Escolar Documentos

Profissional Documentos

Cultura Documentos

Check For Punching Shear:: Pile Cap Design (PC3a)

Enviado por

Sheikh Mizanur RahmanTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Check For Punching Shear:: Pile Cap Design (PC3a)

Enviado por

Sheikh Mizanur RahmanDireitos autorais:

Formatos disponíveis

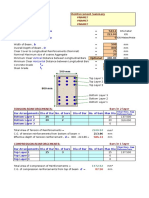

No.

of pile in the group, N =

Pile capacity =

Cap thickness, t =

Pile Cap Design

3

660 kN

0.9 m

Area of cap, A =

Weight of cap, W =

Applied working load =

Applied factored load, P =

Pile reaction, R =

3.81595

82.4

1897.6

2846.4

948.8

Check for punching shear:

Size of pedestal =

Dia. of reinforcing bar =

Concrete strength, f'c =

Effective thickness, d =

Punching perimeter, b0 =

( PC3a )

m2

kN

kN

kN

kN

500 mm Square

25 mm

3625 psi

0.6875 m

25 MPa

4.75 m

y=

0.59375 m

Punching shear, Vp =

2490.568 kN

Punching shear stress, vp =

897.2 kN/m2

Ultimate punching shear =

1660.9 kN/m2

> vp =

897.2 kN/m2

O.K.

Check for one-way shear:

x=

0.3285 m

Sec. width =

1.17 m

Shear, V =

338.7 kN

Shear stress , v =

497.4 kN/m2

Ultimate shear strength =

830.5 kN/m2

> v=

497.4 kN/m2

O.K.

Flexure Design:

b=

Steel strength, fy =

0.800 m

415 MPa

Bending moment, M1 =

821.7 kN.m

b1 =

0.85

rmax =

0.023

dreq =

0.059 m < d =

0.6875 m

O.K.

a=

100.45 mm(Assumed)

Steel area required, As =

3452.1 mm2

a=

84.27 mm

NOT O.K.

Minimum steel ratio, rmin =

0.003324

As,min =

1828 mm2

As,Design =

3452 mm2

No. of bars required =

Bending moment, M2 =

7.0

25 mm f

711.6 kN.m

a=

92.1 mm(Assumed)

Steel area required, As =

2970.1 mm2

a=

77.34 mm

NOT O.K.

As,min =

1714 mm2

As,Design =

Steel ratio =

2970 mm2

0.00540

No. of bars required =

6.1

25 mm f

Você também pode gostar

- Pile CapacityDocumento6 páginasPile Capacitymailmaverick8167Ainda não há avaliações

- Pile Cap Design - ColumnsDocumento6 páginasPile Cap Design - ColumnsSadatcharaMoorthi N100% (1)

- Pilecap DesignDocumento2 páginasPilecap DesignAYEDAinda não há avaliações

- Lateral Pressure CoefficientDocumento1 páginaLateral Pressure CoefficientRoda CadizAinda não há avaliações

- Sheet Pile Analysis Sheet v1.07Documento1 páginaSheet Pile Analysis Sheet v1.07SES DESIGNAinda não há avaliações

- NEH654 CH14 Gabion Wall Stability Vs031606Documento7 páginasNEH654 CH14 Gabion Wall Stability Vs031606DanangAinda não há avaliações

- 3.3.1 Retaining WallDocumento31 páginas3.3.1 Retaining WallNeil SonAinda não há avaliações

- Bearing Capacity - Sand Overlying ClayDocumento1 páginaBearing Capacity - Sand Overlying ClayMehdi.Most100% (1)

- Design of Base Raft: Title Conveyor Tunnel 1Bc-3Documento6 páginasDesign of Base Raft: Title Conveyor Tunnel 1Bc-3Uttam Kumar GhoshAinda não há avaliações

- C922 (G1) - PTP.2 Reaction Pile and Pile Cap Design CalculationDocumento3 páginasC922 (G1) - PTP.2 Reaction Pile and Pile Cap Design CalculationAnonymous S7Cq7ZDgPAinda não há avaliações

- Gabion Wall Typical Design Sheet Front 19 8 2008Documento8 páginasGabion Wall Typical Design Sheet Front 19 8 2008mail_spsah_410639725Ainda não há avaliações

- Pile DesignDocumento1 páginaPile DesignAbdul Hayyi bin AwangAinda não há avaliações

- Calculation of Static Factor of Safety by Method of SlicesDocumento9 páginasCalculation of Static Factor of Safety by Method of SlicesTanmoy DasAinda não há avaliações

- Pile DesignDocumento12 páginasPile DesignRaxKitAinda não há avaliações

- AASHTO GeoTechnical Design of PileDocumento6 páginasAASHTO GeoTechnical Design of PileKashif MuhammadAinda não há avaliações

- Differential Settlement Bh7Documento9 páginasDifferential Settlement Bh7Zhi Ming CheahAinda não há avaliações

- Material Name SPT (N) Unit Weight Young Modulus Poisson Ratio Cohesion Friction Angle Ysat Ysat Eref (kN/m2) V CrefDocumento2 páginasMaterial Name SPT (N) Unit Weight Young Modulus Poisson Ratio Cohesion Friction Angle Ysat Ysat Eref (kN/m2) V CrefnurAinda não há avaliações

- Calculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLDocumento3 páginasCalculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLbhaskardharani50% (2)

- Pile Capacity Calculation (12!12!2011)Documento36 páginasPile Capacity Calculation (12!12!2011)nsureshbabu100% (1)

- Wingwall Soil LoadsDocumento4 páginasWingwall Soil LoadsSharyn PolleyAinda não há avaliações

- Rock Bolt Capacity CalculationDocumento2 páginasRock Bolt Capacity CalculationROHIT PADHARIA100% (1)

- Pre Cast Pile CapacityDocumento19 páginasPre Cast Pile Capacityyogs_184Ainda não há avaliações

- Proposed Two-Storey Residence: Mr. & Mrs Dominid & Cheryll Ann Trinidad Bgy Holy Spirit Quezon CityDocumento1 páginaProposed Two-Storey Residence: Mr. & Mrs Dominid & Cheryll Ann Trinidad Bgy Holy Spirit Quezon CityjologscresenciaAinda não há avaliações

- Pile Conditions: Input Quantities Value Units CommentDocumento18 páginasPile Conditions: Input Quantities Value Units CommentFidel Rodriguez HerrerosAinda não há avaliações

- Basic Design of Counterfort SpreadsheetDocumento6 páginasBasic Design of Counterfort SpreadsheetByron OcampoAinda não há avaliações

- GEO TALK Ground AnchorDocumento50 páginasGEO TALK Ground AnchorWidodo WidodoAinda não há avaliações

- Bored Pile - FS 2.0 PDFDocumento2 páginasBored Pile - FS 2.0 PDFDương TrầnAinda não há avaliações

- Fe Sheet Pile WallDocumento22 páginasFe Sheet Pile WallBogie Prastowo MahardhikaAinda não há avaliações

- Ass 4 Cofferdam Solution 12 13 PTDocumento1 páginaAss 4 Cofferdam Solution 12 13 PTsyakirohAinda não há avaliações

- James Point Port - BH11Documento20 páginasJames Point Port - BH11Jennifer HudsonAinda não há avaliações

- Example of Sheet Pile CalculationDocumento6 páginasExample of Sheet Pile CalculationAtikah Ahmad KhanAinda não há avaliações

- Geotechnics DataDocumento31 páginasGeotechnics DataDid DdeAinda não há avaliações

- 518 PileCapacity PDFDocumento7 páginas518 PileCapacity PDFمرتضى التميميAinda não há avaliações

- Tritech: Tritech Consultants Pte LTDDocumento2 páginasTritech: Tritech Consultants Pte LTDsuman_civilAinda não há avaliações

- Pile Capacity Calculation With Bore-Logs Method (Meyerhof Equation)Documento82 páginasPile Capacity Calculation With Bore-Logs Method (Meyerhof Equation)mathuAinda não há avaliações

- Calculation SettlementDocumento51 páginasCalculation SettlementEngDbtAinda não há avaliações

- Bored Pile - Estimated Pile Length & Capacity: RB6191-DASHDocumento6 páginasBored Pile - Estimated Pile Length & Capacity: RB6191-DASHHoihogo HoiAinda não há avaliações

- Strength Behavior of Cement Treated Dredged SoilDocumento20 páginasStrength Behavior of Cement Treated Dredged SoilTarhata KalimAinda não há avaliações

- Raft Footing DesignDocumento7 páginasRaft Footing DesignPrakash ShresthaAinda não há avaliações

- Pile Calculation Sand+RockDocumento32 páginasPile Calculation Sand+RockSheril ChandraboseAinda não há avaliações

- Experimental Observations and Parametric Study of Piled Raft Foundation Using PlaxisDocumento7 páginasExperimental Observations and Parametric Study of Piled Raft Foundation Using PlaxisAngelinSavioAinda não há avaliações

- Subgrade Modulus Calculation From SPT ValueDocumento1 páginaSubgrade Modulus Calculation From SPT ValueKTMOAinda não há avaliações

- Retaining Wall Counterfort PDFDocumento48 páginasRetaining Wall Counterfort PDFSilver Olguín CamachoAinda não há avaliações

- Squre Footing Design (WSD)Documento3 páginasSqure Footing Design (WSD)api-19753598Ainda não há avaliações

- Retaining WallDocumento6 páginasRetaining Wallantwnhs antwnns100% (1)

- Uplift Capacity Shall Be Taken As 0.7 Times The Shaft Resistance, With A Factor of Safety of 2.5Documento3 páginasUplift Capacity Shall Be Taken As 0.7 Times The Shaft Resistance, With A Factor of Safety of 2.5Ajay KumarAinda não há avaliações

- Pile Foundation Concrete Column DesignDocumento27 páginasPile Foundation Concrete Column DesignSaid FauzieAinda não há avaliações

- Check For Punching Shear:: Pile Cap Design (PC3a)Documento6 páginasCheck For Punching Shear:: Pile Cap Design (PC3a)Sheikh Mizanur RahmanAinda não há avaliações

- Kda - Factory Ii (Gen - Trias, Cavite) Design of MicropilesDocumento4 páginasKda - Factory Ii (Gen - Trias, Cavite) Design of MicropilesRoda Cadiz100% (4)

- Isolated Footing Design ProblemDocumento5 páginasIsolated Footing Design ProblemthabisAinda não há avaliações

- Pile Cap Design 1Documento19 páginasPile Cap Design 1katheranAinda não há avaliações

- Design of Counterfort Retaining WallDocumento14 páginasDesign of Counterfort Retaining WallMonjit Gogoi100% (5)

- Planning Analysis and Design of Shopping MallDocumento46 páginasPlanning Analysis and Design of Shopping MallSanjeev Kumar60% (15)

- Cve 323 Week 11 (Foundation Design)Documento13 páginasCve 323 Week 11 (Foundation Design)Nosa EhiaguinaAinda não há avaliações

- RCC Retaining WallSDocumento25 páginasRCC Retaining WallSAnde BhanuAinda não há avaliações

- Aci BeamDocumento6 páginasAci BeamkumsbamaAinda não há avaliações

- Flat Slab Design by FemDocumento7 páginasFlat Slab Design by FemBathrudeen IshakAinda não há avaliações

- Combined FootingDocumento2 páginasCombined Footingsantosh-a-biraj-3307Ainda não há avaliações

- SpreadsheetDocumento7 páginasSpreadsheetChan Kin CheungAinda não há avaliações

- 2 PC CirDocumento4 páginas2 PC CirSheikh Mizanur RahmanAinda não há avaliações

- Pile Cap of Footing F1Documento4 páginasPile Cap of Footing F1Sheikh Mizanur RahmanAinda não há avaliações

- Check For Punching Shear:: Pile Cap Design (PC3a)Documento6 páginasCheck For Punching Shear:: Pile Cap Design (PC3a)Sheikh Mizanur RahmanAinda não há avaliações

- Septic Tank Design Program RAS2021 Updated 10.8.2009Documento12 páginasSeptic Tank Design Program RAS2021 Updated 10.8.2009Sheikh Mizanur RahmanAinda não há avaliações

- Arch 220 - Steel Frame ConstructionDocumento9 páginasArch 220 - Steel Frame ConstructionSheikh Mizanur RahmanAinda não há avaliações

- Civl432 Bridge Design SummaryDocumento5 páginasCivl432 Bridge Design SummarySheikh Mizanur RahmanAinda não há avaliações

- How To Adjust A NotchDocumento4 páginasHow To Adjust A NotchSheikh Mizanur RahmanAinda não há avaliações

- Custom Elements Basics PDFDocumento5 páginasCustom Elements Basics PDFSheikh Mizanur RahmanAinda não há avaliações

- Main Axis of Contour PlateDocumento2 páginasMain Axis of Contour PlateSheikh Mizanur RahmanAinda não há avaliações

- Structural Mechanics of Buried PipesDocumento11 páginasStructural Mechanics of Buried PipesSheikh Mizanur RahmanAinda não há avaliações