

20 OD 25.400 mm

Tube Type

Plain

Material CARBON STEEL

Shell

ID 205.004 mm

OD

mm

Shell Cover

Channel or Bonnet

Channel Cover

Tubesheet-Stationary

Tubesheet-Floating

Floating Head Cover

Impingement Plate

None

Baffles-Cross

Type SINGLE-SEG.

%Cut (Diam) 45.00

Spacing(c/c) 157.562

Inlet 415.412 mm

Baffles-Long

Seal Type

Supports-Tube

U-Bend

Type

Bypass Seal Arrangement

Tube-Tubesheet Joint

Expansion Joint

Yes

Type

Rho-V2-Inlet Nozzle

353.07 kg/m-s2

Bundle Entrance 186.62

Bundle Exit 134.06 kg/m-s2

Gaskets-Shell Side

Tube Side

-Floating Head

Code Requirements

TEMA Class

Weight/Shell 454.99

Filled with Water 571.65

Bundle 88.41

kg

Remarks:

205

mm

2.93

m

Reprinted with Permission (v6 )

Você também pode gostar

- Chinese Visa RequirementsDocumento1 páginaChinese Visa RequirementsZohaib AhmedAinda não há avaliações

- Project Summary: Group Number Group AdvisorDocumento2 páginasProject Summary: Group Number Group AdvisorZohaib AhmedAinda não há avaliações

- Ansys Heat Transfer Through A Chimney Wall Problem SolutionDocumento8 páginasAnsys Heat Transfer Through A Chimney Wall Problem SolutionZohaib AhmedAinda não há avaliações

- Fundamentals - of - Signals - and - Systems - Using - Web - and - Matlab SolutionsDocumento433 páginasFundamentals - of - Signals - and - Systems - Using - Web - and - Matlab SolutionsMeseret BeyeneAinda não há avaliações

- Nodal Temp Solution Step 1 Sub 1 Time 1Documento1 páginaNodal Temp Solution Step 1 Sub 1 Time 1Zohaib AhmedAinda não há avaliações

- Student Slides Chapter 18Documento15 páginasStudent Slides Chapter 18Zohaib AhmedAinda não há avaliações

- Internship Report - Steel MillsDocumento21 páginasInternship Report - Steel MillsZohaib AhmedAinda não há avaliações

- Flow of Industrial Fluids Theory and EquatiionDocumento431 páginasFlow of Industrial Fluids Theory and EquatiionZohaib Ahmed100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- DNS Amplification Attacks ExplainedDocumento13 páginasDNS Amplification Attacks ExplainedhammAinda não há avaliações

- Screw Conveyor O&M ManualDocumento20 páginasScrew Conveyor O&M Manualjay b100% (1)

- 412 MM CH12Documento28 páginas412 MM CH12Hugo GonzalezAinda não há avaliações

- Fix 3Documento12 páginasFix 3Eng TrAinda não há avaliações

- Line Differential Protection and Control RED615: Product GuideDocumento32 páginasLine Differential Protection and Control RED615: Product GuidebrahimAinda não há avaliações

- Nano Particle Characterization MethodsDocumento32 páginasNano Particle Characterization MethodsVignesh Raja PAinda não há avaliações

- Oracle PLSQL Best Practices and Tuning PDFDocumento270 páginasOracle PLSQL Best Practices and Tuning PDFKeyur Pandya100% (1)

- Pinza Prova 5601Documento2 páginasPinza Prova 5601Sublimec San RafaelAinda não há avaliações

- Maharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARDocumento3 páginasMaharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARPuru BornareAinda não há avaliações

- Chain-On-Edge Spindle Conveyor Coating Systems: Processes & EquipmentDocumento1 páginaChain-On-Edge Spindle Conveyor Coating Systems: Processes & EquipmentRavindra MahadeokarAinda não há avaliações

- X-Arcade Tankstick Manual USADocumento13 páginasX-Arcade Tankstick Manual USAmight69Ainda não há avaliações

- Terminals of Ecm: For M/TDocumento4 páginasTerminals of Ecm: For M/TTdco SonicoAinda não há avaliações

- Clear IM Inventory DifferencesDocumento11 páginasClear IM Inventory DifferencesnguyencaohuygmailAinda não há avaliações

- High-Temp, Non-Stick Ceramic Cookware CoatingDocumento3 páginasHigh-Temp, Non-Stick Ceramic Cookware CoatingTomescu MarianAinda não há avaliações

- Fault Database - Flat TVDocumento3 páginasFault Database - Flat TVZu AhmadAinda não há avaliações

- Exam 1 With SolutionsDocumento11 páginasExam 1 With SolutionsSsebass PozzoAinda não há avaliações

- H61H2 A ManualDocumento88 páginasH61H2 A ManualkuriganoAinda não há avaliações

- B406-4 Rev. DDocumento86 páginasB406-4 Rev. Danshit1Ainda não há avaliações

- UDRPDocumento10 páginasUDRPDomainNameWire100% (1)

- Manual de Teatro en Casa Nuevo PanasonicDocumento56 páginasManual de Teatro en Casa Nuevo PanasonicMiguel Angel Aguilar BarahonaAinda não há avaliações

- Lecture 4-Unit 1 Lesson 4Documento23 páginasLecture 4-Unit 1 Lesson 4Jameel MalikAinda não há avaliações

- 1302 FF6SF6DosingMachine 0Documento3 páginas1302 FF6SF6DosingMachine 0Fawzi ChakirAinda não há avaliações

- Mahindra and Mahindra PPT LibreDocumento11 páginasMahindra and Mahindra PPT LibreMeet DevganiaAinda não há avaliações

- Trajectory ClusteringDocumento58 páginasTrajectory ClusteringPetrick Gonzalez PerezAinda não há avaliações

- Fie's Newton LawDocumento26 páginasFie's Newton LawNida'ul KhasanahAinda não há avaliações

- Comparison of Coaxial CablesDocumento1 páginaComparison of Coaxial CablesAntonis IsidorouAinda não há avaliações

- MSP430 Assembly Lab Manual for Number RepresentationDocumento6 páginasMSP430 Assembly Lab Manual for Number Representation2017 Koh Guan TsinAinda não há avaliações

- Space Exploration-DebateDocumento2 páginasSpace Exploration-Debateadhil afsalAinda não há avaliações

- Notice: Applications, Hearings, Determinations, Etc.: Southern Star Central Gas Pipeline, Inc.Documento2 páginasNotice: Applications, Hearings, Determinations, Etc.: Southern Star Central Gas Pipeline, Inc.Justia.comAinda não há avaliações

- Cyber Dynamic Line UsDocumento8 páginasCyber Dynamic Line UsMilan PitovicAinda não há avaliações