Escolar Documentos

Profissional Documentos

Cultura Documentos

2511A Sour Gas Brochure English

Enviado por

zaffar731Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

2511A Sour Gas Brochure English

Enviado por

zaffar731Direitos autorais:

Formatos disponíveis

Advanced sealing solutions for critical applications

SOUR GAS

RESISTANT ELASTOMERS

SEALING SOLUTIONS

What is Sour Gas?

Sour gas is a gas stream that contains hydrogen sulfide (H2S), a poisonous gas found in oil and gas wells around the world. H2S is highly

corrosive and will react with and degrade polymers including many types of elastomers. Elastomer seals such as O-rings, gaskets

and custom molded parts for sour service require specialized materials and test information to ensure the seal will meet the service

requirements.

Sour Gas Testing

PPE has developed a number of elastomer materials for the oil, gas and chemical processing industries with

third party testing to a number of international test standards and conditions. Table 2 opposite shows the

PPE elastomer sealing materials that have been tested and certified to the various industry standards for

sour gas resistance.

Sour Gas Test Standards

Two of the most commonly used standards are as follows:

NORSOK M-710 Qualification of non-metallic sealing materials and manufacturers, rev 2 October 2001. Annex A, test media, conditions,

media, and procedures for ageing of elastomeric materials.

ISO 10423 Appendix F.1.13.5.2 sour fluid (FF/HH) Petroleum and natural gas industries Drilling and production equipment Wellhead

and Christmas tree equipment, fourth edition, 2009-12-15.

NORSOK M-710

Annex A

(2% H2S)

NORSOK M-710

Annex A

(25% H2S modified)

ISO 10423

(API 6A)

30%

60%

10%

30%

60%

10%

35%

60%

5%

2% H2S

3% CO2

95% CH4

25% H2S

3% CO2

72% CH4

10% H2S

80% CO2

10% CH4

10% toluene

20% cyclohexane

70% heptane

10% toluene

20% cyclohexane

70% heptane

100% kerosene

100% distilled water

100% distilled water

100% deionized water

Oil phase

Oil phase

Oil phase

Temperature:

Various

from 100C to 200C

Various

from 150C to 175C

177C

Test duration:

8 weeks

8 weeks

160 hours

Test vessel composition:

Gas phase

Oil phase

Water phase

Gas phase composition:

Volume (%)

Oil phase composition:

Volume (%)

Water phase compositon:

Volume (%)

Test specimen location:

Table 1: A summary of sour test conditions available from PPE based on the protocols outlined in the test standards.

Please consult PPE sales or engineering teams for specific details on the upper limit tested on specific grades.

www.prepol.com

Elastomer Materials Tested to Sour Gas Standards

Material Grade

Description

PPE V74C

75 durometer, low compression set FKM

PPE V76F

71 durometer, high fluorine FKM

EnDura V91J

90 durometer, versatile FKM

EnDura V91K

90 durometer, low temperature FKM

EnDura V91A

90 durometer, ultra-low temperature FKM

EnDura A90H

90 durometer, Aflas1 based FEPM

EnDura Z95X

90 durometer, medium ACN, HNBR

EnDura Z85L

85 durometer, low ACN, low temperature HNBR

Perlast G92E

90 durometer, FFKM

Perlast ICE G90LT

NORSOK

M710

(2%)

NORSOK

M710ww

(25%)

ISO

10423

(API 6A)

90 durometer, low temperature FFKM

Table 2: A summary of elastomer materials tested to sour gas standards. Please consult with PPE sales and engineering teams for available

certifications or test data. 1Aflas is a trademark of the Asahi Glass Company.

Custom Sealing Solutions

PPE specializes in providing fully customized sealing solutions for critical oil and gas applications. By

pushing the boundaries of elastomer technology, in both high temperature and high concentration

sour gas, PPE can demonstrate the capabilities of its elastomer materials, which are often beyond

the parameters of standard tests. The assurance this information provides is crucial when specifying

materials for sealing valves, pumps, compressors, and other oilfield equipment.

PPE has materials scientists and sealing engineers available to answer questions and develop a

customized sealing solution for your sour gas application.

Case study: H2S Resistant Valve Seals

A major oil and gas operator required sour gas resistant seals for critical valves in a large processing plant. HNBR

seals were being used in the valves but during scheduled maintenance they had shown signs of incompatibility with

sour gas and presented a leak risk. Replacing the seals with HNBR again was not acceptable to the operator.

PPEs Perlast G92E (FFKM) material was selected for its overall fluid resistance and its outstanding resistance to

sour gas, backed up by various third party test reports including NORSOK M-710 Annex A in both 2% and 25% H2S.

The operator needed the O-rings quickly to avoid costly shutdowns. PPE was able to manufacture and deliver a range

of sizes at short notice, enabling the operator to complete the valve installation on time.

For further information or to download test reports, certificates and material datasheets visit the PPE

website: www.prepol.com/h2s

SEALING SOLUTIONS

Advanced sealing solutions for critical applications

Europe, Middle East & Africa

Precision Polymer Engineering Ltd

Head Office

Greenbank Road

Blackburn BB1 3EA

England

Americas

PPE LLC

4702 N. Sam Houston Parkway West

Suite 100

Houston TX 77086

USA

Asia Pacific

Precision Polymer Engineering LLC

RM 3502-3504, Zhao Feng Plaza

No. 1027 Chang Ning Road

Shanghai 200050

China

T: +44 1254 295400

F: +44 1254 680182

E: prepol.sales@idexcorp.com

T: +1 713 482 0123

F: +1 713 623 2332

E: prepol.sales-usa@idexcorp.com

T: +86 21 5241 5599 - 113

F: +86 21 5241 8339

E: prepol.sales-asia@idexcorp.com

The ultimate perfluoroelastomers for sealing

applications where chemical resistance and

high temperature performance are critical.

Exceptional perfluoroelastomers for

extreme low temperature sealing

applications.

The ultimate range of elastomers for

sealing applications in the worlds most

aggressive high pressure environments

Local PPE sales agent:

www.prepol.com

Doc. 2511A

SEALING SOLUTIONS

Você também pode gostar

- Modeling, Control, and Optimization of Natural Gas Processing PlantsNo EverandModeling, Control, and Optimization of Natural Gas Processing PlantsNota: 5 de 5 estrelas5/5 (1)

- M-622 Fabriction and Installation of GRP Piping System Rev1Documento20 páginasM-622 Fabriction and Installation of GRP Piping System Rev1vlong3003Ainda não há avaliações

- Oring Guide Europe Ord 5712ukDocumento0 páginaOring Guide Europe Ord 5712ukramchandra rao deshpandeAinda não há avaliações

- NORSOK M710 Approved MaterialsDocumento6 páginasNORSOK M710 Approved MaterialsEventide AccanoveAinda não há avaliações

- Parker O RingDocumento0 páginaParker O RingRazvan C GoranAinda não há avaliações

- BUL Parker IHP Welding enDocumento20 páginasBUL Parker IHP Welding enMuhammad FerialAinda não há avaliações

- AOC Corrosion Guide Listing UpdatedDocumento32 páginasAOC Corrosion Guide Listing UpdatedYap HS100% (1)

- Elastomer PropertiesDocumento72 páginasElastomer PropertiesBashu PoudelAinda não há avaliações

- M-001 2014 Materials SelectionDocumento32 páginasM-001 2014 Materials Selectionjar_2Ainda não há avaliações

- Pde3350 GB PDFDocumento148 páginasPde3350 GB PDFstrafforAinda não há avaliações

- NORSOK L-002 Edition 3, July 2009 PDFDocumento36 páginasNORSOK L-002 Edition 3, July 2009 PDFKarthick VenkatswamyAinda não há avaliações

- CDI NORSOK Testing Elastomers Tech Report WebDocumento2 páginasCDI NORSOK Testing Elastomers Tech Report WebwholenumberAinda não há avaliações

- SF6 Gas DetailsDocumento2 páginasSF6 Gas DetailsMohd ShahidAinda não há avaliações

- Naf S 125 15 03 07Documento38 páginasNaf S 125 15 03 07Sherif AdelAinda não há avaliações

- Well Testing Recommended PracticesDocumento40 páginasWell Testing Recommended Practicessajithv78100% (1)

- Standardization Document, SEFA-7 Spec Gas EquipmentDocumento5 páginasStandardization Document, SEFA-7 Spec Gas Equipmentveronica880Ainda não há avaliações

- Valves Overview Service enDocumento12 páginasValves Overview Service enBalraj PadmashaliAinda não há avaliações

- V 91 ADocumento1 páginaV 91 AHo Minh VietAinda não há avaliações

- Engine Oil Volatility Noack Evaporation MethodDocumento5 páginasEngine Oil Volatility Noack Evaporation MethodAvinash Gamit100% (1)

- Well Testing Systems: Norsok StandardDocumento40 páginasWell Testing Systems: Norsok StandardBoris Zaslichko100% (1)

- O Ring and Groove DeatislDocumento164 páginasO Ring and Groove DeatislAjith KumarAinda não há avaliações

- TrueUnion - True Union Ball ValveDocumento4 páginasTrueUnion - True Union Ball ValveKarthick VenkateshAinda não há avaliações

- M-001 - Materials Selection (Rev. 4, Aug. 2004)Documento34 páginasM-001 - Materials Selection (Rev. 4, Aug. 2004)AliNaqviAinda não há avaliações

- Sandpiper HDF2Documento6 páginasSandpiper HDF2samago20Ainda não há avaliações

- Oil and Gas Guide James WalkerDocumento72 páginasOil and Gas Guide James WalkermtfrvtAinda não há avaliações

- OMAE2011-49: Qualification of Multi-Composite Hoses For Sts LNG TransferDocumento7 páginasOMAE2011-49: Qualification of Multi-Composite Hoses For Sts LNG TransferMuhammad YasinAinda não há avaliações

- HTTP WWW - Standard NorsokDocumento36 páginasHTTP WWW - Standard NorsokAlina AlecuAinda não há avaliações

- Chemical Resistance GuideDocumento36 páginasChemical Resistance GuideHeiner PalaciosAinda não há avaliações

- Materials and Corrosion For Sour ServiceDocumento60 páginasMaterials and Corrosion For Sour ServiceAnonymous QSfDsVxjZ100% (5)

- New Material Seals Better On HVOF CoatingsDocumento2 páginasNew Material Seals Better On HVOF Coatingssandbad2100% (2)

- Aeroshell Fluid 41Documento2 páginasAeroshell Fluid 41Anonymous oAbjbl4HAinda não há avaliações

- Catalog O Ring Guide ODE5712 GB 0704Documento88 páginasCatalog O Ring Guide ODE5712 GB 0704Ashwanth RameshAinda não há avaliações

- Accumulator EHVDocumento19 páginasAccumulator EHVRobert PradanaAinda não há avaliações

- 055 - Guidelines For NDT of GRP Pipe Systems and TanksDocumento96 páginas055 - Guidelines For NDT of GRP Pipe Systems and Tanksabdulwahabbaba67% (3)

- GMPHOM CatalogueDocumento42 páginasGMPHOM CatalogueLukarsa2013Ainda não há avaliações

- BUL Marine 3000 - 0409Documento4 páginasBUL Marine 3000 - 0409Muhammad FerialAinda não há avaliações

- SPE-181275-MS Successful Development and Implementation of 9 5/8 Subsurface Safety Valve For High Pressure, High Rate Gas WellsDocumento11 páginasSPE-181275-MS Successful Development and Implementation of 9 5/8 Subsurface Safety Valve For High Pressure, High Rate Gas WellsLuis David Concha CastilloAinda não há avaliações

- Material SelectionDocumento34 páginasMaterial SelectionmatsuruAinda não há avaliações

- Norsok Standard P-001: Edition 5, Sep. 2006Documento26 páginasNorsok Standard P-001: Edition 5, Sep. 2006Đào_hải_10Ainda não há avaliações

- Accumulator PP EHV 10-330 90Documento38 páginasAccumulator PP EHV 10-330 90yao nestorAinda não há avaliações

- Norsok M001 MaterialsDocumento31 páginasNorsok M001 MaterialsbreeeeezzzzzeAinda não há avaliações

- Cryogenics Safety Manual: A Guide to Good PracticeNo EverandCryogenics Safety Manual: A Guide to Good PracticeAinda não há avaliações

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesNo EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesNota: 5 de 5 estrelas5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsAinda não há avaliações

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsNo EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsNota: 3.5 de 5 estrelas3.5/5 (14)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesNo EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesNota: 3.5 de 5 estrelas3.5/5 (3)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionNo EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionNota: 4.5 de 5 estrelas4.5/5 (16)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryAinda não há avaliações

- How to prepare Welding Procedures for Oil & Gas PipelinesNo EverandHow to prepare Welding Procedures for Oil & Gas PipelinesNota: 5 de 5 estrelas5/5 (1)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesNo EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesAinda não há avaliações

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNo EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNota: 5 de 5 estrelas5/5 (1)

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldNo EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldNota: 3 de 5 estrelas3/5 (2)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingNo EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingAinda não há avaliações

- 2511A Sour Gas Brochure EnglishDocumento4 páginas2511A Sour Gas Brochure Englishzaffar731Ainda não há avaliações

- Pages From HVAC Design Handbook (301 450)Documento150 páginasPages From HVAC Design Handbook (301 450)zaffar731Ainda não há avaliações

- PIP ARS08390 Blast Resistant Doors FramesDocumento22 páginasPIP ARS08390 Blast Resistant Doors Frameszaffar731Ainda não há avaliações

- 4055 EFX Quick Compliance Guide BookletDocumento28 páginas4055 EFX Quick Compliance Guide Bookletzaffar731Ainda não há avaliações

- TELEMECANIQUE ContactorDocumento252 páginasTELEMECANIQUE Contactorridzuan-othman-2044100% (1)

- Fish Medicine HandbookDocumento61 páginasFish Medicine HandbookGrazyella Yoshida100% (2)

- Code of Federal RegulationsDocumento14 páginasCode of Federal RegulationsdiwolfieAinda não há avaliações

- NiftDocumento3 páginasNiftMegha Nair PillaiAinda não há avaliações

- Slide 7 PV NewDocumento74 páginasSlide 7 PV NewPriyanshu AgrawalAinda não há avaliações

- Reviewer in PE&H 1st Quarter 18-19Documento7 páginasReviewer in PE&H 1st Quarter 18-19rhex minasAinda não há avaliações

- NGCP - Procedures and Requirements For Energy ProjectsDocumento17 páginasNGCP - Procedures and Requirements For Energy ProjectspurplebasketAinda não há avaliações

- Shift Registers NotesDocumento146 páginasShift Registers NotesRajat KumarAinda não há avaliações

- QSMT Chapter 1Documento5 páginasQSMT Chapter 1Rachelle Mae SalvadorAinda não há avaliações

- Auto CadDocumento67 páginasAuto CadkltowerAinda não há avaliações

- WT Capability Statement PE 2020Documento1 páginaWT Capability Statement PE 2020Muhannad SuliemanAinda não há avaliações

- Classical Theories of Economic GrowthDocumento16 páginasClassical Theories of Economic GrowthLearner8494% (32)

- AMiT Products Solutions 2022 1 En-SmallDocumento60 páginasAMiT Products Solutions 2022 1 En-SmallMikhailAinda não há avaliações

- I.A.-1 Question Bank EM-3 (Answers)Documento11 páginasI.A.-1 Question Bank EM-3 (Answers)UmmAinda não há avaliações

- 20235UGSEM2206Documento2 páginas20235UGSEM2206Lovepreet KaurAinda não há avaliações

- Myers Briggs Type Indicator-2Documento1 páginaMyers Briggs Type Indicator-2api-261818438Ainda não há avaliações

- Hypothesis Testing Random MotorsDocumento8 páginasHypothesis Testing Random MotorsLinn ArshadAinda não há avaliações

- TOEFL-Reading Question Type Definitions and ExplanationDocumento5 páginasTOEFL-Reading Question Type Definitions and ExplanationSamara SampaioAinda não há avaliações

- International Supply Chain ManagementDocumento2 páginasInternational Supply Chain ManagementPRASANT KUMAR SAMALAinda não há avaliações

- CE-23113-SP-902-R01-00 Asset SpecificationDocumento14 páginasCE-23113-SP-902-R01-00 Asset SpecificationСветлана ФайберAinda não há avaliações

- HAFOMA Presentation 2022 ENGDocumento9 páginasHAFOMA Presentation 2022 ENGVeljko MilicevicAinda não há avaliações

- Sustainable Development Precautionary PR 2Documento12 páginasSustainable Development Precautionary PR 2PramodAinda não há avaliações

- Cross Border Data Transfer Consent Form - DecemberDocumento3 páginasCross Border Data Transfer Consent Form - DecemberFIDELIS MUSEMBIAinda não há avaliações

- Analysis Chart - Julie Taymor-ArticleDocumento3 páginasAnalysis Chart - Julie Taymor-ArticlePATRICIO PALENCIAAinda não há avaliações

- Mediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsDocumento15 páginasMediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsWitty MindsAinda não há avaliações

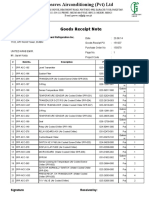

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocumento4 páginasGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanAinda não há avaliações

- ANNEXESDocumento6 páginasANNEXESKyzer Calix LaguitAinda não há avaliações

- Unit 13 Dialogue Writing: ObjectivesDocumento8 páginasUnit 13 Dialogue Writing: ObjectivesAkg GuptAinda não há avaliações

- Contribution of Medieval MuslimDocumento16 páginasContribution of Medieval Muslimannur osmanAinda não há avaliações

- ResumeDocumento3 páginasResumeAstig Kuging63% (8)

- Unit 7 ActivitiesDocumento8 páginasUnit 7 ActivitiesleongeladoAinda não há avaliações

- Paper Ed Mid TermDocumento2 páginasPaper Ed Mid Termarun7sharma78Ainda não há avaliações