Escolar Documentos

Profissional Documentos

Cultura Documentos

Gears: - Toothed Cylindrical or Conical Wheels Used For Power Transmission With or Without Speed Reduction

Enviado por

Randhir KyTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Gears: - Toothed Cylindrical or Conical Wheels Used For Power Transmission With or Without Speed Reduction

Enviado por

Randhir KyDireitos autorais:

Formatos disponíveis

3/22/2016

Gears

Toothedcylindricalorconicalwheelsusedforpower

transmissionwithorwithoutspeedreduction

Spurgears

Teethareparalleltotheaxisofrotation

Usedfortransmittingpowerbetween

parallelshafts

Helical gears

Helicalgears

Teethareinclinedtotheaxisofrotation

Relativelyquieterinoperation

Canbeusedfortransmittingpowerbetween

nonparallelshaftsalso

3/22/2016

Bevelgears

Teethareformedonaconicalsurface

Teethcanbestraightorspiral

Usedfortransmittingpowerbetween

perpendicularintersectingshafts

Hypoidgears

Similartobevelgearbutshaftscanbe

offset,perpendiculartoeachother

WormandWormwheel

Shaftsperpendicular,nonintersecting

Largespeedreductionpossible

3/22/2016

Pitchcircle

Theoreticalcircleuponwhichallcalculationsaremade.Itsdiameteriscalledpitch

circlediameter d.Pitchcirclesoftwomatinggearsaretangenttoeachother

Addendum,a

Radialdistancebetween

toplandandpitchcircle

Dedendum,b

Radialdistancebetween

bottomlandandpitch

circle

Circularpitch(p)

Distancemeasuredonthepitchcirclefromapointonthetoothtothe

correspondingpointonanadjacenttooth

p =tooththickness+widthofspace(measuredonPC)

p =d/N,Nisnumberofteeth

Pinion:thesmallerofthetwomatinggears

Gear:thelargeramongthetwomatinggears

Idler:usedforchangingdirection

Module

m = d/N

d/ (standardvaluesgivenindatabook)

(

d d l

d b k)

Clearancecircle:Thecirclewhichistangenttothe

addendumcircleofmatinggear,c = b-a

Wholeteethdepth,ht = a + b

Backlash

A

Amountbywhichthewidthofthetoothspace

t b hi h th idth f th t th

exceedsthethicknessoftheengagingtooth,both

measuredonPC

a andb havedefiniteproportionwithmina

standardgear

3/22/2016

VA rA A ;

OA

VA

rA

VB

VB rBB

Points A and B are moving

together along line a b

VA cos VB cos

rA A cos rBB cos

rB

A rB cos OB N OB P

B rA cos OA M OA P

Piscalledthepitchpoint(isalso

instantaneouscenterofAandB)

B

OB

IfLOAintersectsLOCatthesamepoint,

thenvelocityratioremainsconstant

Involute profile

Thecircleon whichtheinvolute

isgeneratediscalledBasecircle

LOAisthecommontangenttothebase circleofthetwogears

LOAisalsothenormaltothetoothprofilesatthecontactpoint

3/22/2016

isthepressure angle

rB1 r1 cos

rB2 r2 cos

rB 2

Whentwogearsareinmesh,theirpitchcirclesrollon

eachotherwithoutslipping

Standardpressureangles

1 r2 d 2 mN 2 N 2

20o,25o, 14.5o

2 r1 d1 mN1 N1

Theinvolute profile startsatthebasecircleandextends

uptotheaddendumcircle

Thegeartooth(insomecases)extendsbeyondthebase

circleuptothededendum circletohaveclearance

Theportionoftoothbelowthebasecircle isnotan

involute anddoesnotprovideconjugateaction

Contactinthisportionshouldbeavoided

14.5o

20o

25o

3/22/2016

Lab ra21 rB21 ra22 rB22 (r1 r2 ) sin

Lab

; pb p cos is called base pitch

pb

Contactratioofgreaterthan1impliesthatatsometime

duringmeshingmorethanonepairofteethareincontact

Contactratiooflessthan1.2notrecommended

Increasingcentertocenterdistance(r1 +r2 )candecrease

contactratio

Contact ratio: mc

3/22/2016

Interference

Contactoftoothportionsthatarenotinvolute (conjugate)

iscalledinterference

Inagearmanufacturedbygenerationprocess,

undercuttinghappensandthiseliminatesinterference

Undercuttingweakensthetooth

Avoidinginterference:spurgears

Thesmallestnumberofteethonaspurpinionandgearwhichcan

existwithoutinterferenceis

Np

NG

2k

2

2

m

(1

2

m

)

sin

;

m

G

G

G

G

(1 2mG ) sin 2

Np

Thelargestgearforaspecifiedpiniontoavoidinterference

NG

N p2 sin 2 4k 2

1 for full depth

; k

. for

o sstub

ub dep

depth

s

4k 2 N p sin

0.8

2

Forrackandpinion

Np

2k

sin 2

3/22/2016

Helicalgears

Shapeofthetoothisaninvolute helicoid

Parallelshafts,pinionandgearhasleftand

p

g

righthandteeth

Perpendicularshafts,bothgearandpinionhas

sametype

Inspurgearsthecontactisoveralinewhichisacross

thefaceofthegear

Contactissimultaneousalongthefacewidth

Thelinecontactstartsfromaddendumcircletobase

circle

Inahelicalgear,theinitialcontactisatapointandthen

itextendsintoalineastheteethcomeintoengagement

Thelinecontactextendsdiagonallyacrossthetooth

facegoingfromtiptotheroot

Engagementisthereforemoregradualforapairof

Engagement is therefore more gradual for a pair of

toothwithsmoothloadtransfer

Contactratioisnotaconcern,rathersufficientface

widthshouldbeprovided

Generatesanaxialloadontheshaft

3/22/2016

PCD (d)ismeasuredin

thetransverseplane

Transversecircularpitch

pt

d

N

Transversemodule

mt

d

N

Normalcircularpitch

pn pt cos

Normalmodule

mn mt cos

3/22/2016

Helixangleismeasuredonthecylindricalpitchsurface

Normalpressureangle n

Transversepressureangle

W

Wa

tan n

cos

t tan 1

Wr

t

Wt

cos

tan n

tan t

Wr W sin

i n

Wt W cos n cos

Wa W cos n sin

10

3/22/2016

Commonlyusedstandardtoothsystemsforspurgear

Commonlyusedstandardtoothsystemsforhelicalgear

addendum, a mn

Base diameter :

d cos t for pinion

dedendum, b 1.25mn

PCD : d

N p mn

cos

, D

N G mn

cos

D cos t for gear

Avoidinginterference:helicalgears

Thesmallestnumberofteethonahelicalpinionandhelicalgear

whichcanexistwithoutinterferenceis

Np

NG

2k cos

2

2

m

(1

2

m

)

sin

;

m

G

G

G

t

G

(1 2mG ) sin 2 t

Np

Thelargestgearforaspecifiedpiniontoavoidinterference

NG

N p2 sin 2 t 4k 2 cos 2

1 for full depth

; k

. for

o stub

s ub dep

depth

4k cos 2 N p ssin t

0.8

2

Forrackandpinion

Np

2k cos

sin 2 t

11

3/22/2016

Toothfailuremodes

Bendingstressattherootofthetooth

Yielding

Fatiguefailure

Contactstressatpointofcontact

Pittingorsurfacefatiguefailure

Bendingstress

AnalysisbyWilfredLewis in1892

Treatthetoothasacantileverofspanl, deptht andwidthF

W

Wr

Wt

l

6Wt l

Ft 2

Bothl and t dependsontoothprofile

From similar triangles

Wp

W

t2

x, 2t t

4l

F 3 xp FpY

p is circular pitch

Y

2x

; is called Lewis form factor

3p

12

3/22/2016

Yincreaseswithincreasingnumberofteethor

increasingpressureangle

Theworstconditionistaken;i.e.theloadappliedattipof

thetooth

Onlyonepairofteethisassumedtoengageatatime

Loadsharing(whencontactratiois>1)isnotconsidered

d h i ( h

i i

)i

id d

Stressconcentrationattherootisnotconsidered

Alloftheabovedependsontoothgeometry,numberof

teethetc.

Hencetheformfactorismodifiedfurthertoaccountfor

theseeffects

13

3/22/2016

AGMA DesignEquations

Tooth bending

Wt K O KV K S

1 KH KB

(SI units)

Fmt YJ

F is face width, mt is transverse module

K O is overload factor, KV is dynamic factor

K S is size factor, K H is load distrubution factor

K B is rim thickness factor

YJ is geometry factor for bending strength

(includes the stress concentration factor K F )

F is usually 3 to 5 times circular pitch p

YJ (orJ)geometryfactor

Capturestheeffectoftoothformonbendingstresses

Willbedifferentforpinionandgear

14

3/22/2016

Forhelicalgear,determine

YJ (J)fromthefirstfigure

andmultiplythatwiththe

modifyingfactorfromthe

secondfigure

KO overloadfactor

AccountsforallexternalloadsinexcessofWt

15

3/22/2016

KV dynamicfactor

Thisaccountsforinaccuraciesinmanufacturingand

meshingofagearteethdueto

Vibrationduringmachining

Dynamic unbalance of rotating members

Dynamicunbalanceofrotatingmembers

Wearandpermanentdeformationoftooth

Shaftmisalignmentduetolinearandangulardeflection

Toothfriction

Allofthesecausestransmissionerror(departurefrom

constantangularvelocityratio)

Theseleadtoanincreaseinloadonthetooth

These lead to an increase in load on the tooth

KV dependsonpitchlinevelocity

A 200V

KV

; V in m/sec

A

A 50 56(1 B )

B 0.25(12

( QV ) 2 / 3

These

Thesecurvesarefromtestdataonlargenumberofgears

curves are from test data on large number of gears

QV isAGMA qualitynumber

3to7:Commercialquality

8to12:Precisionquality

KV increasesasVincreasesorQV decreases

16

3/22/2016

KS Sizefactor

Accountsfornonuniformityinmaterialpropertiesdueto

size seepage29ofdatabook

KH Loaddistributionfactor

Accountsfornonuniformityofloadacrossthelineofcontact

(seepage29ofdatabook)

Facewidth(mm)

upto50 150

225

>400

KB Rim thicknessfactor

Thebendingstresscalculationassumesthatthe

toothislikeacantileverwithrootofitfixed.

Largegearshavearimandiftherimisnot

sufficientlythick,thenitcaninducerootflexibility

17

3/22/2016

Allowablebendingstress

all

St YN

S F Y YZ

2

St Bending

B di strengthh (N/mm

(N/

),

) S F AGMA safety

f ffactor

YN Stress cycle factor for bending, Y Temperature factor = 1

YZ Reliability factor (table 14-10)

Gearteetharesubjectedtorepeatedloading

Theteethinanidlergearwillundergotwowaybending,

henceuse0.75St inaboveequation

Gearmaterials

Canbemadeofsteel,bronze,graycastiron,evenplastics

Strengthandpittingresistanceareimportantfactors

g

Throughhardenedsteels

180<HB <400recommended

e.g AISI 3140,4140,4340,6150,8150etc.aregood

%elongationof12%ofmoreisdesired

Casehardenedsteels

HB >400

Inductionhardening,Flamehardening,Ntriding etc.

produceahardsurfacelayerandtoughcore

Thehardeningdepthhastobeensured

18

3/22/2016

RepeatedlyAppliedBendingstrength:St

107 cyclesand0.99reliability

Grade1isbasicstandard

Grade2requireshighdegree

of microstructure control

ofmicrostructurecontrol

YN isusedwhenlifeisnot107 cycles

Inagearset,thenumberofloadcyclesforpinionandgear

aredifferent.Sothisfactorwillbedifferentforpinionand

gear

19

3/22/2016

Surfacedurability

Inagearteethpair,perfectrollinghappensonlywhen

thecontactisatthepitchcircle(P)

Atothercontactpoints,thereisrollingwithsliding

Relativevelocityalongthe

directionperpendicularto

LOAisnotzero

Thesliding velocityreverses

directionasthecontact

direction as the contact

crossesthepitchpoint

Themagnitudeofrelative

velocityisalso notconstant

Surfacedurability

Theslidingcauses

Abrasivewearduetotrappedforeignparticles

Scoring

Highervelocityintheabsenceofproperlubrication(elasto

Higher velocity in the absence of proper lubrication (elasto

hydrodynamic)resultsinhighfriction

Thehighcontactpressureandhighfrictionleadtolocalized

heating

Thisheatingresultsinlocalweldingofsurfaceparticlesand

theirsubsequenttearing

Lubricationandcoolingcanminimizethis

Pittingandspalling

Surfaceandsubsurfacefatiguefailureundercontactstress

20

3/22/2016

Hertzcontactstress

Considertwocylindersarecontactunderloadasshown

Thecontactisoveranarrowrectangularpatchofwidth

2b andlengthL

1/ 2

4 P (1 12 ) / E1 (1 22 ) / E2

1/ 1 1/ 2

L

p0

2P

P 1

1

ZE

bL

L 1 2

ZE

1

1 12 1 22

E2

E1

Contactstressesinmeshinggearteeth

Pittingdamageismostlyobservedaroundthepitchline

Slidingvelocityisverysmallbecauseofwhichhydrodynamic

actionisabsent(nooilfilm)

p

p

Thereforethecontactstressesareevaluatedatthepitchpoint

1 rP sin ; 2 rG sin ; P

rP

c ZE

ZI

Wt

cos

Wt

Fd P Z I

sin cos mG

2

mG 1

+ for external gear set; - for internal gear set

rG

ZI isthegeometryfactorforsurfacestrength

21

3/22/2016

ZI forhelicalgear

n1

rP sin t

cos b

n 2

rG sin t

cos b

b Helix angle measured on base circle

ZI forhelicalgear

Inahelicalgear,thecontactloadactsoveralarger

distancethanthefacewidthduetohelixangle

Thereisloadsharing

sin

i t cos t mG

ZI

2 mN

mG 1

pn cos n

is load sharing ratio

0.95Z

pn is normal circular pitch

mN

Z is length of line of action in transverse plane

2

2

rbG

(rP rG ) sin t

Z raP2 rbP2 raG

base circle radius, rb r cos t ; addendum circle radius, ra r a

22

3/22/2016

AGMA DesignEquations

Tooth pitting

c Z E Wt K O KV K S

KH ZR

(SI units)

dP F ZI

F is face width, d P is PCD of pinion

Z I is geometry factor for pitting resistance

Z R is surface condition factor for accounting effect of

surface finish (=1)

ZE

1

1

1 G2

E

EG

P

2

P

is called the elastic coeffficient

Allowablecontactstress

c ,all

S c Z N ZW

S H Y YZ

SC Contact strength (N/mm 2 )), S H AGMA safety factor

Z N Stress cycle factor for contact strength

Y Temperature factor = 1

YZ Reliability factor (table 14-10)

Z W Hardness ratio factor ((=1 for ppinion))

23

3/22/2016

Repeatedlyappliedcontactstrength,Sc

107 cyclesand0.99reliability

Hardnessratiofactor,ZW

Goodgeardesignpracticesuggests

Makingpinionteethmoreharderthangearteeth

Gearteetharesmoothenedandworkhardenedduring

service and this improves pitting resistance

serviceandthisimprovespittingresistance

Bothpinionandgeararethroughhardened

Pinionissurfacehardened

andgearisthroughhardened

24

3/22/2016

SafetyfactorsSF andSH

all

St YN

1 KH KB

; Wt K O KV K S

S F Y YZ

Fmt YJ

SF

St YN

; stress

t

( ) scales

l linearly

li

l with

ith W t

Y YZ

c , all

SH

Sc Z N ZW

K Z

; c Z E Wt K O KV K S H R

S H Y YZ

dP F ZI

Sc Z N ZW

; stress ( c ) scales with W t

c Y YZ

IfagearisdesignedsuchthatSF =SH =2,inwhich

mode(bendingfatigueorsurfacefatigue)itwillfail?

Whichfailuremodeismorecatasrophic?

Safetyfactorforpinionandgear

Thesafetyfactorsforpinionandgearneednotbethesame

(YJ )P (YJ )G ,(YN )P (YN )G ,(ZN)P (ZN)G

Whataretheimplications?

p

Oneofthemwillfailfirst(theonewithlowersafetyfactor)

Replacingoneelementinasetisnotgoodastheother

element(alreadyweaker)canfailresultinginshutdown

Matchingthefactorofsafetyofpinionandgearistherefore

desirable

S F P S F G S t G S t P

YN P YJ P S S S S Z N P

H G c G c P

Z N G

YN G YJ G H P

1

ZW

Canbeachievedby

Havingdifferenthardnessforpinionandgear

Usingdifferentmaterialsforpinionandgear

25

Você também pode gostar

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsNo EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsNota: 5 de 5 estrelas5/5 (1)

- Chapter 4-Gears and Gear TrainsDocumento93 páginasChapter 4-Gears and Gear TrainssahilrajpootasusAinda não há avaliações

- Roda Gigi Lurus (Spur Gear) : Mott, Robert L., "Machine Elements in Mechanical Design"Documento90 páginasRoda Gigi Lurus (Spur Gear) : Mott, Robert L., "Machine Elements in Mechanical Design"Sandisusanto JsAinda não há avaliações

- GearDocumento26 páginasGearRadhika GandhiAinda não há avaliações

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNo EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionAinda não há avaliações

- Gears Guide: Transmit Power & Change Speeds in 40 CharactersDocumento55 páginasGears Guide: Transmit Power & Change Speeds in 40 CharactersIshank Singh SandhuAinda não há avaliações

- Cylindrical Compression Helix Springs For Suspension SystemsNo EverandCylindrical Compression Helix Springs For Suspension SystemsAinda não há avaliações

- Gears Design MD2Documento52 páginasGears Design MD2Faizan MohyuddinAinda não há avaliações

- Bearings: A Tribology HandbookNo EverandBearings: A Tribology HandbookM. J. NealeNota: 3 de 5 estrelas3/5 (8)

- Toothed GearingDocumento80 páginasToothed GearingArjun RajuAinda não há avaliações

- Performance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisNo EverandPerformance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisAinda não há avaliações

- GearsDocumento70 páginasGearsJayesh NayakantiAinda não há avaliações

- Southern Marine Engineering Desk Reference: Second Edition Volume IiNo EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiAinda não há avaliações

- spur gearDocumento73 páginasspur gearhaymanotAinda não há avaliações

- MEC 410 Chapter 8 Spring 2017Documento68 páginasMEC 410 Chapter 8 Spring 2017Frederick KooAinda não há avaliações

- UNIT-2 Design of Spur GearDocumento56 páginasUNIT-2 Design of Spur GearMarthandeAinda não há avaliações

- Chapter 4 Design of Power Transmission ElementsDocumento43 páginasChapter 4 Design of Power Transmission ElementsMuhamad Arif100% (2)

- Gear Design FundamentalsDocumento136 páginasGear Design FundamentalsRachit100% (1)

- GearDocumento35 páginasGearNIYASAinda não há avaliações

- Gear & Gear TrainDocumento20 páginasGear & Gear Trainniaz kilamAinda não há avaliações

- Unit-3 Helical GearsDocumento38 páginasUnit-3 Helical GearsMarthande100% (1)

- GearsDocumento51 páginasGearsKasi Visweswar Rao100% (1)

- Lecture Design of Spur GearDocumento97 páginasLecture Design of Spur GearOwais Ahmad KhanAinda não há avaliações

- Name:-Yash Shah Enrollment No: - 150120119181 Branch & Class: - Mechanical (7-CG) Subject: - Machine Design (2171909) Topic: - Spur Gear and Design of Spur GearDocumento16 páginasName:-Yash Shah Enrollment No: - 150120119181 Branch & Class: - Mechanical (7-CG) Subject: - Machine Design (2171909) Topic: - Spur Gear and Design of Spur GearBossAinda não há avaliações

- Gears - General: Shigley's Mechanical Engineering DesignDocumento229 páginasGears - General: Shigley's Mechanical Engineering DesignbasitAinda não há avaliações

- Gears: Syed Shaheer Uddin Ahmed Lecturer, MPEDocumento15 páginasGears: Syed Shaheer Uddin Ahmed Lecturer, MPEimranAinda não há avaliações

- Types of Gears ExplainedDocumento50 páginasTypes of Gears ExplainedMuralikrishnan GM100% (1)

- Understanding GearsDocumento44 páginasUnderstanding Gearssamuel mechAinda não há avaliações

- Gears, Types and ItsDocumento22 páginasGears, Types and ItsBravo VermaAinda não há avaliações

- Unit-4 Bevel GearsDocumento27 páginasUnit-4 Bevel GearsMarthande0% (1)

- 7 Gears: 7.1 Gear ClassificationDocumento15 páginas7 Gears: 7.1 Gear ClassificationSimrit Kaur MakanAinda não há avaliações

- Design and Analysis of Helical GearsDocumento14 páginasDesign and Analysis of Helical GearsAjay Kumar Reddy KAinda não há avaliações

- 05 Spur Gear ProblemsDocumento51 páginas05 Spur Gear ProblemsRAMESH KUMAR AAinda não há avaliações

- GearsDocumento48 páginasGearsIshrita SaxenaAinda não há avaliações

- Toothed GearingDocumento33 páginasToothed GearingpvkkrAinda não há avaliações

- Introduction To Mechanisms: 7 GearsDocumento15 páginasIntroduction To Mechanisms: 7 GearsDezert EagleAinda não há avaliações

- Design of GearsDocumento94 páginasDesign of Gears60-Hafiz Muhammad AbdullahAinda não há avaliações

- Chapter 9 - Sections 9.1-9.5Documento26 páginasChapter 9 - Sections 9.1-9.5hanihamoud05Ainda não há avaliações

- GEARSDocumento25 páginasGEARSamitAinda não há avaliações

- Gears-General: Shigley's Mechanical Engineering DesignDocumento60 páginasGears-General: Shigley's Mechanical Engineering DesignLeandre RobinsonAinda não há avaliações

- Gearbox: Fundamental, Operation & MaintenanceDocumento80 páginasGearbox: Fundamental, Operation & MaintenanceGuru VagaAinda não há avaliações

- GEAR TRANSMISSION BASICSDocumento18 páginasGEAR TRANSMISSION BASICSKrishna Kumar AlagarAinda não há avaliações

- Gear and Gear TrainDocumento21 páginasGear and Gear Trainm_er100Ainda não há avaliações

- Gear Geometry & Profile TheoryDocumento24 páginasGear Geometry & Profile Theoryansh1983100% (2)

- Transmission System of Gear BoxDocumento86 páginasTransmission System of Gear BoxAmit Kumar Uke100% (4)

- Design of Gear Drives: Basics and Tooth ProfilesDocumento96 páginasDesign of Gear Drives: Basics and Tooth ProfilesVamshi Reddy100% (1)

- Note On Gear BoxDocumento32 páginasNote On Gear BoxanupbagAinda não há avaliações

- Gear Drive Fundamentals and MaintenanceDocumento80 páginasGear Drive Fundamentals and MaintenanceJojee MarieAinda não há avaliações

- Kinematics of GearsDocumento19 páginasKinematics of Gearsapi-3774614Ainda não há avaliações

- Gear DesignDocumento41 páginasGear DesignJagan NathanAinda não há avaliações

- Bevel GearDocumento9 páginasBevel GearAadil KhanAinda não há avaliações

- ME0403 Ch2 Gear MeasurementDocumento42 páginasME0403 Ch2 Gear MeasurementMANOJ M100% (1)

- Definition of Spur Gear - A Gearwheel With Teeth Projecting Parallel To The Wheel's Axis. Nomenclature of Spur GearDocumento6 páginasDefinition of Spur Gear - A Gearwheel With Teeth Projecting Parallel To The Wheel's Axis. Nomenclature of Spur GearMichael Angelo ComediaAinda não há avaliações

- GEAR AND GEAR TRAINDocumento23 páginasGEAR AND GEAR TRAINingridAinda não há avaliações

- Design of Machine Elements-II: Lecture By: - Engr Aakash Munsif Mechanical Engineering DepartmentDocumento37 páginasDesign of Machine Elements-II: Lecture By: - Engr Aakash Munsif Mechanical Engineering DepartmentMuhammad Mubashar FareedAinda não há avaliações

- Chapter 4 Part 1Documento37 páginasChapter 4 Part 1Izzat FakhriAinda não há avaliações

- Unit - 4Documento85 páginasUnit - 4Shriparno deyAinda não há avaliações

- Introduction To GearsDocumento28 páginasIntroduction To Gearssandeep_gaikwad2100% (4)

- Course OverviewDocumento4 páginasCourse OverviewRandhir KyAinda não há avaliações

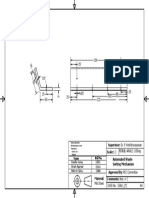

- Automated Waste Sorting Mechanism DWG SSA11_P2Documento1 páginaAutomated Waste Sorting Mechanism DWG SSA11_P2Randhir KyAinda não há avaliações

- Experiment N01 - LatheDocumento6 páginasExperiment N01 - LatheRandhir KyAinda não há avaliações

- Experiment: Grinding: Ayush Sinha Roll No.13188 Group B2G1Documento4 páginasExperiment: Grinding: Ayush Sinha Roll No.13188 Group B2G1Randhir KyAinda não há avaliações

- Manufacturing Processes (ME361) Lecture 3 and 4Documento32 páginasManufacturing Processes (ME361) Lecture 3 and 4Randhir KyAinda não há avaliações

- Cup Forming Graph PDFDocumento1 páginaCup Forming Graph PDFRandhir KyAinda não há avaliações

- Manufacturing Processes (ME361) - Lecture 5 and 6Documento31 páginasManufacturing Processes (ME361) - Lecture 5 and 6Randhir KyAinda não há avaliações

- Automated Waste Sorting Mechanism: Supervisor: Dr. P Venkitnarayanan Scale:1:12 TITLE: A.W.S.M. AssemblyDocumento1 páginaAutomated Waste Sorting Mechanism: Supervisor: Dr. P Venkitnarayanan Scale:1:12 TITLE: A.W.S.M. AssemblyRandhir KyAinda não há avaliações

- Manufacturing Science (ME361) (Lecture 17-19)Documento36 páginasManufacturing Science (ME361) (Lecture 17-19)Randhir KyAinda não há avaliações

- Experiment n03 - EdmDocumento5 páginasExperiment n03 - EdmRandhir KyAinda não há avaliações

- Deep Drawing Cup Experiment Forces StrainsDocumento5 páginasDeep Drawing Cup Experiment Forces StrainsRandhir KyAinda não há avaliações

- Experiment n06 CMMDocumento3 páginasExperiment n06 CMMRandhir KyAinda não há avaliações

- Lathe GraphDocumento2 páginasLathe GraphRandhir KyAinda não há avaliações

- Theoretical Force Vs Experimental Force (Comparision)Documento1 páginaTheoretical Force Vs Experimental Force (Comparision)Randhir KyAinda não há avaliações

- Solution To Mid-Sem ExaminationDocumento8 páginasSolution To Mid-Sem ExaminationRandhir KyAinda não há avaliações

- Theoretical Force Vs Experimental Force (Comparision) : Case NoDocumento1 páginaTheoretical Force Vs Experimental Force (Comparision) : Case NoRandhir KyAinda não há avaliações

- Design 2 Notebook First 2014 - GearTeamDocumento25 páginasDesign 2 Notebook First 2014 - GearTeamRandhir KyAinda não há avaliações

- Lathe GraphDocumento3 páginasLathe GraphRandhir KyAinda não há avaliações

- Design 2 Ch.14 FinalDocumento40 páginasDesign 2 Ch.14 FinalRandhir KyAinda não há avaliações

- Quiz Design LLDocumento2 páginasQuiz Design LLRandhir KyAinda não há avaliações

- Me 301 Chapter 10Documento28 páginasMe 301 Chapter 10Melissa RokaAinda não há avaliações

- Project Lab DesignDocumento28 páginasProject Lab DesignRandhir KyAinda não há avaliações

- CH 10 Slides M PDFDocumento45 páginasCH 10 Slides M PDFRandhir KyAinda não há avaliações

- ch01 PDFDocumento7 páginasch01 PDFssrames7282Ainda não há avaliações

- DESIGN OF SPRINGSDocumento112 páginasDESIGN OF SPRINGSchshbt80% (5)

- Machine Element Design Exercise Welded Plate and Shaft Bearing SelectionDocumento1 páginaMachine Element Design Exercise Welded Plate and Shaft Bearing SelectionRandhir KyAinda não há avaliações

- ch01 PDFDocumento7 páginasch01 PDFssrames7282Ainda não há avaliações

- Assume That The Deflection of Spring at InstallationDocumento1 páginaAssume That The Deflection of Spring at InstallationRandhir KyAinda não há avaliações

- ME351 Lab 06 Solution PDFDocumento4 páginasME351 Lab 06 Solution PDFRandhir KyAinda não há avaliações

- ME351 Lab 01 SolutionDocumento4 páginasME351 Lab 01 SolutionRandhir KyAinda não há avaliações

- CSEC® Chemistry Past Papers January 2015Documento20 páginasCSEC® Chemistry Past Papers January 2015Jonathan RamsundarAinda não há avaliações

- Performance comparison of bored and excavated pilesDocumento10 páginasPerformance comparison of bored and excavated pilesDavid Aponte RojasAinda não há avaliações

- KN Yb 1000Documento13 páginasKN Yb 1000taharAinda não há avaliações

- Tool Geometry and Tool LifeDocumento29 páginasTool Geometry and Tool LifeSudeepHandikherkarAinda não há avaliações

- Symmetric GroupDocumento13 páginasSymmetric GroupPriyanka PatelAinda não há avaliações

- Ug1085 Zynq Ultrascale TRMDocumento1.158 páginasUg1085 Zynq Ultrascale TRMLeandros TzanakisAinda não há avaliações

- Thrust Bearing CalculationsDocumento162 páginasThrust Bearing Calculationslahiru1983100% (1)

- Angle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesDocumento14 páginasAngle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesCHRISTIAN ZAVALAAinda não há avaliações

- Aqa MM1B W QP Jun07Documento8 páginasAqa MM1B W QP Jun07Annan_Faridi_517Ainda não há avaliações

- Inductance Calculations Working Formulas and Tables (Grover-1973)Documento153 páginasInductance Calculations Working Formulas and Tables (Grover-1973)Anonymous 2OxpGvaNW100% (1)

- Dell Emc Data Domain Dd3300 Faq: Frequently Asked QuestionsDocumento14 páginasDell Emc Data Domain Dd3300 Faq: Frequently Asked QuestionseriquewAinda não há avaliações

- 1) Computer Concepts NotesDocumento6 páginas1) Computer Concepts NotesVenus Leilani Villanueva-Granado100% (2)

- A510m 06Documento7 páginasA510m 06psewag100% (1)

- Dynamic Programming Algorithm Explained in ECE 551 LectureDocumento11 páginasDynamic Programming Algorithm Explained in ECE 551 Lectureadambose1990Ainda não há avaliações

- Spe 58987 Propped Fracturing in Gas Carbonate Formations MexicoDocumento12 páginasSpe 58987 Propped Fracturing in Gas Carbonate Formations MexicoJose Gregorio FariñasAinda não há avaliações

- Ray OpticsDocumento41 páginasRay OpticsHannah VsAinda não há avaliações

- Transaction MR22-Cost Component Split in A Single Cost Component.Documento4 páginasTransaction MR22-Cost Component Split in A Single Cost Component.vyigitAinda não há avaliações

- Weld-Ing On in Inservice Pipelines - tcm153574190Documento7 páginasWeld-Ing On in Inservice Pipelines - tcm153574190Freddy Rondonil SAinda não há avaliações

- Diebold ManualDocumento2 páginasDiebold Manualjoseperezlopes069Ainda não há avaliações

- Two-, Three-, and Four-Atom Exchange Effects in bcc3 HeDocumento3 páginasTwo-, Three-, and Four-Atom Exchange Effects in bcc3 HezittoxAinda não há avaliações

- Power Generation Engine Performance DataDocumento4 páginasPower Generation Engine Performance Dataacere18100% (1)

- Lecture - 12 - Project EvaluationDocumento68 páginasLecture - 12 - Project EvaluationEngr. Md. Ashraful AlamAinda não há avaliações

- Quad Encoder Velocity Accel with CRIOLabVIEW FPGADocumento5 páginasQuad Encoder Velocity Accel with CRIOLabVIEW FPGAChâu Tinh TrìAinda não há avaliações

- CS5371 Theory of Computation: Lecture 1: Mathematics Review I (Basic Terminology)Documento23 páginasCS5371 Theory of Computation: Lecture 1: Mathematics Review I (Basic Terminology)Kamal WaliaAinda não há avaliações

- WPMD 3002Documento6 páginasWPMD 3002Adilson LucaAinda não há avaliações

- NCERT Solutions For Class 8 Maths Chapter 14 - FactorizationDocumento25 páginasNCERT Solutions For Class 8 Maths Chapter 14 - FactorizationSATAMANYU BHOLAinda não há avaliações

- Chapter 5 Refraction Through A Lens - Concise Physics Part II - Selina Solutions For Class 10 Physics ICSE - TopperLearningDocumento71 páginasChapter 5 Refraction Through A Lens - Concise Physics Part II - Selina Solutions For Class 10 Physics ICSE - TopperLearningHarsh AhirwarAinda não há avaliações

- JqueryDocumento11 páginasJqueryShreyas GuduriAinda não há avaliações

- Laminar Flow Reactor ProblemDocumento6 páginasLaminar Flow Reactor ProblemAileen Banua Añonuevo100% (1)

- John Deere 772d 6wd GraderDocumento6 páginasJohn Deere 772d 6wd GraderyaserattiaAinda não há avaliações