Escolar Documentos

Profissional Documentos

Cultura Documentos

Preface 2001 Measurement and Instrumentation Principles Third Edition

Enviado por

Motasim_mDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Preface 2001 Measurement and Instrumentation Principles Third Edition

Enviado por

Motasim_mDireitos autorais:

Formatos disponíveis

Preface

The foundations of this book lie in the highly successful text Principles of Measurement

and Instrumentation by the same author. The first edition of this was published in 1988,

and a second, revised and extended edition appeared in 1993. Since that time, a number

of new developments have occurred in the field of measurement. In particular, there

have been significant advances in smart sensors, intelligent instruments, microsensors,

digital signal processing, digital recorders, digital fieldbuses and new methods of signal

transmission. The rapid growth of digital components within measurement systems has

also created a need to establish procedures for measuring and improving the reliability

of the software that is used within such components. Formal standards governing instrument calibration procedures and measurement system performance have also extended

beyond the traditional area of quality assurance systems (BS 5781, BS 5750 and more

recently ISO 9000) into new areas such as environmental protection systems (BS 7750

and ISO 14000). Thus, an up-to-date book incorporating all of the latest developments

in measurement is strongly needed. With so much new material to include, the opportunity has been taken to substantially revise the order and content of material presented

previously in Principles of Measurement and Instrumentation, and several new chapters

have been written to cover the many new developments in measurement and instrumentation that have occurred over the past few years. To emphasize the substantial

revision that has taken place, a decision has been made to publish the book under a

new title rather than as a third edition of the previous book. Hence, Measurement and

Instrumentation Principles has been born.

The overall aim of the book is to present the topics of sensors and instrumentation,

and their use within measurement systems, as an integrated and coherent subject.

Measurement systems, and the instruments and sensors used within them, are of

immense importance in a wide variety of domestic and industrial activities. The growth

in the sophistication of instruments used in industry has been particularly significant as

advanced automation schemes have been developed. Similar developments have also

been evident in military and medical applications.

Unfortunately, the crucial part that measurement plays in all of these systems tends

to get overlooked, and measurement is therefore rarely given the importance that it

deserves. For example, much effort goes into designing sophisticated automatic control

systems, but little regard is given to the accuracy and quality of the raw measurement

data that such systems use as their inputs. This disregard of measurement system

quality and performance means that such control systems will never achieve their full

xviii Preface

potential, as it is very difficult to increase their performance beyond the quality of the

raw measurement data on which they depend.

Ideally, the principles of good measurement and instrumentation practice should be

taught throughout the duration of engineering courses, starting at an elementary level

and moving on to more advanced topics as the course progresses. With this in mind,

the material contained in this book is designed both to support introductory courses in

measurement and instrumentation, and also to provide in-depth coverage of advanced

topics for higher-level courses. In addition, besides its role as a student course text, it

is also anticipated that the book will be useful to practising engineers, both to update

their knowledge of the latest developments in measurement theory and practice, and

also to serve as a guide to the typical characteristics and capabilities of the range of

sensors and instruments that are currently in use.

The text is divided into two parts. The principles and theory of measurement are

covered first in Part 1 and then the ranges of instruments and sensors that are available

for measuring various physical quantities are covered in Part 2. This order of coverage

has been chosen so that the general characteristics of measuring instruments, and their

behaviour in different operating environments, are well established before the reader is

introduced to the procedures involved in choosing a measurement device for a particular

application. This ensures that the reader will be properly equipped to appreciate and

critically appraise the various merits and characteristics of different instruments when

faced with the task of choosing a suitable instrument.

It should be noted that, whilst measurement theory inevitably involves some mathematics, the mathematical content of the book has deliberately been kept to the minimum

necessary for the reader to be able to design and build measurement systems that

perform to a level commensurate with the needs of the automatic control scheme or

other system that they support. Where mathematical procedures are necessary, worked

examples are provided as necessary throughout the book to illustrate the principles

involved. Self-assessment questions are also provided in critical chapters to enable

readers to test their level of understanding, with answers being provided in Appendix 4.

Part 1 is organized such that all of the elements in a typical measurement system

are presented in a logical order, starting with the capture of a measurement signal by

a sensor and then proceeding through the stages of signal processing, sensor output

transducing, signal transmission and signal display or recording. Ancillary issues, such

as calibration and measurement system reliability, are also covered. Discussion starts

with a review of the different classes of instrument and sensor available, and the

sort of applications in which these different types are typically used. This opening

discussion includes analysis of the static and dynamic characteristics of instruments

and exploration of how these affect instrument usage. A comprehensive discussion of

measurement system errors then follows, with appropriate procedures for quantifying

and reducing errors being presented. The importance of calibration procedures in all

aspects of measurement systems, and particularly to satisfy the requirements of standards such as ISO 9000 and ISO 14000, is recognized by devoting a full chapter to

the issues involved. This is followed by an analysis of measurement noise sources,

and discussion on the various analogue and digital signal-processing procedures that

are used to attenuate noise and improve the quality of signals. After coverage of the

range of electrical indicating and test instruments that are used to monitor electrical

Preface

measurement signals, a chapter is devoted to presenting the range of variable conversion elements (transducers) and techniques that are used to convert non-electrical sensor

outputs into electrical signals, with particular emphasis on electrical bridge circuits. The

problems of signal transmission are considered next, and various means of improving

the quality of transmitted signals are presented. This is followed by an introduction to

digital computation techniques, and then a description of their use within intelligent

measurement devices. The methods used to combine a number of intelligent devices

into a large measurement network, and the current status of development of digital

fieldbuses, are also explained. Then, the final element in a measurement system, of

displaying, recording and presenting measurement data, is covered. To conclude Part 1,

the issues of measurement system reliability, and the effect of unreliability on plant

safety systems, are discussed. This discussion also includes the subject of software

reliability, since computational elements are now embedded in many measurement

systems.

Part 2 commences in the opening chapter with a review of the various technologies

used in measurement sensors. The chapters that follow then provide comprehensive

coverage of the main types of sensor and instrument that exist for measuring all the

physical quantities that a practising engineer is likely to meet in normal situations.

However, whilst the coverage is as comprehensive as possible, the distinction is emphasized between (a) instruments that are current and in common use, (b) instruments that

are current but not widely used except in special applications, for reasons of cost or

limited capabilities, and (c) instruments that are largely obsolete as regards new industrial implementations, but are still encountered on older plant that was installed some

years ago. As well as emphasizing this distinction, some guidance is given about how

to go about choosing an instrument for a particular measurement application.

xix

Você também pode gostar

- Mechanical Vibrations and Condition MonitoringNo EverandMechanical Vibrations and Condition MonitoringNota: 5 de 5 estrelas5/5 (1)

- ME 212 - MetrologyDocumento7 páginasME 212 - MetrologyAmunnadi Victor chinazaAinda não há avaliações

- Calibration and Certification of Industrial Sensors - A Global ReviewDocumento23 páginasCalibration and Certification of Industrial Sensors - A Global Reviewmoh1122Ainda não há avaliações

- Measurement and Instrumentation: Theory and ApplicationNo EverandMeasurement and Instrumentation: Theory and ApplicationNota: 4.5 de 5 estrelas4.5/5 (5)

- Functional Elements of Measurement SystemDocumento29 páginasFunctional Elements of Measurement SystemVijayapriya Tamilmaran100% (3)

- Fault Diagnosis and Sustainable Control of Wind Turbines: Robust Data-Driven and Model-Based StrategiesNo EverandFault Diagnosis and Sustainable Control of Wind Turbines: Robust Data-Driven and Model-Based StrategiesNota: 4 de 5 estrelas4/5 (1)

- Measurement and Control Handbook IntroductionDocumento10 páginasMeasurement and Control Handbook IntroductionRaja Prathap SinghAinda não há avaliações

- IEEE Sensor Technology Conference Recent AdvancesDocumento8 páginasIEEE Sensor Technology Conference Recent AdvancesHarsimran KaurAinda não há avaliações

- Control 2Documento26 páginasControl 2Shawqi AssiAinda não há avaliações

- Basics of Vibration Monitoring For Fault Detection and Process ControlDocumento10 páginasBasics of Vibration Monitoring For Fault Detection and Process ControlddadaraAinda não há avaliações

- Sensor TechnologyDocumento6 páginasSensor TechnologyAruna AkkiAinda não há avaliações

- Introduction To Instrumentation Sensors And Process Control BookDocumento5 páginasIntroduction To Instrumentation Sensors And Process Control BookE.C.MADHUDUDHANA REDDYAinda não há avaliações

- (MD Zahurul Haq) Applied Measurement SystemDocumento399 páginas(MD Zahurul Haq) Applied Measurement SystemLaraSamiAinda não há avaliações

- Engineering Metrology and Measurements Unit 1 2Documento82 páginasEngineering Metrology and Measurements Unit 1 2scorpionarnold100% (1)

- Fer 60 1 002 2014Documento3 páginasFer 60 1 002 2014gwapoako9999999 999999Ainda não há avaliações

- 1 s2.0 S0007850610001976 MainDocumento23 páginas1 s2.0 S0007850610001976 MainM Vamshi KrrishnaAinda não há avaliações

- Electronics Measurements Lecture NotesDocumento74 páginasElectronics Measurements Lecture NotesarundhatiAinda não há avaliações

- MEASUREMENT FUNDAMENTALSDocumento36 páginasMEASUREMENT FUNDAMENTALSAlemAinda não há avaliações

- Instrumentation Measurement Process DynamicsDocumento16 páginasInstrumentation Measurement Process DynamicsByron MawoyoAinda não há avaliações

- Metrology NOTEDocumento90 páginasMetrology NOTERyan Goh Chuang HongAinda não há avaliações

- Intro and Generalized ConfigurationsDocumento37 páginasIntro and Generalized Configurationsset letAinda não há avaliações

- Engineering Metrology and MeasurementsDocumento128 páginasEngineering Metrology and MeasurementsArvind Bhosale100% (7)

- LECTURE NOTE ON MEC 314 UpdatedDocumento72 páginasLECTURE NOTE ON MEC 314 UpdatedYoung ProfAinda não há avaliações

- Chapter-1 Introduction of Measurement: Response of Measuring SystemDocumento36 páginasChapter-1 Introduction of Measurement: Response of Measuring SystemYab TadAinda não há avaliações

- Functions of Instruments and Measurement SystemsDocumento6 páginasFunctions of Instruments and Measurement SystemsAmit Kr GodaraAinda não há avaliações

- Chapter-1 Introduction of Measurement: Response of Measuring SystemDocumento36 páginasChapter-1 Introduction of Measurement: Response of Measuring SystemYab TadAinda não há avaliações

- SMR1302Documento286 páginasSMR1302Mr. RAVI KUMAR IAinda não há avaliações

- Unit 1 Mechanical MeasurementDocumento121 páginasUnit 1 Mechanical MeasurementVivek BorkarAinda não há avaliações

- Full download book Mechanical Vibrations And Condition Monitoring 1St Edition Pdf pdfDocumento41 páginasFull download book Mechanical Vibrations And Condition Monitoring 1St Edition Pdf pdfandrew.lindsey981100% (13)

- An Optimization Framework To Computer-Aided DesignDocumento7 páginasAn Optimization Framework To Computer-Aided DesignYaqoob AliAinda não há avaliações

- Engineering Metrology and Measurements NotesDocumento127 páginasEngineering Metrology and Measurements NotesNagendar SelvakumarAinda não há avaliações

- Process Instrumentation in Oil and GasDocumento2 páginasProcess Instrumentation in Oil and GasDEEPAK KUMARAinda não há avaliações

- Engineering Metrology and Measurements NotesDocumento131 páginasEngineering Metrology and Measurements NotesBALAMUGUNDAN91% (32)

- Measurement and MetrologyDocumento84 páginasMeasurement and Metrologyjalim yadavAinda não há avaliações

- Sensors and Transducers IntroductionDocumento60 páginasSensors and Transducers IntroductionTamilnesan P0% (1)

- Instruments and Its TypesDocumento2 páginasInstruments and Its TypesDespicari PiratesAinda não há avaliações

- ELECTRONICS MEASUREMENTS AND INSTRUMENTATION New2020-2021Documento136 páginasELECTRONICS MEASUREMENTS AND INSTRUMENTATION New2020-2021Kristipati Thoyajaksha KashyapAinda não há avaliações

- Measurement of Indoor Lighting SystemDocumento2 páginasMeasurement of Indoor Lighting SystemShrijan BasnetAinda não há avaliações

- Sensor Lec4: Transfer FunctionDocumento6 páginasSensor Lec4: Transfer FunctionKhalifa EltayebAinda não há avaliações

- My Notes PCTDocumento36 páginasMy Notes PCTPortia ShilengeAinda não há avaliações

- Development of Fire Detection Systems in The Intelligent BuildingDocumento14 páginasDevelopment of Fire Detection Systems in The Intelligent BuildingJagadeesh PraveenAinda não há avaliações

- Toma de Informacion Cualitativa para ProcesosDocumento6 páginasToma de Informacion Cualitativa para Procesosvictorpalacio19Ainda não há avaliações

- Measurement Systems and Basic Concepts of Measurement MethodsDocumento25 páginasMeasurement Systems and Basic Concepts of Measurement Methodsgangrowdy76Ainda não há avaliações

- Instrumentation EngineeringDocumento126 páginasInstrumentation EngineeringGaurav UpaAinda não há avaliações

- Lecture Notes: Mrs. R. Rani, Associate ProfessorDocumento93 páginasLecture Notes: Mrs. R. Rani, Associate ProfessorAlaaKhalifaAinda não há avaliações

- Introduction to Sensors and Instrumentation FundamentalsDocumento388 páginasIntroduction to Sensors and Instrumentation FundamentalsRaagul SAinda não há avaliações

- Sensor and Instrumentation - Unit IDocumento96 páginasSensor and Instrumentation - Unit IRaagul SAinda não há avaliações

- Final Control Elements. This Section CoversDocumento3 páginasFinal Control Elements. This Section CoversMohamed LabibAinda não há avaliações

- Identification of Multivariable Industrial Processes: For Simulation, Diagnosis and ControlDocumento199 páginasIdentification of Multivariable Industrial Processes: For Simulation, Diagnosis and ControlSebastian Alarcon100% (1)

- 1-Sheet 1 Measure AnswerDocumento25 páginas1-Sheet 1 Measure AnswerBahaa EmadAinda não há avaliações

- Chapter One Basic Concepts of Measurement and InstrumentationDocumento33 páginasChapter One Basic Concepts of Measurement and InstrumentationhlkjjkAinda não há avaliações

- Chapter 1general Measurement SystemDocumento8 páginasChapter 1general Measurement SystemJaziri Dato JAinda não há avaliações

- Wireless Sensor Networks For Industrial Process Monitoring and Control: A SurveyDocumento18 páginasWireless Sensor Networks For Industrial Process Monitoring and Control: A SurveySameera ChamingaAinda não há avaliações

- Touchless Calibration for Industry 4.0Documento5 páginasTouchless Calibration for Industry 4.0Igor GarciaAinda não há avaliações

- Instrumentation & Measurement LectureDocumento22 páginasInstrumentation & Measurement LectureAleeza AshfaqueAinda não há avaliações

- Sensorless Air Flow Control in HVAC Systems through Deep LearningDocumento19 páginasSensorless Air Flow Control in HVAC Systems through Deep Learningmohamed mansourAinda não há avaliações

- Low-Power System For Detection of Symptomatic Patterns in Audio Biological SignalsDocumento10 páginasLow-Power System For Detection of Symptomatic Patterns in Audio Biological SignalsBhaskar MitraAinda não há avaliações

- Chapter 35 Batch Process Control 2010 Instrumentation Reference Book Fourth EditionDocumento2 páginasChapter 35 Batch Process Control 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- 90 Days of ActionDocumento92 páginas90 Days of ActionPaula StanwyckAinda não há avaliações

- Chapter 26 Chemical Analysis Moisture Measurement 2010 Instrumentation Reference Book Fourth EditionDocumento8 páginasChapter 26 Chemical Analysis Moisture Measurement 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- Chapter 34 Advanced Control For The Plant Floor 2010 Instrumentation Reference Book Fourth EditionDocumento10 páginasChapter 34 Advanced Control For The Plant Floor 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- Appendix 1 Imperial Metric SI Conversion Tables 2001 Measurement and Instrumentation Principles Third EditionDocumento7 páginasAppendix 1 Imperial Metric SI Conversion Tables 2001 Measurement and Instrumentation Principles Third EditionMotasim_mAinda não há avaliações

- Prepare For IELTSDocumento169 páginasPrepare For IELTSapi-3818413100% (2)

- Copyright 2010 Instrumentation Reference Book Fourth EditionDocumento1 páginaCopyright 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- Chapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionDocumento6 páginasChapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- Introduction 2010 Instrumentation Reference Book Fourth EditionDocumento2 páginasIntroduction 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- 1001 Vocabulary and Spelling QuestionsDocumento160 páginas1001 Vocabulary and Spelling Questionssashi01092% (12)

- Switches ExplainedDocumento3 páginasSwitches ExplainedMotasim_mAinda não há avaliações

- Appendix 2 TH Venin S Theorem 2001 Measurement and Instrumentation Principles Third EditionDocumento6 páginasAppendix 2 TH Venin S Theorem 2001 Measurement and Instrumentation Principles Third EditionMotasim_mAinda não há avaliações

- Contributors 2010 Instrumentation Reference Book Fourth EditionDocumento2 páginasContributors 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- Programming With MatLabDocumento23 páginasProgramming With MatLabZia SilverAinda não há avaliações

- Simulation, Modeling, and Performance Analysis of IEEE 802.16e OFDMA Systems For Urban and Rural EnvironmentsDocumento4 páginasSimulation, Modeling, and Performance Analysis of IEEE 802.16e OFDMA Systems For Urban and Rural EnvironmentsMotasim_mAinda não há avaliações

- Avatar Upgrade Program PDFDocumento33 páginasAvatar Upgrade Program PDFMotasim_mAinda não há avaliações

- Appendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionDocumento4 páginasAppendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionMotasim_mAinda não há avaliações

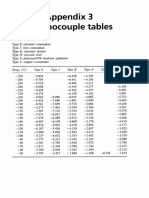

- Appendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionDocumento6 páginasAppendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionMotasim_mAinda não há avaliações

- Appendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionDocumento6 páginasAppendix 3 Thermocouple Tables 2001 Measurement and Instrumentation Principles Third EditionMotasim_mAinda não há avaliações

- Index 2001 Measurement and Instrumentation Principles Third EditionDocumento7 páginasIndex 2001 Measurement and Instrumentation Principles Third EditionMotasim_mAinda não há avaliações

- ISO 9000 Quality Assurance AcknowledgementsDocumento1 páginaISO 9000 Quality Assurance AcknowledgementsMotasim_mAinda não há avaliações

- Appendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionDocumento4 páginasAppendix 4 Solutions To Self Test Questions 2001 Measurement and Instrumentation Principles Third EditionMotasim_mAinda não há avaliações

- Hsu 4 Information and Control Systems AbDocumento43 páginasHsu 4 Information and Control Systems AbMotasim_mAinda não há avaliações

- 1081app A 1 PDFDocumento11 páginas1081app A 1 PDFMotasim_mAinda não há avaliações

- Chapter 5 Security For Industrial Automation1 2010 Instrumentation Reference Book Fourth EditionDocumento2 páginasChapter 5 Security For Industrial Automation1 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- Chapter 4 Simulation and Design Software1 2010 Instrumentation Reference Book Fourth EditionDocumento2 páginasChapter 4 Simulation and Design Software1 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- Chapter 3 Measurement Methods and Control Strategies 2010 Instrumentation Reference Book Fourth EditionDocumento2 páginasChapter 3 Measurement Methods and Control Strategies 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- Appendix C The Institute of Measurement and Control 2010 Instrumentation Reference Book Fourth EditionDocumento4 páginasAppendix C The Institute of Measurement and Control 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- Appendix D International Society of Automation Formerly Instrument Society of America 2010 Instrumentation Reference Book Fourth EditionDocumento2 páginasAppendix D International Society of Automation Formerly Instrument Society of America 2010 Instrumentation Reference Book Fourth EditionMotasim_mAinda não há avaliações

- English 2.2 FPT PolytechnicDocumento10 páginasEnglish 2.2 FPT PolytechnicKieu Mai Trang (FPL HCM)0% (1)

- Liquid Air Energy Storage Systems A - 2021 - Renewable and Sustainable EnergyDocumento12 páginasLiquid Air Energy Storage Systems A - 2021 - Renewable and Sustainable EnergyJosePPMolinaAinda não há avaliações

- BCMEDocumento9 páginasBCMEVenkateshwaran VenkyAinda não há avaliações

- Facelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger FaceDocumento136 páginasFacelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger Faceugur gebologluAinda não há avaliações

- ATM ReportDocumento16 páginasATM Reportsoftware8832100% (1)

- Biology 11th Edition Mader Test BankDocumento25 páginasBiology 11th Edition Mader Test BankAnthonyWeaveracey100% (44)

- Comandos HuaweiDocumento3 páginasComandos Huaweicgottoli0% (1)

- Internal Disease AnsDocumento52 páginasInternal Disease AnsKumar AdityaAinda não há avaliações

- Edtpa Lesson Plan 1Documento3 páginasEdtpa Lesson Plan 1api-364684662Ainda não há avaliações

- French Revolution ChoiceDocumento3 páginasFrench Revolution Choiceapi-483679267Ainda não há avaliações

- Hall Design For SpeechDocumento1 páginaHall Design For SpeechSarovar SaroAinda não há avaliações

- Transactionreceipt Ethereum: Transaction IdentifierDocumento1 páginaTransactionreceipt Ethereum: Transaction IdentifierVALR INVESTMENTAinda não há avaliações

- Plano Electrico 785CDocumento2 páginasPlano Electrico 785CLuis MartínezAinda não há avaliações

- Datasheet AD549Documento14 páginasDatasheet AD549Trần Hồng VănAinda não há avaliações

- Lessons Learned - Risk Management Issues in Genetic Counseling (2007)Documento151 páginasLessons Learned - Risk Management Issues in Genetic Counseling (2007)AditiAinda não há avaliações

- KOREADocumento124 páginasKOREAchilla himmudAinda não há avaliações

- Estimating PSCC for Electrical InstallationsDocumento2 páginasEstimating PSCC for Electrical InstallationsgmuitaAinda não há avaliações

- Tiger Tales: From Colonial MalayaDocumento16 páginasTiger Tales: From Colonial MalayamatarsAinda não há avaliações

- Journey To The ARI-ARhAyas AL-Uma-UN Core of The Krystar Seed Atom FileDocumento14 páginasJourney To The ARI-ARhAyas AL-Uma-UN Core of The Krystar Seed Atom FileSungwon Kang100% (2)

- MechanismDocumento17 páginasMechanismm_er100Ainda não há avaliações

- Hazop Recommendation Checked by FlowserveDocumento2 páginasHazop Recommendation Checked by FlowserveKareem RasmyAinda não há avaliações

- RCC Lintel and Slab PlanDocumento3 páginasRCC Lintel and Slab PlanSaurabh Parmar 28Ainda não há avaliações

- Slope Stability Analysis MethodsDocumento5 páginasSlope Stability Analysis MethodsI am AngelllAinda não há avaliações

- MRP Format MbaDocumento6 páginasMRP Format Mbasankshep panchalAinda não há avaliações

- ARTS 9 Q4 Week 1Documento3 páginasARTS 9 Q4 Week 1Elaissa MaglanqueAinda não há avaliações

- 4439 Chap01Documento28 páginas4439 Chap01bouthaina otAinda não há avaliações

- 1.9 Bernoulli's Equation: GZ V P GZ V PDocumento1 página1.9 Bernoulli's Equation: GZ V P GZ V PTruong NguyenAinda não há avaliações

- Analysis I - SyllabusDocumento3 páginasAnalysis I - SyllabusJUan GAbrielAinda não há avaliações

- ClarifierDocumento2 páginasClarifierchagar_harshAinda não há avaliações

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingNo EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingAinda não há avaliações

- Asset Integrity Management for Offshore and Onshore StructuresNo EverandAsset Integrity Management for Offshore and Onshore StructuresAinda não há avaliações

- Industrial Piping and Equipment Estimating ManualNo EverandIndustrial Piping and Equipment Estimating ManualNota: 5 de 5 estrelas5/5 (7)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNo EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsAinda não há avaliações

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilNo EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilAinda não há avaliações

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisAinda não há avaliações

- Pipeline Integrity: Management and Risk EvaluationNo EverandPipeline Integrity: Management and Risk EvaluationNota: 4.5 de 5 estrelas4.5/5 (6)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesAinda não há avaliações

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsNo EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsNota: 5 de 5 estrelas5/5 (1)

- Subsea Valves and Actuators for the Oil and Gas IndustryNo EverandSubsea Valves and Actuators for the Oil and Gas IndustryNota: 5 de 5 estrelas5/5 (1)

- Petroleum Rock Mechanics: Drilling Operations and Well DesignNo EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignNota: 5 de 5 estrelas5/5 (1)

- Flow Analysis for Hydrocarbon Pipeline EngineeringNo EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAinda não há avaliações

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryAinda não há avaliações

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationNo EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationNota: 4.5 de 5 estrelas4.5/5 (2)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisNo EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisNota: 5 de 5 estrelas5/5 (1)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionNo EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionNota: 4.5 de 5 estrelas4.5/5 (16)

- Corrosion Control in the Oil and Gas IndustryNo EverandCorrosion Control in the Oil and Gas IndustryNota: 4 de 5 estrelas4/5 (12)

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesNo EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertNota: 3 de 5 estrelas3/5 (2)