Escolar Documentos

Profissional Documentos

Cultura Documentos

CFW Brochure

Enviado por

Mauricio MpintoTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CFW Brochure

Enviado por

Mauricio MpintoDireitos autorais:

Formatos disponíveis

CFW

Member

CLEAN

FLIGHT

WING

PULLEY

Clean FlightTM Wing Pulley (CFW)

Martin's Clean Flight Wing Pulley (CFW).

Martin services a wide range of industries

conveying light to extreme bulk materials

The Martin pulley product line features drum

pulleys, wing pulleys, shafting and take-up

frames

Available to ship in assemblies

Extensive inventory of pulleys in over 30 North

American locations

Martin is a predominant manufacturer of

Industrial Grade Conveyor Pulleys

2 CFW Pulley

Structural Advantages

Martin Clean Flight Wing Pulley distinct

construction advantages:

Each flight lies perpendicular to the pulley

core, resulting in a much stronger design

The CFW is constructed with distinctly

aggressive materials with thick flights

Continuous welds available upon request

An open herringbone flight placement

allows for better material rejection

s Weld

nuou

Conti

CFW Pulley

Operational Advantages

NOISE REDUCTION

Users report a reduction in operating decibels from 1422%, depending on belt speed and belt width

LESS VIBRATION IN OPERATION

Since the belt is in constant contact with the Clean

Flight Wing outside diameter (OD), the beltslapping observed in traditional wing pulley operation

is eliminated, as is the operational ambient noise.

Decreased vibration also means less stress on the belt,

splice, and bearings.

ENHANCED BELT TRACKING

Each CFW flight contacts the belt at a helix angle that

contributes to the tracking of the belt. The CFW flight

operates much like a traditional "spiral" wing pulley in

assisting belt tracking. The Martin CFW is also offered in

a crown-face profile.

OPTIMIZED BELT CLEANING

As well as reducing vibration noise and improving belt

tracking, the CFW also cleans the belt more effectively

while in operation by shedding materials away from the

belt surface. Additionally, the CFW operates with less

vibration at the skirt board zones, reducing fines at the

loading zone.

IMPROVED MATERIAL REJECTION

Traditional wing pulley flights contact the conveyed

material at a right angle, whereas the CFW actually

plows material out of harm's way, toward the end of the

pulley, where it safely falls away from the pulley and belt

contact surface.

4 CFW Pulley

Typical Construction Specs

All Clean FlightTM Wing Pulleys (CFW)

use the longest pitch possible for each diameter and face width

Standard Duty

1/2" Flight, 1/4" Rim, 3/8" End-Discs

Mine Duty

3/4" Flight, 3/8" Rim, 1" End-Discs

Quarry Duty

1" Flight, 1/2" Rim, 1-1/4" End-Discs

CFW Pulley

Nomenclature & Special Options

Nomenclature

Examples

T-Bottom, Turbo Disc

and Engineered Mine Duty

Flat &

Crown

Standard (S)

Mine (M)

Quarry (Q)

Engineered (E)

Clean Flight

Wing (CF)

Diameter

(3 digits)

Face Width

(2 digits)

16.0" x 32"

24.0" x 44"

30.0" x 63"

Bushing

XT30 = X30

XT45 = X45

XT60 = X60

Special Features

Assembly Options

Bearing Assemblies

Take Up Frame

Assemblies

Keyless Lockers for

Shaft Connection

6 CFW Pulley

Bushing Options

M-XT

M-HE

QD

Taper Bushed

Keyless Locking Device

Pulley Options

Hard Facing

Custom Epoxy Paint

Special Flight Spacing

Special Pitch

Continuous Welding

of Flights

Information Required for Quoting

FACE WIDTH

FLIGHT THICKNESS

FINISHED

CORE

Basic Pulley Data

Finished Diameter:___________ Face Width:_______________ Bushing Bore:____________________

Conveyed Material Lump Size: _______________ Location on Conveyor:_______________________

Application:______________________________________________________________________________

Notes:____________________________________________________________________________________

__________________________________________________________________________________________

Additional Data & Options:

Duty:___________________ Flight Thickness:________________ Core Diameter:___________________

Pulley Material:______________________

Shaft Diameter:______________ OAL:______________

Notes:____________________________________________________________________________________

Horsepower:__________________ Belt Speed:___________________ Belt Wrap:____________________

Conveyor Take-Up Style (Mechanical or Gravity/Automatic):_______________________________

Bearing Diameter:_________________ Bearing Centers:_________________

Belt Width:_________________________ Belt PIW:__________________________

CFW Pulley

There's a

Martin Near You

Martin has over 30 locations in North America.

For more information contact a branch near you:

USA

Corporate Offices Sales & Manufacturing

MEXICO

Branch Manufacturing Plants

BOSTON, MA

508-634-3990 (FAX508-634-3998)

LOS ANGELES, CA

323-728-8117 (FAX323-722-7526)

CHARLOTTE, NC

704-394-9111 (FAX704-394-9122)

MINNEAPOLIS, MN

952-829-0623 (FAX 952-944-9385)

ALBEMARLE, NC

704-982-9555 (FAX 704-982-9599)

CHICAGO, IL

847-298-8844 (FAX 847-298-2967)

NASHVILLE, TN

615-871-4730 (FAX 615-871-4125)

ATLANTA, GA

404-292-8744 (FAX404-292-7771)

DENVER, CO

303-371-8466 (FAX 303-371-7116)

PITTSBURGH, PA

724-452-4555 (FAX 724-452-5794)

BURLESON, TX

817-295-7151 (FAX817-447-3840)

HOUSTON, TX

713-849-4330 (FAX713-849-4807)

PORTLAND, OR

503-223-7261 (FAX503-221-0203)

DANIELSVILLE, PA

610-837-1841 (FAX 610-837-7337)

KANSAS CITY, MO

816-231-5575 (FAX816-231-1959)

TAMPA, FL

813-623-1705 (FAX 813-626-8953)

ARLINGTON, TX

817-258-3000 (FAX 817-258-3333)

Regional Manufacturing Plants

FT. WORTH, TX

817-258-3000 (FAX 817-258-3173)

MONTPELIER, OH

419-485-5515 (FAX419-485-3565)

SACRAMENTO, CA

916-441-7172 (FAX916-441-4600)

Manufacturing Only

Abilene, TX

Clarksville, TX

Dallas, TX

Mansfield, TX

Paragould, AR

GUADALAJARA, JAL

+52 33-3283-1188

(FAX +52 33-3271-8450)

MONTERREY, N.L.

+52 811 156 6830

(FAX +52 81-1156-6833)

TOLUCA, MEX

+52 722 276 0800

(FAX +52 722-276-0801)

BRAZIL

SO PAULO, SP

+55 19 3877 9400

(FAX +55 19-3877-9429)

CANADA

CAMBRIDGE, ONTARIO

519-621-0546 (FAX 519-621-4413)

EDMONTON, ALBERTA

780-450-0888 (Fax 780-465-0079)

MISSISSAUGA, ONTARIO

905-670-1991 (FAX905-670-2110)

www.martinsprocket.com

COPYRIGHT 2016 Martin SPROCKET & GEAR, INC. ALL RIGHTS RESERVED 1292 MH-CFW 0201

Member

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Tramroll Enclosed Belt Conveyor Assembly Operation Maintenance - 900203 r0Documento44 páginasTramroll Enclosed Belt Conveyor Assembly Operation Maintenance - 900203 r0Mauricio MpintoAinda não há avaliações

- HammersDocumento24 páginasHammersMauricio MpintoAinda não há avaliações

- Literature Ultra Scoop Web2Documento2 páginasLiterature Ultra Scoop Web2Mauricio MpintoAinda não há avaliações

- Literature Stackable Conveyor - 03 2015 PDFDocumento4 páginasLiterature Stackable Conveyor - 03 2015 PDFMauricio MpintoAinda não há avaliações

- Ts-3 Cyclonic Rice Husk Furnace and Its Application On Paddy DryingDocumento9 páginasTs-3 Cyclonic Rice Husk Furnace and Its Application On Paddy DryingMauricio MpintoAinda não há avaliações

- Belt Conveyor: Complimented by ComparisonDocumento3 páginasBelt Conveyor: Complimented by ComparisonMauricio MpintoAinda não há avaliações

- Two Way Diverter ValvesDocumento4 páginasTwo Way Diverter ValvesMauricio MpintoAinda não há avaliações

- Belt Conveyor GBDocumento8 páginasBelt Conveyor GBMauricio MpintoAinda não há avaliações

- Cement Distribution Consultants - Articles - Export Terminals For AsiaDocumento3 páginasCement Distribution Consultants - Articles - Export Terminals For AsiaMauricio MpintoAinda não há avaliações

- 06 Kuenzel Elevators GB 10 07Documento2 páginas06 Kuenzel Elevators GB 10 07Mauricio MpintoAinda não há avaliações

- Idlers Cemad DdsDocumento2 páginasIdlers Cemad DdsMauricio MpintoAinda não há avaliações

- 70 A HydraulicDocumento148 páginas70 A HydraulicMauricio MpintoAinda não há avaliações

- Cilindro Hidraulico MDRDocumento22 páginasCilindro Hidraulico MDRMauricio MpintoAinda não há avaliações

- Full Design of Horizontal TanksDocumento4 páginasFull Design of Horizontal TanksMauricio MpintoAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Example Quality PlanDocumento11 páginasExample Quality PlanzafeerAinda não há avaliações

- Orkot® TLM & TXM Marine Bearings: Trelleborg Se Aling SolutionsDocumento7 páginasOrkot® TLM & TXM Marine Bearings: Trelleborg Se Aling Solutionsprodn123Ainda não há avaliações

- Literature Study Nift ChennaiDocumento5 páginasLiterature Study Nift ChennaiAnkur SrivastavaAinda não há avaliações

- Reduced Chemical Kinetic Mechanisms For Methane Combustion Ino /N and O /co AtmosphereDocumento51 páginasReduced Chemical Kinetic Mechanisms For Methane Combustion Ino /N and O /co Atmosphereariel zamoraAinda não há avaliações

- 2008 Residential CF-1R ADDDocumento8 páginas2008 Residential CF-1R ADDDebo SodipoAinda não há avaliações

- System SizingDocumento50 páginasSystem SizingVictor mulotaAinda não há avaliações

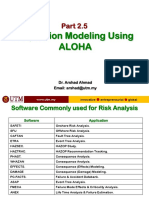

- PLSP 2 6 Aloha PDFDocumento35 páginasPLSP 2 6 Aloha PDFKajenAinda não há avaliações

- Centaour 50 Solar TurbineDocumento2 páginasCentaour 50 Solar TurbineTifano KhristiyantoAinda não há avaliações

- Simatic Wincc: Answers For IndustryDocumento8 páginasSimatic Wincc: Answers For IndustryAlina MirelaAinda não há avaliações

- Sony Chassis Ba-4 (C-TV KV-13M40 - 50 - 51, KV-14MB40, KV-20M40, KV-20S40 - 41, KV-20V80, Kv-21se80, Kv-21se40, Kv-21me40... Service Manual)Documento94 páginasSony Chassis Ba-4 (C-TV KV-13M40 - 50 - 51, KV-14MB40, KV-20M40, KV-20S40 - 41, KV-20V80, Kv-21se80, Kv-21se40, Kv-21me40... Service Manual)Mauro Mendez100% (1)

- Customers at SurveyDocumento10 páginasCustomers at Surveynaren000Ainda não há avaliações

- TX-SMS Remote Programming GuideDocumento2 páginasTX-SMS Remote Programming GuidedjbobyAinda não há avaliações

- Manual Cmp-Smartrw10 CompDocumento66 páginasManual Cmp-Smartrw10 CompAllegra AmiciAinda não há avaliações

- Definition of EbookDocumento14 páginasDefinition of EbookNurul IzzahAinda não há avaliações

- Second Invitation OriginalDocumento4 páginasSecond Invitation Originalsudhakar80Ainda não há avaliações

- Vatan Katalog 2014Documento98 páginasVatan Katalog 2014rasko65Ainda não há avaliações

- Scan 0001Documento1 páginaScan 0001ochiroowitsAinda não há avaliações

- SV50SP2RevB Released User DocumentsDocumento8 páginasSV50SP2RevB Released User DocumentsAhmed RamadanAinda não há avaliações

- III Sem Jan 2010 Examination Results SwatisDocumento21 páginasIII Sem Jan 2010 Examination Results SwatisAvinash HegdeAinda não há avaliações

- Compact FlashDocumento9 páginasCompact Flashenpr87reddyAinda não há avaliações

- Lancaster LinksDocumento3 páginasLancaster LinksTiago FerreiraAinda não há avaliações

- Brendan JoziasseDocumento2 páginasBrendan Joziasseapi-255977608Ainda não há avaliações

- Technical DataSheet (POWERTECH社) -55559-9 (Motormech)Documento2 páginasTechnical DataSheet (POWERTECH社) -55559-9 (Motormech)BilalAinda não há avaliações

- NORSOK Standard D-010 Rev 4Documento224 páginasNORSOK Standard D-010 Rev 4Ørjan Bustnes100% (7)

- NGO-CSR Internship Report TemplateDocumento4 páginasNGO-CSR Internship Report TemplatePriyanka Singh100% (1)

- Niner RIP9 RDODocumento5 páginasNiner RIP9 RDOSwitchback BikesAinda não há avaliações

- Arc Welding ProcessesDocumento153 páginasArc Welding Processespratap biswasAinda não há avaliações

- Naging: Case SelectingDocumento5 páginasNaging: Case SelectingPrabhakar RaiAinda não há avaliações

- C9 Game Guide For VIPsDocumento62 páginasC9 Game Guide For VIPsChrystyanoAinda não há avaliações

- Workshop Manual Group 21-26 - 7745282 PDFDocumento228 páginasWorkshop Manual Group 21-26 - 7745282 PDFabdelhadi houssinAinda não há avaliações