Escolar Documentos

Profissional Documentos

Cultura Documentos

Ie6605 Production Planning and Control L T P C 3 0 0 3

Enviado por

kumar kmDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ie6605 Production Planning and Control L T P C 3 0 0 3

Enviado por

kumar kmDireitos autorais:

Formatos disponíveis

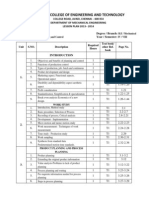

IE6605 PRODUCTION PLANNING AND CONTROL

LTPC 3 0 0 3

OBJECTIVES:

To understand the various components and functions of production planning and control such

as work study, product planning, process planning, production scheduling, Inventory Control.

To know the recent trends like manufacturing requirement Planning (MRP II) and Enterprise

Resource Planning (ERP).

UNIT I INTRODUCTION

9

Objectives and benefits of planning and control-Functions of production control-Types of production

job- batch and continuous-Product development and design-Marketing aspect - Functional aspectsOperational aspect-Durability and dependability aspect aesthetic aspect. Profit considerationStandardization, Simplification & specialization- Break even analysis-Economics of a new design.

UNIT II WORK STUDY

9

Method study, basic procedure-Selection-Recording of process - Critical analysis, Development Implementation - Micro motion and memo motion study work measurement - Techniques of work

measurement - Time study - Production study - Work sampling - Synthesis from standard data Predetermined motion time standards.

UNIT III PRODUCT PLANNING AND PROCESS PLANNING

9

Product planning-Extending the original product information-Value analysis-Problems in lack of

product planning-Process planning and routing-Pre requisite information needed for process planningSteps in process planning-Quantity determination in batch production-Machine capacity, balancingAnalysis of process capabilities in a multi product system.

UNIT IV PRODUCTION SCHEDULING

9

Production Control Systems-Loading and scheduling-Master Scheduling-Scheduling rules-Gantt

charts-Perpetual loading-Basic scheduling problems - Line of balance Flow production schedulingBatch production scheduling-Product sequencing Production Control systems-Periodic batch

control-Material requirement planning kanban Dispatching-Progress reporting and expeditingManufacturing lead time-Techniques for aligning completion times and due dates.

UNIT V INVENTORY CONTROL AND RECENT TRENDS IN PPC

9

Inventory control-Purpose of holding stock-Effect of demand on inventories-Ordering procedures.

Two bin system -Ordering cycle system-Determination of Economic order quantity and economic lot

size- ABC analysis-Recorder procedure-Introduction to computer integrated production planning

systems elements of JUST IN TIME SYSTEMS-Fundamentals of MRP II and ERP.

TOTAL:

45 PERIODS

OUTCOMES:

Upon completion of this course, the students can able to prepare production planning and

control activities such as work study, product planning, production scheduling, Inventory

Control.

They can plan manufacturing requirements manufacturing requirement Planning (MRP II) and

Enterprise Resource Planning (ERP).

TEXT BOOKS:

1. Martand Telsang, Industrial Engineering and Production Management, First edition, S.

Chand and Company, 2000.

2. James.B.Dilworth,Operations management Design, Planning and Control for manufacturing and

services Mcgraw Hill International edition 1992.

REFERENCES:

1. Samson Eilon, Elements of Production Planning and Control, Universal Book Corpn.1984

2. Elwood S.Buffa, and Rakesh K.Sarin, Modern Production / Operations Management, 8th

Edition, John Wiley and Sons, 2000.

3. Kanishka Bedi, Production and Operations management, 2nd Edition, Oxford university

press, 2007.

4. Melynk, Denzler, Operations management A value driven approach Irwin Mcgraw hill.

5. Norman Gaither, G. Frazier, Operations Management, 9th edition, Thomson learning IE,

2007

6. Jain. K.C & L.N. Aggarwal, Production Planning Control and Industrial Management, Khanna

Publishers, 1990.

Você também pode gostar

- TheAncientWisdom AnnieBesantDocumento153 páginasTheAncientWisdom AnnieBesantJose Fernandez Romero100% (2)

- Meta Masters PDFDocumento272 páginasMeta Masters PDFGarb Poub100% (1)

- SubpoenaDucesTecum 315Documento6 páginasSubpoenaDucesTecum 315earlcando33% (3)

- Puchta H Think 4 Teacher S BookDocumento128 páginasPuchta H Think 4 Teacher S BookLoc Nguyen100% (1)

- PPC Lesson PlanDocumento2 páginasPPC Lesson PlanSathiya MoorthyAinda não há avaliações

- Practical Guide To Production Planning & Control [Revised Edition]No EverandPractical Guide To Production Planning & Control [Revised Edition]Nota: 1 de 5 estrelas1/5 (1)

- Master Scheduling: A Practical Guide to Competitive ManufacturingNo EverandMaster Scheduling: A Practical Guide to Competitive ManufacturingAinda não há avaliações

- MATLab Manual PDFDocumento40 páginasMATLab Manual PDFAkhil C.O.Ainda não há avaliações

- PP PI MaterialDocumento141 páginasPP PI MaterialLeandro Junior50% (2)

- Cathodic Protection For New Fixed Offshore Steel Structures (AmendmentsSupplements To DNVGL-RP-B401)Documento22 páginasCathodic Protection For New Fixed Offshore Steel Structures (AmendmentsSupplements To DNVGL-RP-B401)Abd.Buhari Abd.GalimAinda não há avaliações

- PPC SyllabusqDocumento1 páginaPPC SyllabusqKannan MuthusamyAinda não há avaliações

- Production Planning and Control SyllabusDocumento2 páginasProduction Planning and Control SyllabusdsathiyaAinda não há avaliações

- Ie 6605 - PPC - SyllabusDocumento2 páginasIe 6605 - PPC - SyllabusmuthusAinda não há avaliações

- Ie6605 Production Planning and Control L T P C 3 0 0 3Documento2 páginasIe6605 Production Planning and Control L T P C 3 0 0 3Sathrudhan ChoudharyAinda não há avaliações

- PPC SYLLABUSDocumento2 páginasPPC SYLLABUSddeepak123Ainda não há avaliações

- Production Planning and ControlDocumento2 páginasProduction Planning and Controlmontu chahurpagarAinda não há avaliações

- 03.ie6605 Production Planning and Control PDFDocumento40 páginas03.ie6605 Production Planning and Control PDFARAVIND MAARTINAinda não há avaliações

- Ie8693 Production Planning and Control: Diploma, Anna Univ UG & PG CoursesDocumento2 páginasIe8693 Production Planning and Control: Diploma, Anna Univ UG & PG CoursesVig NeshAinda não há avaliações

- Pom IeDocumento5 páginasPom IepmagrawalAinda não há avaliações

- B.Tech Iv Year-Ii Sem: Malla Reddy College of Engineering &technologyDocumento54 páginasB.Tech Iv Year-Ii Sem: Malla Reddy College of Engineering &technologyTinsae AdaneAinda não há avaliações

- Production and Operations ManagementDocumento1 páginaProduction and Operations ManagementYash GargAinda não há avaliações

- Production and Operations Management: Unit - IDocumento1 páginaProduction and Operations Management: Unit - IvamsibuAinda não há avaliações

- ME404 Industrial EngineeringDocumento2 páginasME404 Industrial Engineeringnandan144Ainda não há avaliações

- Syllabus: B.B.A. Iii Sem Subject - Operations ManagementDocumento7 páginasSyllabus: B.B.A. Iii Sem Subject - Operations ManagementomAinda não há avaliações

- ME404 Industrial EngineeringDocumento2 páginasME404 Industrial EngineeringRam RenAinda não há avaliações

- Production Planning & ControlDocumento2 páginasProduction Planning & ControlJobin AbrahamAinda não há avaliações

- Syllabus: B.B.A. Iii Sem Subject - Operations ManagementDocumento46 páginasSyllabus: B.B.A. Iii Sem Subject - Operations Managementharshbhatt100% (1)

- Om & SCM Mba AimsDocumento75 páginasOm & SCM Mba Aimsbhupesh joshiAinda não há avaliações

- Product Design 1Documento10 páginasProduct Design 1elango_mm3307Ainda não há avaliações

- Om & SCM Mba AimsDocumento75 páginasOm & SCM Mba Aimsbhupesh joshi100% (1)

- ME404 Industrial EngineeringDocumento2 páginasME404 Industrial EngineeringHusni mubsshirAinda não há avaliações

- ProductivityDocumento1 páginaProductivityroscillaAinda não há avaliações

- DOMS403Documento340 páginasDOMS403vsimanpalliAinda não há avaliações

- IARE PPC Lecture NotesDocumento65 páginasIARE PPC Lecture NotesJaveed802Ainda não há avaliações

- Syllabus - Operations ManagementDocumento2 páginasSyllabus - Operations ManagementjvanandhAinda não há avaliações

- B.S Anangpuria Institute of Technology and Management FaridabadDocumento92 páginasB.S Anangpuria Institute of Technology and Management Faridabadwigivi4421Ainda não há avaliações

- Ais10 ch12Documento105 páginasAis10 ch12Shella FrankeraAinda não há avaliações

- PPC Notes PDFDocumento36 páginasPPC Notes PDFIbrahim UjjainwalaAinda não há avaliações

- PPC 2marksDocumento22 páginasPPC 2marksS20M048 HARIRAM MAinda não há avaliações

- Undefined - MEE2033 Production Planning and ControlDocumento1 páginaUndefined - MEE2033 Production Planning and ControlMechnovate 2017Ainda não há avaliações

- Bba Erp SyllabusDocumento2 páginasBba Erp Syllabussebastian cyriacAinda não há avaliações

- Operation ManagementDocumento200 páginasOperation Managementarjit jaguriAinda não há avaliações

- Om Merged PDF - Last-2.5 Units PDFDocumento58 páginasOm Merged PDF - Last-2.5 Units PDFCherry TejAinda não há avaliações

- Syllabi-Book Mapping Table: Production and Operations ManagementDocumento3 páginasSyllabi-Book Mapping Table: Production and Operations ManagementArun SasiAinda não há avaliações

- ERP (Enterprise Resource Planning)Documento32 páginasERP (Enterprise Resource Planning)NasikhuddinAinda não há avaliações

- OPERATIONS MANAGEMENT - Model Questions and AnswersDocumento34 páginasOPERATIONS MANAGEMENT - Model Questions and AnswersAkshay KsAinda não há avaliações

- Production Planning and Control Unit-IDocumento1 páginaProduction Planning and Control Unit-IHareendra Teja Reddy DonapatiAinda não há avaliações

- Advanced Operations ManagementDocumento2 páginasAdvanced Operations ManagementF JAinda não há avaliações

- Production Planning and ControlDocumento36 páginasProduction Planning and ControlPadmavathi Putra LokeshAinda não há avaliações

- 11-Production and Operations Management - Bosvr21Documento6 páginas11-Production and Operations Management - Bosvr210025 Divya reddyAinda não há avaliações

- CP0826 SybDocumento2 páginasCP0826 SybstalinkbcAinda não há avaliações

- iNDUSTRIAL ENGINEERING UINTRODUCTIOMDocumento49 páginasiNDUSTRIAL ENGINEERING UINTRODUCTIOMe tutorAinda não há avaliações

- Om SylabusDocumento2 páginasOm SylabusArun SinghAinda não há avaliações

- Production AND Operation: Jonafe F. Gamer BSCM-3Documento3 páginasProduction AND Operation: Jonafe F. Gamer BSCM-3jona gamerAinda não há avaliações

- Lecture-01 (IE)Documento8 páginasLecture-01 (IE)2223401015Ainda não há avaliações

- Mba611 Technology Management 3 0 0 3Documento3 páginasMba611 Technology Management 3 0 0 3Selva Shri NathAinda não há avaliações

- Syllabus - Lean and Agile ManufacturingDocumento2 páginasSyllabus - Lean and Agile ManufacturingjvanandhAinda não há avaliações

- New Microsoft Office Word DocumentDocumento6 páginasNew Microsoft Office Word DocumentBala NarayanasamyAinda não há avaliações

- Production Planning and Control: Unit NotesDocumento44 páginasProduction Planning and Control: Unit Notespho tosAinda não há avaliações

- PMM Notes All UnitsDocumento205 páginasPMM Notes All UnitsSwethaAinda não há avaliações

- Production Planning OverviewDocumento11 páginasProduction Planning OverviewTilmann AuchAinda não há avaliações

- 05b5aea126563e - Ch-1 - Kiran - Production Planning & ControlDocumento22 páginas05b5aea126563e - Ch-1 - Kiran - Production Planning & ControlRonaldo FlorezAinda não há avaliações

- 4 Operations Management PERT CPMDocumento323 páginas4 Operations Management PERT CPMawaisjinnahAinda não há avaliações

- Two Marks BA9221.Documento9 páginasTwo Marks BA9221.sanmira_geetha5271Ainda não há avaliações

- St. Joseph'S College of Engineering St. Joseph'S Institute of Technology Me6602 - Automobile EngineeringDocumento1 páginaSt. Joseph'S College of Engineering St. Joseph'S Institute of Technology Me6602 - Automobile Engineeringkumar kmAinda não há avaliações

- Advanced IC EnginesDocumento19 páginasAdvanced IC Engineskumar kmAinda não há avaliações

- Unit III Class Notes ProblemsDocumento37 páginasUnit III Class Notes Problemskumar km0% (2)

- DOM Assignment 5Documento1 páginaDOM Assignment 5kumar kmAinda não há avaliações

- Directions To Solve: Paper Cutting - Section IDocumento30 páginasDirections To Solve: Paper Cutting - Section Ikumar kmAinda não há avaliações

- Blood RelationsDocumento24 páginasBlood Relationskumar kmAinda não há avaliações

- Assignment 1Documento1 páginaAssignment 1kumar kmAinda não há avaliações

- GE6152 / Engineering Graphics / Unit-1 Assignment-1Documento1 páginaGE6152 / Engineering Graphics / Unit-1 Assignment-1kumar kmAinda não há avaliações

- GE6152 / Engineering Graphics / Unit-3 Assignment-3Documento1 páginaGE6152 / Engineering Graphics / Unit-3 Assignment-3kumar kmAinda não há avaliações

- How Do You Classify IC Engines?Documento1 páginaHow Do You Classify IC Engines?kumar kmAinda não há avaliações

- GE6152 / Engineering Graphics / Unit-2 Assignment-2Documento1 páginaGE6152 / Engineering Graphics / Unit-2 Assignment-2kumar kmAinda não há avaliações

- CCF DesignDocumento5 páginasCCF Designkumar kmAinda não há avaliações

- Assembly-Modeling ClassDocumento63 páginasAssembly-Modeling Classkumar km100% (4)

- ME2302 - Dynamics of Machinery Assignment 4 Questions UNIT 2 - Balancing of Masses Questions Part ADocumento1 páginaME2302 - Dynamics of Machinery Assignment 4 Questions UNIT 2 - Balancing of Masses Questions Part Akumar kmAinda não há avaliações

- Ce6451 Fluid Mechanics and Machinery L T P C 3 0 0 3: ObjectivesDocumento3 páginasCe6451 Fluid Mechanics and Machinery L T P C 3 0 0 3: Objectiveskumar kmAinda não há avaliações

- CAD Unit I & IIDocumento21 páginasCAD Unit I & IIkumar kmAinda não há avaliações

- Electronically Controlled Diesel Injection SystemDocumento5 páginasElectronically Controlled Diesel Injection Systemkumar kmAinda não há avaliações

- Balancing of Rotating MassesDocumento29 páginasBalancing of Rotating Masseskumar kmAinda não há avaliações

- Home AutomationDocumento19 páginasHome AutomationsatyajitAinda não há avaliações

- Corporate Social Responsibility (CSR) Theory and Practice in A Developing Country ContextDocumento20 páginasCorporate Social Responsibility (CSR) Theory and Practice in A Developing Country ContexteduarvilAinda não há avaliações

- ESS ManualDocumento72 páginasESS ManualMayank MevchaAinda não há avaliações

- Websphere MQ AdministrationDocumento601 páginasWebsphere MQ Administrationchiragparikh89100% (1)

- Study Guide Locke Berkeley Kant HumeDocumento4 páginasStudy Guide Locke Berkeley Kant HumeEarl DatanAinda não há avaliações

- Trade Life Cycle1Documento2 páginasTrade Life Cycle1ezefatAinda não há avaliações

- Astm d2624Documento8 páginasAstm d2624mehrez100% (1)

- Transferring A 38DLP - FTP Format File Using 2GB MicroSD CardDocumento5 páginasTransferring A 38DLP - FTP Format File Using 2GB MicroSD CardBoulHich BoulHichAinda não há avaliações

- Positive&Negative LogicDocumento12 páginasPositive&Negative LogicMahesh GonuguntlaAinda não há avaliações

- Action Research PaperDocumento37 páginasAction Research PaperKATE SHELOU TABIANAinda não há avaliações

- Sastec2 - Technical Offer - 220kv Gis JSPL - Angul - Rev CDocumento18 páginasSastec2 - Technical Offer - 220kv Gis JSPL - Angul - Rev CRakesh Kumar Singh (Phase 1B)Ainda não há avaliações

- Water ResearchDocumento16 páginasWater ResearchCarlos AlvarezAinda não há avaliações

- Chapter SixDocumento5 páginasChapter Sixyimenueyassu100% (1)

- Mil JingleDocumento3 páginasMil JingleJan AprilAinda não há avaliações

- Quiz On Parts of A Research PaperDocumento5 páginasQuiz On Parts of A Research Paperyscgudvnd100% (1)

- VICTORY ES LEAST-MASTERED-COMPETENCIES 2nd QuarterDocumento27 páginasVICTORY ES LEAST-MASTERED-COMPETENCIES 2nd QuarterWilliam FelisildaAinda não há avaliações

- Queuing Part 1 PDFDocumento13 páginasQueuing Part 1 PDFabhaymainiAinda não há avaliações

- CorelDRAW VBA Object Model PDFDocumento0 páginaCorelDRAW VBA Object Model PDFSunilkumar DubeyAinda não há avaliações

- EXAMPLE CV - Torevei KurashaDocumento4 páginasEXAMPLE CV - Torevei KurashatkurashaAinda não há avaliações

- Catatan Statisktik FIXDocumento59 páginasCatatan Statisktik FIXAndrian WicaksonoAinda não há avaliações

- Discourse Analysis: Using Knowledge of The World in Discourse Analysis/ Representation of KnowledgeDocumento19 páginasDiscourse Analysis: Using Knowledge of The World in Discourse Analysis/ Representation of KnowledgeIgor NajdertAinda não há avaliações

- Article RevDocumento2 páginasArticle RevSudip Kumar KarAinda não há avaliações

- G121 - AY20S2 - CA3 - Student Instructions - 20201117Documento4 páginasG121 - AY20S2 - CA3 - Student Instructions - 20201117Lim Liang XuanAinda não há avaliações

- AMC124 FinalsReviewerDocumento2 páginasAMC124 FinalsReviewerIan De La CruzAinda não há avaliações

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)