Escolar Documentos

Profissional Documentos

Cultura Documentos

EPDM Formulation Technical Rubber

Enviado por

anant_z12Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

EPDM Formulation Technical Rubber

Enviado por

anant_z12Direitos autorais:

Formatos disponíveis

TECHNICAL INFORMATION | RUBBER

CLAYS IN

TECHNICAL RUBBER

Clays find use in a variety of applications, either because of specific technical properties and/or because of their

very favourable cost/performance ratio.

Fine clays have semi-reinforcing properties and may be used as

either the primary filler in rubber or in order to partially replace

or extend more highly reinforcing carbon blacks. Less fine (filler)

clays confer lower levels of reinforcement and may be more

readily used at higher volume loadings. In addition, the processing

properties of filler clays are often more advantageous, since they

are easier to disperse efficiently. If light coloured articles are to

be produced, then china clays such as Speswhite & Polwhite

E or PoleStar 200R calcined clay can be used in brightly

coloured compounds.

WASHING MACHINE SEAL

Formulation

phr

Vistalon 3666

175

Zinc oxide

Stearic acid

Titanium dioxide

20

Speswhite clay

100

Polyvest 25

Sunpar 2280

25

Struktol WB212

TMTD

0,8

Tetrone A

0,8

ZBDC

2,0

Sulphur

2,0

Properties

Tensile Strength

Modulus at 300%

10,7 MPa

All clay fillers share some common features because of the platelike shape of their particles, which results in some stiffening of

the rubber compound. This gives much better extrusion and

calendering properties (exhibiting low die swell and good

dimensional stability) than can be obtained from most other

mineral fillers.

FLOORING COMPOUND

Formulation

phr

Vistalon 4608

60

Vistalon 2504

40

Zinc oxide

Stearic acid

Paraffin wax

Polwhite E clay

Sunpar 150

200

30

Sulphur

1,5

ZDC

0,5

TMTD

0,5

MBT

1,5

Properties

Tensile Strength

5,8 MPa

Modulus at 300%

3,7 MPa

Elongation at break

440%

Hardness

73 IRHD

Compression set at 70C

79,3%

2,8 MPa

Elongation at break

800%

Tear Strength

20 N/mm

Hardness

45 Shore A

Compression set at 70C

24,2%

Compression set at 100C

31,3%

In injection mouldings platey china clays or talcs can cause

anistropy while synthetic silicas or aluminium silicates give a high

viscosity causing difficulties in mold filling. Calcined clay gives,

as a consequence of its shape and size, little anistropy and low

viscosity. Properties are also very good (but may be boosted by

small amounts of synthetic silica) and a typical EPDM injection

moulding for a spark plug cap is given overleaf.

TECHNICAL INFORMATION | RUBBER

SPARK PLUG CAP

phr

Vistalon 7606

100

Polyethylene Wax

PoleStar 200R

120

Precipitated Silica

30

Plasticiser

30

Polyethylene glycol

ZMTI

Sulphur

0.2

Peroxide (40% on carrier)

Curing characteristics

Minimum torque (lb/in)

9.7

Maximum torque (lb/in)

73.4

T2 (min)

1.0

T90 (min)

7.7

Mechanical Properties

Tensile Strength (Mpa)

10.1

Elongation at Break (%)

43.0

Modulus at 100%

PFME/R205 - Fourth Edition - 10/08 | World Minerals is a Member of Imerys

Hardness (Share A)

3.0

64

The information contained herein was obtained as a result of work carried out on materials thought to be representative and accordingly is believed to

be correct. Such information shall not, however constitute any representation, condition or warranty as to any fact contained herein, and accordingly

IMERYS Minerals Ltd hereby disclaims all and any liability arising from the use of such information howsoever caused.

IMERYS PERFORMANCE & FILTRATION MINERALS

Par Moor Centre, Par Moor Road, Par, Cornwall, UK PL24 2SQ

t: +44 (0)1726 818000 f: +44 (0)1726 811200

e: perfmins@imerys.com

www.imerys-perfmins.com

154 rue de lUniversit, 75007 Paris - France

t: +33 1 49 55 66 37 f: +33 1 49 55 66 57

e: info.europe@worldminerals.com

www.worldminerals.com

Você também pode gostar

- Essential Rubber Formulary: Formulas for PractitionersNo EverandEssential Rubber Formulary: Formulas for PractitionersNota: 3 de 5 estrelas3/5 (1)

- STP0260 - Processing of Tire Treads - 2007 AtlantaDocumento25 páginasSTP0260 - Processing of Tire Treads - 2007 AtlantaVarun SharmaAinda não há avaliações

- Fundamentals of Compounding Epdm For Cost - PerformanceDocumento14 páginasFundamentals of Compounding Epdm For Cost - PerformanceJicheng PiaoAinda não há avaliações

- Rubber Metal Adhesion PDFDocumento6 páginasRubber Metal Adhesion PDFRubber TeamAinda não há avaliações

- Viton Processing GuideDocumento24 páginasViton Processing GuideAkash KumarAinda não há avaliações

- AcceleratorsDocumento25 páginasAcceleratorsDaniel MartinsAinda não há avaliações

- Injection Molding of RubberDocumento39 páginasInjection Molding of RubberadhityaAinda não há avaliações

- 029 Butyl Rubber CompoundsDocumento6 páginas029 Butyl Rubber Compoundsrossifam777Ainda não há avaliações

- Chemistry and Technology of Rubber PDFDocumento215 páginasChemistry and Technology of Rubber PDFCharlie CB Portner100% (1)

- Rubber Mixing SimulationDocumento147 páginasRubber Mixing Simulationalperen52100% (2)

- Rubber Compounding PDFDocumento28 páginasRubber Compounding PDFbodekiz71% (7)

- Overview of Primary Accelerators in RubberDocumento7 páginasOverview of Primary Accelerators in RubberSuchismita Sahoo100% (1)

- Rubber Compounds: Elastomers IntroductionDocumento7 páginasRubber Compounds: Elastomers Introductionanvesha raoAinda não há avaliações

- Rubber Technology by Maurice Morton 0442264224Documento5 páginasRubber Technology by Maurice Morton 0442264224Vikash singh100% (1)

- Compounding Guide StruktolDocumento154 páginasCompounding Guide Struktoldusik007100% (6)

- Handbook of Rubber BondingDocumento400 páginasHandbook of Rubber Bondingdusik007100% (1)

- Rubber FormulationsDocumento17 páginasRubber FormulationsAkash Kumar83% (6)

- Akron Acs RubberDocumento41 páginasAkron Acs RubberAmadeus HuangAinda não há avaliações

- Rubber TechnologyDocumento28 páginasRubber Technologyluis martinez100% (1)

- The Basic Rubber CompoundDocumento19 páginasThe Basic Rubber CompoundPIRZADA TALHA ISMAIL100% (1)

- Article - CURE MEASUREMENT AS QUALITY TOOL - RUBBER COMPOUNDING BASICS PDFDocumento7 páginasArticle - CURE MEASUREMENT AS QUALITY TOOL - RUBBER COMPOUNDING BASICS PDFChanin NgudsuntearAinda não há avaliações

- November 2013 - Blooming in RubberDocumento5 páginasNovember 2013 - Blooming in Rubberalperen52Ainda não há avaliações

- 3MDyneon FKM Compounding Guide 98050413248RevCDocumento28 páginas3MDyneon FKM Compounding Guide 98050413248RevCDyaniAinda não há avaliações

- The Reactive Extrusion of Thermoplastic PolyurethaneDocumento158 páginasThe Reactive Extrusion of Thermoplastic PolyurethanePieter HanssenAinda não há avaliações

- Blends of Natural RubberDocumento292 páginasBlends of Natural Rubberanbuchelvan100% (3)

- 32 Battling The Effects of Reversion in Natural Rubber Compounds Ken Bates STRUKTOLDocumento20 páginas32 Battling The Effects of Reversion in Natural Rubber Compounds Ken Bates STRUKTOLfrancisco ñancoAinda não há avaliações

- RubberDocumento4 páginasRubberSunu Panji UtamaAinda não há avaliações

- Introduction To Rubber TechnologyDocumento3 páginasIntroduction To Rubber Technologymasimsaleem0% (1)

- Rubber BasicsDocumento213 páginasRubber Basicsprashantmauka67% (6)

- Rubber RollerDocumento3 páginasRubber RollerOfflinebatch PrintingAinda não há avaliações

- Polymer DesignDocumento16 páginasPolymer DesigndalilahatiyahibrahimAinda não há avaliações

- Rubber Compounds TableDocumento2 páginasRubber Compounds TablestrganeshkumarAinda não há avaliações

- Rubber 1571Documento20 páginasRubber 1571Paradiso SitorusAinda não há avaliações

- Rubber Compounds MOS Sept 2011Documento92 páginasRubber Compounds MOS Sept 2011Ws Lim80% (5)

- Blooming Bob FrancisDocumento58 páginasBlooming Bob FrancisThiyagarajan RajagopalAinda não há avaliações

- Compounding Guide Struktol PDFDocumento154 páginasCompounding Guide Struktol PDFFrancesca NettoAinda não há avaliações

- The Complete Book On Rubber Processing and Compounding TechnologyDocumento10 páginasThe Complete Book On Rubber Processing and Compounding TechnologyRuby_Warren_UTsB50% (2)

- Rubber IngredientsDocumento7 páginasRubber IngredientsBhushan VermaAinda não há avaliações

- How Does Temperature Affect A Rubber Band's Elasticity?: 2005 Project SummaryDocumento1 páginaHow Does Temperature Affect A Rubber Band's Elasticity?: 2005 Project SummaryrochelleAinda não há avaliações

- Vulcanization and AcceleratorsDocumento35 páginasVulcanization and AcceleratorsJatin Darve100% (1)

- Natural Rubber-Basics PDFDocumento116 páginasNatural Rubber-Basics PDFTeohYeeThuanAinda não há avaliações

- A Guide To Grades, Compounding and Processing of Neoprene Rubber (Bament Guide)Documento48 páginasA Guide To Grades, Compounding and Processing of Neoprene Rubber (Bament Guide)Neeraj BhallaAinda não há avaliações

- Epdm IirDocumento7 páginasEpdm IirQuangHưngPAinda não há avaliações

- Practical Guide To HNBR Chapter 2Documento8 páginasPractical Guide To HNBR Chapter 2Azizol WahabAinda não há avaliações

- The Complete Book On Rubber Processing and Compounding TechnologyDocumento10 páginasThe Complete Book On Rubber Processing and Compounding TechnologyBilal Ahmad Chishti100% (2)

- Rubber Compounds TableDocumento2 páginasRubber Compounds TableSrikanth Pothapragada100% (2)

- Bber Compounding Technology-FinalDocumento61 páginasBber Compounding Technology-Finalbodekiz90% (59)

- Rubber Products Industry StandardDocumento135 páginasRubber Products Industry Standardronald rodrigo100% (1)

- Rubber FillersDocumento28 páginasRubber FillersD.W.W.SewwandiAinda não há avaliações

- Methyl Methacrylate Grafted Rubber (MG Rubber)Documento15 páginasMethyl Methacrylate Grafted Rubber (MG Rubber)syahidah5342Ainda não há avaliações

- ELASTOMERSDocumento9 páginasELASTOMERSAmbar ShahAinda não há avaliações

- 17rubbercompoundingpptkiran 150318135628 Conversion Gate01Documento16 páginas17rubbercompoundingpptkiran 150318135628 Conversion Gate01Madan Saini100% (1)

- Additives For RubberDocumento30 páginasAdditives For RubberAkash Kumar100% (2)

- Rubber Technology-Manuel Morato Gomes PDFDocumento110 páginasRubber Technology-Manuel Morato Gomes PDFTamalika DasAinda não há avaliações

- Cure Reactivity - A Route To Improved Performance in Halobutyl Applications TIDocumento46 páginasCure Reactivity - A Route To Improved Performance in Halobutyl Applications TIGrzegorz WierzbaAinda não há avaliações

- Extrusion GuideDocumento8 páginasExtrusion GuideWu Li Lung100% (1)

- Bromo ManualDocumento48 páginasBromo Manualit4728Ainda não há avaliações

- Aac Block Plant 100m3 DayDocumento32 páginasAac Block Plant 100m3 DaysantocreatoraAinda não há avaliações

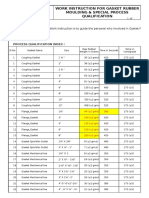

- Work Instruction For Gasket Rubber Moulding & Special Process QualificationDocumento4 páginasWork Instruction For Gasket Rubber Moulding & Special Process Qualificationanant_z12Ainda não há avaliações

- TPE BlendingDocumento4 páginasTPE Blendinganant_z12Ainda não há avaliações

- Alternatives To Toluene & XyleneDocumento2 páginasAlternatives To Toluene & Xyleneanant_z12Ainda não há avaliações

- Understanding BLOOM (Revised) PDFDocumento24 páginasUnderstanding BLOOM (Revised) PDFEr Roxstar ParitoshAinda não há avaliações

- Arcoline 60Documento2 páginasArcoline 60anantAinda não há avaliações

- TechniqueDocumento1 páginaTechniqueanant_z12Ainda não há avaliações

- Synthetic PrimerDocumento3 páginasSynthetic Primeranant_z12Ainda não há avaliações

- Gordon Low Products LTD.: Sheet SpecificationDocumento1 páginaGordon Low Products LTD.: Sheet Specificationanant_z12Ainda não há avaliações

- Bank Exam Clerks Previous PapersDocumento11 páginasBank Exam Clerks Previous PapersAllExamPapersAinda não há avaliações

- Chapter 7: Protein Function Part I: Myoglobin and HemoglobinDocumento27 páginasChapter 7: Protein Function Part I: Myoglobin and HemoglobineliAinda não há avaliações

- Resume: Satyam KumarDocumento3 páginasResume: Satyam KumarEr Satyam Kumar KrantiAinda não há avaliações

- TheBasicsofBrainWaves - RS PDFDocumento4 páginasTheBasicsofBrainWaves - RS PDFOnutu Adriana-LilianaAinda não há avaliações

- The Indian & The SnakeDocumento3 páginasThe Indian & The SnakeashvinAinda não há avaliações

- Goa Daman & Diu Factory Rules PDFDocumento141 páginasGoa Daman & Diu Factory Rules PDFmrudang1972100% (1)

- Contoh CV / Daftar Riwayat HidupDocumento2 páginasContoh CV / Daftar Riwayat HiduprusmansyahAinda não há avaliações

- Flow Zone Indicator Guided Workflows For PetrelDocumento11 páginasFlow Zone Indicator Guided Workflows For PetrelAiwarikiaar100% (1)

- Tabla9 1Documento1 páginaTabla9 1everquinAinda não há avaliações

- ELS 06 Maret 223Documento16 páginasELS 06 Maret 223Tri WinarsoAinda não há avaliações

- 1.1.3.12 Lab - Diagram A Real-World ProcessDocumento3 páginas1.1.3.12 Lab - Diagram A Real-World ProcessHalima AqraaAinda não há avaliações

- The Working of KarmaDocumento74 páginasThe Working of KarmaSuhas KulhalliAinda não há avaliações

- Ujian 1 THN 4Documento13 páginasUjian 1 THN 4Che Shuk ShukaAinda não há avaliações

- Pellicon 2 Validation Guide PDFDocumento45 páginasPellicon 2 Validation Guide PDFtakwahs12135Ainda não há avaliações

- Minimalist KWL Graphic OrganizerDocumento2 páginasMinimalist KWL Graphic OrganizerIrish Nicole AlanoAinda não há avaliações

- Etoricoxib - Martindale 39thDocumento2 páginasEtoricoxib - Martindale 39thCachimbo PrintAinda não há avaliações

- FebvreDocumento449 páginasFebvreIan Pereira AlvesAinda não há avaliações

- Las Tech Drafting 3Q WKDocumento13 páginasLas Tech Drafting 3Q WKClemenda TuscanoAinda não há avaliações

- SAT Practice Test 10 - College BoardDocumento34 páginasSAT Practice Test 10 - College BoardAdissaya BEAM S.Ainda não há avaliações

- Exercise On Word Formation 2 (Unit 2 - Advanced) : Tran Dai Nghia High School For The GiftedDocumento3 páginasExercise On Word Formation 2 (Unit 2 - Advanced) : Tran Dai Nghia High School For The GiftedEveryonehateshiuzo 2.0Ainda não há avaliações

- Management of DredgedExcavated SedimentDocumento17 páginasManagement of DredgedExcavated SedimentMan Ho LamAinda não há avaliações

- Anderson, Poul - Flandry 02 - A Circus of HellsDocumento110 páginasAnderson, Poul - Flandry 02 - A Circus of Hellsgosai83Ainda não há avaliações

- BITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball TesterDocumento10 páginasBITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball Testerakash chAinda não há avaliações

- Psle Science Keywords !Documento12 páginasPsle Science Keywords !Aftertea CarousellAinda não há avaliações

- 988611457NK448908 Vehicle Scan ReportDocumento5 páginas988611457NK448908 Vehicle Scan ReportVictor Daniel Piñeros ZubietaAinda não há avaliações

- Comparative Study On Serial and Parallel Manipulators - ReviewDocumento23 páginasComparative Study On Serial and Parallel Manipulators - ReviewShaik Himam SahebAinda não há avaliações

- Case 445Documento4 páginasCase 445ForomaquinasAinda não há avaliações

- Manuscript FsDocumento76 páginasManuscript FsRalph HumpaAinda não há avaliações

- YoungMan EN131 GUIDEDocumento16 páginasYoungMan EN131 GUIDErcpawar100% (1)

- Theoretical CyclesDocumento49 páginasTheoretical CyclesMariaEzzaSyUyAinda não há avaliações

- ECE199R-C12 Final Document OJTDocumento48 páginasECE199R-C12 Final Document OJTRigel ZabateAinda não há avaliações