Escolar Documentos

Profissional Documentos

Cultura Documentos

United States Patent (191

Enviado por

PhanHathamTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

United States Patent (191

Enviado por

PhanHathamDireitos autorais:

Formatos disponíveis

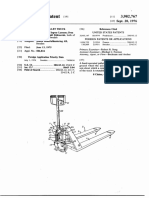

USOO5439273A

United States Patent [191

[11]

[45]

Price et al.

Patent Number:

Date of Patent:

5,439,273

Aug. 8, 1995

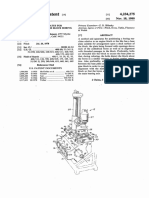

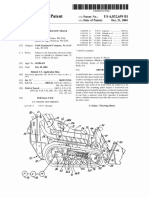

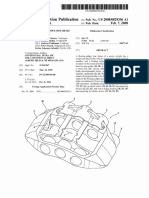

[54] CONCRETE BREAKER AND METHOD

Hammer, (publication date unknown) published by

[75] Inventors: Robert E. Price, Grand Rapids;

James R. Trutsch, Middleville, both

Rockford Industries, Inc., McAlester, Okla.

Primary Examiner-David J. Bagnell

[73] Assignee:

of Mich.

Attorney, Agent, or FirmPrice, Heneveld, Cooper,

Price Industries, Inc., Dutton, Mich.

[57]

DeWitt & Litton

[21] Appl. No.: 234,272

[22] Filed:

[51]

[52]

A concrete breaker includes a wheeled frame having

front and rear wheels, a blade frame pivotally mounted

to the wheeled frame between the front and rear

Apr. 28, 1994

wheels, and a heavy concrete breaking blade slideably

mounted to the blade frame for busting concrete. The

Int. Cl.6 ..................... .. 12010 23/12; E21C 27/12

U.S. Cl. ...................................... .. 299/37; 173/28;

blade frame is pivotally moveable by a hydraulic cylin

404/ 133.1

[58]

der assembly over-center to a stable transport position,

and further is moveable over-center to an upright posi

Field of Search .................... .. 299/37, 69; 404/90,

404/l33.l, 133.05; 173/28; 241/101]

[56]

tion on the wheeled frame for use. Wheels on the blade

frame rest on the concrete being broken and support the

References Cited

operating weight of the blade frame and the blade when

U.S. PATENT DOCUMENTS

'

ABSTRACT

2,254,477

9/1941

Ferguson ........................ .. 299/37 X

2,587,969

3/1952

Cornett

.... ...

2,659,583 11/1953

Dorkins ..

2,659,584 11/1953

Dorkins .... ..

. . . . . ..

the blade is in use. The blade frame is moveable relative

to the wheeled frame to reduce transmission of vibra

tion from the blade and blade frame to the wheeled

299/37 X

.... .. 404/l33.l X

frame. The hydraulic cylinder assembly is connected

404/l33.05 X

between the blade frame and the wheeled frame and

acts as a draw-bar-like member during use of the con

crete breaker to overcome torsional forces on the blade

OTHER PUBLICATIONS

Exhibit A are photographs disclosing a known prior art

Breaker, (publication date unknown), published by

frame as wheels on the blade frame engage rough ter

rain such as broken or irregular concrete under the

blade frame. A hydraulic system is connected to the

blade to raise the blade to a lifted position, and includes

Chief Industries, Inc., Grand Island, Neb.

Exhibit C is a product brochure entitled Fairmont

the cylinder without restriction when the blade is hy

concrete breaker mounted on a truck bed. (undated).

Exhibit B is a product brochure entitled EZ

a double line discharge to exhaust hydraulic ?uid from

Hydraulics Has Gotten Bigger . . . and Better, (publi

draulically released and dropped onto the cement to

cation date unknown) published by Greenlee Textron

Inc., Fairmont, Minn.

break the cement.

35 Claims, 5 Drawing Sheets

Exhibit D is a product brochure entitled New Drop

[12

:I /

30

I. "0

10:4

90

96B

96

I08

92

82 ,1

20

38

:1!

58

1' "1"

24

1. la

34

26

26

US. Patent

Aug. s, 1995

Sheet 1 of 5

5,439,273

US. Patent

Aug. s, 1995

Sheet 3 of 5

5,439,273

72

88

ii'64

~60

FIG 6A

US. Patent

Aug. 8, 1995

Sheet 4 of 5

5,439,273

US. Patent

Aug. s, 1995

Sheet 5 of 5

5,439,273

5,439,273

CONCRETE BREAKER AND METHOD

BACKGROUND OF THE INVENTION

The present invention relates to construction equip

ment for breaking concrete, and in particular to a con

crete breaker for busting concrete slabs into pieces to

facilitate removal of the concrete, such as is commonly

FIG. 6A is a fragmentary plan view of the support

member shown in FIG. 6;

FIG. 7 is a front view of the concrete breaker shown

in FIG. 4, the cab and fuel tank of the concrete breaker

having been removed to better show the blade and

blade frame;

FIG. 8 is a rear elevational view of the concrete

breaker shown in FIG. 4;

FIG. 9 is an enlarged fragmentary side view of the

used in highway renovation.

IO blade and blade frame shown in FIG. 4;

Concrete breakers are often used to break up worn

FIG. 10 is a hydraulic schematic for the concrete

out concrete sections of highway to facilitate removal

breaker shown in FIG. 1; and

of the concrete. A: common concrete breaker is a guil

FIG. 11 is a fragmentary perspective view of the

lotine style breaker which includes a heavy blade that

blade and blade frame shown in FIG. 9.

is repeatedly lifted and dropped against the concrete. In

known guillotine style breakers, the heavy blade is

DETAILED DESCRIPTION OF PREFERRED

slideably supported at the rear of the apparatus in a

EMBODIMENT

blade guide positioned ion the main frame for guiding

A concrete breaker 20 (FIGS. 1-3) includes a

the movement of the guillotine blade. However, the

wheeled frame 22 having front and rear wheels 24 and

shocks and vibration generated by the blade contacting

26. A blade frame 28 is pivotally mounted to the

the concrete are transferred directly to the guides and

wheeled frame 22 generally midway between the

to the main frame, causing considerable wear and tear

wheels 24 and 26 for movement over-center between an

to the frame and to other components mounted on the

upright/use position (FIGS. 1-2 and 4) and a storage/

frame.

transport position (FIG. 3). A guillotine style con

Usually, the blade is mounted on the rear of a heavy 25 crete breaking blade 30 is slideably mounted to blade

duty truck. However, there are smaller self-propelled

frame 28 for engaging and busting up concrete 32. Blade

units with drop hammers mounted over the rear wheels.

frame 28 is independently supported by wheels 34 when

in the upright position (FIGS. 1-2 and 4), and is slide

SUMMARY OF THE INVENTION

ably mounted to wheeled frame 22 such that it floats

In the present invention, the blade frame is pivotally b) O on wheeled frame 22 in a manner that reduces transmis

mounted to a wheeled frame between the front and rear

wheels. A blade is movably connected to the blade

frame, and is lifted and dropped to break concrete. The

blade frame is moveable on the wheeled frame between

an upright position for using the blade and a lowered

transport position facilitating transport. In a preferred

form, the blade frame includes wheels engageable with

the terrain under the blade frame for supporting the

working weight of the blade and the blade frame inde

pendent of the wheeled frame during use, and further

the blade frame is preferably mounted about midway

between the front and rear wheels on the wheeled frame

for stability.

These and other features, advantages and objects of

sion of shocks and vibration from blade 30 to wheeled

frame 22-during use of breaker 20.

Wheeled frame 22 (FIG. 5) includes side frame mem

bers 38 and 40 interconnected by cross frame members

42 and 44. A front axle and steering mechanism 46 is

secured to the front of side frame members 38 and 40,

and front wheels 24 are mounted on mechanism 46. A

vehicle cab 48 is also secured to the front of side frame

members 38 and 40, and vehicle controls (not speci?

40 cally shown) such as are well known in the vehicle arts

are located in cab 48. A fuel tank 50 is located behind

and adjacent cab 48.

A diesel engine 52 is mounted on a platform 54 at the

rear of side frame members. Diesel engine 52 is con?g

the present invention will be further understood and 45 ured to drive one or both of front and rear wheels 24

appreciated by those skilled in the art by reference to

and 26 by means such as are known in the vehicle arts,

the following speci?cation, claims and appended draw

such as by hydraulic drives located at each wheel. A

ings.

hydraulic pump 56 and reservoir 58 are located on plat

BRIEF DESCRIPTION OF THE DRAWINGS

form 54 generally adjacent diesel engine 52, along with

a hydraulic system described hereinafter.

FIG. 1 is a front perspective view of a concrete

A support member 60 (FIGS. 45) for supporting

breaker embodying the present invention, the blade and

blade frame 28 is pivotally connected to side frame

members 38 and 40 by bearings 62. Support member 60

blade frame being shown in an upright position on the

wheeled frame;

FIG. 2 is a rear perspective view of the concrete

breaker shown in FIG. 1, the blade being shown in an

upright and lifted position;

FIG. 3 is a side view of the concrete breaker with the

blade and blade frame being shown in the inclined trans

port position;

FIG. 4 is a side view comparable to FIG. 3 but with

the blade and blade frame being shown in the upright

position;

includes a shaft 64 that engages bearings 62 and extends

between side frame members 38 and 40. Support mem

ber 60 further includes a pair of side brackets 66 and 68

secured to each end of tubular shaft 64 inside of and

adjacent side frame members 38 and 40. Side brackets

66 and 68 are mirror images of each other, and thus only

side bracket 66 will be described in detail below.

Side bracket 66 (FIG. 6) includes a tube engaging end

70, and a plate-shaped member 72 that extends generally

parallel the inside of side frame member 38. An arm 74

extends from plate-shaped member 72 over side frame

FIG. 4, the top bracket on the blade frame having been 65 member 38. An anchor bracket 76 is located on side

frame member 38 proximate arm 74. Arm 74 includes a

removed to more clearly show components therebelow;

FIG. 6 is a fragmentary enlarged view of the circled

hole 78 and anchor bracket 76 includes a hole 80, which

area labelled VI in FIG. 5;

holes 78 and 80 are aligned when blade frame 28 is in the

FIG. 5 is a top view of the concrete breaker shown in

5,439,273

upright position so that a bolt (not shown) can be ex

tended through holes 78 and 80 to secure blade frame 28

in the upright position. Web 81 reinforces arm 74 on

plate 72.

A U-shaped channel 82 (FIG. 6A) includes a pair of

angle beams 84 and 85 and three elongated plates 86, 87

A pair of actuator mechanisms or blade pivoting

cylinder assemblies 112 (FIG. 4) are connected between

the front of wheeled frame 22 and transverse beam 94B.

Each cylinder assembly 112 includes a cylinder 114

5

pivotally connected to wheeled frame 22, and an ex

tendable rod 116 pivotally connected to transverse

and 88 welded together to de?ne an inwardly facing

beam 94B by a hinged joint 115A. By extending and

channel for mateably receiving a second U-shaped

retracting rod 116 in cylinder 114, blade frame 28 and

channel 90 (FIG. 6) on blade frame 28. Channels 82 of

support member 60 are pivoted between an upright

side brackets 66 and 68 (FIG. 1) are interconnected by 10 portion (FIG. 4) and a retracted position (FIG. 3), re

at least one intermediate cross beam 109 to rigidify

spectively. Notably, since cylinder assembly 112 ex

support member 60. Second U-shaped channel 90 (FIG.

tends between the front of wheeled frame 22 and blade

6) is slideably positioned in ?rst channel 82. Second

frame wheels 34, it acts like a draw bar to overcome

channel 90 includes a pair of angled beams 92 and 93

torque generated on blade frame 28 as wheels 34 engage

and three elongated plates 94, 95 and 96 which de?ne a 5 rough terrain, such as broken concrete 32A. Resilient

second inwardly facing channel for slideably receiving

canvas or rubber ?aps 122A and 122B (FIG. 9) are

secured to bottom cross beams 94A and 94B along with

blade 30.

Blade frame 28 (FIG. 5) includes the U-shaped chan

safety guards 122C. Flaps or safety guards 122A and

nel 90 on one side and further includes a corresponding

122B drape downwardly onto cement 32 on either side

U-shaped channel 92 that is a mirror image of channel

of blade 30 and thus reduce ?ying debris generated

90 on its other side. Channels 90 and 92 are intercon

nected at the bottom by bottom cross beams 94A and

94B (FIG. 9). Channels 90 and 92 are further intercon

when blade 30 contacts cement 32.

nected by top beams and 96A and 96B and connecting

brackets 96C. (See also FIGS. 1-2.) Diagonal braces 98

and 100 (FIGS. 5 and 9) extend upwardly from bottom

The hydraulic system for actuating the lift cylinder

assembly 104 is schematically shown in FIG. 10. Nota

bly, a number of different hydraulic arrangements are

25 contemplated, only one of which is shown. Blade 30 is

cross beam 94A and interconnect to support an interme

diate transverse beam 106. Diagonal braces 98 and 100

rigidify blade frame 28.

illustrated as operably connected to rod 110 by bracket

112, and cylinder 108 is supported by blade frame beam

94A. Hydraulic pump 56 is operably connected to hy

draulic ?uid reservoir 58 by a line 56A for receiving a

Wheels 34 are operably mounted at the lower end of

channels 90 and 92 and bottom cross beams 94A and

94B by a structural bracket 111 so that the wheels 34

engage concrete 32 under blade frame 28 when blade

blade lifting position (shown) and is spring returned to

frame 28 is in the upright position. Blade frame 28 is

a blade dropping position by a spring 127A. In the blade

supply of hydraulic fluid therefrom. Pump 56 communi'

cates pressurized hydraulic fluid through a line 124 to a

valve 126. Valve 126 is shiftable by a solenoid 127 to a

permitted to move or ?oat relative to wheeled frame 22 35

lifting position, pressurized hydraulic fluid is communi

(i.e. slide vertically within channels 82 on side brackets

66 and 68) to reduce communication of shocks and

vibration from blade 30 through blade frame 28 to

wheeled frame 22. Wheels 34 further support the work

cated through a two inch line 128 to the lower end of

cylinder 108 for extending rod 110. A second two inch

line 130 connected to the lower end of cylinder 108 is

blocked by valve 126 when in the blade lifting position.

ing weight of blade frame 28 and blade 30. However, 40 When rod 110 reaches the fully extended position, valve

when blade frame 28 and blade 30 are ready to be piv

126 is shifted to the blade dropping position. In the

oted to the transport/storage position, a releasable stop

blade dropping position, valve 126 connects both lines

(not speci?cally shown) can be engaged with blade

128 and 130 to two inch drain lines 132 and 134, respec

frame 28 so that blade frame 28 cannot telescopingly

tively, so that there is substantially no hydraulic restric~

slide out the bottom of pivot forming member 60. The 45 tion when dropping blade 30. Thus, maximum energy is

stop includes a ?rst shaft or bolt that extends through

alignable holes in channel 90, side bracket 66, and blade

30, and a second bolt that extends through alignable

holes in channel 92, side bracket 68, and the other side

retained in blade 30 for busting up concrete 32 into

broken concrete 32A (FIG. 4). A relief valve 136 is

gravity of blade frame 28 and blade 30 moves over the

provided on line 124 to prevent over-pressure of pump

56.

Thus, there is provided a concrete breaker wherein

an independently supported blade and blade frame are

provided to reduce vibrational forces transmitted to the

axis of rotation de?ned by bearings 62 as blade frame 28

main wheeled frame of the breaker. Further, the blade

and blade 30 are moved between the use and transport

and blade frame are pivotable over-center across the

pivot axis of rotation such that the blade is held in a

stable position between the front and rear wheels of the

of blade 30. A second stop 107 is located on side frame

members 38 and 40 (FIG. 3). Notably, the center of

positions. This over-center relationship causes the blade

frame 28 and blade 30 to stably rest in either the upright

position or the storage position.

Lift cylinder assembly 104 (FIG. 9) includes a cylin

vehicle for transport.

In the foregoing description, it will be readily appre

der 108 secured to blade frame bottom cross beam 94A,

ciated by those skilled in the art that modi?cations may

and further includes an extendable rod 110 operably 60 be made to the invention without departing from the

connected to blade 30 by bracket 112 (FIG. 2). Lift

concepts disclosed herein. Such modi?cations are to be

cylinder assembly 104 is located between transverse

considered as included in the following claims, unless

beam 106 and blade 30 such that, when rod 110 is fully

these claims by their language expressly state otherwise.

extended and blade 30 is raised to a maximum height,

The embodiments of the invention in which an exclu

the transverse beam 94A supports cylinder assembly 65 sive property or privilege is claimed are de?ned as

104. It is noted that blade 30 can be upwards of 15,000

pounds, and that the overall gross weight of breaker 20

can be upwards of 30,000 pounds.

follows:

1. A concrete breaker comprising:

a wheeled frame including front and rear wheels;

5,439,273

a blade frame pivotally mounted to said wheeled

frame between said front and rear wheels;

a moveable blade operably mounted to said blade

13. A concrete breaker as de?ned in claim 1 wherein

said lift mechanism includes a lift cylinder and an ex

tendable cylinder rod operably connected to said blade

frame and said blade for lifting said blade, and further

includes a hydraulic system comprising:

frame for breaking concrete;

a lift mechanism operably connected to said blade for

lifting said blade; and

a hydraulic ?uid pump, a hydraulic fluid reservoir

connected to said pump, a ?rst hydraulic line for

said blade frame being moveable between an upright

position for using said blade and a transport posi

tion facilitating transport of said concrete breaker.

communicating pressurized hydraulic ?uid from

said pump to said lift cylinder to extend said rod

and thus lift said blade, a second hydraulic line

operably connected to said lift cylinder for ex

2. A concrete breaker as defined in claim 1 including

a blade frame support for pivotally mounting said blade

frame to said wheeled frame, said blade frame being

operably mounted to said support to allow said blade

hausting hydraulic ?uid when retracting said rod,

and a valve operably connected to said ?rst and

second lines, said valve being shiftable to a lift

frame to move relative to said wheeled frame to thus

said blade frame includes a ?rst pair of opposing chan

nels with capture said blade therebetween, and wherein

position wherein said ?rst hydraulic line is open

and said second hydraulic line is blocked such that

pressurized hydraulic fluid can be communicated

to said lift cylinder by said pump, said valve further

being shiftable to an exhaust position wherein both

said support includes a second pair of opposing chan 20

nels that capture said ?rst pair of channels but permit

hydraulic ?uid reservoir such that said blade will

reduce transmission of vibrational loads from said blade

through said blade frame to said wheeled frame.

3. A concrete breaker as de?ned in claim 2 wherein

of said ?rst and second lines are vented to said

drop without signi?cant restriction from hydraulic

fluid being exhausted from said cylinder.

said blade frame to ?oat within said second pair of

channels to reduce transmission of loads from said blade

frame to said wheel frame.

14. A concrete breaker as de?ned in claim 1 wherein

4. A concrete breaker as de?ned in claim 1 wherein 25 said blade weighs about 15,000 pounds.

said blade frame includes blade frame wheels for sup

15. A concrete breaker as de?ned in claim 1 including

a safety guard located on a lower end of said blade

porting the working weight of said blade frame when

said blade frame is in said upright position.

frame for containing ?ying debris thrown from said

5. A concrete breaker as de?ned in claim 4 including

a draw-bar simulating member connected between said

blade frame wheels and said front wheels of said

wheeled frame.

6. A concrete breaker as de?ned in claim 4 including

blade when said blade contacts and breaks cement.

a draw-bar simulating member connecting said blade

frame to said wheeled frame for overcoming torsional

force caused by resistance of said blade frame wheels as

said safety guard includes a ?ap of resilient material.

16. A concrete breaker as de?ned in claim 15 includ'

ing a pair of said safety guards which are located on

opposite sides of said blade.

17. A concrete breaker as de?ned in claim 15 wherein

18. A concrete breaker as de?ned in claim 1 wherein

said blade frame is mounted to said wheeled frame

about midway between said front and rear wheels in a

balanced position which facilitates stable movement of

said wheeled frame when said blade frame is in said

said blade frame wheels roll over rough terrain such as

broken concrete.

7. A concrete breaker as de?ned in claim 6 wherein

said blade frame de?nes an axis of rotation as said blade

upright position and when in said transport position.

frame is moved between said upright position and said

transport position, said draw bar being connected to

a pair of said front wheels, and wherein said front

said lMade frame in a location spaced below said access

wheels are steerable.

19. A concrete breaker as de?ned in claim 1 including

of rotation.

20. A concrete breaker as de?ned in claim 19 wherein

8. A concrete breaker as de?ned in claim 1 wherein 45 said blade weighs about 15,000 pounds.

said blade frame includes a pivot for pivotally mounting

said blade frame to said wheeled frame, said pivot de?n

21. A concrete breaker comprising:

a-wheeled frame;

a blade for breaking concrete operably supported by

said wheeled frame; and

ing an axis of rotation as said blade frame is moved

between said upright position and said transport posi

tion, said blade frame and said blade having a center of

mass that travels over-center of said axis of rotation

when moved between said upright position and said

transport position such that said blade frame and said

a lift mechanism for lifting said blade, said lift mecha

nism comprising a lift cylinder supported by said

wheeled frame, an extendable cylinder rod

mounted in said lift cylinder and operably con

nected to said blade for lifting said blade, a hydrau

blade are located in a stable position when in said trans

port position.

55

9. A concrete breaker as de?ned in claim 1 including

an engine operably connected to said rear wheels for

propelling said wheeled frame.

lic ?uid pump, a motor for operating said pump, a

hydraulic ?uid reservoir operably connected to

said pump, a ?rst hydraulic line for communicating

pressurized hydraulic ?uid to said lift cylinder to

10. A concrete breaker as de?ned in claim 9 wherein

extend said rod and thus lift said blade, a second

said engine is operably connected to said front and rear

hydraulic line operably connected to said lift cylin

der for exhausting hydraulic ?uid when retracting

wheels for powering said front and rear wheels in a four

wheel drive arrangement.

11. A concrete breaker as de?ned in claim 9 wherein

said blade weighs about 15,000 pounds.

12. A concrete breaker as de?ned in claim 1 including 65

a hydraulic tilt mechanism connected to said blade

frame for moving said blade frame between said upright

position and said transport position.

said rod, and a valve operably connected to said

?rst and second lines, said valve being shiftable to

a lift position wherein said ?rst hydraulic line is

open and said second hydraulic line is blocked such

that pressurized hydraulic ?uid can be communi

cated to said lift cylinder by said pump, said valve

further being shiftable to an exhaust position

5,439,273

wherein both of said ?rst and second lines are ex

30. A concrete breaker as de?ned in claim 29 wherein

hausted such that said blade will drop without

said terrain engaging structure includes terrain engag

signi?cant restriction from the hydraulic ?uid

being exhausted from said cylinder.

ing wheels.

22. A concrete breaker as de?ned in claim 21 includ

ing a blade frame on said wheel frame for carrying said

blade, said subframe including blade frame wheels for

engaging the terrain below said blade frame to carry the

working weight of said blade and said blade frame when

using said concrete breaker.

23. A concrete breaker comprising:

a wheeled frame including a guide;

a blade slideably mounted in said guide for breaking

15

concrete;

a lift mechanism for lifting said blade; and

a chip guard attached to said wheeled frame, said

chip guard being located proximate a lower end of

31. A concrete breaker comprising:

a main frame including a pair of spaced frame side

members and further including a pair of from

wheels and a pair of rear wheels supporting said

main frame;

a blade frame;

a concrete busting blade operably connected to said

blade frame and having suf?cient mass for effec

tively busting concrete, said blade extending be

tween said pair of spaced frame side members and

being located between said pairs of front and rear

wheels; and

a pivot pivotally mounting said blade frame to said

main frame for movement between an upright posi

tion for use and a storage position, said pivot de?n

said guide for obstructing ?ying debris thrown

ing an axis of rotation as said blade frame is moved

when said blade contacts cement for breaking the

between said upright position and said transport

cement.

position, said blade frame and said blade having a

24. A concrete breaker as de?ned in claim 23 includ

ing a pair of said chip guards which are located on

opposite sides of said blade.

25

25. A concrete breaker as de?ned in claim 23 wherein

said chip guard includes a ?ap of ?exible material.

center of mass that travels over-center of said axis

of rotation when moved between said upright posi

tion and said transport position such that said blade

frame and said blade are located in a stable position

when in said transport position.

32. A concrete breaker as de?ned in claim 31 wherein

26. A concrete breaker as de?ned in claim 23 wherein

said main frame is portably supported on wheels.

said wheeled frame includes front and rear wheels, and

33. A concrete breaker as de?ned in claim 31 wherein

including a blade frame mounted to said wheeled frame 30 said concrete busting blade weighs at least about 15,000

about midway between said front and rear wheels in a

pounds.

balanced position which facilitates stable movement of

34. A lift mechanism for lifting and dropping a blade,

comprising:

said wheeled frame when said blade frame is in said

a lift cylinder, an extendable cylinder rod mounted in

upright position and in said transport position.

said lift cylinder and operably connected to said

27. Aconcrete breaker for breaking concrete sections

blade for lifting said blade, a hydraulic fluid pump,

comprising: a main frame;

a motor for operating said pump, a hydraulic ?uid

a blade frame, said main frame including supports for

reservoir operably connected to said pump, a ?rst

slideably supporting said blade frame in said up

right position for independent vertical movement;

a blade slideably mounted to said blade frame;

terrain engaging structure on said blade frame for

movably supporting said blade frame on the con

crete sections independent of said main frame; and

a lift mechanism operably connected to said blade for 45

lifting said blade.

28. A concrete breaker as de?ned in claim 27 wherein

said terrain engaging structure includes wheels on said

supports.

50

29. A concrete breaker comprising:

a wheeled frame;

a blade frame pivotally connected to said wheeled

frame for movement between an operating position

and an angled transport position, said blade frame

including terrain engaging structure movably sup

porting the working weight of said blade frame on

terrain below said blade frame when in said operat

ing position;

a concrete busting blade operably connected to said

blade frame; and

a draw bar connecting said blade frame to said

wheeled frame for overcoming torsional force on

said blade frame caused by resistance of said terrain

engaging structure as said terrain engaging struc 65

ture moves over terrain below said blade frame.

hydraulic line for communicating pressurized hy

draulic ?uid to said lift cylinder to extend said rod

and thus lift said blade, a second hydraulic line

operably connected to said lift cylinder for ex

~hausting hydraulic ?uid when retracting said rod,

and a valve operably connected to said ?rst and

second lines, said valve being shiftable to a lift

position wherein said ?rst hydraulic line is open

and said second hydraulic line is blocked such that

pressurized hydraulic ?uid can be communicated

to said lift cylinder by said pump, said valve further

being shiftable to an exhaust position wherein both

of said ?rst and second lines are exhausted such

that said blade will drop without signi?cant restric~

tion from the hydraulic ?uid being exhausted from

said cylinder.

35. A method of breaking concrete comprising:

supporting a main frame on front and rear wheels;

slideably supporting a blade frame on said main frame

between said front and rear wheels in an upright

operating position;

slideably supporting a blade on said blade frame for

busting concrete; and

independently supporting said blade frame on the

concrete sections being broken when operating

said blade and where moving the main frame over

the concrete sections.

*

=|<

Você também pode gostar

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDocumento7 páginasUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinAinda não há avaliações

- EP1321438B1Documento10 páginasEP1321438B1Alessandro PatanèAinda não há avaliações

- Thrust BlockDocumento2 páginasThrust Blockkyaw yaAinda não há avaliações

- United States Patent (19) : Dec. 10, 1991 (45) Date of PatentDocumento4 páginasUnited States Patent (19) : Dec. 10, 1991 (45) Date of PatentKeval KamaniAinda não há avaliações

- United States Patent (19) : Johnston (11) Patent Number: (45) Date of PatentDocumento9 páginasUnited States Patent (19) : Johnston (11) Patent Number: (45) Date of Patentsanjay0910Ainda não há avaliações

- US20010024927A1Documento7 páginasUS20010024927A1MahnooshAinda não há avaliações

- United States Patent 1111 3,595,128Documento9 páginasUnited States Patent 1111 3,595,128rte678Ainda não há avaliações

- United States: (12) Patent Application Publication (10) Pub. No.: US 2006/0213595 A1Documento9 páginasUnited States: (12) Patent Application Publication (10) Pub. No.: US 2006/0213595 A1dfus603Ainda não há avaliações

- Patent Application Publication (10) Pub. No.: US 2010/0105516 A1Documento11 páginasPatent Application Publication (10) Pub. No.: US 2010/0105516 A1KrozeAinda não há avaliações

- Back Wheel PatentDocumento5 páginasBack Wheel PatentlawAinda não há avaliações

- Us4854065 PDFDocumento7 páginasUs4854065 PDFJin SongAinda não há avaliações

- D6a - D8a PDFDocumento168 páginasD6a - D8a PDFduongpn63% (8)

- United States Patent (10) Patent No.: US 6,341,790 B1: Chen (45) Date of Patent: Jan. 29, 2002Documento10 páginasUnited States Patent (10) Patent No.: US 6,341,790 B1: Chen (45) Date of Patent: Jan. 29, 2002Eric Manuel Mercedes AbreuAinda não há avaliações

- United States Patent (19) (11) Patent Number: 4,727,781: Yuehui Et Al. (45) Date of Patent: Mar. 1, 1988Documento31 páginasUnited States Patent (19) (11) Patent Number: 4,727,781: Yuehui Et Al. (45) Date of Patent: Mar. 1, 1988Siul OtreborAinda não há avaliações

- The Line Boring MachineDocumento8 páginasThe Line Boring MachineJinky L. LavegaAinda não há avaliações

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsAinda não há avaliações

- 01Documento4 páginas01Santos JustinAinda não há avaliações

- Cumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2Documento3 páginasCumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2monem2014Ainda não há avaliações

- Operating InstructionsDocumento34 páginasOperating InstructionsCarlos IntriagoAinda não há avaliações

- Compressed Air MotorDocumento10 páginasCompressed Air Motorjahson362Ainda não há avaliações

- US20090183398A1Documento9 páginasUS20090183398A1PUVAN TSTAinda não há avaliações

- M2 HB Bolt Side Change US2529391Documento4 páginasM2 HB Bolt Side Change US2529391apoorva singhAinda não há avaliações

- 242B3 - M.serviceDocumento2.226 páginas242B3 - M.serviceJuliano Daiana Muller SantosAinda não há avaliações

- W, B. Kidder. : Tree Climbing MotorDocumento4 páginasW, B. Kidder. : Tree Climbing Motormonem2014Ainda não há avaliações

- EP000003126210B1 ROAD WHEEL HutchineDocumento25 páginasEP000003126210B1 ROAD WHEEL Hutchine임학진Ainda não há avaliações

- Us 5492401Documento10 páginasUs 5492401daygo21Ainda não há avaliações

- EjectionDocumento32 páginasEjectionsk9145Ainda não há avaliações

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheNo EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheNota: 4.5 de 5 estrelas4.5/5 (2)

- Wagner Iron Works v. Koehring Company, A Wisconsin Corporation, Wagner Iron Works v. Henry Manufacturing Company, Inc., 282 F.2d 317, 10th Cir. (1960)Documento10 páginasWagner Iron Works v. Koehring Company, A Wisconsin Corporation, Wagner Iron Works v. Henry Manufacturing Company, Inc., 282 F.2d 317, 10th Cir. (1960)Scribd Government DocsAinda não há avaliações

- Nemesgáz Motor Patent US20110113772 PDFDocumento12 páginasNemesgáz Motor Patent US20110113772 PDFGergely HollóAinda não há avaliações

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Documento13 páginas(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuAinda não há avaliações

- US20110274550A1Documento9 páginasUS20110274550A1雷黎明Ainda não há avaliações

- United States Patent: BauvinDocumento3 páginasUnited States Patent: Bauvingibson_sx87Ainda não há avaliações

- European Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorDocumento16 páginasEuropean Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorSelvaraji MuthuAinda não há avaliações

- Us 3601426 RearDocumento4 páginasUs 3601426 Rearanup tiwariAinda não há avaliações

- Kom MCQ With 2 Marks and 16 MarksDocumento20 páginasKom MCQ With 2 Marks and 16 MarksMushini Nagabhushan0% (1)

- EP06808858NWB1Documento13 páginasEP06808858NWB1keikhosravy.mAinda não há avaliações

- BY 4W1?" Mal/MM : July 4, 1957 A. Roque V 3,329,192Documento2 páginasBY 4W1?" Mal/MM : July 4, 1957 A. Roque V 3,329,192Namelezz ShadowwAinda não há avaliações

- Us 2912244Documento9 páginasUs 2912244alexhkiAinda não há avaliações

- Us 4234275Documento6 páginasUs 4234275MahnooshAinda não há avaliações

- United States Patent: (12) (10) Patent N0.: US 7,377,754 B2Documento23 páginasUnited States Patent: (12) (10) Patent N0.: US 7,377,754 B2Selvaraji MuthuAinda não há avaliações

- US6832659Documento12 páginasUS6832659Baiuliang BaiuliangAinda não há avaliações

- European Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)Documento10 páginasEuropean Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)shamsAinda não há avaliações

- Us 8210068us 8210068us 8210068us 8210068Documento9 páginasUs 8210068us 8210068us 8210068us 8210068JameszouqunAinda não há avaliações

- Machine Drawing1Documento11 páginasMachine Drawing1Sreedhar MadhanaAinda não há avaliações

- Ariel Leader Sheetmetal1Documento20 páginasAriel Leader Sheetmetal1Thunderbird3Ainda não há avaliações

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Documento14 páginasUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Kalai SelvanAinda não há avaliações

- United States Patent: IP IPDocumento11 páginasUnited States Patent: IP IPAdriana Daniela SanduAinda não há avaliações

- 68 PDFDocumento6 páginas68 PDFVicky SuryawanshiAinda não há avaliações

- Rig-E???': Gill!Documento6 páginasRig-E???': Gill!luiscremaschiAinda não há avaliações

- United States Patent (191: BlakesleyDocumento7 páginasUnited States Patent (191: BlakesleyRavindra JillepalliAinda não há avaliações

- US6581308Documento5 páginasUS6581308PUVAN TSTAinda não há avaliações

- United States: (12) Patent Application Publication (10) Pub. No.: US 2008/0029356 A1Documento12 páginasUnited States: (12) Patent Application Publication (10) Pub. No.: US 2008/0029356 A1Marc GlebAinda não há avaliações

- Roll ForgingDocumento6 páginasRoll ForgingSaptarshi SinhaAinda não há avaliações

- EP09166154NWA1Documento10 páginasEP09166154NWA1maes.daan1Ainda não há avaliações

- US3982767Documento6 páginasUS3982767takanobu ouraAinda não há avaliações

- ME2203 M.J 2007Documento0 páginaME2203 M.J 2007Venkatesh RajamaniAinda não há avaliações

- Jose/0H Schu/Man.:, Sept-7, 1937 - J. Schulman 2,092,476Documento3 páginasJose/0H Schu/Man.:, Sept-7, 1937 - J. Schulman 2,092,476akomocarAinda não há avaliações

- TEPZZ - 98 - Z9B - T: European Patent SpecificationDocumento30 páginasTEPZZ - 98 - Z9B - T: European Patent SpecificationMrSebolliniAinda não há avaliações

- MD r19 - Part - B PPT NewDocumento42 páginasMD r19 - Part - B PPT Newashok junapudiAinda não há avaliações

- 1001-Experimental Evaluation of A Digital Hydraulic Power Management SystemDocumento15 páginas1001-Experimental Evaluation of A Digital Hydraulic Power Management SystemPhanHathamAinda não há avaliações

- Sample and Vocabs For 16 Ielts Speaking Topics Part 2part 3 PDFDocumento75 páginasSample and Vocabs For 16 Ielts Speaking Topics Part 2part 3 PDFNguyễn Ngọc ĐứcAinda não há avaliações

- Tu Vung Hoc Thuat Moi Nhat Hien NayDocumento39 páginasTu Vung Hoc Thuat Moi Nhat Hien NayPhanHathamAinda não há avaliações

- Superior Technology. Optimal Compaction.: Articulated Tandem Rollers, 5 T and OverDocumento28 páginasSuperior Technology. Optimal Compaction.: Articulated Tandem Rollers, 5 T and OverPhanHathamAinda não há avaliações

- 8.Power-Saving Magnetizing Device For Magnetorheological Fluid Control Using Permanent MagnetDocumento4 páginas8.Power-Saving Magnetizing Device For Magnetorheological Fluid Control Using Permanent MagnetPhanHathamAinda não há avaliações

- Energies 12 00415Documento15 páginasEnergies 12 00415PhanHathamAinda não há avaliações

- 1974-PP-Pressure Transients in An Axial Piston Hydraulic PumpDocumento15 páginas1974-PP-Pressure Transients in An Axial Piston Hydraulic PumphathamphanAinda não há avaliações

- IELTS - Write Right - Retyped by Hội các sĩ tử luyện thi IELTSDocumento260 páginasIELTS - Write Right - Retyped by Hội các sĩ tử luyện thi IELTSNguyen Duc Tuan100% (16)

- Modeling Simulation and Identification of The Serv PDFDocumento12 páginasModeling Simulation and Identification of The Serv PDFPhanHathamAinda não há avaliações

- ADocumento11 páginasAPhanHathamAinda não há avaliações

- Scholarships 2019 eDocumento38 páginasScholarships 2019 etalla mbexAinda não há avaliações

- 0906-Energy Efficient Hydraulic Hybrid DrivesDocumento15 páginas0906-Energy Efficient Hydraulic Hybrid DrivesPhanHathamAinda não há avaliações

- 10 5445ir1000070929 PDFDocumento239 páginas10 5445ir1000070929 PDFPhanHathamAinda não há avaliações

- Transfer Functions and Block Diagrams PDFDocumento21 páginasTransfer Functions and Block Diagrams PDFJuliana NepembeAinda não há avaliações

- 2014-PP - Adaptive Fuzzy PID Control For Servo Motor Direct-Drive Pump ControlDocumento7 páginas2014-PP - Adaptive Fuzzy PID Control For Servo Motor Direct-Drive Pump ControlPhanHathamAinda não há avaliações

- Scholarships 2019Documento38 páginasScholarships 2019Didi GuciAinda não há avaliações

- Scholarships 2019 eDocumento38 páginasScholarships 2019 etalla mbexAinda não há avaliações

- IndexDocumento197 páginasIndexPhanHathamAinda não há avaliações

- 2011-PP-Fuzzy PID Control For Direct Drive Electro-Hydraulic Position Servo SystemDocumento4 páginas2011-PP-Fuzzy PID Control For Direct Drive Electro-Hydraulic Position Servo SystemPhanHathamAinda não há avaliações

- 0-Development of New Hybrid Excavator PDFDocumento4 páginas0-Development of New Hybrid Excavator PDFPhanHatham100% (1)

- 0-Development of New Hybrid ExcavatorDocumento9 páginas0-Development of New Hybrid ExcavatorPhanHathamAinda não há avaliações

- Equal Coded Digital Hydraulic Valve System - Improving Tracking Control With Pulse Frequency ModulationDocumento9 páginasEqual Coded Digital Hydraulic Valve System - Improving Tracking Control With Pulse Frequency ModulationPhanHathamAinda não há avaliações

- ComparisonDocumento17 páginasComparisonPhanHathamAinda não há avaliações

- Sách Hán Tự Cấp 5 - JvcDocumento1 páginaSách Hán Tự Cấp 5 - JvcPhanHathamAinda não há avaliações

- English Rhetoric PDFDocumento1 páginaEnglish Rhetoric PDFPhanHathamAinda não há avaliações

- Comparison of Fatigue Provisions in Codes and StandardsDocumento70 páginasComparison of Fatigue Provisions in Codes and StandardsEn XieAinda não há avaliações

- English RhetoricDocumento1 páginaEnglish RhetoricPhanHathamAinda não há avaliações

- Finite Element Analysis On Crane Girder With Variable Cross Sections Based On ANSYSDocumento6 páginasFinite Element Analysis On Crane Girder With Variable Cross Sections Based On ANSYSPhanHathamAinda não há avaliações

- Finite Element Analysis On Crane Girder With Variable Cross Sections Based On ANSYSDocumento6 páginasFinite Element Analysis On Crane Girder With Variable Cross Sections Based On ANSYSPhanHathamAinda não há avaliações

- Finite Element Analysis On Crane Girder With Variable Cross Sections Based On ANSYSDocumento5 páginasFinite Element Analysis On Crane Girder With Variable Cross Sections Based On ANSYSPhanHathamAinda não há avaliações

- Egg Hatching Poster en 2015Documento1 páginaEgg Hatching Poster en 2015mahmudAinda não há avaliações

- Anugrah Raya: Shear ConnectorDocumento6 páginasAnugrah Raya: Shear ConnectordedeAinda não há avaliações

- Changing The Pump Seals: (All Pumps Except The G1361A Preparative Pump)Documento2 páginasChanging The Pump Seals: (All Pumps Except The G1361A Preparative Pump)sarasaAinda não há avaliações

- List of Activity For HIRA Prep As Per ISO45001Documento6 páginasList of Activity For HIRA Prep As Per ISO45001Mohammad ArifAinda não há avaliações

- Batch Dyeing Process, Batch Dyeing Process For Textiles, Process of Batch DyeingDocumento3 páginasBatch Dyeing Process, Batch Dyeing Process For Textiles, Process of Batch DyeingVipin Singh KandholAinda não há avaliações

- Birdhouse PlansDocumento8 páginasBirdhouse Plansroose1Ainda não há avaliações

- Recycle and Management of Waste Lead Acid BatteriesDocumento9 páginasRecycle and Management of Waste Lead Acid BatteriesJoyce Wm WongAinda não há avaliações

- 6 - Baker Hughes - Glen BengeDocumento21 páginas6 - Baker Hughes - Glen BengegeosedAinda não há avaliações

- Mini Project in Process Equipment Design & Economics Course at IITBDocumento1 páginaMini Project in Process Equipment Design & Economics Course at IITBAman ShahAinda não há avaliações

- PROSEDUR REFRIGERANT QUALITY GUIDANCE-Flame TestDocumento2 páginasPROSEDUR REFRIGERANT QUALITY GUIDANCE-Flame TestAnonymous DFoXVEHIAinda não há avaliações

- Cargo Handling Manual - SOE 12k LEG (01-TECHNICAL - 1304275 - 1 - 01) PDFDocumento283 páginasCargo Handling Manual - SOE 12k LEG (01-TECHNICAL - 1304275 - 1 - 01) PDFМаксим Шабатын100% (2)

- E FSS5 Attm3 Tooling-manual-Lathe Rev1 090330 PDFDocumento9 páginasE FSS5 Attm3 Tooling-manual-Lathe Rev1 090330 PDFonnoAinda não há avaliações

- Technical Paper SiC Ceramic MembranesDocumento5 páginasTechnical Paper SiC Ceramic MembranesEman El DsoukyAinda não há avaliações

- Semi-Detailed Lesson Plan in Tle8 (Productivity, Humility) January 26, 2017Documento3 páginasSemi-Detailed Lesson Plan in Tle8 (Productivity, Humility) January 26, 2017gaea louAinda não há avaliações

- Mepoxe ANewDocumento4 páginasMepoxe ANewHasbi Ashidiqi PAinda não há avaliações

- Commscope Trunk & Distribution Cable ProductsDocumento51 páginasCommscope Trunk & Distribution Cable ProductsMauro Barragan SanchezAinda não há avaliações

- Plastic CollapseDocumento10 páginasPlastic CollapseVijaya Kumar Manikandan100% (1)

- Acroni PDFDocumento15 páginasAcroni PDFIgor GrujićAinda não há avaliações

- FP 238Documento32 páginasFP 238Mahmoud Atia100% (2)

- Expt 3Documento5 páginasExpt 3Debmalya1997Ainda não há avaliações

- 4KN Enuk V3 1Documento8 páginas4KN Enuk V3 1MustaphaMehdiHamamineAinda não há avaliações

- UOP 1006-14 Trace Silicon in Petroleum Liquids by ICP-MSDocumento11 páginasUOP 1006-14 Trace Silicon in Petroleum Liquids by ICP-MSMorteza Sepehran100% (1)

- Coupling Inspection SOP GSE FinalDocumento11 páginasCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- RUD Industrial ChainsDocumento12 páginasRUD Industrial ChainsBenjamin ČakićAinda não há avaliações

- Argus General Brochure V8Documento20 páginasArgus General Brochure V8danieldayettddAinda não há avaliações

- 2016good and ImportantDocumento4 páginas2016good and ImportantMahdi koolivandAinda não há avaliações

- Service Manual: CB 18S CB 27S CB 37SDocumento85 páginasService Manual: CB 18S CB 27S CB 37SMack DieselAinda não há avaliações

- Pile ReportDocumento14 páginasPile ReportChen E LikAinda não há avaliações

- Pyrolysis Presentation - PPTM (Autosaved) .PPTMDocumento13 páginasPyrolysis Presentation - PPTM (Autosaved) .PPTMSoul LyricsAinda não há avaliações

- ASTM D3359-17 - Adhesion TestDocumento9 páginasASTM D3359-17 - Adhesion TestAizacAinda não há avaliações