Escolar Documentos

Profissional Documentos

Cultura Documentos

Structural Steel en 10025-10027

Enviado por

apply19842371Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Structural Steel en 10025-10027

Enviado por

apply19842371Direitos autorais:

Formatos disponíveis

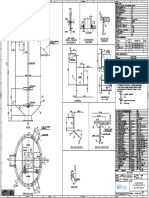

Structural steel grade designations according to EN-10025 & EN-10027

according to EN 10027-1: 2005, EN 10025-2: 2004, EN 10025-4: 2004

Treatment conditions

Steel group

structural steel

Mechanical characteristics

XXX

thermomechanical rolling

normalised rolling

AR

as rolled

min. yield strength in MPa

example

EN 10025-2:

355

J2

Mechanical characteristics

min. 40 J

Temp. C

JR

KR

20

J0

K0

J2

K2

-20

Z15

min. 15% reduction of area

Z25

min. 25% reduction of area

Z35

min. 35 % reduction of area

Physical characteristics - group 2

for low temperatures

thermomechanical rolling

normalised rolling

weathering

example

Special requirements

notch toughness

min. 27 J

Z35

EN 10025-4:

S 355 ML

Explanation of the EN 10025 - 10027 specifications

The latest European Standards incorporate numbers and letters which identify the Properties of the various

grades within the Standard. A typical Specification example might be:- EN 10025 : S275J0H.

EN indicates that it holds the status of a European Standard.

10025 indicates the number of the relevant Standard.

Next is a Letter denoting the type of steel, followed by a number, being the characteristic Yield Strength in

N/mm2 or the specified Minimum Tensile Strength in N/mm2.

G =

Steel Castings.

S =

Structural Steels.

The Number = minimum yield strength for smallest thickness.

P =

Pressure Vessel Steels.

The Number = minimum yield strength for smallest thickness.

L =

Linepipe Steels.

The Number = minimum yield strength for smallest thickness.

E =

Engineering Steels.

The Number = minimum yield strength for smallest thickness.

B =

Steels for Reinforcing Concrete.

The Number = characteristic yield strength.

Y =

Steels for prestressing concrete. The Number = minimum tensile strength.

R =

Steels for or in the form of Rails. The Number = minimum tensile strength.

H =

Steels for Cold Rolled Flat Products of high strength steels for Cold Forming.

The Number = characteristic yield strength.

D =

Flat Products for Cold Forming (except H).

Followed by C for Cold Rolled, D for Hot Rolled products for direct Cold Forming and X for

non specified rolled condition.

T =

Tinmill Products.

M =

Electrical Steels.

JR

indicates that the Charpy Impact Test was conducted to 27 joules minimum at room temperature.

J0

indicates that the Impact Test was performed to 27 joules minimum at 0C.

J2

indicates that the Impact Test was performed to 27 joules minimum at 20C.

K2

indicates that the Impact Test was performed to 40 joules minimum at 20C.

G3

indicates delivery conditions are at the manufacturers discretion.

The last letter, if applicable:

H

indicates Hollow Section.

indicates qualities with specified minimum values of impact energy at a temp. of 50C.

indicates Thermomechanically rolled feedstock material.

indicates Normalised or Normalised Rolled Feedstock material.

Você também pode gostar

- Bolt Preload Calculation: AnswerDocumento2 páginasBolt Preload Calculation: AnswerPedja100% (1)

- Perhitungan WeldingDocumento4 páginasPerhitungan WeldingjunarkoAinda não há avaliações

- 4DMechanical VesselDocumento26 páginas4DMechanical VesselBowo Edhi WibowoAinda não há avaliações

- Roof TrussDocumento2 páginasRoof Trussanbukgi100% (1)

- C1155Documento8 páginasC1155dinhtung2210Ainda não há avaliações

- Me136p Experiment No. 9 Proof Strength Load Test of Bolts and NutsDocumento8 páginasMe136p Experiment No. 9 Proof Strength Load Test of Bolts and NutsJohn Henry SalvadoAinda não há avaliações

- Analysis of Corrugated Web Beam To Column Extended End Plate Connection UsingDocumento75 páginasAnalysis of Corrugated Web Beam To Column Extended End Plate Connection UsingLina Lina LoulouAinda não há avaliações

- Comp 2Documento9 páginasComp 2YYo YudiAinda não há avaliações

- Anchor BoltDocumento1 páginaAnchor BoltNugraha BintangAinda não há avaliações

- Seismic Load Calculation of The Tank As Per IS 1893Documento1 páginaSeismic Load Calculation of The Tank As Per IS 1893ParthibanAinda não há avaliações

- Hilti Design CalculationDocumento4 páginasHilti Design CalculationJohn Vincent MusngiAinda não há avaliações

- Rectangular Hollow Section Cold Formed..BS en 102191997Documento4 páginasRectangular Hollow Section Cold Formed..BS en 102191997Jagdish ChhuganiAinda não há avaliações

- Weight CalculatorDocumento2 páginasWeight CalculatorenjoygurujiAinda não há avaliações

- Tolerance CalculatorDocumento4 páginasTolerance CalculatorAshok Kumar UppariAinda não há avaliações

- Bolt Load Design CalculationDocumento2 páginasBolt Load Design CalculationDamanpreet SinghAinda não há avaliações

- Gunung Gahapi BaharaDocumento6 páginasGunung Gahapi BaharamagiAinda não há avaliações

- Steel Beam DesignDocumento36 páginasSteel Beam DesignTan Choon LengAinda não há avaliações

- PGAS-KJ-E1001-CON-CA-0002 Calculation For Pipe Support Steel Structure and FoundationDocumento38 páginasPGAS-KJ-E1001-CON-CA-0002 Calculation For Pipe Support Steel Structure and FoundationTaufik BimoAinda não há avaliações

- (Electric Resistance Welded) : Specification ASTM A 53 SCH 40Documento12 páginas(Electric Resistance Welded) : Specification ASTM A 53 SCH 40M FaizAinda não há avaliações

- Frustum of A ConeDocumento11 páginasFrustum of A Coneayushi_n72Ainda não há avaliações

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocumento3 páginas"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionSung Woong MoonAinda não há avaliações

- Mounting Structure PV SystemsDocumento36 páginasMounting Structure PV SystemsEhsan Ur RehmanAinda não há avaliações

- Autopipe Vessel Guide 1-5Documento5 páginasAutopipe Vessel Guide 1-5fiuto_rights_1404802Ainda não há avaliações

- Ladder Rung Calc.Documento1 páginaLadder Rung Calc.Azwan ShahAinda não há avaliações

- Manual Tank 2016Documento159 páginasManual Tank 2016stiglatAinda não há avaliações

- Amine Stripper Column Crack 3501-1-T-004: PQR Test CouponDocumento2 páginasAmine Stripper Column Crack 3501-1-T-004: PQR Test Couponpstechnical_43312697100% (1)

- Beam Design CalculationDocumento33 páginasBeam Design CalculationsmijusAinda não há avaliações

- Agitator Blade Ii: Ga Drawing For 4 KL, Vertical Mixing TankDocumento1 páginaAgitator Blade Ii: Ga Drawing For 4 KL, Vertical Mixing TankAshokAinda não há avaliações

- Lifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Documento7 páginasLifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Steve MoonAinda não há avaliações

- Testing & Consultancy Cell Deptt of Civil Engg NIT Jamshedpur Final ApprovedDocumento12 páginasTesting & Consultancy Cell Deptt of Civil Engg NIT Jamshedpur Final ApprovedsirfmeinAinda não há avaliações

- Lifting Lug CalculatorDocumento5 páginasLifting Lug CalculatorJOHNAinda não há avaliações

- Eq Base Shear CalculationsDocumento9 páginasEq Base Shear Calculationsirshad313Ainda não há avaliações

- DIN 17100 ST 37-2 SteelDocumento1 páginaDIN 17100 ST 37-2 Steelisaaa100% (1)

- Mechanical Design SpreadsheetDocumento1 páginaMechanical Design SpreadsheetHoney TiwariAinda não há avaliações

- JIS SectionDocumento2 páginasJIS SectionthakrarhitsAinda não há avaliações

- Anchor BoltDocumento2 páginasAnchor BoltYudi Herdiansah100% (2)

- Final Soil Test ReportDocumento7 páginasFinal Soil Test ReportPrateek JhanjiAinda não há avaliações

- R D H W FW: Design of Tailing LugDocumento2 páginasR D H W FW: Design of Tailing LugvpjagannaathAinda não há avaliações

- A Review On Various Welding TechniquesDocumento7 páginasA Review On Various Welding TechniquesIJMER100% (1)

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocumento2 páginas2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebAinda não há avaliações

- Ccsviiid1 2260Documento2 páginasCcsviiid1 2260DieguitoOmarMoralesAinda não há avaliações

- EX02. 2D Beam Analysis (Simply Supported Beam)Documento6 páginasEX02. 2D Beam Analysis (Simply Supported Beam)Lisa DiasAinda não há avaliações

- Skid BeamDocumento2 páginasSkid BeamYuni Ari WibowoAinda não há avaliações

- Wall FootingDocumento7 páginasWall FootingKramyer100% (1)

- Hemispherical Head Blank DiameterDocumento1 páginaHemispherical Head Blank DiameterdombipinAinda não há avaliações

- Brosur Pt. Srirejeki Perdana Steel-1Documento16 páginasBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahAinda não há avaliações

- BS4190 Grade 4: Anchor Bolt Type A Anchor Bolt Type BDocumento1 páginaBS4190 Grade 4: Anchor Bolt Type A Anchor Bolt Type BmodarthAinda não há avaliações

- KDS 41 17 00 2019Documento75 páginasKDS 41 17 00 2019Suso IglesiasAinda não há avaliações

- EN 13480-3 Straight Pipes PDFDocumento1 páginaEN 13480-3 Straight Pipes PDFmasatusAinda não há avaliações

- 2400 Tema DCDocumento7 páginas2400 Tema DCMasoodMiyanAinda não há avaliações

- New Storage Tanks Design GuidelinesDocumento6 páginasNew Storage Tanks Design GuidelinespaaryAinda não há avaliações

- Calculation For Sight Glass FlangeDocumento4 páginasCalculation For Sight Glass FlangeOmil Rastogi0% (2)

- Wind Load AS1170 2Documento15 páginasWind Load AS1170 2Divesh rahulAinda não há avaliações

- ISO 10025 & 10027 Steel SymbolsDocumento0 páginaISO 10025 & 10027 Steel SymbolsbreeeeezzzzzeAinda não há avaliações

- Annex 1.8 I Beams European GradesDocumento12 páginasAnnex 1.8 I Beams European GradesAbdullah NajjarAinda não há avaliações

- Table of Material Properties For Structural Steel S235, S275, S355, S420Documento4 páginasTable of Material Properties For Structural Steel S235, S275, S355, S420vodounnou0% (1)

- En 10025 2004 BDocumento10 páginasEn 10025 2004 BPrasanna RajaAinda não há avaliações

- En 10025 S235JR SteelDocumento1 páginaEn 10025 S235JR SteelNestor OliAinda não há avaliações

- Carbon Steel Tubes Buy Stainless Steel Coil Ferrite Meter MF300F+Documento8 páginasCarbon Steel Tubes Buy Stainless Steel Coil Ferrite Meter MF300F+Stoyan PetkovAinda não há avaliações

- Ruukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Documento6 páginasRuukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Cad AutocadAinda não há avaliações

- Inspecting NPTF ThreadsDocumento2 páginasInspecting NPTF Threadsapply19842371Ainda não há avaliações

- Blind Flange Thickness ChartDocumento2 páginasBlind Flange Thickness Chartapply19842371Ainda não há avaliações

- Quality Assurance Audit For Piping FabricationDocumento3 páginasQuality Assurance Audit For Piping Fabricationapply19842371Ainda não há avaliações

- Weld Weave WidthDocumento4 páginasWeld Weave Widthapply19842371Ainda não há avaliações

- The Detection of Alpha Prime in Duplex Stainless SteelsDocumento10 páginasThe Detection of Alpha Prime in Duplex Stainless Steelsapply19842371Ainda não há avaliações

- Phenicon HS: Epoxy Novolac Phenolic Tank LiningDocumento2 páginasPhenicon HS: Epoxy Novolac Phenolic Tank Liningapply19842371Ainda não há avaliações

- Casting Definitions and TerminologyDocumento15 páginasCasting Definitions and TerminologyCharlie ChongAinda não há avaliações

- Welding Topic-Weld Joint Fit-Up PDFDocumento2 páginasWelding Topic-Weld Joint Fit-Up PDFapply19842371Ainda não há avaliações

- DesignGuidelinesforStainlessSteelinPipingSystems 9024Documento25 páginasDesignGuidelinesforStainlessSteelinPipingSystems 9024Klich77Ainda não há avaliações

- Epoxy HR: Technical Data SheetDocumento5 páginasEpoxy HR: Technical Data Sheetapply19842371Ainda não há avaliações

- Radial Projection PDFDocumento1 páginaRadial Projection PDFapply19842371100% (1)

- En 10204 2004 - Type 3.2 Inspection Certification by LRDocumento2 páginasEn 10204 2004 - Type 3.2 Inspection Certification by LRapply19842371Ainda não há avaliações

- API 570 ResponsibilitiesDocumento6 páginasAPI 570 Responsibilitiesapply19842371Ainda não há avaliações

- Fluorokote #1 PDFDocumento8 páginasFluorokote #1 PDFapply19842371Ainda não há avaliações

- Stellite 6 DS01-21708 (S R0808)Documento2 páginasStellite 6 DS01-21708 (S R0808)bwv1006Ainda não há avaliações

- Stellite 21 DatasheetDocumento2 páginasStellite 21 Datasheetapply19842371100% (3)

- Weld MapsDocumento2 páginasWeld MapsikhlitAinda não há avaliações

- Mechanical Properties Inch Fasteners ThruwayDocumento4 páginasMechanical Properties Inch Fasteners Thruwayapply19842371Ainda não há avaliações

- Fundamentals of Orifice Metering FMCDocumento7 páginasFundamentals of Orifice Metering FMCapply19842371Ainda não há avaliações

- Specification For Hot Insulation PDFDocumento55 páginasSpecification For Hot Insulation PDFapply19842371Ainda não há avaliações

- Piping Design For Potentially Lethal Chemicals WS PDFDocumento11 páginasPiping Design For Potentially Lethal Chemicals WS PDFapply19842371Ainda não há avaliações

- Guidelines On DP, Op, Mop, Maop, Mawp, PSV SetpointsDocumento3 páginasGuidelines On DP, Op, Mop, Maop, Mawp, PSV Setpointsankur2061Ainda não há avaliações

- Permissible Imperfections in Flange Facing Finish For Raised Face and Large Male and Female FlangesDocumento1 páginaPermissible Imperfections in Flange Facing Finish For Raised Face and Large Male and Female Flangesapply19842371Ainda não há avaliações

- ASME B31.1&Section I Material IdentificationDocumento2 páginasASME B31.1&Section I Material Identificationapply19842371Ainda não há avaliações

- RT&Radiographic Interpretation NotesDocumento85 páginasRT&Radiographic Interpretation Notesapply19842371100% (1)

- AQA - Chemistry - Using Resources - GraspIT - GCSE - NO SPACESDocumento4 páginasAQA - Chemistry - Using Resources - GraspIT - GCSE - NO SPACESBenjamin WatsonAinda não há avaliações

- Quotation: Tianjin Youfa Steel Pipe Group Tianjin Youfa International Trade Co., LTDDocumento3 páginasQuotation: Tianjin Youfa Steel Pipe Group Tianjin Youfa International Trade Co., LTDAnonymous 6HjnToW6Ainda não há avaliações

- Basic Principles of Heat TreatmentDocumento26 páginasBasic Principles of Heat TreatmentYaser Mohamed AbasAinda não há avaliações

- Chemistry of The Atmosphere R0 - 220830Documento31 páginasChemistry of The Atmosphere R0 - 220830Kelly Roxelle De GuzmanAinda não há avaliações

- Compression Spring Material and FormulasDocumento23 páginasCompression Spring Material and FormulasVignesh T ShekarAinda não há avaliações

- LORD AC-902 LC Experimental TDSDocumento2 páginasLORD AC-902 LC Experimental TDSVenkata ChadaAinda não há avaliações

- Fosroc Supercast SW20: Constructive SolutionsDocumento2 páginasFosroc Supercast SW20: Constructive SolutionsTejinder KumarAinda não há avaliações

- 10.1111@jerd.12615Documento9 páginas10.1111@jerd.12615Mairen RamirezAinda não há avaliações

- Calculating Movement and Other Effects When Establishing Sealant Joint WidthDocumento21 páginasCalculating Movement and Other Effects When Establishing Sealant Joint WidthlearsiAinda não há avaliações

- Types of Solutions - C11-4-01Documento8 páginasTypes of Solutions - C11-4-01Shashi PareekAinda não há avaliações

- CE8011 Design of Prestressed Concrete Structure - by WWW - Learnengineering.inDocumento185 páginasCE8011 Design of Prestressed Concrete Structure - by WWW - Learnengineering.inSourav DasAinda não há avaliações

- Pds Insulyte 9Documento1 páginaPds Insulyte 9pulakjaiswal85Ainda não há avaliações

- Dhule, Maharashtra-lINDIA: 1000TC-80Compx14Den/225x78 8-123"satinDocumento1 páginaDhule, Maharashtra-lINDIA: 1000TC-80Compx14Den/225x78 8-123"satinDeepak ThoratAinda não há avaliações

- D449Documento2 páginasD449Rangga Adi100% (2)

- Mahalakshmi: Engineering CollegeDocumento16 páginasMahalakshmi: Engineering CollegeVijeesh VijayalayamAinda não há avaliações

- Modification of Dielectric Properties, After Barium Titanate Nanoparticles Sintering, From A Thermoplastic Polymer MatrixDocumento6 páginasModification of Dielectric Properties, After Barium Titanate Nanoparticles Sintering, From A Thermoplastic Polymer MatrixScarlatache VladAinda não há avaliações

- Brosur Deltagrout CG - REV - 20100725MTDocumento2 páginasBrosur Deltagrout CG - REV - 20100725MTjimdabrondAinda não há avaliações

- A Review On Use of FRP Mesh and Bamboo Fiber Composite Material For AAC Block Masonry Wall Strengthening and WaterDocumento5 páginasA Review On Use of FRP Mesh and Bamboo Fiber Composite Material For AAC Block Masonry Wall Strengthening and WaterIJRASETPublicationsAinda não há avaliações

- Chapter OneDocumento17 páginasChapter OneAlemayehu MitekuAinda não há avaliações

- Elvaloy AsphaltDocumento10 páginasElvaloy AsphaltHafiz IrzaAinda não há avaliações

- 4 E308 Sus FcawDocumento1 página4 E308 Sus FcawMohd Farid OsmanAinda não há avaliações

- Cleat WiringDocumento10 páginasCleat WiringBhaswati PandaAinda não há avaliações

- En 1090 2 Ex3 PDFDocumento1 páginaEn 1090 2 Ex3 PDFlai nguyenAinda não há avaliações

- AlAloy PDFDocumento376 páginasAlAloy PDFDr J KandasamyAinda não há avaliações

- Worksheet For Design of Concrete Mix: Type 1 Portland CementDocumento1 páginaWorksheet For Design of Concrete Mix: Type 1 Portland CementLuis PacquiaoAinda não há avaliações

- Key 1Documento4 páginasKey 1Rhieza Perez UmandalAinda não há avaliações

- By Stephen West: InstructionsDocumento3 páginasBy Stephen West: InstructionsTejidos RomeroAinda não há avaliações

- SAI Global - Watermark Certificate Pex FittingsDocumento18 páginasSAI Global - Watermark Certificate Pex FittingsLogan BrownAinda não há avaliações

- Progress in Organic Coatings: R. Torkaman, S. Darvishi, M. Jokar, M. Kharaziha, M KarbasiDocumento8 páginasProgress in Organic Coatings: R. Torkaman, S. Darvishi, M. Jokar, M. Kharaziha, M Karbasireza torkamanAinda não há avaliações

- Ceramic Tile Failure in A Dairy Processing PlantDocumento10 páginasCeramic Tile Failure in A Dairy Processing PlantjeccoAinda não há avaliações

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindAinda não há avaliações

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNo EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNota: 4.5 de 5 estrelas4.5/5 (27)

- 507 Mechanical Movements: Mechanisms and DevicesNo Everand507 Mechanical Movements: Mechanisms and DevicesNota: 4 de 5 estrelas4/5 (28)

- Laws of UX: Using Psychology to Design Better Products & ServicesNo EverandLaws of UX: Using Psychology to Design Better Products & ServicesNota: 5 de 5 estrelas5/5 (9)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNo EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNota: 4.5 de 5 estrelas4.5/5 (2)

- Design for How People Think: Using Brain Science to Build Better ProductsNo EverandDesign for How People Think: Using Brain Science to Build Better ProductsNota: 4 de 5 estrelas4/5 (8)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsAinda não há avaliações

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneNo EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneNota: 4.5 de 5 estrelas4.5/5 (5)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsNo EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsNota: 4 de 5 estrelas4/5 (5)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!No EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Nota: 4 de 5 estrelas4/5 (3)

- Analog Design and Simulation Using OrCAD Capture and PSpiceNo EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceAinda não há avaliações

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceNo EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceNota: 4 de 5 estrelas4/5 (19)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsAinda não há avaliações

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsAinda não há avaliações

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNo EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNota: 4 de 5 estrelas4/5 (10)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionNo EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionAinda não há avaliações

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsNo EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsNota: 5 de 5 estrelas5/5 (1)