Escolar Documentos

Profissional Documentos

Cultura Documentos

15 187 Ciobotici 15

Enviado por

Iulia TerrynTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

15 187 Ciobotici 15

Enviado por

Iulia TerrynDireitos autorais:

Formatos disponíveis

Environmental Engineering and Management Journal

March 2016, Vol.15, No. 3, 613-625

http://omicron.ch.tuiasi.ro/EEMJ/

Gheorghe Asachi Technical University of Iasi, Romania

ECO-INNOVATIVE TECHNOLOGIES FOR MITIGATING GASEOUS

EMISSIONS FROM WASTEWATER COLLECTION SYSTEMS

Iulia Carmen Ciobotici Terryn, Andreea Cocarcea Rusei,

Marius Stamate, Iuliana Lazar

Vasile Alecsandri University of Bacau, Faculty of Engineering, Calea Marasesti 157, 600115 Bacau, Romania

Abstract

The study aims to identify important challenges that the practitioners and researchers in wastewater collection systems are facing

in order to reduce the emissions of hydrogen sulphide and greenhouse gas emissions. Based on literature review, it identifies the

main technologies used for avoiding and removing odorous compounds from wastewater gas streams. The paper also highlights

issues pertaining to the emission and biofiltration of hydrogen sulphide, methane and nitrous oxide from sewage conveyance

from Bacau city. The results illustrate that the eco-innovative technologies as it is the case in the vacuum system and biofiltration

have an important potential to mitigate the environmental impact of wastewater collection in what concerns the emission of

harmful gases (hydrogen sulphide) and greenhouse gas emissions at the level of lift stations or vacuum stations.

Key words: biofiltration, green-technologies, sewer gas emissions, vacuum sewer system, wastewater conveyance

Received: August, 2015; Revised final: February, 2016; Accepted: February, 2016

1. Introduction

Due to worldwide increasing of urbanization

and large connection to wastewater collecting

systems, the development of economic and effective

techniques to control air emissions are necessary to

fight global warming and other air-related issues. Air

pollution has become a worldwide concern because

different pollutants play an important role in

atmospheric pollution and global warming (Aldabe et

al., 2012; Iordache and Dunea, 2013; Vincze-Csom

et al., 2012). The sustainable design thinking and

operations around the carbon footprint and

greenhouse gas emissions (GHG) abatement

technologies represent an important aspect on

environmental policy agenda (Li et al., 2014).

There are two types of innovations:

incremental and radical (Valle and Vazquez-Bustelo,

2009). Some of the GHG emissions abatement

technologies are labelled as radical innovations, and

it is considered that they have the capacity to

contribute to the overall impact on the climate

change. A radical innovation (Garcia and Calantone,

2002; Schuh et al., 2016), as it is the case of vacuum

sewer system, requires flexibility and creativity in

resource use and functioning, with a strong resilience

capacity, while incremental innovations follow more

formal and predictable route, considering the

traditional model of wastewater collection.

Incremental innovations do not have the capacity to

improve the environmental conditions radically; that

is why our study focuses both on radical and

incremental innovations.

In what concerns the impact of wastewater

collection, the literature points out on hydrogen

sulphide and fugitive greenhouse gas emissions

(carbon dioxide, methane, nitrous oxide, etc.). These

sewer gases bring an important contribution to the

global warming impact category (GHG), or pose

human health risks for operators and population and

may deteriorate de structural integrity of the sewers

(H2S). The review of the most important literature

Author to whom all correspondence should be addressed: e-mail: julyci@yahoo.com; Phone: + 40745434232

Ciobotici Terryn et al./Environmental Engineering and Management Journal 15 (2016), 3, 613-625

emphasizes that the level of sewer system emissions

is not sufficiently analyzed, and there are

uncertainties associated with these emissions in what

concerns the emission factors (Table 1). There are no

standardized methods of evaluating fugitive

emissions in sewer networks. Regarding the

conventional wastewater collection, the literature

points out on the fugitive emissions as methane

(Czepiel et al., 1993; Daelman et al., 2012; Foley et

al., 2010a; Lane and Lant, 2012) nitrous oxide

(Denman et al., 2007; Foley et al., 2010b; Short et

al., 2014) and hydrogen sulphide (Lahav et al., 2006)

generated at the level of manholes and wastewater

lift stations that bring an important contribution to

the impact category global warming.

The paucity of research in technologies to

control and remove the odorous compounds from the

wastewater stream gas can have a significant impact

on the implementation of innovative technologies for

wastewater collection. Nowadays, the choice of the

most suitable techniques needs to be taken into

consideration because there are different air

emissions abatement methods that can be used based

on the wastewater system characteristics, flow rate

and concentration of volatile organic compounds

(VOCs) and other gases in the effluent sewer gas to

be treated. The purpose of this paper is to address this

research gap to conduct a check of literature

regarding main sewer emissions and available

technologies that have the potential to make a

considerable contribution to reduce the emissions of

GHG production and hydrogen sulphide in

wastewater collection process. New perspectives on

the potential of eco-innovative technologies for

greening the wastewater collection make the subject

of investigation.

The development of alternative wastewater

collecting systems or technologies to treat odorous

gases from wastewater collection system has the

potential to reduce the emissions of sewer gases, and

consequently their impact on the environment and

human health. The study is the result of a literature

review on main sewer gases emissions, technological

advancement on sewer gases treatment. Literature

review surveyed scholarly articles, books and other

sources relevant to the topic of sewer gases emissions

and techniques and technologies that have the

potential to mitigate these emissions. Technical

standards, regulations, websites of the companies that

produce or supply vacuum sewer systems, were

reviewed to catch up with the newest advancements

wastewater collections and treatment of sewer gases.

Case studies, where biofilters were used successfully

to treat emissions from wastewater facilities, made de

subject of the literature review. Limitations of

biofiltration were obtained from the literature and

discussed. Technical details and performance

indicators about the vacuum sewer systems were

obtained from the respondents of DFR System

Romania and Valrom Industrie, companies that

supply in Romania vacuum sewer technologies. A

case study was analyzed in order to test the potential

614

of application of biofiltration for mitigating sewer

gases from wastewater lift stations in Bacau City.

2. Review of odor problems around conventional

wastewater collection system

There are two types of conventional sewers

based on hydraulic characteristics and purposes:

gravity and pressure sewers. Gravity sewers are used

when the natural slopes are sufficient enough to

convey a flow while the pressure or pumped sewer

transports wastewater using pressure to collect

wastewater (Lim et al., 2013). The conventional

sewer system is used to collect wastewater from

multiple sources and convey the wastewater by

gravity to a wastewater treatment plant or one or

more lift stations, and then gradually to a wastewater

treatment plant (Buchanan et al., 2010b; USEPA,

2013). The sewers are designed that the slope and the

pipe dimensions are adequate to maintain flow

towards the discharge point and create self-cleaning,

therefore preventing suspended solids from settling.

The sewers follow a specific alignment, with

manholes placed at set intervals. Concrete or PVC

manholes allow access for inspection, cleaning, and

repair. The installation of the system on flat terrain

typically requires deep excavations (between 2 to 6

m below ground level), and proper preparation and

bedding materials are required in the pipeline

trenches. Installation of pipes, manholes, lift stations,

building connections, junction chambers or boxes

and terminal cleanouts, requires large amounts of

excavation. When required, one or more lift stations

are installed at lower elevations of the network to

collect and pump the sewage up to another gravity

line, to convey wastewater over higher elevations or

up to a wastewater treatment plant. Lift stations can

be compact, but sufficient space is needed to install a

wet-well, pumps and control panels and the electric

service.

Fig. 1. The level of wastewater in the gravity sewer and

rising main

The system has several advantages. The most

important it is the opportunity for collecting

wastewater from large urban areas where other

solutions are less feasible. Another advantage reflects

the capacity of the system to retain grit and solids in

sanitary sewage at lift station level (baskets) with less

pressure on the wastewater treatment plant.

Eco-innovative technologies for mitigating gaseous emissions from wastewater collection systems

Instead, it's important function associated with

wastewater collection, which generates some

environmental and health benefits for household and

economic consumers, the system presents some

negative externalities represented by wastewater

seepage and greenhouse gases emissions at the level

of the lift stations and manhole lids. During the

conveyance process, a periodic inspection and

maintenance of sewers must be performed

particularly for aging pipes since the wastewater

collection system components are subject to damage

from aging, excessive traffic, and biochemical

reactions (Fenner, 2000). Periodic flushing of the

sewers is needed. Leaky pipe connections or cracks

of the sewers are a potential source of groundwater

pollution and the stormwater infiltration in the pipes

exerting pressure on the wastewater treatment plant

to treat extra water during the wet weather

conditions. Sewers exist as widespread networks, and

malodorous are identified where the sewer

atmosphere is in contact with the anaerobic

wastewater and sewer gas escapes into the

atmosphere. Conventional wastewater collection is

an open system through its manhole lids and lift

stations that are evident at the surface but not

obtrusive. Odors are associated with access points,

and odor control may be necessary, aspects that will

be approached later.

A review of the recent literature provides

evidence on fugitive greenhouse gas emissions from

the wastewater system. Biochemical reactions that

occur in sewer pipes produce a considerable amount

of hydrogen sulphide gas, methane gas, carbon

dioxide, nitrous oxide and other volatile substances

known as in-sewer gases (Foley et al., 2010a, 2010b;

Lane and Lant, 2012). These toxic gases lead to

contamination of the natural environment, ozone

layer depletion, sewer pipe corrosion, costly

operational expenses and operators safety issues.

During the conveyance of wastewater three

types of in- sewer processes occur: physical,

chemical and biological. Physical processes taking

place are related to the bio-film build-ups and erosion

of sewer walls. Chemical processes occur due to the

gas transfer over the air-water interface within sewers

(emission of hydrogen sulphide) and the chemical

oxidation and precipitation of sulphide. In biological

processes, bacteria degrade organic compounds, to

obtain carbon for cellular growth. Aerobic conditions

produce carbon dioxide, whereas anaerobic

conditions generate volatile substances (Lim et al.,

2013).

3. Emissions from wastewater conveyance

Emissions

can

occur

by

diffusive

mechanisms. Diffusion occurs when organic

concentrations at the surface of wastewater are much

higher than ambient concentrations. Thus, organic

volatilize or diffuse into the air to reach an

equilibrium between aqueous and vapor phases. The

main emissions resulted from the conveyance of

wastewater are methane, nitrous oxide, and hydrogen

sulphide. There are contradictory data concerning the

generation of methane in sewer networks. Even

though the IPCC assumes that the potential for CH4

formation from the sewer is negligible, recent studies

concluded that the generation of CH4 was substantial

in sewer networks. Thus, the CH4 generation was

observed in sewer network (Guisasola et al., 2009).

Worldwide, wastewater was the fifth largest source

of anthropogenic CH4 emissions in 2000 (Gupta and

Singh, 2012). Methane is generated by anaerobic

degradation of organic matter and has a potential of

global warming of 25 eq. CO2 (IPCC, 2007). The

main cause of CH4 generation in sewers is the

microbiological activity in anaerobic conditions.

IPCC formulated a methodology for calculation of

CH4 emissions using the maxim amount of CH4 that

can be produced from a given quantity of organic

matter expressed in BOD or COD and a methane

correction factor (0-0.8) that indicates the degree to

which the capacity to produce CH4 is realized for

each type of system or treatment technology (IPCC,

2007). The methane correction factor it is an

indication of the degree to which the system is

anaerobic. If country-specific data are not available, a

default value, 0.6 kg CH4/kg BOD or 0.25 kg CH4/kg

COD can be used.

In comparison with emission factors

calculated at the level of wastewater treatment plants

(WWTP), few studies were conducted in what

concerns the emission level of CH4 at the sewer level,

including both dissolved methane and gas phase

(Table 1).

Table 1 resumes the main CH4 emission

factors the literature highlights.

The studies done on the CH4 emissions do not

provides insight on the potential and level of CH4

stripped along the entire sewer network.

Another gas with global warming potential is

nitrous oxide, associated with the degradation of

nitrogen components in the wastewater. Nowadays,

the N2O exceeds the CFC-12 and worldwide,

wastewater is the sixth largest contributor to N2O

emissions, accounting for 3% of N2O emissions from

all sources (Denman et al., 2007; Gupta and Singh,

2012; IPCC, 2007; Short et al., 2014). N2O is a

greenhouse gas with tremendous global warming

potential (GWP). When compared to carbon dioxide

(CO2), N2O has 298 times the ability per molecule of

gas to trap heat in the atmosphere.

Nitrous oxide also causes ozone depletion

(USEPA, 2013) due to its capacity to absorb infrared

rays, inertia and long lifespan in the atmosphere. In

what concerns the N2O production into the sewer, the

literature highlights emission factors as they are

presented in the Table 2.

The production of N2O in wastewater sewers

varies according to the type of wastewater, organic

load, aeration regime, pH, relative abundance and

activity of bacteria (Foley et al., 2010b). The IPCC

guide indicates that the closed sewers do not

represent a source of N2O.

615

Ciobotici Terryn et al./Environmental Engineering and Management Journal 15 (2016), 3, 613-625

Table 2 resumes the main N2O emission

factors the literature highlights.

Hydrogen sulphide (H2S) has been

investigated in the last years in the gravitational

wastewater collection networks, especially due to the

specific smell of rotten eggs and health risks for the

maintenance staff and increased corrosion of metals

and concrete sewer disintegration, phenomenon

created by the accumulation of H2S in the space

above the wastewater flow in the sewers (Lahav et

al., 2006).

Usually, the gas concentration increases with

temperature and daylight (Cabezas et al., 2005).

Collection systems in warm climates, summer

conditions or the situations that do not ensure the

flow-through velocities (0.7 m/s) to prevent the

stagnation of the wastewater allow for the occurrence

of septic conditions. In these situations, bacteria use

all the available oxygen in the water to decompose

the organic matter. The anaerobic bacteria reduce

sulphur compounds (SO4) to produce sulphides

(SO2). Under anaerobic conditions, sulphides

combine with hydrogen to produce hydrogen

sulphide gas. The damp surface above the water line

is the place of aerobic conditions in partly full

sewers. Here the aerobic bacteria oxidize the H2S to

produce sulphuric acid (H2SO4) agent responsible for

the corrosion and potential collapse of the pipes,

especially at the joints. H2S is present in

concentrations that generally fluctuate from 100 ppm

to more than 1000 ppm, and the concentration

increases with temperature and daylight (Cabezas et

al., 2005).

According to the Romanian regulations

(Romanian Government, 2005), the maximum H2S

value admitted in the sewer network is of 1 mg/L (1

ppm). The normative does not contain admissible

values for CH4 and N2O.

Table 3 resumes the main H2S emission

factors the literature highlights.

4. Odor containment and treatment

Nowadays, a number of technologies have

been developed to avoid and treat odorous air

emissions from wastewater collecting systems. These

include end-of-pipe methods (physical, biological

and chemical methods), but also clean technologies

that radically restructure the classical solution, with

material and energy savings, as is the case of in the

vacuum sewer. The advanced technologies lead to

phasing out the polluting technical systems that

cannot be reconciled with environmental goals. The

emphasis is on preventive measures and not so much

on repairing the damage.

This section discusses the main advantages

and disadvantages of the main technologies and

techniques used for the reduction of in-sewer

emissions.

Table 1. Methane emission factors at the level of wastewater system

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Author

Daelman et al. (2013)

Czepiel et al. (1993)

Wang and Li (2011)

Lane and Lant (2012)

Guisasola et al. (2009)

Foley et al. (2009)

Liu et al. (2015)

EU (2014)

GWRC (2011)

Liu et al. (2015)

Chaosakul et al. (2014)

Place of emission

WWTP- dissolved methane

WWTP- dissolved methane

WWTP - dissolved methane

WWTP - dissolved methane

WWTP - dissolved methane

WWTP - dissolved methane

sewer sediments- dissolved methane

sewer- dissolved methane

Rising main

Rising main

Gravity sewer

Lift station- gas phase concentration

Sewer - gas phase concentration

Manholes- gas phase concentration

Sewer - gas phase concentration

Liu et al. (2015)

GWRC (2011)

Chaosakul et al. (2014)

Emission factors

8.5-11.0 g CH4/kg COD influent

1.6 CH4/kg COD influent

0.8 g CH4/kg COD influent

5 mg/l; 7 mg/l; 12 mg/l

2025 mg/L wastewater

1.26 g CH4/m2-d

0.13 to 2.09 g CH4/ m2-d

0.24 kg CH4/kg COD

5.3 mg/l

4.8 mg/l

10.1 mg/l

7,000-12,000 ppmv

1,400-2,800 ppmv

50,00 ppmv

1,350-12,000 ppmv

Table 2. N2O emission factors at the level of wastewater system

1

2

Author

Short et al. (2014)

IPCC (2007)

Place of emission

Conventional sewer system

Wastewater treatment plant

Emission factors

0.85 g N2O/person/year to 3.5 g N2O /person/year

3.2 g N2O/person/year

Table 3. H2S emission factors at the level of wastewater system

1

2

616

Author

Cabezas et al. (2005)

Romanian Government (2005)

Place of emission

Conventional sewer system

Conventional sewer system

Emission factors

100 ppm to 1,000ppm

1 ppm

Eco-innovative technologies for mitigating gaseous emissions from wastewater collection systems

4.1. Biological methods for the reduction of in-sewer

emissions Biofiltration

Biofiltration can be traced to its earliest roots

for odor control at sewage treatment plants in 1923.

Bach, a German scientist, used biological processes

to treat the hydrogen sulphide emissions at sewage

treatment plants in Germany. Later, the first patent

for a soil bed biofilter designed to treat odorous gases

was issued by the United States in 1957 to Richard

Pomeroy (Leson and Winer, 1991). Patents continued

to be issued for methods of cleaning waste-gas

streams using biofiltration technology for the next

several decades. Biofiltration can be considered an

incremental innovation.

Biofiltration is an environmentally friendly

technology for the treatment of odorous and toxic

emissions (Auterska and Keder, 2008; Cabezas et al.,

2005). Biofiltration is capable of degrading a wide

variety of contaminants as aliphatic hydrocarbons

(methane,

propane),

aromatic

hydrocarbons

(benzene, phenol, and toluene), chlorinated

hydrocarbons (carbon tetrachloride, chloroform, and

trichloroethylene), amines, nitrites, alcohols,

aldehydes, esters, inorganic compounds (ammonia,

hydrogen sulphide, and nitrogen oxide), ketones,

sulphur containing compounds, terpenes. The best

biodegradability has aromatic hydrocarbons, amines,

alcohols, aldehydes, esters, inorganic compounds,

ketones (Govind, 2005). Mainly, the biofiltration is

seen as a viable alternative to reduce emissions of

CO2, NOx, SOx and particulate matters (PM).

Biofiltration represents a method for the global

demands of reduced carbon dioxide emissions

(Govind, 2009). The microorganisms break the

organic matter into CO2 and H2O (Eq. 1). This

process is enzymatic catalyzed.

Organic pollutant + OxygenCO2 + H2O + heat +

biomass

(1)

Biofilters can be either classified into simple

(open-bed) or engineered biofilters (closed-bed) and

horizontal or vertical.

4.1.1. Common biofilters

In these stations, the contaminated air

generated in the wastewater is injected into a bed

filled with an appropriate natural porous medium

(peat, turf, mulch, brier, wood chips, pinewood bark)

that serve as a carrier for microorganism where the

pollutants are converted by bacteria into innocuous

gases, water, and organic biomass. Media moisture

control is essential for effective treatment in the

biofilter (Janni et al., 2011). Another important key

factor that influences the biofilter performance is the

residence time, defined as the empty bed filter

volume divided by the airflow rate. Biofilters with

higher moisture contents and longer retention times

were shown to have the best removal of ammonia

and hydrogen sulphide (Sun et al., 2000).

Some of the disadvantages of natural media

include the inability to handle biomass growth,

resulting in clogging of media, inability to provide

nitrogen and phosphorus and other nutrients, inability

to handle small particulate matters in the gas phase,

and transformation of hydrogen sulphide to sulphate

pH decrease and shut down of the bed because of

acidification (Govind, 2009). The conventional

biofiltration is capable of degrading concentrations

that range between <1 ppmv-25 ppmv. The general

scheme of a biofilter is presented in Figs. 2 and 3.

The odorous air from the wastewater facility

(vacuum station/lift station) is introduced by air ducts

into the biofilter where the media breaks the organic

matter into CO2 and H2O.

Fig. 3 exemplifies the structure of a common

biofilter and subsequent processes that degrade the

organic matter to CO2 and H2O.

4.1.2. Multi-phase biofilters

In the last years synthetic media are used in

biofilters (ceramic, plastic, metallic, other composite

material) in order to counteract the problems with

low biodegradability rates of naturally bioactive

media (peat, compost settling) and limited capacity to

neutralize acidic products of degradation and for

enhancing the treatment of air with high

concentration contaminants (>25 ppmv - 5,000 ppmv

/ 0 - 8.3 g/m3).

These synthetic media are known as

biotrickling filters. Synthetic support media can be

in the form of high surface area pellets and some

situations can be coated with activated carbon to

enhance absorption of contaminants.

Fig. 2. General scheme of a biofilter including biofilter media, the air plenum and air ducts that introduce the odorous air

617

Ciobotici Terryn et al./Environmental Engineering and Management Journal 15 (2016), 3, 613-625

Fig. 3. Structure of a biofilter (adapted from http://eponline.com/articles/2010/09/13/good-compost-neighbor-uses-robust-odourcontrol.aspx?admgarea=Features)

Due to a high void fraction in the synthetic

media support (>80%), the biofilter provides more

space for the biofilm to grow without clogging of the

biomass on the support media. The media never has

to be replaced since the mineral nutrients are

supplied from an external source. The contact

between the biofilm and gas contaminants is also

large. The incoming gas is sprayed with water in the

incoming duct to humidify the gas. In a biotrickling

filter water is re-circulated through the biomedia bed,

therefore humidifying the gas stream and providing

water to the organisms attached to the surface of

biomedia. In Fig. 4 the biotrickling filter for H2S

degradation mechanism is represented. Fig. 4

highlights the structure of biotrickling filter and

processes that take place within it, specifically the

introduction of foul air, absorption and degradation

of H2S, and recycling of water and evacuation of

clean air.

accumulate in the recirculating water and re-entrain

into the exit at the top of the bed, reducing the

treatment efficiency (Govind, 2009). In another

approach, the term bioscrubber has been used when

water containing organisms from an activated sludge

water treatment system, is re-circulated through the

biomedia,

providing

active organisms

for

contaminant degradation in the gas phase, making the

system more robust against starvation. The system

present similar disadvantages as biotrickling filter.

Moreover, high inlet gas temperature can result in a

gradual heating of the external water treatment

system (Govind, 2009). Fig. 5 represents the general

structure of a bioscrubber.

Fig. 5. Diagram of a bioscrubber consists in a gas scrubber

and a biological reactor (taken from

http://cdn.intechopen.com/pdfs-wm/45120.pdf)

Fig. 4. Biotrickling filter (taken from

www.pnas.org/content/100/11/6308/F1.expansion.html)

In comparison with the normal biofilter, in the

biotrickling filter the pH can be controlled by adding

buffers in the nutrient flow. The volume of the

biotrickling filter is smaller than the volume of a

conventional biofilter for the same treatment

efficiency. Since the synthetic media is open, and

high gas velocities can be maintained, the oxygen

transfer is higher and, therefore, anaerobic regions

are not created in the biofilter.

Biotrickling filters also feature a series of

disadvantages as: high media costs, matter in the gas

phase clogs up the bed, biomass clogging can occur;

water soluble compounds in the gas phase

618

Well-designed and managed biofilters can

reduce odors and hydrogen sulphide (H2S) by as

much as 95% and ammonia (NH3) by 80% (Janni et

al., 2011). In some cases, biofilters treat 100% of the

exhausted ventilation air. In many other cases,

biofilters treat a portion of the exhaust ventilation air.

4.1.3. Application of the biofilters in the wastewater

management. Biofilters for wastewater lift stations

emission mitigation

Biofilters can be used in some locations for

the treatment of odors emitted from wastewater lift

stations. Lift stations are usually the last collection

unit prior to the treatment system, accepting

wastewater from one or several sewer lines

Eco-innovative technologies for mitigating gaseous emissions from wastewater collection systems

(Buchanan et al., 2010b). The main function of the

lift station is to provide sufficient head pressure to

transport the collected wastewater to the wastewater

treatment plant. One or more pumps are used to

provide the head pressure and are generally designed

to operate or cut off based on preset high and low

wastewater levels.

The removal efficiency of the H2S proved to

be higher than 85% after three months of operation in

a case study in Bronsville, Texas, at wastewater lift

station 64 where both a simple and an engineered

biofilters were installed (Cabezas et al., 2005). It was

expected the efficiency of the biofiltration to increase

with the growth of microorganisms. Another

conclusion of the study mentioned above was that the

generation of H2S in the wet well is affected by the

water pumping frequency. The H2S concentration

decreased when one pump was on. The concentration

of H2S decreases at night due to lower temperature

and lower water consumption. High acidity affects

the microorganisms growth in the biofilter; that is

why the injection of clean water into the recycling

system is needed. Magnesium hydroxide helps to

control stripping of water acidity.

Another case study approaches the use of a

synthetic rock wool fiber material compact biofilter

at a lift station at the entrance of University of the

town of Lulea, northern Sweden (Andersson and

Hanus, 2006). The pilot biofilter composed of three

filter units was set-up inside the lift station. The filter

media was made of rockwool fiber with low density

(30 kg/m3), high porosity (65%) and a fiber diameter

of 4 m. A mixed bacterial culture from the

wastewater treatment plant was used as inoculums,

and nutrient pellets were added to the filter media.

The biofilter was endowed with an irrigation system

with spray nozzles at the inlet and the top of the

biofilter. Drainage was collected at the bottom of the

filter. The low concentration of pollutants rendered

the analytical evaluation of the biofilter performance

difficult. The screening of VOCs and reduced

sulphur compounds in the waste gas showed no

VOCs above the blank/threshold, but just dimethyl

sulphide, hydrogen sulphide, methyl mercaptan and

carbon sulphide, present at levels above the threshold

values. It was considered that the short empty bed

residence time (5-6 seconds), low-pressure drop

(350-500 Pa/m), low moisture content of the

rockwool (6%12%) and steady temperature

(102C) at the inlet of biofilter would negatively

affect the microbiological activity.

4.2. Physical methods for the reduction of in-sewer

emissions

Physical

methods

include

augmented

ventilation by injection of oxygen or air into the

sewer net to reduce anaerobic conditions, application

that incurs significant costs for chemical usage

(Gutierrez et al., 2008). Adsorbent systems represent

another physical method for removing odors,

consisting in static beds of granular material such as

activated carbon. The adsorbent system involves

higher costs for replacing and disposing of adsorbent.

The system is only feasible for soluble components

and not efficient in removing multiple odorous

compounds.

4.3. Chemical methods for the reduction of in-sewer

emissions

Chemical

methods

include

chemical

scrubbers,

chemical

precipitation,

chemical

oxidation, masking agents. A variety of chemicals are

used to prevent anaerobic conditions: ozone, chlorine

dioxide,

sodium

hypochlorite,

potassium

permanganate, hydrogen peroxide, ferric and calcium

nitrates, ferric chloride (Andersson and Hanus,

2006). Using chemicals has disadvantages as the

additional cost and formation of residual products.

5. Vacuum sewer system as a green technology for

wastewater collection and solution for odor

problems

Even though the gravity sewer system is one

of the most widely used conventional wastewater

collection systems, a great attention has been paid in

the last 30 years to the vacuum sewer system, a

radical innovation that brings both environmental

improvements and economic savings during the

construction and functioning phases (Airvac Inc.,

2013; Buchanan et al., 2010b; Roediger, 2013).

Vacuum sewer system a technology-push

innovation comes from radical changes in technology

without any change in the meaning of product (Dosi,

1982).

According to the information collected from

the European Standard (2013), and vacuum

technology providers as Roediger Vacuum GmbH

(Roediger, 2013) and AIRVAC Inc. (2013) vacuum

wastewater collection systems are based on the

principle of using differential pressure in vacuum

pipelines to collect the wastewater and transport it to

a vacuum station, then gradually to a centralized

wastewater treatment plant (Buchanan et al., 2010b).

The general conditions conducting to the use of the

vacuum system include special terrain conditions as

unstable soil, flat terrain, rolling land with small

elevations, high water table, sensitive eco-systems,

and developed rural areas. If the vacuum system is

more economic in flat terrain, it has a limited

capacity to pull water uphill that is why in conditions

with high elevations or hilly areas the gravity system

is more feasible to be implemented or a combination

of the two systems. The general structure of the

vacuum sewer system it is presented in Fig. 6.

Vacuum sewer systems rely on gravity to

move wastewater from homes to a vacuum chamber.

Then the system uses differential air pressure as the

motive force to transport sewage. The main pipes are

under a vacuum of -0.5 to -0.7 bar, created by the

vacuum pumps located at the vacuum station. The

collecting chambers serve as an interface between the

619

Ciobotici Terryn et al./Environmental Engineering and Management Journal 15 (2016), 3, 613-625

gravitational line from consumers and vacuum line.

The wastewater is collected in a collecting reservoir

until the pressure sensor tube connected to the

controller that activates the opening of the vacuum

valve. The vacuum valve that is placed in a separate

chamber above the collecting reservoir is

pneumatically controlled and does not need energy

for functioning. When the valve is opened, the entire

system is maintained under vacuum. When the valve

opens, the wastewater is sucked from the collecting

chamber in the vacuum line and then in the vacuum

tank.

Vacuum mains are slightly sloped towards the

vacuum station (min 0.2%) excepting the lifts in the

saw tooth profile that help in keeping the sewer lines

shallow. The vacuum sewers are connected to a

vacuum station equipped with hydraulic, electrical,

ventilation and control unit installations. The vacuum

station is the heart of the system. The vacuum station

is a concrete building that shelters the vacuum

pumps, discharge pumps, and vacuum tank. The

vacuum stations maintain the vacuum in the system

though the vacuum pumps; collect the wastewater in

one or more vacuum tanks and pump the wastewater

towards a lift station, wastewater treatment plant or a

nearby sewer system.

The vacuum pumps maintain a negative

pressure between -0.4 and -0.6 bar in the collection

tank. The vacuum tank is made of steel dimensioned

according to the hourly flow rate and vacuum suction

capacity of the vacuum pumps. When the tank

pressure falls under a preset limit, the vacuum pumps

start working to restore the pressure. As such,

vacuum pumps run only for 2-3 hours a day. A

monitoring system is designed to indicate the status

of the vacuum valves and collection chambers. A

particular problem with the functioning of vacuum

sewers is the noise and odor created by the central

vacuum station. As air is drawn through the system,

sewer gases are extracted (Buchanan et al., 2010a).

The exhaust air leaving the vacuum reservoir is

treated in a biofilter, which can absorb most of the

gases and reduce odors. The biofilter uses a concrete

structure and a 1.3-1.5 deep media bed heaped on an

air piping system embedded in 30-60 cm gravels.

Odorous gases dissolve in a biofilm and

microbes in the biofilm absorb and metabolize the

odorous compounds, converting them into dissolved

mineral products of decomposition. Ground wood is

usually used and advantageous as a packing material

because it has high porosity and its organic content is

readily colonized by micro-organisms.

The filter media absorbs odors and volatile

compounds from the air stream by oxidation to

carbon, inorganic salts and water with the support of

micro-organisms.

According

to

Roediger

respondents, for most biofilters used for sewer gas

treatment, the residence time ranges from 30 seconds

to 1 minute. Longer residence times produce higher

efficiency. However, a design must minimize

residence time to allow the biofilter to accommodate

larger flow rates.

In comparison with the control technology as

is the case of the gravity or pressure wastewater

collection systems, the emissions at the level of

vacuum sewer system are reduced in the biological

filter mainly to carbon dioxide and water. By sucking

out the sewage out of the pipes, the vacuum pumps

generate unrefined gas that is eliminated 95-100% by

the biological filter (Roediger, 2013). According to

vacuum sewer system providers, bio-filters achieve a

reduction of sulphuric acid greater than 95%

(Roediger, 2013).

The vacuum sewer system is an ecoinnovative solution in wastewater management due

to the reduction of the environmental impact,

considering the high security of the system in what

concerns the spillage and odours, energy savings,

therefore internalizing the externalities (Buchanan et

al., 2010b).

Figs 7-9 exemplify the structure of a biofilter

designed for treating the vacuum station air stream

leaving the vacuum tank: concrete shaft, gravel layer,

PVC air ducts for air distribution and filter mass

represented by pinewood bark, chip woods and see

grass). The contaminated air is injected into the

bottom of the filter.

It moves up by advection through the porous

media where the pollutants are converted into

innocuous gases and water. The biofilter does not

need adding a supplementary source of water for

media humidification due to the water vapors

presented in the air stream.

The water resulted from the decomposition of

the organic matter in the biofilter it is drained and

introduced back a collecting chamber by pipes for

dewatering. Biofilter at the vacuum station in Prundu,

Giurgiu County, Romania is exemplified bellow.

The biofilter is designed according to the

vacuum pumps capacity as is exemplified in Table 4.

Fig. 6. Vacuum sewer system (taken from Airvac http://www.airvac.com/downloads_literature.htm)

620

Eco-innovative technologies for mitigating gaseous emissions from wastewater collection systems

Table 4. Relation between the vacuum pump capacity, area of biofilter and diameter of air ducts. Dimensioning of the biofilter is

related to the capacity of the vacuum pumps that also determine the diameter of the main air ducts and distribution air ducts

Absorption capacity of vacuum pumps

220 Nm/h

from 220 to 440 Nm/h

from 440 to 660 Nm/h

from 660 to 880 Nm/h

from 880 to 1100 Nm/h

Minimum area of biofilter

2.5 m

5.0 m

7.0 m

9.0 m

12.0 m

Fig. 7. Air ducts in the biofilter (Valrom Industrie, 2014)

Fig. 8. Gravel layer in the biofilter (Valrom Industrie,

2014)

Fig. 9. Packing material in the biofilter (Valrom Industrie,

2014)

The vacuum sewer system brings about

reductions of the construction costs, emissions cut

and reduced energy consumption in the operational

phase (Roediger, 2013).

The vacuum system uses smaller diameters

pipes, with a slight slope and reduced volume of

excavations. The vacuum sewer system proved to be

with 23.91% cheaper than the gravity sewer system,

while the pressure sewer system is only with 1.7%

cheaper than the gravity system (Panfil et al., 2013).

Because vacuum sewer lines can be buried in

shallower trenches, installation costs can be 25% less

Air duct/exhaust pipe

DN 125

DN 125

DN 150

DN 200

DN 200

Distribution air duct in biofilter

DN 80

DN 80

DN 100

DN 100

DN 100

than a comparable gravity or low-pressure sewer

system.

Electricity is used for the vacuum generators

to evacuate the pipelines and for the discharge pumps

to discharge wastewater out of the vacuum system in

an existing sewage system or a wastewater treatment

plant. Unlike the pressure system where the power is

provided at every entry point in the system using lift

stations, in vacuum sewerage, a vacuum is generated

at a single point in the sewerage system, thus

requiring only one point of energy consumption,

simplifying

power

sourcing

and

reducing

construction and ongoing operational costs. It is

reported that monthly power costs range from $1.66

to $3.34 per month per connection. Larger stations

typically have lower power consumption per

connection (Buchanan et al., 2010a). A comparative

study proved that the energy costs for the classical

solution exceed with 0.016 euro/m3 the vacuum

sewage solution (Terryn et al., 2014). Moreover,

based on the damage costs, the vacuum sewer system

is more efficient when analyzing the environmental

externalities. Based on a projection of the possibility

of the seepage occurrence, it was demonstrated that

the level of penalties for the classical system is 17

times higher in what concerns the biologic oxygen

demand (BOD5) and 14 times for suspended solids

(SS) (Terryn et al., 2014).

In what concerns the maintenance, the system

promises savings in costs, but also a reduction of the

environmental impact through the high security of

the system in what concerns the spillage and odors.

Even though the vacuum sewer system is feasible to

be implemented in flat terrain, with reduction of

construction costs, the appropriateness of the system

increases once with the number of connections. A

number of minimum 50-75 connections or more is

necessary, thus the entire investment including the

vacuum station, connection chambers, monitoring

system justifies the investment, and the investment

costs are recovered.

The vacuum system is economically efficient

and environmentally effective on long term,

integrating the environmental concerns into its design

(Buchanan et al., 2010b).

6. Potential of application of biofiltration for

mitigating sewer gases from wastewater lift

stations in Bacau City

According to the General Urban Plan for

Bacau municipality, Bacau County, Romania, the

entire sewer network measures 212.64 km. The

621

Ciobotici Terryn et al./Environmental Engineering and Management Journal 15 (2016), 3, 613-625

wastewater collecting system, built in the 1970s, is a

combined one, constructed of concrete and PVC

pipes with diameters ranging from 250 to 2200 mm.

For the new districts, the wastewater system is a

separated for two categories of flows.

For the lower areas seven wastewater lift

stations are used to move wastewater from gravity

pipelines to higher elevations. Sewage is fed into a

wet well. The well is equipped with electrical sensors

to detect the level of sewage. When the sewage level

rises to a predetermined point, one or more pumps

start to lift the sewage upward through a pressurized

pipe system called rising main from where the

sewage is discharged into a gravity manhole. The lift

stations were designed and constructed based on peak

hourly flow. The basins drain both the dry weather

and wet weather flows. For the lift stations, the

design is made on the basis of 4 x DWF (Dry weather

flow), running full.

Because of emissions of sewer gases and

malodorous that can occur in the wet well, especially

in the warm, dry season, the present chapter proposes

an estimation of the main sewer gases at the level of

each lift station and a basic technology to mitigate

the emissions. Wet-well maximum detention time in

constant speed pumps is typically 20 to 30 minutes.

When the volume of the wastewater in the wet well

increases, the sewer gases are pushed out. When the

volume of wastewater decreases, the surrounding

ambient air is dragged into the well to fill the water

column with the air. Therefore, the concentrations in

the air volume of the wet well changes depending

upon the water level in the well, according to water

consumption.

Odor and emission control is frequently

required for lift stations in many European Countries.

A simple and widely used odor control alternative is

minimizing wet-well turbulence. More effective

options include collection of odors generated at the

lift station and treating them in biofilters. The method

for estimation of main sewer gases is based on

emission factors. The Annual European Union

greenhouse gas inventory 1990-2012 and inventory

report 1014 (EU, 2014), estimated for wastewater

handling in Romania for the year 2012, an emission

factor (EF) of 0.24 kg CH4/kg degradable organic

component. The same document estimated an

emission factor of 0.01 kg N20-N/kg N in

wastewater, considering a protein consumption of

37.78 kg proteins/person/year and a N fraction of

0.16 kg N/kg proteins. For the H2S, the estimation

was made according to Romanian regulations.

Considering the emission factors, the dry

weather flow and the organic load in raw wastewater

expressed in biological oxygen demand (BOD), the

total yearly emission of CH4, N2O and H2S were

calculated as presented in Table 5.

In Bacau city, there are no technologies in

place to reduce sewer gas emissions at the level of

the sewer system. In this respect, this study proposes

the filtration of the air from the wet wells of lift

stations in biofilters. The method includes the

622

collection of sewer gases generated at the lift station

and treating them in biofilters. For the selected case

study, the biofiltration involves retrofitting the

existing lift stations, including some technical

modifications as installing a fan, a duct air to exhaust

the sewer air into a biofilter. The volume flow of gas

treated by one square meter of biofilter surface

(specific load of biofilter), is typically expressed as

m3 /m2 of filter surface/hour. This design parameter

may vary over a range of 100 to 400 Nm3/m2/hour

(IPCC, 2007).

In order to treat the air from wet wells, the

sewer air is expelled on the filter with an axial plate

mounted fans (the air flow Q=280 m3/h, maxim

pressure 26 mmCA, power absorbed - 120 kW),

resisting the corrosive nature of these compounds.

The entire ventilation flow from lift stations is lead

through the biofilters, resulting in a load 280 m3

air/m2/h. The proposed height of filter material is 1

m. Typically, the optimum temperature in a biofilter

is considered to be within the range of 30 to 38C.

Moisture balance is very critical. Gas moisture of

about 95% is required (IPCC, 2007). If the velocity

of wastewater does not assure the minimum

moisture, the filter material needs to be moisturized

with the help of a gas scrubber. A norm of 5 liters of

water at 1000 m3 of gas is considered as optimum.

In order to get a maximum odor reduction

from a biofilter, the air passing through the filter

must contact the filter media for a given amount of

time. This amount of time is known as the residence

time or empty bed contact time (EBCT). The selected

residence time is 30 seconds. According to IPCC

(2003), the performance rates of biofilters range from

75-95% for hydrocarbons and odors. Table 2 present

the maximum remaining sewer gases after

biofiltration, thus explaining the potential benefits of

applying bio-filtration for wastewater lift stations.

7. Conclusions

This section discusses the main findings and

implications obtained from the analysis, with respect

to the dimensions of GHG and other odorous

emissions from wastewater conveyance and

emissions abatement technologies that have the

capacity to contribute to the overall impact on

climate change and health impact.

The paucity of research in technologies to

control and remove the odorous compounds from a

wastewater stream gas can have a significant impact

on the implementation of innovative technologies for

wastewater collection. The research was subject to

several limitations. One of the main limitations of

this study is that the research focused only on main

hazardous gases (CH4, H2S, N2O) and hence, the

results over the sewer system gaseous emissions

cannot be considered representative for entire variety

of contaminants in the wastewater, especially when

consider the variety of chemical substances that are

evacuated in the sewer systems (detergents,

petroleum hydrocarbons etc.).

Eco-innovative technologies for mitigating gaseous emissions from wastewater collection systems

Table 5. Estimation of sewer gases at station level in Bacau city

Lift station

Capacity of

pumps (m3/h)

Dry

weather

flow

(m3/h)

Organic

load

BOD

(mg/L)

EF- CH4

(kg

CH4/kg

BOD)

EF- N2O

(kg N2O/

kg BOD)

EFH2S

(mg/L)

CH4

(to/year)

N2O

(t/year)

H2S

(t/year)

LS1-Serbanesti

District

(combined)

3 pumps

Q=3x 270

135

300

0.24

0.01

85.15

3.55

1.18

LS2-Arcade

Septilici Street

(combined)

2 pumps

Q=2 x 25

(domestic)

3 pumps

Q=3 x 110

(rain water)

2 separate

collection

basins

25

300

0.24

0.01

15.77

0.66

0.22

2 pumps

Q=2 x 80

20

300

0.24

0.01

12.61

0.53

0.18

2 pumps

Q=2 x 50

50

300

0.24

0.01

31.54

1.31

0.44

2 pumps

Q=2 x 65

65

300

0.24

0.01

41.00

1.71

0.57

4 pumps

Q=9-72 mc/h

120

300

0.24

0.01

75.69

3.15

1.05

5 pumps

Q=5 x 36

144

300

0.24

0.01

90.82

3.78

1.26

352.57

88.14

17.63

14.69

3.67

0.73

4.90

1.22

0.24

LS3- Triumfului

Street

(combined)

LS4- Gheraesti

district

(domestic

wastewater)

LS5- Muncii

street (domestic

wastewater)

LS6- Rozelor

street (domestic

wastewater)

LS7- Ciprian

Porumbescu

street (domestic

wastewater)

Total emissions

Minimum efficiency removal- 75% (emissions released into the atmosphere after biofiltration)

Maximum efficiency removal- 95% (emissions released into the atmosphere after biofiltration)

The article illustrates that the eco-innovative

technologies as it is the case of the vacuum sewer

system and biofiltration have an important potential

to mitigate the environmental impact of wastewater

collection in what concerns the emission of harmful

gases (hydrogen sulphide) and greenhouse gas

emissions at the level of lift stations or vacuum

stations. Regarding costs and benefits, vacuum sewer

system is more efficient than classical sewer system.

The solution of biofilters installation for the

treatment of sewer gases in the classical sewer

system is opportune; anyhow, the efficiency of the

system in removing sewer gases is lower than within

the vacuum sewer due to fugitive emissions at the

level of manhole lids. When radical innovations

cannot be introduced, as can be drawn from the case

study for Bacau City, small interventions as installing

biofilters at the level of lift stations can contribute to

the removal of main sewer gases from conventional

wastewater systems. The physical and chemical

methods are less used and costly as they involve

higher costs for replacing and disposing of

adsorbents or risk of formation of residual products.

To cope with the global warming threat,

wastewater system planning needs more robust

greenhouse

gas

emissions

analysis

when

implementing projects for wastewater collection. In

this respect, GHG mitigation represents the single

largest opportunity for avoiding further depletion of

the ozone layer (N2O).

The introduction of performance standards

and design for technological abatement catch-up for

GHG emissions and other hazardous gases in what

concerns emission level for the new wastewater

collection system might represent a window of

opportunity for greening the wastewater systems and

surpassing the environmental crises.

This study evaluated the available techniques

and technologies for removing odorous and GHG

emissions at the level of wastewater collection

system, providing a different perspective on the

control and pro-active measures and technologies for

avoiding, treating and reducing the air emissions

from wastewater collecting systems.

References

Airvac Inc., (2013), Airvac Presentation, On line at:

http://www.airvac.com/.

Aldabe J., Santamara C., Elustondo D., Parra A., Foan L.,

Simon V., Santamara J.M., (2012), Polycyclic

623

Ciobotici Terryn et al./Environmental Engineering and Management Journal 15 (2016), 3, 613-625

aromatic hydrocarbons (PAHs) sampled in aerosol

phase at different sites of the Western Pyrenees in

Navarra (Spain), Environmental Engineering and

Management Journal, 11, 1049-1058.

Andersson C.A., Hanus J., (2006), Odorous wastewater

emissions, Vatten, 62, 227-236.

Auterska P., Keder J., (2008), Assessment of odorant

emission rate from biofilters, Chemical Engineering

Transactions, 15, 23-28.

Buchanan J.R., Deal N.E., Lindbo D.L., Hanson A.H.,

Gustafson D.G., Miles R.J., (2010a), Gravity sewer

systems,

On

line

at:

http://www.werf.org/c/DecentralizedCost/C1_Gravity

_Sewers.aspx.

Buchanan J.R., Deal N.E., Lindbo D.L., Hanson A.H.,

Gustafson D.G., Miles R.J., (2010b), Vacuum sewer

systems,

On

line

at:

www.werf.org/c/DecentralizedCost/C4_Vacuum_Sew

ers.aspx.

Cabezas J., Martinez A., Jones K., Rathibandla S., Boswell

J., (2005), Performance Evaluation of Biofilters for

Wastewater Lift Station Emissions, Proc. of the 95th

A&WMA Annual Conference, June 21-24,

Minneapolis.

Chaosakul T., Koottatep T., Polprasert C., (2014), A model

for methane production in sewers, Journal of

Environmental Science Health A, 49, 13161321.

Czepiel P.M., Crill P.M., Harriss R.C., (1993), Methane

emissions from municipal wastewater treatment

processes, Environmental Science & Technology, 27,

2472-2477.

Daelman M.R.J., van Voorthuizen E.M., van Dongen

U.G.J.M., Volcke E.I.P., van Loosdrecht M.C.M.,

(2012), Methane emission during municipal

wastewater treatment, Water Research, 46, 3657-3670.

Daelman M.R., van Voorthuizen E.M., van Dongen U.G.,

Volcke E.I., van Loosdrecht M.C., (2013), Methane

and nitrous oxide emissions during municipal

wastewater treatment- results from a long term study,

Water Science and Technology, 67, 2350-2355.

Denman K.L., Brasseur G., Chidthaisong A., Ciais P., Cox

P.M., Dickinson R.E., et al., (2007), Couplings

Between Changes in the Climate System and

Biogeochemistry, In: Climate Change 2007: The

Physical Science Basis. Contribution of Working

Group I to the Fourth Assessment Report of the

Intergovernmental Panel on Climate Change,

Solomon S., Qin D., Manning M., Chen Z., Marquis

M., Averyt K.B., et al. (Eds.), Cambridge, United

Kingdom and New York, USA, Cambridge University

Press, 501-588.

Dosi G., (1982), Technological paradigms and

technological trajectories. A suggested interpretation

of the determinants and directions of technical change,

Research Policy, 11, 147-162.

EU, (2014), The Annual European Union greenhouse gas

inventory 1990-2012 and inventory report 1014, On

line

at:

http://www.eea.europa.eu/publications/europeanunion-greenhouse-gas-inventory-2014.

European Standard, (2013), European Standard DIN EN

1091 Vacuum Sewerage outside buildings.

Fenner R., (2000), Approaches to sewer maintenance: A

review, Urban Water, 2, 343-356.

Foley J., Yuan Z.G., Lant P., (2009), Dissolved methane in

rising main sewer systems: field, measurements and

simple model development for estimating greenhouse

gas emissions, Water Science and Technology, 60,

29632971.

624

Foley J., de Haas D., Hartley K., Lant P., (2010a),

Comprehensive life cycle inventories of alternative

wastewater treatment systems, Water Research, 44,

1654-1666.

Foley J., de Haas D., Yuan Z., Lant P., (2010b), Nitrous

oxide generation in full-scale biological nutrient

removal wastewater treatment plants, Water Research,

44, 831-844.

Garcia R., Calantone R., (2002), A critical look at

technological innovation typology and innovativeness,

The Journal of Product Innovation Management, 19,

110-132.

Govind R., (2005), Biofiltration: An innovative technology

for the future, On line at: http://www.environmentalexpert.com/Files\1367\articles\7436\11s2-PR.pdf.

Govind R., (2009), Multiphase biosystem. Review of

biofiltration and its implications for climate change,

On

line

at:

https://www.yumpu.com/en/document/view/4787399/

biofiltration-alternative-to-catalytic-oxidation-tri-mercorporation.

Guisasola A., Sharma K.R., Keller J., Yuan Z., (2009),

Development of a model for assessing methane

formation in rising main sewers, Water Research, 43,

2784-2884.

Gupta D., Singh S.K., (2012), Greenhouse gas emissions

from wastewater treatment plants: A case study of

Noida, Journal of Water Sustainability, 2, 131-139.

Gutierrez O., Mohanakrishnan J., Sharma K.R., Meyer

R.L., Keller J., Yuan Z., (2008), Evaluation of oxygen

injection as a means of controlling sulfide production

in a sewer System, Water Research, 42, 45494561.

GWRC, (2011), Global Water Research Coalition Report,

N2O and CH4 emission from Wastewater Collection

and Treatment Systems: State of the Art Report.

Iordache S., Dunea D., (2013), Cross-spectrum analysis

applied to air pollution time series from several urban

areas of Romania, Environmental Engineering and

Management Journal, 12, 677-684.

IPCC, (2007), Climate Change 2007: The Physical Science

Basis. Contribution of Working Group I to the Fourth

Assessment. Report of the Intergovernmental Panel on

Climate

Change,

On

line

at:

http://www.ipcc.ch/publications_and_data/publication

s_ipcc_fourth_assessment_report_wg1_report_the_ph

ysical_science_basis.htm.

Janni K.A., Nicolai R.K., Hoff S., Stenglein R.M., (2011),

Biofilters for Odor and Air Pollution Mitigation in

Animal

Agriculture,

On

line

at:

http://www.extension.org/sites/default/files/Biofiltersf

orOdor%20FINAL_0.pdf.

Lahav O., Sagiv A., Friedler E., (2006), A different

approach for predicting H2S(g) emission rates in

gravity sewers, Water Research, 40, 259-266.

Lane J., Lant P., (2012), Application of Life Cycle

Assessment to Wastewater Systems Planning, UWSRA

technical report, Brisbane: Urban Water Security

Research Alliance.

Leson G., Winer A.M., (1991), Biofiltration: An Innovative

Air Pollution Control Technology For VOC

Emissions, Journal of the Air & Waste Management

Association, 41, 1045-1054.

Li X., Xiao R., You Y., (2014), Dynamic change and

influential factors of carbon footprint for energy

consumption: a case study of Wuhan City, Hubei

Province, China, Environmental Engineering and

Management Journal, 13, 1497-1508.

Lim J.S., Kim J., Friedman J., Lee U., Vieira L., Rosso D.,

Gerla M., Srivastava M.B., (2013), SewerSnort: A

Eco-innovative technologies for mitigating gaseous emissions from wastewater collection systems

drifting sensor for in situ Wastewater Collection

System gas monitoring, Ad Hoc Networks, 11, 14561471.

Liu Y., Ni B.J., Sharma K.R., Yuan Z., (2015), Methane

emission from sewers, Science of the Total

Environment, 524525, 4051

Panfil C., Mirel I., Szigyarto I., Isacu M., (2013),

Technical, economical, social and ecological

characteristics

of

vacuum

sewage

system,

Environmental Engineering and Management Journal,

12, 1017-1022.

Roediger, (2013), Vacuum Sewer Systems, On line at:

http://www.roevac.com/page/en/page_ID/42?PHPSES

SID=bc787a142fc280fd831fb0263db6c084.

Romanian Government, (2005), Norms concerning

conditions of waswater discharge into sewerage

networks of localities and direct to wastewater

treatment plants, NTPA 002.

Schuh G., Garten T., Basse F., Schley E., (2016), Enabling

Radical Innovation Through Highly Iterative Product

Expedition in Ramp up and Demonstration Factories,

48th CIRP Conference on Manufacturing systemsCIRP CMS 2015, Procedia CIRP 41, 620-625

Short M.D., Daikeler A., Peters G.M., Mann K., Ashbolt

N.J., Stuetz R.M., Peirson W.L., (2014), Municipal

gravity sewers: An unrecognised source of nitrous

oxide, Science of the Total Environment, 468469,

211-218.

Sun Y., Clanton C.J., Janni C.J., Malzer G.L., (2000),

Sulfur and nitrogen balances in the biofilters for

odorous gas emission control, Transactions of ASABE,

43, 1861-1875.

Terryn I.C.C., Lazar I., Nedeff V., Lazar G., (2014),

Conventional vs. vacuum sewer systems in rural areasan

economic

and

environmental

approach,

Environmental Engineering and Management Journal,

13, 1847-1859.

USEPA, (2013), Revisions to the Greenhouse Gas

Reporting Rule and Final Confidentiality, On line at:

http://www.gpo.gov/fdsys/pkg/FR-2013-1129/pdf/2013-27996.pdf.

Valle S., Vzquez-Bustelo D., (2009), Concurrent

engineering performance: Incremental versus radical

innovation, International Journal of Production

Economics, 119, 136-148.

Valrom Industrie, (2014), Pictures provided by Valrom

Industrie with different stages of biofilter construction

from a sewer project implemented with vacuum

technology, On line at www.valrom.ro..

Vincze-Csom V., Domokos E., Bui P., Nagy G., Rdey .,

(2012), Study on the impact of the traffic on air quality

by using diffusive sampling method in Veszprm,

Environmental Engineering and Management Journal,

11, 2083-2090.

Wang H., Li H., (2011), Design and application of biofilter

to control odor in wastewater treatment plant, Energy

Procedia, 11, 3965-3969.

Web sites:

http://eponline.com/articles/2010/09/13/good-compostneighbor-uses-robust-odourcontrol.aspx?admgarea=Features.

http://cdn.intechopen.com/pdfs-wm/45120.pdf.

http://www.airvac.com/downloads_literature.htm.

www.pnas.org/content/100/11/6308/F1.expansion.html.

625

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Articol SGEM 2016Documento13 páginasArticol SGEM 2016Iulia TerrynAinda não há avaliações

- Infrastructure Resilience To Disasters - (RESIN) ChangpaperDocumento4 páginasInfrastructure Resilience To Disasters - (RESIN) ChangpaperIulia TerrynAinda não há avaliações

- Eco Innovative TechnologiesDocumento13 páginasEco Innovative TechnologiesIulia TerrynAinda não há avaliações

- Vacuum SewerDocumento13 páginasVacuum SewerIulia TerrynAinda não há avaliações

- Sewer ExfiltrationDocumento41 páginasSewer ExfiltrationIulia TerrynAinda não há avaliações

- 12 184 Terryn 15Documento10 páginas12 184 Terryn 15Iulia TerrynAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Module: Planning Studio Ii Physical Development Plan of Marpha Village, Marpha, MustangDocumento164 páginasModule: Planning Studio Ii Physical Development Plan of Marpha Village, Marpha, MustangPoonam BajracharyaAinda não há avaliações

- Pub (WRN) Advisory Note On Prevention of Damage To Public Sewerage System (Revised Edition-Oct 2019)Documento12 páginasPub (WRN) Advisory Note On Prevention of Damage To Public Sewerage System (Revised Edition-Oct 2019)Koh Jia JieAinda não há avaliações

- Zone DDocumento30 páginasZone DAshlesha WadikhayeAinda não há avaliações

- ASTM F412-12 TerminologyDocumento18 páginasASTM F412-12 TerminologyMarlon TurnerAinda não há avaliações

- Role of A Munciple Corporation Mayor KarnatakaDocumento397 páginasRole of A Munciple Corporation Mayor KarnatakaSachinDushiAinda não há avaliações

- Plumbing in ArchitectureDocumento8 páginasPlumbing in ArchitectureNethajiAinda não há avaliações

- Strom DrainageDocumento16 páginasStrom DrainageammarrafeiAinda não há avaliações

- Astm C990-03Documento4 páginasAstm C990-03Joanne WaiAinda não há avaliações

- Chapter 3 - Off Site SanitationDocumento75 páginasChapter 3 - Off Site SanitationMekuannint DemekeAinda não há avaliações

- Saes S 020Documento28 páginasSaes S 020dissanayake90kanishkaAinda não há avaliações

- A81936-3 Trans Mountain Appendix A Part 2 of 7 Condition 26 - A5J1X3Documento352 páginasA81936-3 Trans Mountain Appendix A Part 2 of 7 Condition 26 - A5J1X3suphissAinda não há avaliações

- We Advocate Thorough Environmental Review P.O. Box 873 Mt. Shasta, CA 96067Documento10 páginasWe Advocate Thorough Environmental Review P.O. Box 873 Mt. Shasta, CA 96067api-392139141Ainda não há avaliações

- BS 8002 (2015) Code of Practice For Retaining StructuresDocumento104 páginasBS 8002 (2015) Code of Practice For Retaining Structuresrichardhenrylamb100% (3)

- Att Inox Drain Polonia - Rigola Standard - Cu Gratar - EngDocumento6 páginasAtt Inox Drain Polonia - Rigola Standard - Cu Gratar - EngIstvan MadacsyAinda não há avaliações

- Commissioning Checklist For Sewerage Pumping StationsDocumento3 páginasCommissioning Checklist For Sewerage Pumping Stationssajidziyan67% (3)

- Testing of Sewers and Purpose of Sewage TreatmentDocumento2 páginasTesting of Sewers and Purpose of Sewage TreatmentZacharul ShahAinda não há avaliações

- Sewer ShapesDocumento11 páginasSewer ShapesShashank BhardwajAinda não há avaliações

- Astm F 412 - 06 PDFDocumento13 páginasAstm F 412 - 06 PDFRaul Humberto Mora VillamizarAinda não há avaliações

- Ten States Standard-Waste WaterDocumento152 páginasTen States Standard-Waste WaterymordenverayAinda não há avaliações

- Training Presentation KAASHIDHOODocumento57 páginasTraining Presentation KAASHIDHOOThilina Lakmal EdirisinghaAinda não há avaliações

- Sewage Disposal SystemDocumento35 páginasSewage Disposal SystemKent Jonas C. GensisAinda não há avaliações

- 01 Al Munaif PVC - CPVC - PipesDocumento44 páginas01 Al Munaif PVC - CPVC - PipesmohammedAinda não há avaliações

- KSP RBT P1 Rac CD RPT Civ 0004Documento34 páginasKSP RBT P1 Rac CD RPT Civ 0004alaa sadikAinda não há avaliações

- Training Manual For Civil 3DDocumento3 páginasTraining Manual For Civil 3Doseni momoduAinda não há avaliações

- Question Paper Code:: Time: Three Hours Maximum: 100 Marks Answer ALL Questions Part - ADocumento3 páginasQuestion Paper Code:: Time: Three Hours Maximum: 100 Marks Answer ALL Questions Part - ASrikrishnan DhanajiAinda não há avaliações

- South Metro Fire Rescue Authority Proposed 2014 BudgetDocumento124 páginasSouth Metro Fire Rescue Authority Proposed 2014 BudgetRonda ScholtingAinda não há avaliações

- ACO Passavant - Technical Handbook and Product CatalogueDocumento24 páginasACO Passavant - Technical Handbook and Product CatalogueACO PassavantAinda não há avaliações

- Design of STPDocumento53 páginasDesign of STPChanel100% (1)

- Types of ManholesDocumento6 páginasTypes of ManholesEvonYongAinda não há avaliações

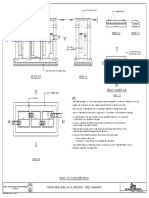

- Standard Oil Interceptor SectionDocumento1 páginaStandard Oil Interceptor SectionSpaceEngAinda não há avaliações