Escolar Documentos

Profissional Documentos

Cultura Documentos

4 R 4

Enviado por

JAGADEESHTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

4 R 4

Enviado por

JAGADEESHDireitos autorais:

Formatos disponíveis

Q: What is 'Blister Copper'?

(2 Marks)

A: When copper matte is heated with hot air and sand, 98% pure

copper is formed. Due to evolution of SO2 gas, solidified Cu

Chemistry

Surface Chemistry, Metallurgy

4 Marks Questions

Q: What is Catalysis? How is catalysis classified? Give one example for each type.

A: The phenomenon in which a small quantity

of substance, which can alter the rate of a

chemical reaction but its mass and chemical

nature remain unchanged after the reaction.

Homogeneous Catalysis: The catalysis in

which reactants and catalyst are in the same

phase.

NO(g)

Eg: 2SO2 (g) + O2 (g)

2SO3

Heterogeneous Catalysis: The catalysis in

which reactants and catalyst are in different

phases.

Eg: N2 (g) + 3H2 (g)

Fe(S)

2NH3

Q: What are 'emulsions'? Classify them with 2

examples each.

A: The colloidal systems in which both the

Dispersed Phase (D.P.) and Dispersion

Medium (D.M.) are in liquid phase.

Oil in water type: DP is oil and DM is water.

Eg: Vanishing cream, Milk

Water in oil type: DP is water and DM is oil.

Eg: Cold cream, Butter

Q: Give any 4 differences between physisorption and chemisorption.

A:

Physisorption

Chemisorption

1) Multi layered at

Unilayered

high pressure.

2) Caused by Vander

Waals forces.

Caused by chemical bonds.

3) Low temperature is

favoured.

High temperature is

favoured.

4) Reversible in nature

Irreversible

Q: Explain the terms:

a) Tyndal effect b) Brownian movement

c) Peptization

d) Coagulation

A: a) The phenomenon of scattering of light by

colloidal particles in all directions and formation of bright glowing tyndal cones.

b) The continuous rapid zig-zag movement

by colloidal particles in the dispersion

medium.

c) The phenomenon of conversion of precipitate when electrolyte is added into colloidal solution.

d) The process of setting down of colloidal

particles due to neutralisation of charge

when electrolyte is added to it.

2 Marks Questions

Q: Give the Composition of Brass & German

Silver.

A: Brass: 60% Cu & 40% Zn

German Silver: 25 - 40% Cu, 25 - 35% Zn,

40 - 50% Ni

Q: What is the role of Cryolite in the metallurgy

of Al?

A: To increase conductivity

To decrease M.P. of electrolytic mixture.

has blister appearance.

2Cu2S + 3O2 2Cu2O + 2SO2

2Cu2O + Cu2S 6Cu + SO2

What are 'emulsions'..?

Q: Explain the terms:

a) Promoter b) Poison

c) Critical micelle concentration

d) Kraft temperature

A: a) The substance that enhances the adsorption activity of catalyst.

b) The substance that decreases the activity

of catalyst.

c) The concentration above which micelle is

formed.

d) The temperature above which micelle is

formed.

Q: What are Lyophilic and Lyophobic Sols?.

Explain.

A: Lyophilic Sols: the colloidal solutions in

which attraction is present between D.P. and

D.M. They are reversible, stable, can't be

coagulated easily.

Lyophobic sols: The colloidal solutions in

which repulsion is present between

Dispersed Phase (D.P.) and Dispersion

Medium (D.M.). They are irreversible, unstable, can be coagulated easily.

Q: What are "micelles"? Cleaning action of

soap is due to emulsification and micelle formation. Comment.

A: Micelle: The colloidal sized particle

is formed due to

oil

aggregation

of

strong electrolyte at

higher concentration.

Stearate micelle

Soap is considered

as sodium stearate. It has Na+ and C17H35

COO ions. Stearate ion has non polar part

(tail) C17H35 and polar part (head) COO.

Tail part dissolves grease, dirt and head part

attracts water to form oil in water type emulsion. In concentrated soap solution, micelles

are formed due to association of many

stearate ions. Due to formation of micelles

and emulsion (oil in water type) grease of

cloth is to be removed upon rinsing in water.

Q: Explain: a) Hardy Schulze rule and

b) Gold number

A: a) The coagulating ability of oppositely

charged ions is directly proportional to the

charge of coagulating ions.

Q: What is the role of Silica in the metallurgy of

Cu?

A: It removes FeO impurity as slag

FeO + SiO2 FeSiO3

Q: Write 2 ores of Al & Zn.

A: Al: 1) Bauxite Al2O3 . x H2O

2) Cryolite Na3AlF6

Zn: 1) Zinc blende ZnS

2) Calamine ZnCO3

Q: Explain a) Gangue and b) Slag.

A: Gangue: Earthy materials, unwanted

chemical compounds present in the Ore.

Slag: Fused mass (having light weight)

formed when gangue reacts with flux.

gangue + flux slag

Q: Write 2 ores of Fe & Cu.

A: Fe: 1) Haematite: Fe2O3

2) Magnetite: Fe3O4

Cu: 1) Copper glance: Cu2S

Writer :

- A.N.S. Sankara Rao

Subject expert

b) The mass in milligrams of lyophilic colloid

which prevents coagulation of 10 ml of

gold Sol on adding 1 ml of 10% NaCl

solution.

Q: Give 4 applications of Adsorption.

A: In froth flotation process.

In the separation of noble gases from their

mixture on activated charcoal.

In controlling humidity by Silica gel.

In the removal of colouring matter from solutions by animal charcoal.

Q: Explain briefly the extraction of Al from

bauxite.

A: Al can be extracted either from red bauxite

or from white bauxite. Powdered bauxite is

concentrated by NaOH at 35 bar pressure

and 200C 250C temperature.

Al2O3 + 2NaOH + 3H2O 2Na [Al (OH)4]

Sodium aluminate is neutralised by CO2

2Na [Al (OH)4] + CO2

Al2O3 . x H2O + 2NaHCO3

Hydrated alumina is filtered, dried, ignited.

1200C

Al2O3 . x H2O Al2O3 + xH2O

Fluorospar, cryolite are added to purified

Al2O3 in order to decrease fusion temperature

and to increase conductivity. It is taken in steel

vessel coated with carbon lining (Cathode)

and graphite as anode and electrolysed.

2 Al2O3 + 3C 4 Al + 3 CO2

+3

+ 3e Al

at Cathode: Al

at Anode: C + 2O2 CO2 + 4 e

Q: Explain a) Calcination and b) Roasting

A: a) Calcination: The process of heating ore

below its melting point in absence of air

Eg: ZnCO3

ZnO + CO2

b) Roasting: The process of heating ore

strongly below its M. P. in presence of air.

Eg: 2ZnS + 3O2 2ZnO + 2SO2

2) Copper pyrites: CuFeS2

Q: What is the role of graphite rod in the electrometallurgy of Al?

A: In Hall - Heroult process graphite rod is

used as anode to remove Oxygen liberated

from Al2O3.

C + O2 CO + 2e

C + 2O2 CO2 + 4e

Q: Why lime stone is added to the ore in the

metallurgy of iron?

A: It removes SiO2 impurity as slag

CaCO3

CaO + CO2

CaO + SiO2 CaSiO3

Q: What is 'matte'?

A: When concentrated copper pyrites ore is

heated with silica in reverberatory furnace, Cu is produced in the form of copper matte which contains more Cu2S and

little FeS.

Q: Explain the purification of sulphide ore by

froth flotation method.

A: This process is used to purify sulphide ores.

Finely powered ore is taken into a tank along

with water.

Pine oil (Froth collector), sodium ethyl

xanthate (for non-wettability of ore particles),

Aniline (to stabilize the froth) are added.

Suspension is agitated with rotating paddle

and air to form froth.

Ore particles are wetted by oils and gangue

particles are wetted by water.

Froth is separated and dried to get ore particles.

Q: How Zn is extracted from Zinc blende?

A: Zinc blende (ZnS) is finely powdered and

concentrated by froth flotation method.

Concentrated ore is roasted.

2ZnS + 3O2 2ZnO + 2SO2

ZnO is reduced with Coke in Belgian process

1400C

ZnO + C Zn + CO

Zn is refined by electrolysis

Anode: impure Zn rod

Cathode: Pure Zn Sheet

Electrolyte: ZnSO4 + H2SO4

Q: Explain the reactions occurring in the blast

furnace in the extraction of iron.

A: A mixture of iron ore, coke, lime stone (in 8 :

4 : 1 ratio) introduced from the top and hot air

is blown from bottom (2200 K) of blast furnace.

In reduction zone (823 K): Iron oxide is

reduced to sponge iron.

3Fe2O3 + CO 2 Fe3O4 + CO2

Fe3O4 + 4CO 3Fe + 4CO2

Fe2O3 + CO 2FeO + CO2

In slag formation zone (1123 K): Slag is

formed

1123 K

CaCO3 CaO + CO2

CaO + SiO2 CaSiO3 (Slag)

In heat absorption zone (1423 K)

C + CO2 2CO

In fusion zone (1423 K 1673 K) : Pig iron is

formed

FeO + CO Fe (fused) + CO2

Pig iron contains 4% C and impurities S, P,

Si, Mn.

Q: Explain: a) Zone refining, b) Poling.

A: a) Zone refining: The method of obtaining

highly pure metals as well as Si, Ge, Ga,

B, In. It is based on the principle that the

impurities are more soluble in molten

state than that in solid state of metal.

b) Poling: It is the refining process in which

molten metal is stirred with poles of green

wood. Blister Copper is purified by removing

impurities by the gases evolved from wood.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Enzymes: Biology Matters G.C.E. 'O' Level (2 Edition) : Textbook AnswersDocumento2 páginasEnzymes: Biology Matters G.C.E. 'O' Level (2 Edition) : Textbook Answerslee40% (5)

- TDS-Dow SPECFIL FT630 & SPECFIL FE100-EN - 20181226Documento2 páginasTDS-Dow SPECFIL FT630 & SPECFIL FE100-EN - 20181226Mallampati RamakrishnaAinda não há avaliações

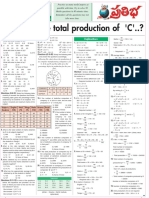

- The Total Production of 'C'..?: Quantitative AptitudeDocumento1 páginaThe Total Production of 'C'..?: Quantitative AptitudeJAGADEESHAinda não há avaliações

- Big SST OverviewDocumento15 páginasBig SST OverviewJAGADEESHAinda não há avaliações

- Police Constables Prelims Model Paper: No. of Questions: 200 Marks: 200 Time: 3 HrsDocumento1 páginaPolice Constables Prelims Model Paper: No. of Questions: 200 Marks: 200 Time: 3 HrsJAGADEESHAinda não há avaliações

- The Most Polluted City Is... : WriterDocumento1 páginaThe Most Polluted City Is... : WriterJAGADEESHAinda não há avaliações

- What Is The Difference Between The Carnot Cycle and The Rankine Cycle - QuoraDocumento3 páginasWhat Is The Difference Between The Carnot Cycle and The Rankine Cycle - QuoraJAGADEESHAinda não há avaliações

- 001rotary Gear Pumps, Reciprocating Pumps, Chemical Dosing Pumps Industry ApplicationsDocumento2 páginas001rotary Gear Pumps, Reciprocating Pumps, Chemical Dosing Pumps Industry ApplicationsJAGADEESHAinda não há avaliações

- 01condensate Polisher Systems - Degremont Technologies - Worldwide Water and Wastewater Treatment SpecialistsDocumento2 páginas01condensate Polisher Systems - Degremont Technologies - Worldwide Water and Wastewater Treatment SpecialistsJAGADEESHAinda não há avaliações

- Bearing Sensor Stock InventoryDocumento5 páginasBearing Sensor Stock InventoryJAGADEESHAinda não há avaliações

- Plain Bearing - WikipediaDocumento10 páginasPlain Bearing - WikipediaJAGADEESHAinda não há avaliações

- 001BGR Energy Systems LimitedDocumento1 página001BGR Energy Systems LimitedJAGADEESHAinda não há avaliações

- Generator: How It Makes Electricity Reactor Turbine Generator Cooling Fuel Containment LinksDocumento2 páginasGenerator: How It Makes Electricity Reactor Turbine Generator Cooling Fuel Containment LinksJAGADEESHAinda não há avaliações

- Diesel Engines: Home Boilers Feed Systems Steam Turbines Fuel Treatment Pumps Valves RefrigerationDocumento5 páginasDiesel Engines: Home Boilers Feed Systems Steam Turbines Fuel Treatment Pumps Valves RefrigerationJAGADEESHAinda não há avaliações

- Safety Data Sheet: 1. IdentificationDocumento7 páginasSafety Data Sheet: 1. IdentificationGan Chai SInAinda não há avaliações

- R304 0307 Env HHDocumento221 páginasR304 0307 Env HHsyamsundariitmiitmAinda não há avaliações

- Metabolism Exam 2 - GIFT - Spring 2016Documento9 páginasMetabolism Exam 2 - GIFT - Spring 2016shafa_nathani100% (2)

- Module 7 LipidsDocumento3 páginasModule 7 Lipidsgarciamigueld23Ainda não há avaliações

- Epilux 5: Product DescriptionDocumento2 páginasEpilux 5: Product DescriptionShyam ShrishAinda não há avaliações

- 2012 Form 5 (Paper 3)Documento6 páginas2012 Form 5 (Paper 3)Nieda IbrahimAinda não há avaliações

- Design of Machine Elements 2019 BeemerDocumento145 páginasDesign of Machine Elements 2019 BeemerSandeep MandaAinda não há avaliações

- Level 3 Post Emulsifiable Fluorescent Penetrant: Product Data SheetDocumento2 páginasLevel 3 Post Emulsifiable Fluorescent Penetrant: Product Data SheetAnand AmanAinda não há avaliações

- Crack Identification in Reinforced Concrete Beams Using ANSYS SoftwareDocumento13 páginasCrack Identification in Reinforced Concrete Beams Using ANSYS SoftwarethaibinhkxAinda não há avaliações

- Cystatin CDocumento4 páginasCystatin CГалина МиловановаAinda não há avaliações

- Tutorial ERP StudentsDocumento2 páginasTutorial ERP StudentsHariz MiorAinda não há avaliações

- Numerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaDocumento8 páginasNumerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaAlexander ProkhorenkoAinda não há avaliações

- Simulation of Wax Deposition Model For Various FieldDocumento53 páginasSimulation of Wax Deposition Model For Various FieldAyauwu LovedayAinda não há avaliações

- Lecture 7 Rayleigh PDFDocumento34 páginasLecture 7 Rayleigh PDFWendirad BeshadaAinda não há avaliações

- Final Examination: Your Answer On The Space Provided For. (40 Points)Documento5 páginasFinal Examination: Your Answer On The Space Provided For. (40 Points)Wichel AnnAinda não há avaliações

- ECSS Q ST 70 15C (1may2021)Documento124 páginasECSS Q ST 70 15C (1may2021)Navamani Prakash100% (1)

- Materials and Processes For Agricultural and Biosystems EngineeringDocumento17 páginasMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioAinda não há avaliações

- Crystex HD OT 20 PDFDocumento2 páginasCrystex HD OT 20 PDFmeidyAinda não há avaliações

- WM Catalog 2015 - 1506 - Water Maze Catalogo y Guia de AplicaciónDocumento56 páginasWM Catalog 2015 - 1506 - Water Maze Catalogo y Guia de AplicaciónPablo FaldutiAinda não há avaliações

- Hacon TMDocumento68 páginasHacon TMTiago CoutoAinda não há avaliações

- David Scanu, Natalia P. Yevlampieva and Robert Deschenaux - Polar and Electrooptical Properties of (60) Fullerene-Containing Poly (Benzyl Ether) Dendrimers in SolutionDocumento7 páginasDavid Scanu, Natalia P. Yevlampieva and Robert Deschenaux - Polar and Electrooptical Properties of (60) Fullerene-Containing Poly (Benzyl Ether) Dendrimers in SolutionGlade680Ainda não há avaliações

- 11718-Article Text-42418-1-10-20161220Documento7 páginas11718-Article Text-42418-1-10-20161220BibahAinda não há avaliações

- 5070 s23 QP 42 MergedDocumento100 páginas5070 s23 QP 42 MergedMuhammad QasimAinda não há avaliações

- Biological and Physicochemical Indicators of Water Quality in Libreville and Its SurroundingsDocumento7 páginasBiological and Physicochemical Indicators of Water Quality in Libreville and Its SurroundingsInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- ES GTU Study Material E-Notes Chapter-8 12012020013605PMDocumento15 páginasES GTU Study Material E-Notes Chapter-8 12012020013605PMRIPAinda não há avaliações

- UV VIS CaffeineDocumento15 páginasUV VIS CaffeineTinuviele EsguerraAinda não há avaliações

- Ne335 Macro Lab1Documento17 páginasNe335 Macro Lab1Moeen Khan RisaldarAinda não há avaliações

- 0199152152Documento138 páginas0199152152Afzal UsmanAinda não há avaliações