Escolar Documentos

Profissional Documentos

Cultura Documentos

PS Chapter 3

Enviado por

Barlo Yñigo AlcantaraDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PS Chapter 3

Enviado por

Barlo Yñigo AlcantaraDireitos autorais:

Formatos disponíveis

CHAPTER 3

METHODOLOGY

Research Design

The study utilized a research and developmental design, which intends to innovate and

optimize the existing machine. Fabrication of this project study will prove the workability of the

proposed design of the machine that is based on the conducted research and application of

engineering design calculation.

Project Development

Information Gathering

Conceptualization

Project Design

Fabrication and Acquisition

Testing and Evaluation

Modification

Information Gathering

Information and data will be collected through reliable internet, sites, books,

engineering magazines and brochures. Mechanical engineering professors will be

consulted for their insights and suggestions that might aid the conceptualization of

the project also the design will be compared to the rotating sieving machine. All the

data gathered will be gathered and studied until the researchers come-up with the

final concept of the project.

Conceptualization

The machine will be constructed primarily for the comparison of the

machines efficiency to the rotating sieving machine. The reciprocating sieving

machine will be design to operate on its optimum or maximum capacity. In its

design an attempt has been made to include operations illustrating the more

important factors in order to achieve the design goal results. Moreover, in this

machine a 3-layer of sand screener will be used.

Acquisition and Fabrication

This phase is the transformation of the design into functional prototype.

Based on the information gathered, the group decided to use angular steel bar for

the frames and supports will be assembled using screw fasteners and by welding.

The motor that will be used is a 1hp AC motor (60 cycles). The motor power will be

transmitted using a v-belt and sheaves that will be computed using engineering

principles.

The fabrication of this machine especially in its design mechanism will be

installed with precision that will meet the required dimensions and design. The

machine must be operated based on its maximum capacity.

Testing and Evaluation

Mechanical testing will be conducted after the fabrication of the machine and

the assembly of parts. Each part will be evaluated before full operation. The motor

that will drive the whole system will be evaluated based on its type and its

specifications to determine the factors that will cause an effect to the machine.

Also, evaluation will ensure the smooth operation of the system.

Phases of operation and its results will be observed after trials in order to

determine to what angle position of the sand screen will be its maximum position.

Você também pode gostar

- Redesign-Rollator's Parking Brake SystemDocumento16 páginasRedesign-Rollator's Parking Brake Systemjerrison samuelAinda não há avaliações

- Hydraulic-Powered Robotic Arm PDFDocumento8 páginasHydraulic-Powered Robotic Arm PDFsaurabh satsangiAinda não há avaliações

- Motor Learning Chapter 1 To 8Documento15 páginasMotor Learning Chapter 1 To 8shafieAinda não há avaliações

- Invisible Women: Contemporary Chinese Film and Women's CinemaDocumento26 páginasInvisible Women: Contemporary Chinese Film and Women's CinemalanzhoucityAinda não há avaliações

- Literature Review: Automatic Pneumatic Bumper and Braking SystemDocumento10 páginasLiterature Review: Automatic Pneumatic Bumper and Braking Systemkathir venkatachalamAinda não há avaliações

- Design and Fabrication of Motorized Hydraulic Jack SystemDocumento8 páginasDesign and Fabrication of Motorized Hydraulic Jack SystemIJRASETPublicationsAinda não há avaliações

- A ProjectDocumento14 páginasA Projectajay0% (1)

- Chapter 10Documento78 páginasChapter 10Si Thu AungAinda não há avaliações

- Motorized Ramming MachineDocumento53 páginasMotorized Ramming Machineilayaraja6100% (1)

- Regenerative Suspension SystemDocumento24 páginasRegenerative Suspension Systemvineeth100% (1)

- Vishal 35426455tyre Changer Machine NEWDocumento22 páginasVishal 35426455tyre Changer Machine NEWSushant ManeAinda não há avaliações

- Cylinder Management 1Documento31 páginasCylinder Management 1Falgon IslamAinda não há avaliações

- Fabrication of Reverse Gear in Two WheelerDocumento26 páginasFabrication of Reverse Gear in Two WheelerSai RamAinda não há avaliações

- Final ProjectDocumento24 páginasFinal ProjectAnik GangulyAinda não há avaliações

- Remote Controlled Screw Jack 2014 AcDocumento58 páginasRemote Controlled Screw Jack 2014 AcChockalingam AthilingamAinda não há avaliações

- Working of Single Plate ClutchDocumento1 páginaWorking of Single Plate ClutchBikash Das50% (2)

- Automatic Head Lamp Alignment SystemDocumento48 páginasAutomatic Head Lamp Alignment SystemAakash Dindigul100% (1)

- Fabrication of Pneumatic Drill JigDocumento2 páginasFabrication of Pneumatic Drill JigvikasysAinda não há avaliações

- Self Centering Four Jaw ChuckDocumento6 páginasSelf Centering Four Jaw ChuckbalakaleesAinda não há avaliações

- ENGINE FINS Final Report - Phase 1Documento44 páginasENGINE FINS Final Report - Phase 1Boopathi KalaiAinda não há avaliações

- A Design of 360 Degree Flexible Drilling MachineDocumento26 páginasA Design of 360 Degree Flexible Drilling MachineSai RamAinda não há avaliações

- A Review On Multi Spindle Drilling Speci PDFDocumento3 páginasA Review On Multi Spindle Drilling Speci PDFAdelina RomanAinda não há avaliações

- Hybrid Metal Additive ManufacturingDocumento75 páginasHybrid Metal Additive ManufacturingNursultan JyeniskhanAinda não há avaliações

- Wireless Multiple Agriculture Robot - SynopsisDocumento10 páginasWireless Multiple Agriculture Robot - SynopsisShailesh RanawareAinda não há avaliações

- Designof Power Driven Dough Mixing MachineDocumento5 páginasDesignof Power Driven Dough Mixing MachineTewodros B.Ainda não há avaliações

- AGRIDocumento15 páginasAGRISantosh DineshAinda não há avaliações

- DESIGN - AND - FABRICATION - OF - AUTOMATIC - SPRAY - PAINTING - MACHINE - Ijariie7676 PDFDocumento7 páginasDESIGN - AND - FABRICATION - OF - AUTOMATIC - SPRAY - PAINTING - MACHINE - Ijariie7676 PDFHussain MuslimAinda não há avaliações

- Automated Punching MachineDocumento8 páginasAutomated Punching MachineMohamed IbrahemAinda não há avaliações

- Accident Avoiding of Punching Machine - ReportDocumento38 páginasAccident Avoiding of Punching Machine - ReportPrathmeshBhokari0% (1)

- Fabrication of Portable Noodle Making Ma Fd82a2eeDocumento4 páginasFabrication of Portable Noodle Making Ma Fd82a2eeankush belkarAinda não há avaliações

- Bullock Cart: Aarushree KhobragadeDocumento13 páginasBullock Cart: Aarushree KhobragadeAzure MidoriyaAinda não há avaliações

- Research On Automatic Bike Starter KitDocumento38 páginasResearch On Automatic Bike Starter KitGokul RajaAinda não há avaliações

- Design and Fabrication of Seed Sowing and Spraying Machine For AgricultureDocumento8 páginasDesign and Fabrication of Seed Sowing and Spraying Machine For AgricultureIJRASETPublicationsAinda não há avaliações

- Pnumatic Ramming and Punching Machine ReportDocumento28 páginasPnumatic Ramming and Punching Machine ReportSun SriAinda não há avaliações

- Mahindra Gears Transmiision Training ReportDocumento32 páginasMahindra Gears Transmiision Training Reportbestmadeeasy50% (2)

- Syringe Actuated Mechanical ArmDocumento17 páginasSyringe Actuated Mechanical ArmMohd Subhan0% (1)

- Fabrication of Ground DrillerDocumento47 páginasFabrication of Ground DrillerAjith manjuAinda não há avaliações

- ME2309 CAD CAM Lab ManualDocumento36 páginasME2309 CAD CAM Lab Manualkumar km100% (1)

- ProjectDocumento31 páginasProjectMR. CØØLAinda não há avaliações

- Gearless Transmission Research PaperDocumento10 páginasGearless Transmission Research PaperresonancebansalAinda não há avaliações

- CMPT 641-Digital Transformation Plan - Phase 1 - Part 2Documento18 páginasCMPT 641-Digital Transformation Plan - Phase 1 - Part 2raghavAinda não há avaliações

- Design and Devolopment of Semi Automatic Glass Cleaning MachineDocumento14 páginasDesign and Devolopment of Semi Automatic Glass Cleaning MachineNandkumar BabarAinda não há avaliações

- Group No. 2 Project Report Review 2Documento35 páginasGroup No. 2 Project Report Review 2Devansh SharmaAinda não há avaliações

- 360 Rotating Trolly Shubham Rawat ProjectDocumento30 páginas360 Rotating Trolly Shubham Rawat ProjectShubham RawatAinda não há avaliações

- Brake Failure Indicator Design: Bachelor of TechnologyDocumento19 páginasBrake Failure Indicator Design: Bachelor of TechnologyAniket KarmakarAinda não há avaliações

- Mentsnot GetuDocumento68 páginasMentsnot GetuLợi Lê Đình100% (1)

- Project Bevel GearDocumento7 páginasProject Bevel GearSubramaniAinda não há avaliações

- 1.1 Background of The StudyDocumento12 páginas1.1 Background of The StudyStephen DuamorAinda não há avaliações

- Pneumatic Speed Breaker With Day Night Control (PSB)Documento40 páginasPneumatic Speed Breaker With Day Night Control (PSB)Giri TharanAinda não há avaliações

- EEE Hybrid VehiclesDocumento1 páginaEEE Hybrid Vehiclesashoku24007Ainda não há avaliações

- Numerical Investigation of Fluidic Injection As A Means of Thrust ModulationDocumento10 páginasNumerical Investigation of Fluidic Injection As A Means of Thrust Modulationpeyman71Ainda não há avaliações

- Project ReportDocumento15 páginasProject ReportPrakhar AgrawalAinda não há avaliações

- Project Synopsis: Department of Mechanical Engineering Submitted byDocumento10 páginasProject Synopsis: Department of Mechanical Engineering Submitted byMintu VermaAinda não há avaliações

- Dual Energy Generator Using Solar & Tidal PowerDocumento4 páginasDual Energy Generator Using Solar & Tidal PowerTysoñ ßAinda não há avaliações

- Product Design Project Report On Device To Aid Outdoor CleaningDocumento23 páginasProduct Design Project Report On Device To Aid Outdoor CleaningNajiAinda não há avaliações

- Railway ProjectDocumento51 páginasRailway Projectsanojjose75Ainda não há avaliações

- Box Shifting Mechanism PDFDocumento2 páginasBox Shifting Mechanism PDFHarika Harry60% (5)

- RulebookDocumento50 páginasRulebookGAinda não há avaliações

- Magneto Abrasive Flow MachiningDocumento24 páginasMagneto Abrasive Flow MachiningArjun M BetageriAinda não há avaliações

- Design and Fabrication of Oil Skimmer RobotDocumento46 páginasDesign and Fabrication of Oil Skimmer RobotSathiya Udumalpet100% (2)

- Solid Modeling Final - Manual-06!05!19 New by MailDocumento276 páginasSolid Modeling Final - Manual-06!05!19 New by MailRajat ShrirameAinda não há avaliações

- Mechanical Design Process and Review of Dynamics Lecture #1Documento21 páginasMechanical Design Process and Review of Dynamics Lecture #1abdullah 3mar abou reashaAinda não há avaliações

- AlibabaDocumento12 páginasAlibabaBarlo Yñigo AlcantaraAinda não há avaliações

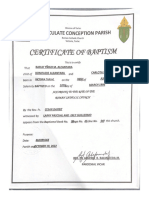

- Immaculate Conception ParishDocumento2 páginasImmaculate Conception ParishBarlo Yñigo AlcantaraAinda não há avaliações

- Personal Loan TNC FormDocumento7 páginasPersonal Loan TNC FormBarlo Yñigo AlcantaraAinda não há avaliações

- Vacant Position November 09 2021Documento1 páginaVacant Position November 09 2021Barlo Yñigo AlcantaraAinda não há avaliações

- Christian Living 3 LESSON 2Documento4 páginasChristian Living 3 LESSON 2Barlo Yñigo AlcantaraAinda não há avaliações

- Power Plant Excel DesignDocumento12 páginasPower Plant Excel DesignBarlo Yñigo AlcantaraAinda não há avaliações

- Sugar Plant Design CalculationDocumento78 páginasSugar Plant Design CalculationBarlo Yñigo AlcantaraAinda não há avaliações

- 03 HD202 Family Life CycleDocumento3 páginas03 HD202 Family Life CycleBarlo Yñigo Alcantara0% (1)

- Reasons and Objectives For Engine TestDocumento2 páginasReasons and Objectives For Engine TestBarlo Yñigo AlcantaraAinda não há avaliações

- 01 HD202 Theories of DevelopmentDocumento6 páginas01 HD202 Theories of DevelopmentBarlo Yñigo Alcantara100% (1)

- Yantra Puja WorshipDocumento12 páginasYantra Puja Worshipspirit571Ainda não há avaliações

- FC Sem 4 Right To InformationDocumento9 páginasFC Sem 4 Right To Informationansh patelAinda não há avaliações

- The Role of Culture Bump in Developing Intercultural Communication Competency and Internationalizing Psychology EducationDocumento9 páginasThe Role of Culture Bump in Developing Intercultural Communication Competency and Internationalizing Psychology EducationSyahid Khusnul KhotimahAinda não há avaliações

- Verbal Aspect in The Greek of The New Testament, With Reference To Tense and Mood (PDFDrive)Documento597 páginasVerbal Aspect in The Greek of The New Testament, With Reference To Tense and Mood (PDFDrive)Róger AraújoAinda não há avaliações

- Impact of Counter-Terrorism On Communities - Methodology ReportDocumento56 páginasImpact of Counter-Terrorism On Communities - Methodology ReportPaulo FelixAinda não há avaliações

- Isi 2Documento15 páginasIsi 2Nasser KalanAinda não há avaliações

- God's Law and SocietyDocumento92 páginasGod's Law and SocietyNarrowPathPilgrim100% (5)

- Stony Brook University Psych 310 SyllabusDocumento5 páginasStony Brook University Psych 310 SyllabusJhonAinda não há avaliações

- Philo of Alexandria An Exegete For His Time - Peder BorgenDocumento10 páginasPhilo of Alexandria An Exegete For His Time - Peder BorgenTemirbek BolotAinda não há avaliações

- Feser-Reply To Marie George - RevisedDocumento10 páginasFeser-Reply To Marie George - RevisedDiogo AugustoAinda não há avaliações

- Motivational Interviewing ManualDocumento206 páginasMotivational Interviewing ManualSean Cho100% (1)

- Vasthu Part1Documento147 páginasVasthu Part1vinay100% (1)

- Cowan A., Women, Gossip and Marriage in VeniceDocumento23 páginasCowan A., Women, Gossip and Marriage in Veniceneven81Ainda não há avaliações

- The Teaching of The History of Rwanda, A Participative ApproachDocumento113 páginasThe Teaching of The History of Rwanda, A Participative ApproachKagatamaAinda não há avaliações

- SCSC PDP Hamish Tamlin 2015 EndcycleDocumento16 páginasSCSC PDP Hamish Tamlin 2015 Endcycleapi-298158473Ainda não há avaliações

- Unit 1 of The Grade 8 Integrated Science Deals With ForceDocumento4 páginasUnit 1 of The Grade 8 Integrated Science Deals With ForceNorvie Magdato RuelAinda não há avaliações

- Test of Reasoning (Arihant)Documento402 páginasTest of Reasoning (Arihant)Aratrik Banerjee0% (2)

- 1.coulomb Law and Superposition PrincipleDocumento5 páginas1.coulomb Law and Superposition PrincipleArjunAinda não há avaliações

- Negarestani - 'Navigate With Extreme Prejudice'Documento5 páginasNegarestani - 'Navigate With Extreme Prejudice'Kam Ho M. WongAinda não há avaliações

- Discourse Analysis 7 OppositiesDocumento19 páginasDiscourse Analysis 7 OppositiesSaman OthmanAinda não há avaliações

- Introduction To Clinical Health PsychologyDocumento271 páginasIntroduction To Clinical Health Psychologyshafijan100% (1)

- Angels and DemonsDocumento3 páginasAngels and Demonsapi-310046060Ainda não há avaliações

- Thematic TeachingDocumento20 páginasThematic TeachingClea Allosa JunillerAinda não há avaliações

- BibliographiesDocumento7 páginasBibliographiesINA ISABEL FULOAinda não há avaliações

- جودة الخدمة ودورها في الاداء المتميزDocumento28 páginasجودة الخدمة ودورها في الاداء المتميزqoseAinda não há avaliações

- Bakhtin X VygotskyDocumento17 páginasBakhtin X VygotskyMARCOS MORAES CALAZANSAinda não há avaliações

- Eseu UlyssesDocumento2 páginasEseu UlyssesAnca ConstantinAinda não há avaliações