Escolar Documentos

Profissional Documentos

Cultura Documentos

PIB2030 275 Series PDF

Enviado por

Rached DouahchuaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PIB2030 275 Series PDF

Enviado por

Rached DouahchuaDireitos autorais:

Formatos disponíveis

275 Series

Integrated Pump Mounted Electric Actuator

1

Selection Chart

Connectors & Harnesses

Actuator Type

24

VDC

Product No.

Multi

VDC

Connector

MIL

Modifications

Heavy Duty

Bearing

Retention

Packard

Position

Feedback

Sensor

Connectors

System

Voltage

Oil Drain

Fitting

ACB275

ACB275C

Harnesses

ACB275H

ACE275H-24

ACE275HD-24

ACE275J-24

ACE275K

ACB275F

Connector

Description

ACB, ADB

EC1000

Military - Straight

ACB, ADB

EC1010

Military -90

ADD, ACE

EC1300

Packard Matting Connector

ADD, ACE

EC1310

Packard Replacement Connector

ACE275K

EC1515

AB Position Sensor (Requires

EC1300)

ACB, ADB

CH1203

Military - Straight 12 ft [3.6m]

ACB, ADB

CH1210

Military - 90 12 ft [3.6m]

ADD

CH1215

Packard 6 ft. [1.8m]

ACE275K

CH1515

AB Position

Sensor 6 ft [1.8m]

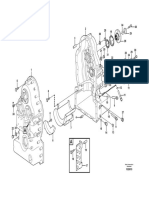

Outlines & Dimensions

Dimensions: [mm]

in

View 2

Additional Notes

ACB275C

Designed specifically for MTU with a sand cast housing and

aluminum cover plate. Installation requires bearing retainer kit

KT3000-MT or KT7001-MT / Contact GAC.

ACE275J-24

Features a compression style oil drain fitting that accepts a 10

mm diameter tube, for engines with high crankcase pressure.

KT278-1

Optional installation kit for Bosch RP21 Pump

View 1

90.50

3.56

46.75

1.84

46.75

1.84

90.50

3.56

[86.61]

3.41

29.67

1.17

29.67

1.17

[86.61]

3.41

Camshaft Bearing Retainer Kits

Bosch P3000 Pump

KT275

Bosch P7000 Pump

KT276

103.71

4.08

PERFORMANCE

13.2 lbf. Max (58.7 N)

Operating Stroke

0.79 in. Max (20mm)

Operating Voltage

29.03

1.14

12 or 24 VDC

Normal Operating Current

3.0 Amps @ 12 VDC

1.5 Amps @ 24 DVC

Maximum Current (Continuous)

9.0 Amps @ 12 VDC

4.5 Amps @ 24 VDC

Relative Humidity

All Surface Finishes

38.62

1.52

29.03

1.14

109.98

4.33

109.98

4.33

Military connector shown. ACE

46.75

Versions have a 16in [400mm]

1.84

harness which29.67exits from the

1.17

bottom of the actuator.

19.05 164.34

0.75 6.47

164.34

6.47

[86.61]

3.41

3.56

41.52

1.63

19.05

0.75

14.78

0.58

See Outline & Dimensions

12 lb (5.4 kg)

19.05

.75

14.78

0.58

46.99

1.85

68.85

2.71

4 X .25

26.72

1.05

Dimensions

31.65

1.25

19.05

R .75

41.52

1.63

23.53

0.93

Fungus Proof and Corrosion Resistant

Appx. Weight

38.62

1.52

31.65

1.25

68.28

2.69

35.97

1.42

[57.15]

2.25

Up to 100%

PHYSICAL

Mounting

103.71

4.08

NOTE

90.50

-40F to 195F (-40C to +90C)

[112.63]

4.43

[112.63]

4.43

View 3

ENVIRONMENT

Operating Temperature Range

MIL CONNECTOR SHOWN

19.05

.75

ELECTRICAL POWER INPUT

23.53

0.93

23.53

0.93

MIL CONNECTOR SHOWN

6

2

68.28

2.69

35.97

1.42

180.80

7.12

180.80

7.12

SPECIFICATIONS

Force

26.72

1.05

26.72

1.05

[57.15]

2.25

[57.15]

2.25

MIL CONNECTOR SHOWN

65.00

2.56

[112.63]

4.43

180.80

7.12

38.62

1.52

103.71

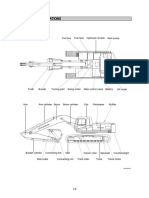

Directly on RP, P 3000 and P 7000 Bosch

4.08

fuel injection pumps in place of the mechanical governor. Requires camshaft bearing

retainer kit. See section 4 for more info.

41.52

1.63

19.05

R .75

31.65

1.25

65.96

2.60

29.13

1.15

19.05

.75

Reliability

Testing Agency

100% CE, RoHs, BV, Lloyd's Register, DNV/

29.03

GL

1.14

109.98

4.33

164.34

6.47

19.05

0.75

14.78

0.58

46.99

1.85

68.85

2.71

55.17

2.17

275 Series Integrated Pump Mounted Electric Actuator 07.26.16 PIB 2030 G

2016 Copyright All Rights Reserved

Link Assembly

INSTALLING THE ACTUATOR

VIEW 1

1.

Remove the four screws that fasten the top cover (with label) to the actuator and expose the linkage used to connect the actuator to the fuel rack.

2.

Remove the screw that attaches the ball bearing rod end to the lever. Do

not remove or loosen the lever from the actuator shaft.

3.

The opposite end of the linkage must be attached to the top of the fuel

rack with the screw and lock nut provided. Tighten the screw and nut

securely to 4.0 4.5 Nm. The linkage is preset to a specific length and

locked. Any adjustment of rack travel must be made using the slot on the

actuator lever. If linkage length adjustment is needed, consult with GAC or

its distributors first.

4.

The gasket supplied in the installation parts kit fits between the actuator

and pump. Clean the mounting surfaces of the actuator and the pump on

one side of the gasket to the actuator. A small amount of gasket sealant,

such as RTV silicone, is recommended for the pump side of the gasket.

5.

Loosen the two M8 hex nuts that hold the lower mounting bar to the

actuator.

VIEW 2

6.

Place the actuator over the rack and linkage. Fit the lower part of the

actuator onto the bearing retainer plate. Attach the actuator to the pump

with four M5 22mm screws and washers through the upper mounting

holes. Tighten these screws securely to 9 Nm so that the gasket is compressed evenly.

7.

Push the lower mounting bar against the bearing retainer plate and tighten the two M6 nuts onto the studs that are in the pump to 10 Nm.

8.

Tighten the two M8 nuts on the studs that hold the mounting bar onto the

actuator to 20 Nm.

9.

The linkage attached to the fuel rack must be free when moved from shut

off to full fuel. Pull the linkage fully away from the pump. Push the linkage

1mm toward the pump and attach it to the slot in the actuator lever with

the M5 screw, two flat washers and locking nut. Tighten securely to 4 Nm.

The fuel rack should be 1mm or less away from its internal physical stop.

The zero fuel stop of the system will now be provided by the actuator

instead of inside the fuel pump.

VIEW 3

10. Manually move the actuator lever and linkage through its full range of

motion. No binding should be noticed. The actuator operating lever &

assembly must not contact the inside of the housing.

HEX BOLT, M6 x 25

BUTTON SOCKET CAP SCREW, M5 X20

HEX NUT, M5

HEX LOCK NUT, M5

THREADED ROD, M5 X 40

LOCK WASHER, M5

LOCK NUT, M6

FLAT WASHER M6

11. A maximum fuel stop adjustment is located on the actuator lever. The set

screw and lock nut may be adjusted to limit the travel of the fuel rack.

12. Push the linkage to the full fuel position and operate the manual shut

off to insure that the shut off lever correctly contacts the stop plate and

forces the linkage to zero fuel.

13. After the maximum fuel delivery has been adjusted on an engine or dynamometer, the top cover may be installed. Place the special sealing screw

in the lower left hand corner. Lockwire the two covers together to prevent

tampering if available.

INSTALLATION

If the pump is equipped with a mechanical governor, it must be

removed. GAC recommends that the modification be done by a

qualified fuel injection shop. The following steps are a generalized procedure.

WARNING

PREPARING THE FUEL INJECTION PUMP

1.

Remove the rear housing of the mechanical governor and disconnect the

governor assembly from the fuel rack.

2.

Remove the flyweight assembly.

3.

Remove the intermediate governor housing, this leaves only the rack and

camshaft protruding from the housing.

4.

Install the appropriate camshaft bearing retainer kit. This kit includes the

correct shims to ensure that the retainer plate rests on the bearing and

also prevents oil from leaking out around the camshaft. See page one for

retainer kits. See PIB2031 for retainer kit installation details.

5. Located on the pump between the fuel rack and the camshaft, the oil hex

plug may be removed to allow any oil, leaking from the fuel rack, to drain

back into the pump.

NOTE

Removal of oil from the mechanical governor is required.

2

275 Series Integrated Pump Mounted Electric Actuator 07.26.16 PIB 2030 G

2016 Copyright All Rights Reserved

Wiring

The engine should be equipped with an independent shut

down device to prevent overspeed which can cause equipment damage or personal injury.

The EC1000 or EC1010 electrical connector that mates with the actuator must

be pre-wired in a configuration to match the system voltage. Cable Harnesses

CH1203, CH1215, & CH1515 are available from GAC. Refer to Connectors & Harnesses in the Specifications Section.

CAUTION

If the governor system fails to operate, make the following tests at the actuator

mounted connector while moving the actuator through its stroke.

Cable Harness

#16 Gauge (1.5 mm)

12 Volt System

Troubleshooting test

#16 Gauge (1.5 mm)

24 Volt System

Energize the actuator to full fuel (follow steps in control unit publication and

manually move the actuator through its range using the stop lever. No binding

or sticking should occur. If the actuator passes three tests, the problem is elsewhere in the system. Refer to the troubleshooting section the speed control

units literature.

Fabricate a cable harness to connect the speed control unit to the actuator.

The recommended wire size of the cable harness is:

Larger gauge wire will be necessary for cable lengths greater than

12ft. (4m).

NOTE

TROUBLESHOOTING

MILITARY Connector

MILITARY Connector

MEASURING THE RESISTANCE

12 Volt - ACB275H Only

24 Volt - All MIL

to Actuator Terminal A

on Speed Control Unit

F

E

ADD RESISTOR FOR

32 V

OPERATION ONLY

ACB275C & ACB275H WIRING

(12V) 2.5 Ohms

B to D

(12V) 2.5 Ohms

A to D

(24V) 4.7 Ohms

A to Housing

Infinity

C to Housing

Infinity

E to F

Infinity

FEEDBACK SENSOR

(Female Receptacle)

* SEE NOTE BELOW

B

To

For 32 V operation, wire the connector

as shown for

24 V operation

To

Control Unit

E a 1.5 ohm, 25 V resistor in series with

E

Control Unit

and add

pin

A of the actuaC

D

D C

tor connector and the corresponding output terminal of the speed control unit.

NOTE

12 VOLT OPERATION

A TO C

B TO D

A AND D TO ACTUATOR TERMINALS OF

SPEED CONTROL UNIT

Packard Connector

MEASURING THE RESISTANCE

FeedBack Sensor24 VOLT OPERATION

ADB275F / ACB275F WIRING

Harness

B TO C

A AND D TO ACTUATOR TERMINALS

ADB275F / ACB275F WIRING ONLY

RESISTANCE

A to C

ACE275K WIRING

to Actuator Terminal B

on Speed Control Unit

F

TERMINALS

TO SPEED CONTROL UNIT

ACTUATOR TERMINALS

A

SENSOR GROUND

SENSOR SIGNAL TO SPEED CONTROL UNIT

POSITION SENSOR TERMINALS

TERMINALS

RESISTANCE

A to B (24V)

4.7 Ohms

A to Housing

Infinity

B to Housing

Infinity

SENSOR POWER

(14 VDC MAX)

SHIELD GROUND

ACE275K Only

ACE275K WIRING

HARNESS

FEEDBACK SENSOR

(Female Receptacle)

PACKARD

CONNECTOR

Harness

PIN

SIGNAL

+5V Input

GND

OUT (0.5-4.5V)

Packard Connector

AB

B

PACKARD

CONNECTOR

AB

275 Series Integrated Pump Mounted Electric Actuator 07.26.16 PIB 2030 G

2016 Copyright All Rights Reserved

Você também pode gostar

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento32 páginasInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768CarlosAinda não há avaliações

- Service Bulletin: More Care. Built inDocumento5 páginasService Bulletin: More Care. Built inAnthony Pozo100% (2)

- 620520714-Volvo-g900-Modelos-PDF (1) - 316-345Documento30 páginas620520714-Volvo-g900-Modelos-PDF (1) - 316-345Rached DouahchuaAinda não há avaliações

- Caterpillar SIS 2018 -اطلاعات PDFDocumento120 páginasCaterpillar SIS 2018 -اطلاعات PDFmehdi kamali50% (2)

- 10 11648 J Her 20200505 13Documento13 páginas10 11648 J Her 20200505 13Rached DouahchuaAinda não há avaliações

- Krok 05-18Documento312 páginasKrok 05-18Purwa Rane100% (1)

- Manual For The Application of Cold Milling Machines: Edition: January 2004Documento164 páginasManual For The Application of Cold Milling Machines: Edition: January 2004nenad100% (1)

- Krok 1 Medicine 2019 Online KitaabsDocumento38 páginasKrok 1 Medicine 2019 Online KitaabsRached DouahchuaAinda não há avaliações

- Códigos de Falha Escavadeira HyundaiDocumento8 páginasCódigos de Falha Escavadeira HyundaiGuemep Guemep100% (3)

- Group 3 Swing Device ( #0408) : 1. StructureDocumento22 páginasGroup 3 Swing Device ( #0408) : 1. Structuredeniden2013Ainda não há avaliações

- Group 4 Travel Device: 1. ConstructionDocumento7 páginasGroup 4 Travel Device: 1. ConstructionRached DouahchuaAinda não há avaliações

- Section 1 GeneralDocumento10 páginasSection 1 GeneralSergey MovchanAinda não há avaliações

- 4 2 Pages 16 PDFDocumento1 página4 2 Pages 16 PDFRached Douahchua100% (1)

- Transaction - 2020-04-22 15 - 15 - 04Documento1 páginaTransaction - 2020-04-22 15 - 15 - 04Rached DouahchuaAinda não há avaliações

- JCB 4cx TRANSMISSION PDFDocumento1 páginaJCB 4cx TRANSMISSION PDFRached DouahchuaAinda não há avaliações

- Foreword: 1. StructureDocumento8 páginasForeword: 1. Structuredeniden2013Ainda não há avaliações

- Group 3 Swing Device ( #0408) : 1. StructureDocumento22 páginasGroup 3 Swing Device ( #0408) : 1. Structuredeniden2013Ainda não há avaliações

- 1 2 PDFDocumento19 páginas1 2 PDFRached DouahchuaAinda não há avaliações

- R210-7 Anti Restart System PDFDocumento1 páginaR210-7 Anti Restart System PDFarfa ujiantoAinda não há avaliações

- Section 6 TroubleshootingDocumento4 páginasSection 6 TroubleshootingRached DouahchuaAinda não há avaliações

- Section 1 GeneralDocumento10 páginasSection 1 GeneralSergey MovchanAinda não há avaliações

- Section 3 Hydraulic SystemDocumento3 páginasSection 3 Hydraulic Systemdeniden2013Ainda não há avaliações

- GROUP 6 RCV PEDAL STRUCTURE AND OPERATIONDocumento6 páginasGROUP 6 RCV PEDAL STRUCTURE AND OPERATIONdeniden2013Ainda não há avaliações

- Contents PDFDocumento2 páginasContents PDFRached DouahchuaAinda não há avaliações

- Section 3 Hydraulic SystemDocumento3 páginasSection 3 Hydraulic Systemdeniden2013Ainda não há avaliações

- 2 2 PDFDocumento25 páginas2 2 PDFRached DouahchuaAinda não há avaliações

- Group 4 Travel Device: 1. ConstructionDocumento7 páginasGroup 4 Travel Device: 1. ConstructionRached DouahchuaAinda não há avaliações

- Códigos de Falha Escavadeira HyundaiDocumento8 páginasCódigos de Falha Escavadeira HyundaiGuemep Guemep100% (3)

- Group 5 RCV Lever: 1. StructureDocumento7 páginasGroup 5 RCV Lever: 1. StructureالمهندسوليدالطويلAinda não há avaliações

- Pump Structure and FunctionsDocumento42 páginasPump Structure and FunctionsRached Douahchua100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Obiafatimajane Chapter 3 Lesson 7Documento17 páginasObiafatimajane Chapter 3 Lesson 7Ayela Kim PiliAinda não há avaliações

- School Quality Improvement System PowerpointDocumento95 páginasSchool Quality Improvement System PowerpointLong Beach PostAinda não há avaliações

- Device Interface Device Type (Router, Switch, Host) IP Address Subnet Mask Default GatewayDocumento2 páginasDevice Interface Device Type (Router, Switch, Host) IP Address Subnet Mask Default GatewayRohit Chouhan0% (1)

- Restructuring Egypt's Railways - Augst 05 PDFDocumento28 páginasRestructuring Egypt's Railways - Augst 05 PDFMahmoud Abo-hashemAinda não há avaliações

- Honors Biology Unit 2 - Energy Study GuideDocumento2 páginasHonors Biology Unit 2 - Energy Study GuideMark RandolphAinda não há avaliações

- Liber Chao (Final - Eng)Documento27 páginasLiber Chao (Final - Eng)solgrae8409100% (2)

- Symmetry (Planes Of)Documento37 páginasSymmetry (Planes Of)carolinethami13Ainda não há avaliações

- PREMIUM BINS, CARDS & STUFFDocumento4 páginasPREMIUM BINS, CARDS & STUFFSubodh Ghule100% (1)

- Socially Responsible CompaniesDocumento2 páginasSocially Responsible CompaniesItzman SánchezAinda não há avaliações

- Username: Password:: 4193 Votes 9 Days OldDocumento6 páginasUsername: Password:: 4193 Votes 9 Days OldΘώμηΜπουμπαρηAinda não há avaliações

- 10 Slides For A Perfect Startup Pitch DeckDocumento6 páginas10 Slides For A Perfect Startup Pitch DeckZakky AzhariAinda não há avaliações

- EE290 Practice 3Documento4 páginasEE290 Practice 3olgaAinda não há avaliações

- AtmDocumento6 páginasAtmAnkit JandialAinda não há avaliações

- Job Description Support Worker Level 1Documento4 páginasJob Description Support Worker Level 1Damilola IsahAinda não há avaliações

- ASTM D256-10 - Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsDocumento20 páginasASTM D256-10 - Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsEng. Emílio DechenAinda não há avaliações

- Living Nonliving DeadDocumento11 páginasLiving Nonliving DeadArun AcharyaAinda não há avaliações

- The Learners Demonstrate An Understanding Of: The Learners Should Be Able To: The Learners Should Be Able ToDocumento21 páginasThe Learners Demonstrate An Understanding Of: The Learners Should Be Able To: The Learners Should Be Able ToBik Bok50% (2)

- Chapter 1: The Critical Role of Classroom Management DescriptionDocumento2 páginasChapter 1: The Critical Role of Classroom Management DescriptionJoyce Ann May BautistaAinda não há avaliações

- Micropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldDocumento8 páginasMicropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldIJBSS,ISSN:2319-2968Ainda não há avaliações

- Conceptual FrameworkDocumento24 páginasConceptual Frameworkmarons inigoAinda não há avaliações

- Translation EquivalenceDocumento6 páginasTranslation EquivalenceJamal Anwar TahaAinda não há avaliações

- Cianura Pentru Un Suras de Rodica OjogDocumento1 páginaCianura Pentru Un Suras de Rodica OjogMaier MariaAinda não há avaliações

- Sekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Documento11 páginasSekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Rohana YahyaAinda não há avaliações

- Reflection Paper #1 - Introduction To Action ResearchDocumento1 páginaReflection Paper #1 - Introduction To Action Researchronan.villagonzaloAinda não há avaliações

- Robocon 2010 ReportDocumento46 páginasRobocon 2010 ReportDebal Saha100% (1)

- Um 0ah0a 006 EngDocumento1 páginaUm 0ah0a 006 EngGaudencio LingamenAinda não há avaliações

- Machine Spindle Noses: 6 Bison - Bial S. ADocumento2 páginasMachine Spindle Noses: 6 Bison - Bial S. AshanehatfieldAinda não há avaliações

- Furnace ITV Color Camera: Series FK-CF-3712Documento2 páginasFurnace ITV Color Camera: Series FK-CF-3712Italo Rodrigues100% (1)

- Post Marketing SurveillanceDocumento19 páginasPost Marketing SurveillanceRamanjeet SinghAinda não há avaliações

- CGSC Sales Method - Official Sales ScriptDocumento12 páginasCGSC Sales Method - Official Sales ScriptAlan FerreiraAinda não há avaliações