Escolar Documentos

Profissional Documentos

Cultura Documentos

Ottomotor Steuerung

Enviado por

andreslcosta3861Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ottomotor Steuerung

Enviado por

andreslcosta3861Direitos autorais:

Formatos disponíveis

International Summer School Hochschule Mnchen

Gasoline (Otto) Engine Control

by Frank Owen, PhD, P.E., Mechanical Engineering/Fakultt 03,

Cal Poly/Hochschule Mnchen

(revised 11 August 2008)

Introduction

The automobile of today is quite different than that of a decade ago or two decades

ago. The introduction of electronics and the development of the fields of

mechatronics and specifically automotive mechatronics have wrought huge

technological changes on the autos of today. The refinement of automotive

technology has been helped along by electronic and mechatronic development. These

improvements have been in response to customer demand and satisfaction and also in

response to ever more stringent demands for energy efficient cars and emissions

reduction.

Central to this is the development of engine control systems. In autos that predate the

electronic era, there was a direct, mechanical coupling between the accelerator pedal

and the engine intake throttle valve. Pressing on the accelerator opened the throttle

valve directly, which resulted in a greater flow of air and gas into the engine. In

todays cars this direct connection has been severed. A mechatronic system stands

between the accelerator pedal and the engine throttle valve. The demand for more

power, expressed by a change in the accelerator pedal angle, can be met in a variety of

ways and can be met while taking account of the engine operating condition and in a

manner that maximize fuel economy. So through the mediation of a mechatronic

engine control system the operation of the engine is improved through intelligent

control.

A ir

A c c e le ra to r

P edal

T h ro ttle

V a lv e

Non-Mechatronic System, direction connection between accelerator and throttle

valve

Gasoline (Otto) Engine Control

Hochschule Mnchen - International Summer School

A c c e le ra to r

P edal

A ir

M e c h a tro n ic

S y ste m

t

T h ro ttle

V a lv e

Mechatronic System mediates engine power changes

This decoupling of the driver demand and the throttle valve has enabled many other

changes that improved engine operation. The purpose of this section is to use this

example, a primary example in automotive mechatronic technology to give you an

idea of how mechatronics has changed the way a car works.

Electronic engine control was initially introduced in the 1970s and has grown

significantly since then. The demands of emissions control, first in the U.S.,

particularly in California, and then later in Europe, led to the replacement of

mechanical linkages with electronic controls. Nowadays engine control takes place in

an atmosphere of conflicting interests: customers want more power, comfort, and

economy, while air control agencies want more emissions reductions. Nowadays

great emphasis is placed on emissions monitoring and on engine diagnostics in engine

control systems. Air/fuel mixture and amount are the primary factors in affecting

emissions. Spark timing also plays an important role in emissions control. In the

fully mechatronic car of today, the spark can be set off at a time determined by the

engine control unit.

One other important mechanical decoupling found in many modern automobiles is the

elimination of the camshaft, which governs valve timing. The age-old manner of

valve actuation is through the camshaft, which opens and closes the valves. The

camshaft is driven through a belt or a chain from the crankshaft. So the point at

which an intake or exhaust valve opens is fixed. The length of time it is open is also

fixed by the shape of the cam.

Instead of cams driving the valves open, in a fully mechatronic car the valves are

opened using electrical solenoids controlled by the engine control unit. So when a

valve opens during a pistons cycle can be altered to fit the engine control strategy.

How long the valve remains open is also controllable in a crankshaft-less engine. So

the possibilities of engine operation are greatly expanded with these mechanical

decouplings. This allows emissions reduction, fuel economy, engine protection, etc.

System configuration

The mechatronic unit that governs engine operation takes input signals for the system

sensors, makes decisions based on this input information, and then issues commands

to the system actuators. The actuators take action based on the wishes of the driver,

input through the gas pedal, and based on the current situation of the engine as

2

Gasoline (Otto) Engine Control

Hochschule Mnchen - International Summer School

perceived by the sensors. As you can see, what was done mostly through mechanical

connections prior to the days of automotive mechatronics is now a complex

orchestration managed by the mechatronic brain in the automobile.

Sensors

Actuators

Accelerator pedal

Throttle valve angle

Crankshaft angle

Camshaft angle

Intake air flow

Inlet air temperature

Turbocharger pressure

Ambient air pressure

Cooling water temperature

-sensor signal

Exhaust gas temperature

Clutch position

Gasoline pressure

Coil

Injector

Throttle valve

Camshaft control

Exhaust gas recirculation

Intake manifold switching

Fan

Gasoline pump

Secondary air

Exhaust gas valve

Supercharger bypass

Fuel tank vent

Engine

Control

System

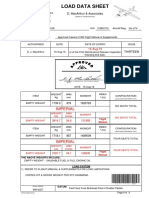

The engine control system is subdivided as shown in the drawing below:

Engine Control System

Input

Signal Development

Output

Signal processing

Micro-controller

Output processing

Storage

Diagnostics

Overseeing

Diagnostics

The input signals from the sensors can be analog, digital 1/0 states, or pulse sequences

from instruments. The purpose of the input module is to convert these signals into

digital bit sequences that are understandable by the micro-controller. On the output

side such real-world signals (voltages, digital voltage levels, pulses) have to be

generated to drive the actuators. The output module takes the commands generated in

the micro-controller and converts them into signals that drive the actuators.

So the brain of the unit is the micro-controller. The engine control program runs in

the micro-controller and implements the engine control strategy developed by the

engine manufacturer. The micro-controllers programs are stored in a Flash-EPROM

which retains the program even in the absence of electrical power. That the program

Gasoline (Otto) Engine Control

Hochschule Mnchen - International Summer School

is stored in a writeable device enables the engine control software to be updated as

improvements are made in the software.

Control Strategy

As you will see in the following description of the engine control system, there is a lot

going on. There are dozens of control loops to take care of orchestrating the complex

sequence of events that bring the right amount of air with the right amount of fuel into

the cylinder, where at the right moment a spark ignites the mixture. Another thing

that you will notice is that in controlling the air, the spark timing, etc., a base control

signal is developed. But then this signal is modified in taking into account other

constraints within which the engine operates. So the development of a command

signal to an actuator is a two-stage process: 1) development of the base signal and 2)

modification from this base to take other things into account.

Current engine control can be characterized as a torque management strategy and is

called torque-based control. The driver expresses his or her wish for more torque by

pressing on the gas pedal. The system perceives the state of the car, including the

load on it. The torque wish can then be met in a variety of ways. This all takes place

under the heavy constraint of meeting emissions demands.

Torque-based control is divided into three different functions:

The coordination and prioritization of the various torque demands

The filtering and correction of the demand according to drivability criteria

The coordination of the torque delivery through various operation methods

Coordination of torque demands Besides the torque demand expressed by the driver

through the gas pedal, other demands impinge on this wish. Part of the torque

delivered by the engine is diverted by belt drives to supply power to other devices,

like the air-conditioning compressor. Also modern mechatronic cars have handling

control systems and driver-assistance systems. The driving condition of the car must

also be taken into account by an engine control system. For example if a car is on the

verge of shifting into a higher gear (automatically), it is the job of the shift control

system to remove torque delivery from the engine while the gearshift is actuated. So

the torque demand expressed by the driver cannot be immediately and directly met

without taking account of all these other demands and prevailing conditions. The

drivers wish for more torque must be coordinated with other demands. All these

demands are prioritized and converted into a tuned demand that includes all these

considerations. The figure below graphically expresses this situation.

Gasoline (Otto) Engine Control

Hochschule Mnchen - International Summer School

Drivers torque wish

Catalyst heat function

Idle control

Coordination

and

Prioritization

Transmission control

Resolved

torque demand

Handling control

Driver assistance system

Filtering and correction of torque demand At this stage the torque demand of the

driver has been reconciled with all the other competing demands. The resulting

resolved torque demand must now be matched with the actual driving situation. If

torque is delivered too suddenly to the drive train, it will actually cause an oscillation

in the drive train that can damage it. The torque must be delivered more gradually to

avoid this oscillation. The figure below shows a possible scenario for torque demand.

The driver presses on the accelerator pedal which represents an immediate step

increase in torque demand (dotted line). This demand is modified , so that the torque

demand is expressed more gradually (solid line).

D riv e r

to rq u e

dem and

M o d ifie d

to rq u e

dem and

t

Coordination of torque implementation This is the third phase of torque control, the

delivery of the torque wish onto the actuators that deliver air, fuel, and spark to the

engine. These actuators are divided into a so-called slow path and a fast path.

The slow path is associated with the air flow. Here there are time constants on the

order of 100 ms. The fast path is the fuel injection and the spark. These three must be

well coordinated because the timing is short and critical, both for power, reaction

time, and emissions control.

In direct-injection engines the gasoline is injected directly into the cylinder. It is

possible in such engines to stratify the charge. This means that the mixture in the

cylinder is not uniform or homogeneous. Rather the mixture is lean and in fact may

just be air at the far reaches of the cylinder away from the spark plug. But near the

5

Gasoline (Otto) Engine Control

Hochschule Mnchen - International Summer School

spark plug the mixture is richer and, especially important, ignitable. Thus in a

stratified charge engine, the mixture is rich near the spark plug and then leaner and

leaner the farther way it is from the spark plug. Thus the spark can ignite the mixture,

which then ignites the ever leaner mixture as the flame front propagates through the

cylinder. A direct-injection, stratified charge engine thus can burn a leaner mixture

and save around 15% of the gasoline burned in an engine with only homogeneous

charges.

One problem that results from this is that NOx production results from lean burning.

NOx is also produced by high-temperature burning. In a stratified charge the mixture

at the far reaches of the engine may be only air. Thus the expanding flame front of the

lean burn encounters this and is cooled, leading to low NOx production. As we shall

see, NOx control is a primary goal of emissions control. A primary purpose of the

catalytic converter is to remove NOx from the exhaust gas.

Another strategy that can be implemented in a firing strategy for an engine allows

overcoming the slowness associated with air flow control. Even though a time

constant of 0.01 seconds may seem fast, quick response is very important to the

driver, who gets a primary feel for the car from its response to a sudden torque

demand. There are driving regimes where the likelihood of a sudden increase in

demand is high, for instance at idle. Here it is possible to run the engine with nonoptimal spark timing. If a sudden torque demand is expressed by the driver, the spark

timing can be immediately switched to optimal to get a optimal burn and to get an

immediate torque response. In such non-optimal spark timing the difference between

non-optimal torque and optimal torque is called torque reserve.

T o rq u e

A c tu a l

e n g in e

o p e ra tin g

p o in t

T o rq u e re se rv e

O p tim a l e n g in e

o p e ra tin g p o in t

S p ark

tim in g

o ffs e t

fro m

o p tim a l

S p a rk tim in g

Inlet air control Intake flow and composition in filling the cylinders is primary in

determining the resulting torque as well as the accompanying fuel economy and

emissions control. Part of this also is exhaust gas recirculation (EGR), where part of

the exhaust gas (5-15%) is recirculated back into the inlet to become part of the

air/fuel cylinder charge. This has various effects, but the primary effect that results

from introducing an inert (non-burning) content into the inlet mixture is to reduce the

burn temperature in the cylinder. This leads to NOx reduction, because NOx is the

result of burning a mixture of oxygen and nitrogen (such as air) at high temperatures.

Gasoline (Otto) Engine Control

Hochschule Mnchen - International Summer School

So EGR is also a part of inlet flow control. Exhaust gasses can be circulated

internally or externally. Internal recirculation is really not recirculation. The exhaust

valve timing is controlled so that part of the just-burned mixture actually remains in

the cylinder. So mechatronically the exhaust valve timing controls inert-gas content

of the cylinder charge. External EGR involves controlling the flow through a flow

path that connects the exhaust manifold with the intake manifold.

Intake valve control is used to control the flow of air into the cylinder. If the valve

opening is kept small, this increases the turbulence of the intake charge, which

promotes mixing in the cylinder. In a supercharged engine, the intake air pressure can

be increased to increase the amount of air that enters the cylinder at a given intake

valve opening. In non-supercharged engines it is possible to change the effective

length of the inlet manifold. This can be done with controllable baffles in the inlet

manifold or with telescoping sections of the inlet manifold. This allows setting up a

pressure resonance within the inlet manifold that helps load the cylinder with air. The

needed resonance varies with flow so must be controlled depending on the operating

level of the engine.

Other settable parameters for the engine that depend on operating level are spark

timing, throttle valve angle, exhaust recirculation, and the valve stroke (how far the

valve moves). These are set for various operating levels using either an on-line model

(equations that model the engine in the engine control micro-controller) or by look-up

tables stored in the micro-controller.

The cylinder air charge is very important in engine control. This changes with

operating levels and conditions. Flows are notoriously hard to measure, especially in

compressible flows under transient conditions. So a good deal of effort is expended

trying to measure or estimate flow through mathematical models of the cylinder

charge. As the car ages the charge changes too. The inlet suction created by the

piston becomes gradually less as the piston rings wear. This can be detected through

measurements and the mathematical models in the micro-processor can be adjusted to

compensate for this aging. If a car has an exhaust-driven turbocharger, the inlet

model also has to include part of the exhaust system to be complete.

Mixture control The purpose of mixture control is to provide the right amount of

fuel at the proper time for burning, at all operation levels and also in transient

conditions. This is critical to torque generation and fuel economy as well as to

emissions control. Mixture control has three parts:

1. Calculation of correct fuel charge. This is calculated from the air charge and the

engine speed. This is a base calculation. The result is then tuned to account for

transient effects, like wall-film-compensation and transient states like starting or

warm-up.

2. Control of fuel/air ratio. This is the so-called control, named after the sensor

that measures exhaust gas content. The exhaust gas is analyzed to measure the

oxygen remaining in it. This is measured by two sensors, one in the exhaust

stream just downstream of the engine and one after the catalytic converter. The

main measurement comes from the sensor immediately downstream of the

Gasoline (Otto) Engine Control

Hochschule Mnchen - International Summer School

engine. But because this is a very hot, hostile environment, the sensor is crude. A

second sensor is placed after the catalytic converter, where the conditions are

more benign, so a more accurate sensor can be used. This sensors reading is used

to trim the main measurement.

D e s ire d

C o m p e n s a tio n fo r

tim e d e la y

e rro r

+

-

C o m p e n s a tio n fo r

tim e d e la y

C o rre c te d

in je c tio n

com m and

T rim m e d

m e a s u r e m e n t

m e a s u r e m e n t

a f te r c a ta ly tic

c o n v e rte r

T rim m in g o f

b a s e s ig n a l

B ase

m e a su re m e n t

Notice also that this measurement has time delays associated with it. This must be

taken into account as shown above by noting that the current reading is old and

that any resulting change will not take effect until a little time has passed. The

result of analyzing the exhaust flow will be an adjustment in the fuel injection

command.

Because of the time delays associated with this sensor, it doesnt work very well

in transient operations. So the control scheme associated with exhaust gas

measurement can be disabled or simplified for transient operations. With a

mechatronic system it is possible to adjust the control scheme for transient

operations, something impossible to do with non-mechatronic engine control.

3. Time coordination of the injection. The time that the injection valve remains open

can be controlled in an engine with solenoid-operated valves. As previously

mentioned in a stratified charge engine, there needs to be an ignitable charge in

the vicinity of the spark plug. Also the amount of gas injected into the engine

depends on the pressure in the fuel supply system. This has a separate control

loop to maintain the pressure at a specified value.

Spark timing control The figure below shows the two-tiered development of the

spark timing decision. Again the strategy of developing a base signal (from the

engine RPM and from the load) and then tuning it to take account of other

considerations (engine temperature, exhaust gas content, and residual oxygen) is

followed. The engine operating map is empirical data developed on an engine test

stand to cover all operating conditions and levels of an engine. Once the tuned spark

timing wish is developed, this signal is further modified to take account of the

crankshaft angle and to avoid knocking (see below). The resulting signal from all this

development and then account taking is used as the control signal to the ignition coil.

8

Gasoline (Otto) Engine Control

Hochschule Mnchen - International Summer School

E n g in e s p e e d

L oad

E n g in e

o p e ra tin g

m ap

T e m p e ra tu re

R e s id u a l O

C o o rd in a tio n

a n d L im ita tio n

D e s ire d

sp a rk

in s ta n t

C ran k sh a ft

A n g le

K n o c k C o n tro l

C o rre c tio n

Knock control Knocking or pre-ignition happens when two flame fronts collide in a

cylinder. One flame originates at the spark plug. The other often originates at a hot

spot in the cylinder, often where a speck of exhaust residue adheres to the cylinder

head. Knocking results when the spark is set off too early. It is advantageous to set

the spark off early to give the mixture time to burn. This results in better fuel

economy. So knocking takes place when this desire for complete burning is overly

aggressive. The engine control system wants to make the spark early but not early

enough to cause knocking. Knocking and the violence associated with it can be

damaging to the engine if it is not controlled.

In a modern engine knocking can be sensed. A piezo-electric sensor supplies the

signal. So stresses caused by knocking in the sensor are converted to an electrical

signal. This signal is very dirty, because the engine is normally subjected to stresses

that cause the sensor to output an electrical signal. What is done is that a

measurement window is taken around TDC on the power stroke. This noisy signal is

then filtered, and then a decision is made on whether knocking is present or not.

In a modern engine control system, each and every firing can be evaluated for the

presence of knocking, the electronics are so fast. If knocking is detected, the spark

timing is retarded. Actually an over-compensation takes place. Knocking causes

elevated temperatures in the cylinder, which make further knocking more likely. So

the spark timing is retarded considerably and then slowly advanced thereafter to avoid

further knocking.

Gasoline (Otto) Engine Control

Hochschule Mnchen - International Summer School

Balancing output from cylinders On top of all the control described heretofore, the

engine control system also looks at the contribution of each cylinder to the entire

engine torque output. Unequal cylinder output causes vibration and also less-thanoptimal operation of the engine. Unequal cylinder contributions are detected by a

careful measurement of the engines rotational speed. If all cylinders are contributing

equally, what should be seen is a set of equal pulses with two revolutions of the

crankshaft. If the speed pulses are unequal, that indicates unequal contributions from

each cylinder. The pulses can be tied back to individual cylinders through the

corresponding crankshaft angle. Then measures can be taken to equalize the

contribution of the deviating cylinder(s).

Exhaust and emissions control Emissions control is a primary function of the engine

control system, now stringently mandated by law. The catalyst in the catalytic

converter must also be protected from overtemperature. Secondary air can be

introduced into the exhaust system upstream of the catalytic converter for this

purpose. It is also necessary to regenerate the catalyst on a regular basis, when it

becomes saturated with NOx.

Most emissions occur in the first few seconds after the engine is started. The catalyst

is still saturated with NOx and therefore not effective. It is desirable to bring the

catalyst to the reaction temperature as quickly as possible. Warmed secondary air can

be introduced into the catalyst to speed up its heating.

NOx saturation of the catalyst results from lean burning, which is a by-product of

stratified charges. If the catalyst gets NOx-saturated, the firing control can be

temporarily switched to homogeneous, richer burning. This allows the catalyst to

regenerate itself. The NOx in the catalyst converts to N2 and CO2. Once the catalyst

has regenerated itself, the engine control can switch back to stratified charging. There

is also a procedure to flush the catalyst of sulpher if it become saturated with it. The

catalyst is brought to an elevated temperature for a period of time. All of this takes

place automatically, under the control of the engine control system and is not

perceived by the driver.

Diagnostics There is an extensive diagnostic system built into such a mechatronic

engine control system. The health of the system must be watched, the functioning of

the sensors, which feed the mechatronic brain with information, must be secure and

certain. This allows also an assessment of the physical condition of the engine and its

degradation with age.

Summary

As you can see, the operation of a modern engine is a complicated orchestration of a

number of control loops and reconciliation with competing and conflicting demands.

The replacement of mechanical linkages, especially the mechanical connection

between accelerator pedal and throttle valve, has allowed modes of operation and

selective tuning that were impossible in pre-mechatronic cars. Emissions control is a

primary consideration, mandated by law. The engine control system plays a decisive

role in assuring more efficient and economic operation of a modern engine, while

meeting the demands of air pollution control agencies.

10

Gasoline (Otto) Engine Control

Hochschule Mnchen - International Summer School

References

Reif, Konrad, Automobilelektronik, Eine Einfhrung fr Ingenieure, ATZ/MTZFachbuch, Vieweg & Sohn Verlag, Wiesbaden, 2006.

Schmitz, Gnter und 42 Mitautoren, Mechatronik im Automobil: Aktuelle Trends in

der Systementwicklung fr Automobile, Expert Verlag, Renningen, 2000.

Wermuth, Gispert, Unterlagen des Labors fr Fahrzeugmechatronik,

Fachhochschule Mnchen, Fakultt 03, 2003.

Wikipedia, Exhaust gas recirculation,

en.wikipedia.org/wiki/Exhaust_gas_recirculation, 2007.

Wikipedia, Stratified charge engine,

en.wikipedia.org/wiki/Stratified_charge_engine, 2006.

11

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Catalog Celule Siemens 8DJHDocumento80 páginasCatalog Celule Siemens 8DJHAlexandru HalauAinda não há avaliações

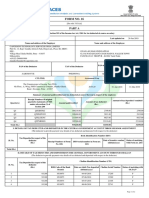

- Load Data Sheet: ImperialDocumento3 páginasLoad Data Sheet: ImperialLaurean Cub BlankAinda não há avaliações

- FIRE FIGHTING ROBOT (Mini Project)Documento21 páginasFIRE FIGHTING ROBOT (Mini Project)Hisham Kunjumuhammed100% (2)

- Tivoli Performance ViewerDocumento4 páginasTivoli Performance ViewernaveedshakurAinda não há avaliações

- GR L-38338Documento3 páginasGR L-38338James PerezAinda não há avaliações

- Star Link SafetyDocumento2 páginasStar Link SafetyJeronimo FernandezAinda não há avaliações

- Basic DfwmacDocumento6 páginasBasic DfwmacDinesh Kumar PAinda não há avaliações

- Unit-5 Shell ProgrammingDocumento11 páginasUnit-5 Shell ProgrammingLinda BrownAinda não há avaliações

- PCDocumento4 páginasPCHrithik AryaAinda não há avaliações

- Form16 2018 2019Documento10 páginasForm16 2018 2019LogeshwaranAinda não há avaliações

- Aluminum 3003-H112: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyDocumento2 páginasAluminum 3003-H112: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyJoachim MausolfAinda não há avaliações

- SBL - The Event - QuestionDocumento9 páginasSBL - The Event - QuestionLucio Indiana WalazaAinda não há avaliações

- 1400 Service Manual2Documento40 páginas1400 Service Manual2Gabriel Catanescu100% (1)

- Anaphylaxis Wallchart 2022Documento1 páginaAnaphylaxis Wallchart 2022Aymane El KandoussiAinda não há avaliações

- Uppsc Ae GSDocumento18 páginasUppsc Ae GSFUN TUBEAinda não há avaliações

- Labstan 1Documento2 páginasLabstan 1Samuel WalshAinda não há avaliações

- Information Security Chapter 1Documento44 páginasInformation Security Chapter 1bscitsemvAinda não há avaliações

- Difference Between Mountain Bike and BMXDocumento3 páginasDifference Between Mountain Bike and BMXShakirAinda não há avaliações

- Doterra Enrollment Kits 2016 NewDocumento3 páginasDoterra Enrollment Kits 2016 Newapi-261515449Ainda não há avaliações

- The Electricity Act - 2003Documento84 páginasThe Electricity Act - 2003Anshul PandeyAinda não há avaliações

- CA Inter Group 1 Book November 2021Documento251 páginasCA Inter Group 1 Book November 2021VISHAL100% (2)

- Missouri Courts Appellate PracticeDocumento27 páginasMissouri Courts Appellate PracticeGeneAinda não há avaliações

- LOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCDocumento1 páginaLOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCMAinda não há avaliações

- TLE - IA - Carpentry Grades 7-10 CG 04.06.2014Documento14 páginasTLE - IA - Carpentry Grades 7-10 CG 04.06.2014RickyJeciel100% (2)

- Dissertation On Indian Constitutional LawDocumento6 páginasDissertation On Indian Constitutional LawCustomPaperWritingAnnArbor100% (1)

- Oem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Documento43 páginasOem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Farhad FarajyanAinda não há avaliações

- MRT Mrte MRTFDocumento24 páginasMRT Mrte MRTFJonathan MoraAinda não há avaliações

- NOP PortalDocumento87 páginasNOP PortalCarlos RicoAinda não há avaliações

- Lab Session 7: Load Flow Analysis Ofa Power System Using Gauss Seidel Method in MatlabDocumento7 páginasLab Session 7: Load Flow Analysis Ofa Power System Using Gauss Seidel Method in MatlabHayat AnsariAinda não há avaliações

- LMU-2100™ Gprs/Cdmahspa Series: Insurance Tracking Unit With Leading TechnologiesDocumento2 páginasLMU-2100™ Gprs/Cdmahspa Series: Insurance Tracking Unit With Leading TechnologiesRobert MateoAinda não há avaliações